Infrared Heaters

Infrared heaters can be likened to miniature versions of the Sun. These electric or gas-powered devices rely on electromagnetic radiation to warm objects, materials, or spaces. The heat they produce originates from infrared light, which emits long electromagnetic waves found just outside the range of visible light on the electromagnetic spectrum. Unlike traditional heaters, they do not require a medium like air or other molecules to transfer heat.

The History of Infrared Heaters

Infrared radiation was first identified in 1800 by German-British astronomer Sir William Herschel during an experiment using a spectrometer of his own invention. He employed the device to measure radiant energy at various wavelengths, leading to the discovery of infrared light.

Despite the early discovery, infrared technology did not find widespread use until World War II, when it was applied to curing and drying paints and lacquers on military equipment. At that time, manufacturers directed infrared heat through arrays of lamp bulbs. Although the power output was low by modern standards, these infrared lamps significantly outperformed fuel-based convection heaters in drying efficiency.

Following the war, manufacturers continued experimenting with infrared heat, but its adoption didn’t accelerate again until the mid-1950s. The turning point came when the automotive industry introduced infrared tunnels on production lines for paint curing.

Today, infrared heaters are more popular than ever, thanks to their energy efficiency and growing versatility. Engineers continue to refine their designs to improve safety, effectiveness, and appeal across a broader range of applications.

Infrared Heater Applications

Because infrared heaters use energy efficiently, they are well-suited to heating spaces of nearly any size, from compact rooms to expansive warehouses, garages, and sheds. They’re commonly used in applications such as industrial oven heating, central heating systems, small space heating, process heating, plastic welding, coating and paint drying, glass processing, zoo and veterinary animal care, and even therapeutic relief for arthritic joints.

Infrared heating can be integrated into a wide range of heater designs, making it versatile for both industrial and residential purposes. It’s commonly found in space heaters, radiant heaters, radiant gas heaters

, indoor and outdoor heating units, tube heaters, infrared patio heaters, and many other specialized systems.

Advantages of Infrared Heaters

-

Less Time to Heat Up

Infrared heater systems emit energy beams that warm people or objects directly, rather than heating the surrounding air first. As a result, the targeted area or individual experiences warmth almost instantly. In contrast, conventional heaters distribute warmth gradually by circulating heated air throughout the space, leading to slower overall heating.

Quiet Operation

Infrared heaters typically operate without the use of fans, making them exceptionally quiet. Their near-silent performance has earned them the nickname “silent heaters,” making them ideal for noise-sensitive environments.

Even Heating Distribution

By using a metallic coil wrapped around the heat source, infrared heaters deliver consistent, uniform heat across the entire application area. Traditional heating systems often rely on convection currents, which can create uneven hot and cold zones—a drawback for industrial processes requiring precise temperature control.

Health and Environmental Friendliness

Since infrared heaters don’t rely on combustion, they produce no harmful fumes or emissions. This not only makes them safer for nearby individuals but also reduces the risk of fire and other heat-related hazards compared to fuel-burning systems.

Energy Efficiency

Infrared heaters are known for their excellent energy efficiency. Their ability to directly heat surfaces and objects without wasteful air circulation makes them a “green” heating solution that supports environmental sustainability.

Infrared Heater Design

Infrared Heater Components

Infrared heaters consist of a heating element and a reflective surface. The heating element converts energy—whether from electricity or gas—into radiant heat, measured in microns. The reflective surface directs these heat rays toward objects, enabling direct and efficient warming. Regardless of the energy source, the heating element is housed inside a radiating tube, giving rise to the common term “tube heaters.”

Parts of an Infrared Heater

Infrared heating elements may be made of ceramic, glass, or metal, but quartz tube heaters are among the most popular due to quartz’s rapid heating capabilities. The heating element is enclosed in a protective casing made of heat-resistant materials like aluminum, brass, copper, iron, stainless steel, or steel—each chosen for its ability to withstand intense temperatures.

Design Considerations and Customization

Infrared heater manufacturers take several factors into account when designing a unit. These include the material of the shield, the type of heating element or heat exchanger, the internal temperature range, required input voltage, and the maximum wattage the unit can safely produce. Designers must also determine whether the heater will be electric or gas-powered.

Some radiant heaters incorporate fans or air-moving components to help circulate warm air more quickly throughout a space. However, fans are not necessary for effective infrared heat distribution. Most heaters also include a protective casing around the heating element to minimize contact injuries and enhance operational safety.

Infrared Heater Images, Diagrams and Visual Concepts

Infrared heating, a method for heating materials that uses electromagnetic waves to transfer energy from the infrared source without heating the air between.

Infrared heating, a method for heating materials that uses electromagnetic waves to transfer energy from the infrared source without heating the air between.

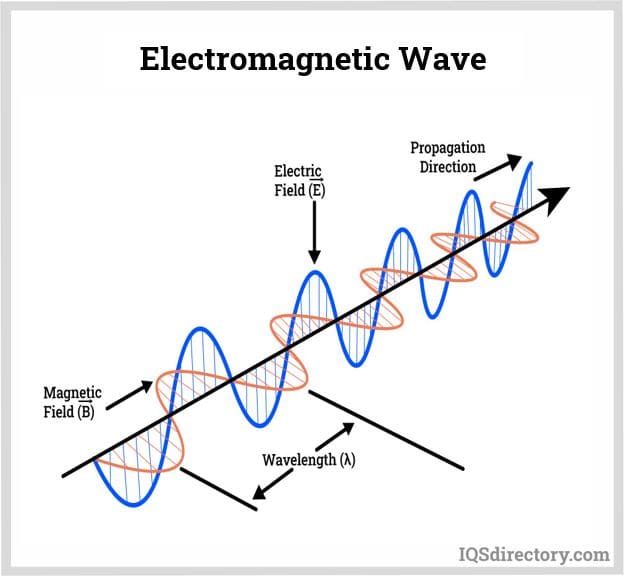

Electromagnetic waves, are composed of waves one electric field and one magnetic field which sways perpendicular to each other

Electromagnetic waves, are composed of waves one electric field and one magnetic field which sways perpendicular to each other

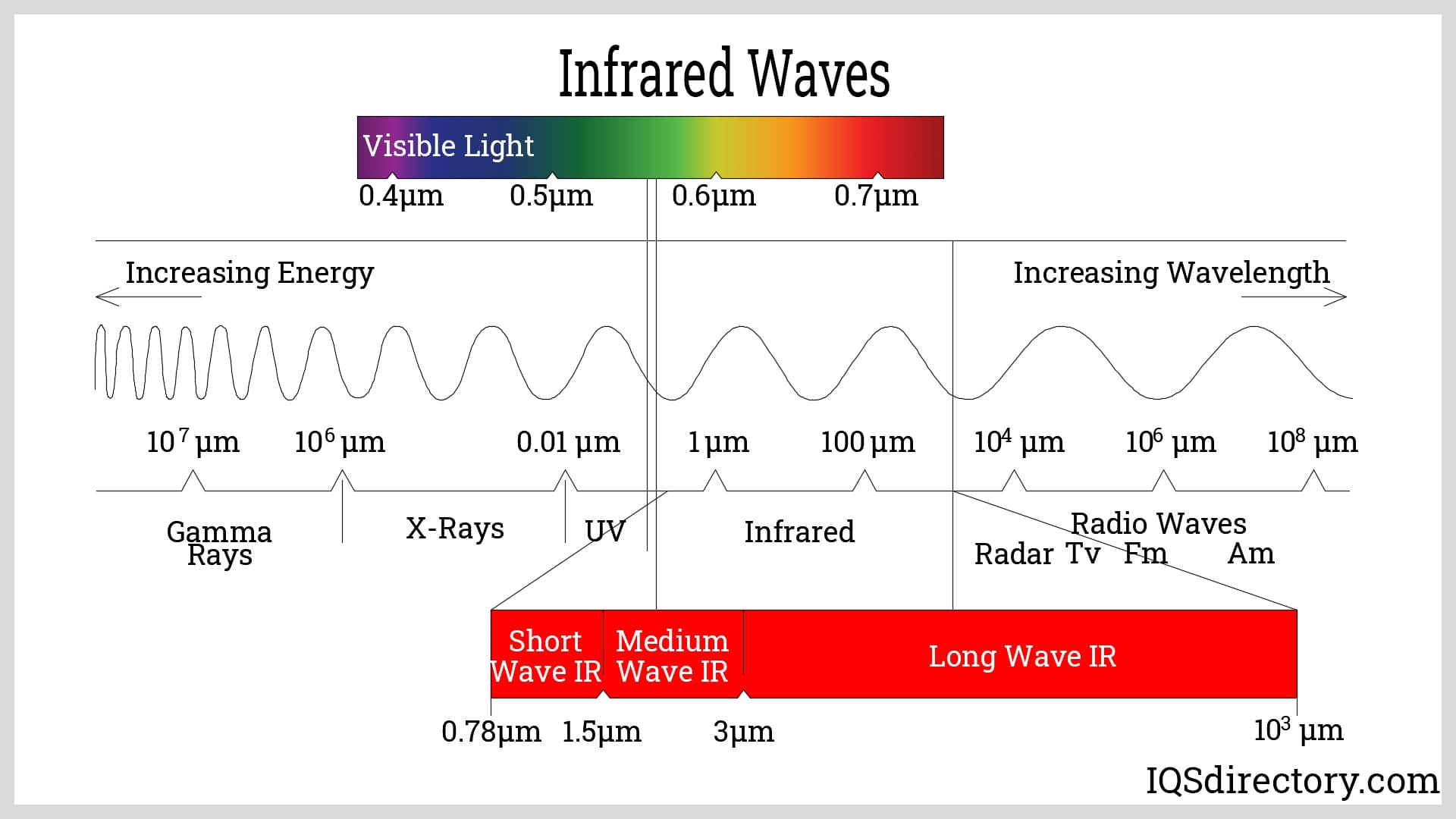

The infrared region is between the visible and the microwave regions of the electromagnetic spectrum with the wavelength range from 700nm to 1mm.

The infrared region is between the visible and the microwave regions of the electromagnetic spectrum with the wavelength range from 700nm to 1mm.

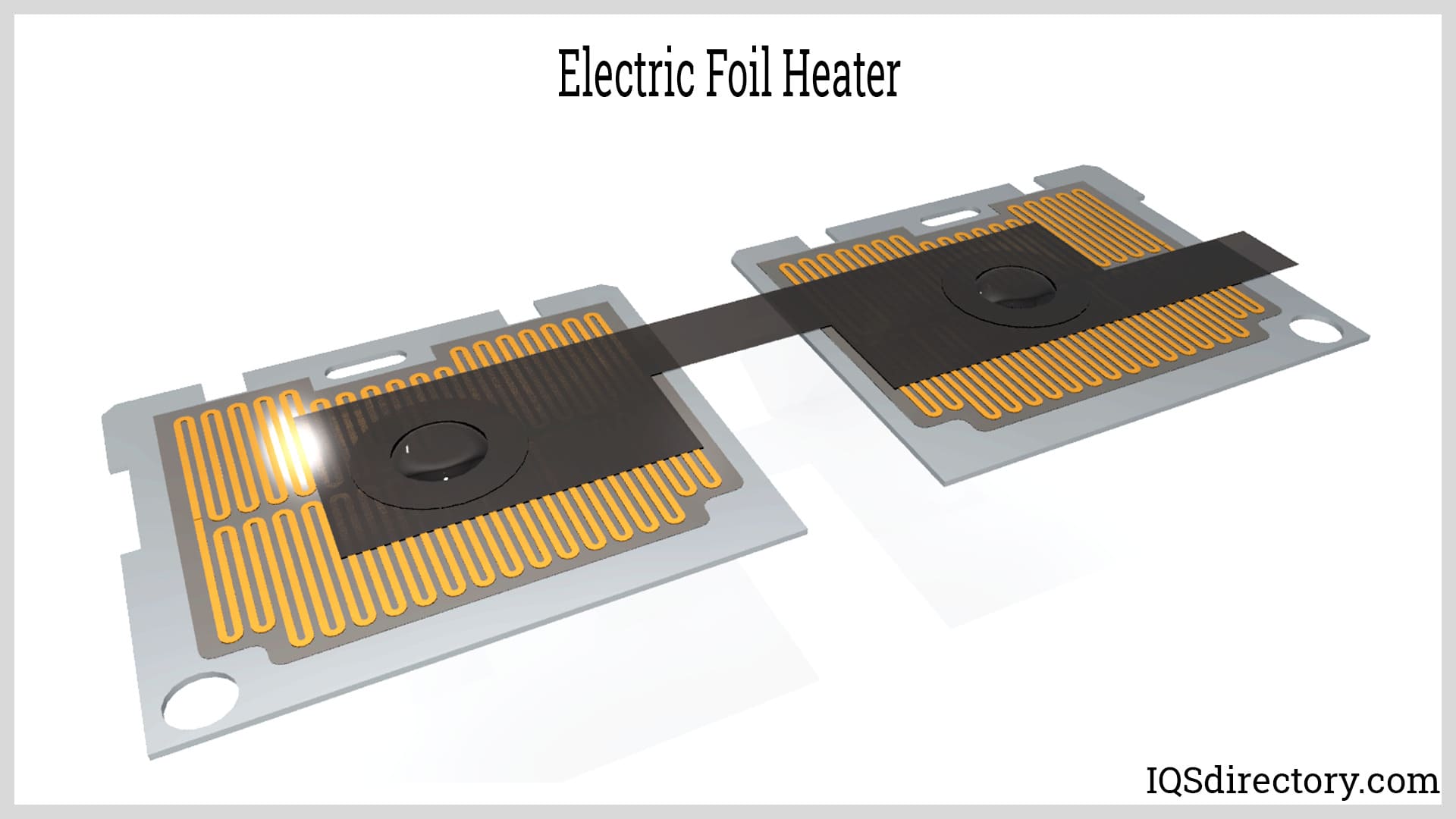

Electric infrared heaters utilizes electricity to transfer heat using the principle of resistive heating.

Electric infrared heaters utilizes electricity to transfer heat using the principle of resistive heating.

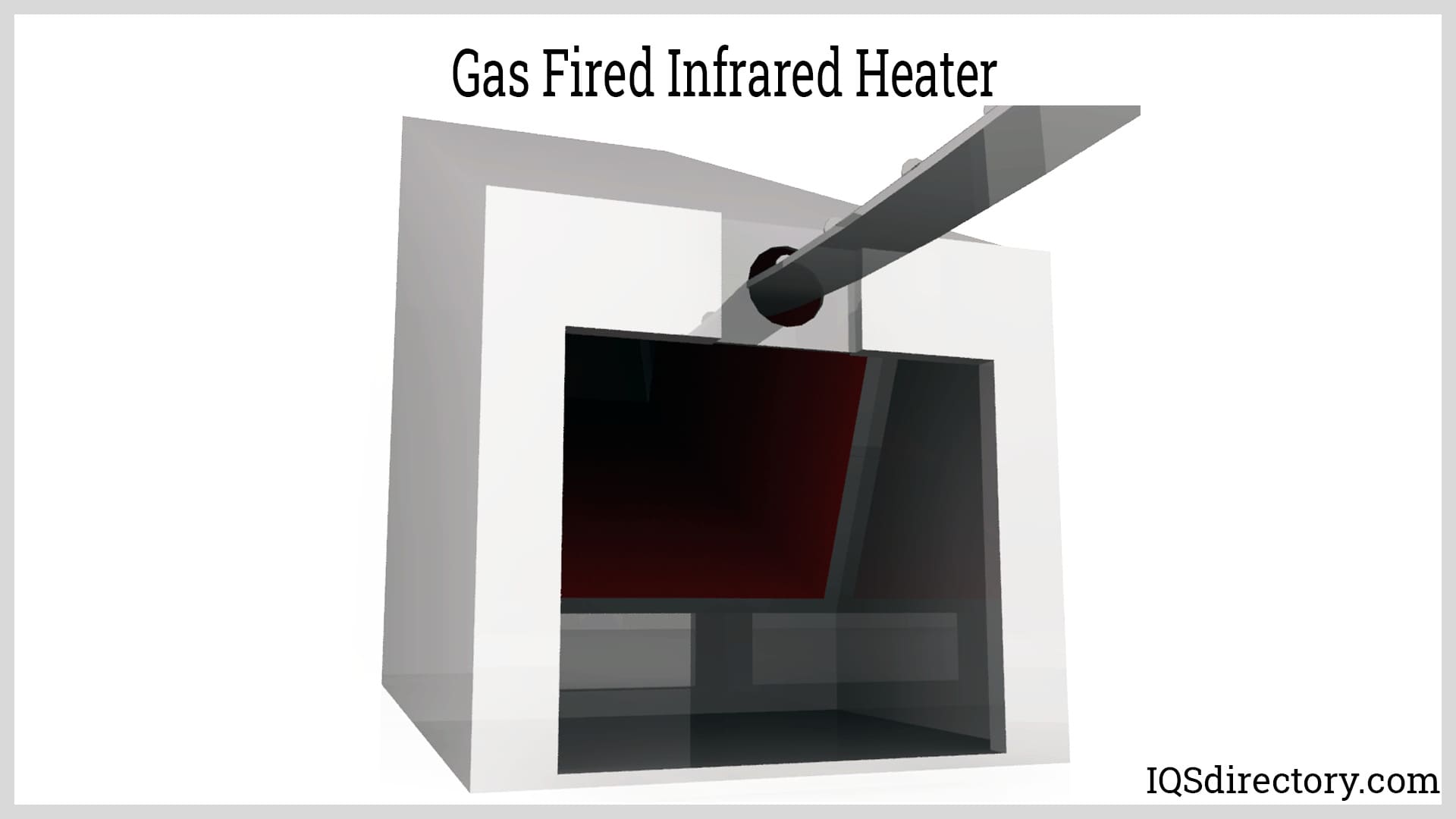

Gas fired infrared heaters, uses a heating element to convert chemical energy stored in various natural gases into heating energy.

Gas fired infrared heaters, uses a heating element to convert chemical energy stored in various natural gases into heating energy.

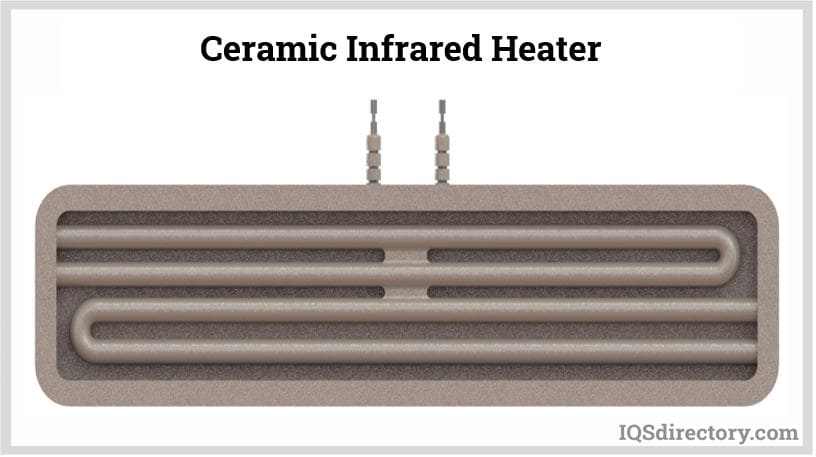

Ceramic heaters, uses a heating element directly cast into the ceramic material which emits medium to long infrared waves.

Ceramic heaters, uses a heating element directly cast into the ceramic material which emits medium to long infrared waves.

Infrared Heater Types

Electric Infrared Heater

Electric infrared heaters generate heat using electricity and transfer that heat directly to spaces or objects. They are widely favored in industrial and residential settings for their energy efficiency and quick response. These heaters often feature coiled tungsten wire elements and are especially common in domestic applications where immediate warmth is desired.

Gas-Based Infrared Heater

Gas infrared heaters produce heat from a gas flame, which is then converted into infrared radiation using filaments, tubes, or ceramic heat exchangers. Reflectors direct the radiant energy to the target area. Most models use propane or natural gas, although petroleum-fueled options also exist. While effective, gas heaters can be expensive to operate.

Low-Intensity Infrared Heater

These tube heaters use a radiant tube that emits heat at lower temperatures as exhaust gas flows through it. Sometimes referred to as positive or negative pressure heaters, they utilize fresh air for combustion and are commonly installed in building heating systems for consistent, low-intensity warmth.

High-Intensity Infrared Heater

Also known as ceramic, luminous, plaque, or radiant heaters, high-intensity infrared units create heat through combustion on a ceramic surface. Ideal for settings that require high heat and significant air exchange, they use ceramic reflectors to efficiently distribute radiant energy.

Short Wave Infrared Heater

Also called near-infrared (NIR) heaters, these operate at filament temperatures exceeding 1800°C and deliver extremely high power densities. They are not ideal for drying processes involving water, but they are effective in applications like deep silica heating.

Medium Wave Infrared Heater

Medium wave and carbon infrared (CIR) heaters operate at approximately 1000°C. They are capable of reaching up to 60 kW/m² (medium wave) and 150 kW/m² (CIR), offering powerful and efficient heat suited for various industrial tasks.

Far Infrared Emitter (FIR)

These heaters use low-watt ceramic plates that remain cool while emitting far infrared radiation. Unlike traditional high-temperature emitters, FIR units are quieter and used in niche applications like small saunas due to their unique heating characteristics.

Construction Heater

Also known as tank top heaters, these portable infrared units mount directly onto propane tanks and are commonly used for outdoor or spot heating in construction environments. The ceramic or steel surface glows red-hot to emit radiant heat.

Door Heater

Installed above or near building entrances, door heaters project a stream of warm air to form an invisible thermal barrier. This prevents heat loss and helps maintain interior temperatures despite frequent door openings.

Garage Heater

Electric or infrared garage heaters provide effective warmth in spaces like workshops, storage areas, or home garages. Their long infrared waves offer immediate, absorbable heat without warming the surrounding air.

Warehouse Heaters

Designed for large open spaces, warehouse infrared heaters deliver energy-efficient heat in environments where insulation is limited and convection heating methods prove ineffective. They help maintain comfortable or climate-controlled conditions in expansive facilities.

Infrared Heater Standards and Specifications

The U.S. Consumer Product Safety Commission (CPSC) enforces numerous regulations for products including electric heater systems. If your heater is intended for use by the general public in the United States, it’s essential that it complies with all applicable CPSC standards.

International organizations like the International Organization for Standardization (ISO) also issue important regulatory guidelines. For heating systems that may be distributed or used abroad, obtaining ISO certification is highly advisable. Additionally, consider compliance with CAN/ANSI/AHRI 1330-2015, the joint Canada–USA standard for gas infrared heaters.

Many countries maintain energy efficiency rating systems for electric appliances. If your heater will be sold internationally, be sure to research and comply with the relevant efficiency standards in each target market.

Things to Consider When Purchasing a Heater

Be it home heating or industrial heating, infrared heaters should be purchased with care. To do so, keep the following considerations in mind.

Look for Power Saving Models

To minimize installation costs and energy usage, consult your vendor about creating a smart heating plan tailored to the layout and zoning of your home or facility.

Buy the Appliance That Fits Your Needs

Make sure the heater you select is suited to your space or application. Speak with your supplier about the size of the area you need to heat, and they can guide you toward an appropriately sized unit.

Select the Latest Model

Even if an older model has glowing reviews, it’s often best to opt for the most recent version. Newer models feature updated technology and improved efficiency, offering better overall performance.

Consider Portability

Ask your supplier about portable infrared heaters. These lightweight options are useful when centralized heating isn’t needed. You can easily move them to another room, a cold corner, or any space that could benefit from direct radiant heat.

Look for a Low Maintenance Heater

Choose a model that is simple to operate and doesn’t require frequent upkeep. A low-maintenance heater will help reduce long-term maintenance costs and minimize downtime.

Find the Right Heater Supplier

Ultimately, securing a quality infrared heater depends on working with a reputable, experienced supplier. Review the manufacturers listed near the top of this page—each is known for quality and reliability. We recommend visiting their websites, narrowing your options to three or four, and then reaching out with your requirements. Be sure to cover the factors discussed above so you can confidently select the supplier best suited to meet your needs.

Proper Care for Infrared Heaters

To keep yourself, others, and your surrounding environment safe, be sure to follow these important guidelines:

Avoid Flammable Materials

Never store or use flammable liquids, vapors, or objects near the heater. Doing so creates a serious fire hazard.

Do Not Obstruct or Hang Items

Avoid hanging anything from the heater or placing objects underneath the reflector, between the tubes, or within decorative elements. These areas must remain clear to prevent overheating and reduce fire risk.

Maintain a Clean Reflector Surface

Wipe down the reflector with a soft cloth whenever you notice dust or debris. Regular cleaning keeps the heater functioning properly and efficiently. Establish a routine maintenance schedule.

Inspect for Wear or Damage

Check for any signs of cracking, sagging, or warping on the reflector. Also be alert for obstructions, corrosion, dirt buildup, loose seals, or visible cracks. If any of these are present, do not use the heater until it has been professionally inspected or repaired.

Check for Gas Leaks

If you're using a gas-powered heater, conduct regular leak checks. The presence of gas leaks can be extremely dangerous and must be addressed immediately.

Accessories for Heaters

Accessories worth considering for your heating system include replacement reflector sets, replacement heating elements, protective guards, ground fault interrupters, built-in disconnect features, and tip-over shutdown safety functions.

Infrared Heaters Terms

-

BTU (British Thermal Unit)

Measurement of heat based on the amount required to raise the temperature of water by one degree.

Closed Loop Control

Control method that adjusts system performance by comparing actual response to the desired output and correcting deviations accordingly.

Convection

Heat transfer and distribution through fluid or gas movement, serving as an alternative to infrared.

Conduction

Heat transfer through direct contact with solids, offering another alternative to infrared.

Curing

The enhancement of coating durability by heating polymeric materials to trigger structural improvements. (Explore curing oven manufacturers on IQS Directory.)

Drying

The use of heat to remove moisture or solvents without altering the material's composition.

Feedback

The return of part of a system’s output to its input for regulation and stability.

Forced Warm Air System

A central heating method that distributes air through ducts to various rooms.

Heat Treating

Heating materials to achieve specific outcomes such as drying, curing, hardening, or tempering.

Infrared

A section of the electromagnetic spectrum located just beyond visible light, used for efficient heat transfer.

Kelvin

An international unit for measuring absolute temperature.

Maximum Operating Temperature

The peak temperature the infrared heater’s sheath can safely reach.

Micron

A unit of length equal to one-millionth of a meter, also known as a micrometer.

Powder Coating

The application of a dry polymer powder that is melted and cured into a smooth finish using heat. (Suitable ovens are listed on IQS Directory.)

Radiant Heat

Heat transferred by infrared waves from a central source, warming solid objects that then heat the air.

Reflector

A component used to redirect or concentrate heat waves to a desired area.

Substrate

The surface or object that receives a coating or thermal treatment.

Therm

A unit of heat equal to approximately 100,000 BTUs per hour.

Wavelength

The distance a wave travels to complete one cycle, especially in electromagnetic applications.