Laser Cutting

Laser cutting is a high-precision, low-distortion thermal cutting process that typically utilizes a CO₂ laser to cut various materials, most commonly metal or sheet metal. Due to its widespread use in metalworking, a laser designed for this purpose is sometimes referred to as a metal laser.

The term "laser" is derived from the acronym Light Amplification by Stimulated Emission of Radiation and refers to a focused beam of light containing a significant concentration of electromagnetic radiation. Unlike conventional light sources, this highly concentrated radiation maintains a specific wavelength without dispersing. The laser beam is significantly stronger and more densely packed with energy than any other form of light known to us. The emission device responsible for generating the beam can be programmed to suit different applications, allowing for precise control over both the intensity and characteristics of the laser beam based on specific cutting requirements.

The History of Laser Cutting

Although laser technology is relatively modern, its roots trace back to the early 1900s, when Albert Einstein laid the theoretical foundation for stimulated emission. However, the first functioning laser was not built until 1960, when Theodore H. Maiman successfully created it. Just five years later, in 1965, laser cutting was introduced on an industrial scale. Developed at the Western Electric Engineering Research Center, the first laser cutting system was used to drill holes into diamond dies. By 1967, engineers in Great Britain had taken the next step, developing the first laser-assisted oxygen jet cutting systems, which were used for cutting and fabricating sheet metal.

The 1970s marked a period of rapid advancements in laser cutting technology. Early in the decade, the process was adapted for specialized applications, such as aerospace titanium cutting, enabling precision machining for high-performance industries. Around the same time, CO₂ lasers were introduced for cutting non-metal materials like textiles. However, at that stage, CO₂ lasers lacked the power necessary to cut through metal efficiently.

Since then, laser cutting has advanced significantly, with improvements in power efficiency, cost reductions, expanded wavelength bands, and enhanced precision. Modern laser cutting plays a crucial role in fields ranging from surgery and weapons technology to intricate machining and fabrication. As science and engineering continue to progress, so too will laser cutting technology, further refining its capabilities and expanding its applications.

The Benefits of Laser Cutting

Laser cutting offers numerous advantages over conventional methods such as thermal machining, mechanical machining, arc welding, electrical discharge machining (EDM), and flame cutting. These advantages make it a preferred choice for precision cutting and fabrication.

- Laser Cutting Quality

- One of the defining characteristics of laser cutting is its exceptional beam control and motion stability, allowing for precise cuts with superior edge quality. Unlike traditional cutting methods, laser-cut parts exhibit minimal edge deformation and do not experience roll-off, ensuring clean, sharp edges with almost no burrs.

- Accuracy of Laser Cutting

- Although laser cutting does not offer the same cost efficiency as cold-water jet cutting or the completely burr-free edges produced by water jet cutting, it excels in creating tighter tolerances on a smaller scale than any other metal-cutting process. This makes it an ideal choice for applications requiring intricate detailing and high precision.

- Laser Cutting Turnaround Time

- Compared to conventional tool-making techniques, laser cutting boasts significantly faster processing times. Its efficiency allows for rapid production, even for complex parts. Additionally, laser cutting systems can easily accommodate design modifications, making them well-suited for prototyping and short-run manufacturing.

- Laser Safety

- Despite emitting a high-intensity CO₂-based laser beam, laser cutting systems are safe when proper protocols are followed. Because these systems are controlled by CNC machining, they require minimal human intervention, reducing the risk of operator injury. However, safety precautions must still be observed. Extra care is necessary when working with flammable materials, and all operators in proximity to the laser must wear appropriate protective eyewear to prevent exposure to harmful radiation.

- Cutting Versatility

- Laser cutting technology offers remarkable versatility, accommodating a wide range of materials and thicknesses. Various laser cutting services optimize material usage, minimizing waste and improving efficiency. This adaptability makes laser cutting suitable for diverse industries, from aerospace and automotive to consumer electronics and medical devices.

- Ease of Maintenance

- Laser cutting and engraving systems require minimal maintenance. Proper ventilation is crucial to maintain a clean working environment and prevent the buildup of potentially hazardous fumes. Additionally, ensuring that no flammable gases or chemical droplets are present in the atmosphere enhances safety. Installing an effective air filtration system can significantly improve workplace conditions and extend the lifespan of laser equipment.

- Energy Efficiency

- Laser cutting machines, including laser engravers and laser drilling systems, are designed for energy efficiency. They consume relatively low amounts of power compared to other industrial cutting methods, leading to cost savings on electricity bills. This energy-efficient nature, combined with their precision and speed, makes laser cutting a sustainable and economical choice for modern manufacturing and fabrication processes.

Laser Cutting Design

When developing a custom laser-cut product, manufacturers carefully consider a range of factors to ensure precision and quality. These factors include the required tolerances, material thickness, optimal material selection, the most suitable laser cutting system, the sharpness and cleanliness of the laser cutter, and the precise positioning of the nozzle or laser head. Each of these elements plays a crucial role in achieving accurate, clean cuts that meet design specifications.

- Cutter Cleaning

- A critical aspect of maintaining laser cutting accuracy is ensuring that the lens or cutting mechanism is thoroughly cleaned. Before beginning the cutting process, laser cutting services verify that the lens is in optimal condition and free of debris. A properly maintained lens ensures consistent beam performance, preventing inconsistencies or defects in the final product.

- Nozzle Position

- To confirm that the nozzle is correctly aligned, laser cutting service providers perform a calibration test using a thin tape and a low-intensity laser beam. By examining the location of the hole created by the beam, they determine whether the nozzle is properly centered. This essential step ensures that the laser drilling machine is precisely aligned and ready for operation, minimizing errors during the cutting process.

- Manufacturers offer an extensive range of custom laser cutting services, adjusting various parameters to meet specific design needs. By fine-tuning key elements of the laser system—including cutting speed, assist gas flow, CNC programming inputs, and heat-affected zone management—they achieve the required tolerances and part thicknesses. This meticulous control allows for highly precise, efficient, and customized laser cutting solutions tailored to a variety of applications.

Laser Cutting Images, Diagrams and Visual Concepts

Laser cutting is material-cutting that uses an intensely focused laser to cut metals, paper, wood, and acrylics.

Laser cutting is material-cutting that uses an intensely focused laser to cut metals, paper, wood, and acrylics.

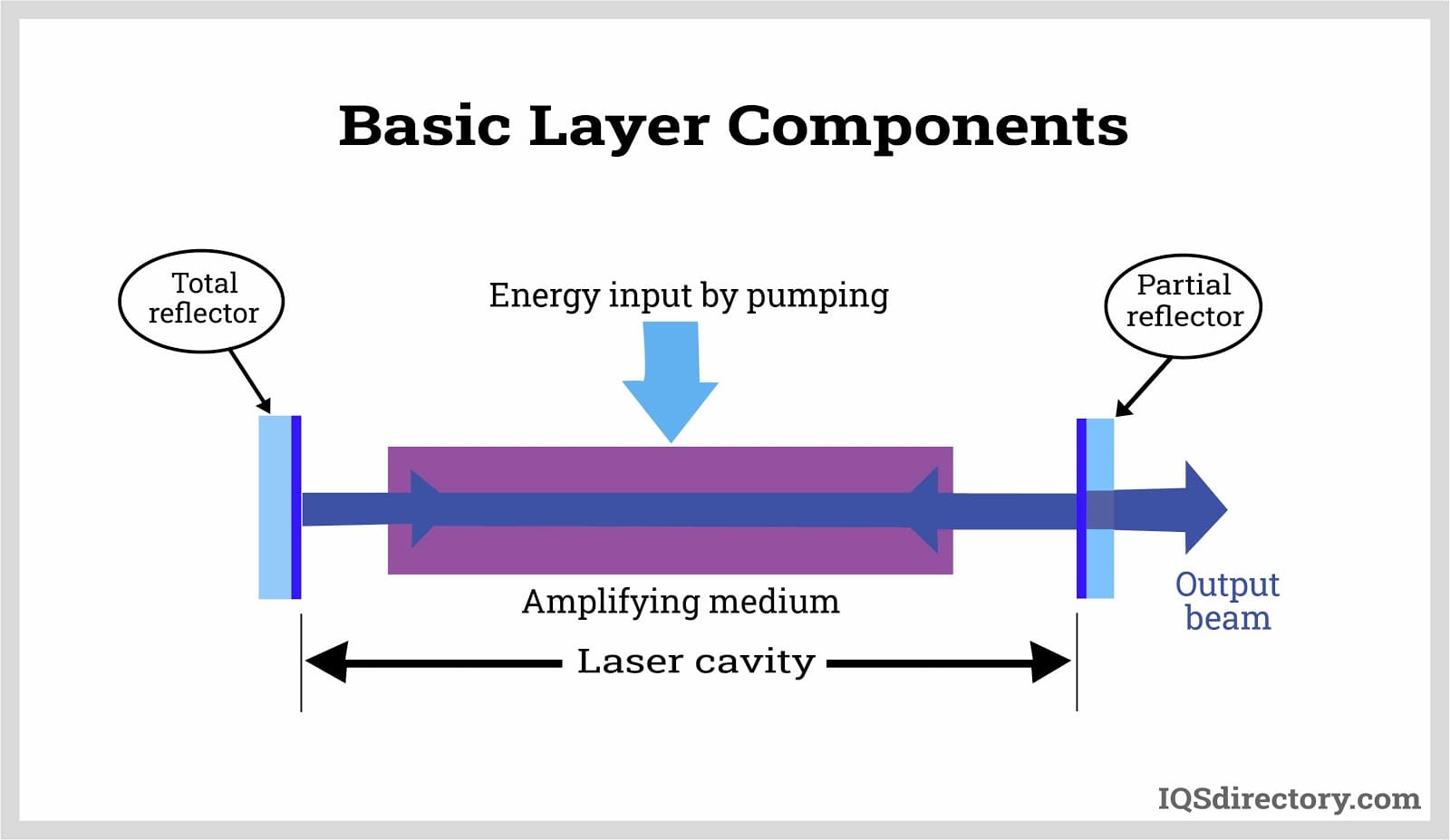

Lasers are generated by a high-intensity light source inside a reflective laser cavity, which contains a laser rod to generate radiation.

Lasers are generated by a high-intensity light source inside a reflective laser cavity, which contains a laser rod to generate radiation.

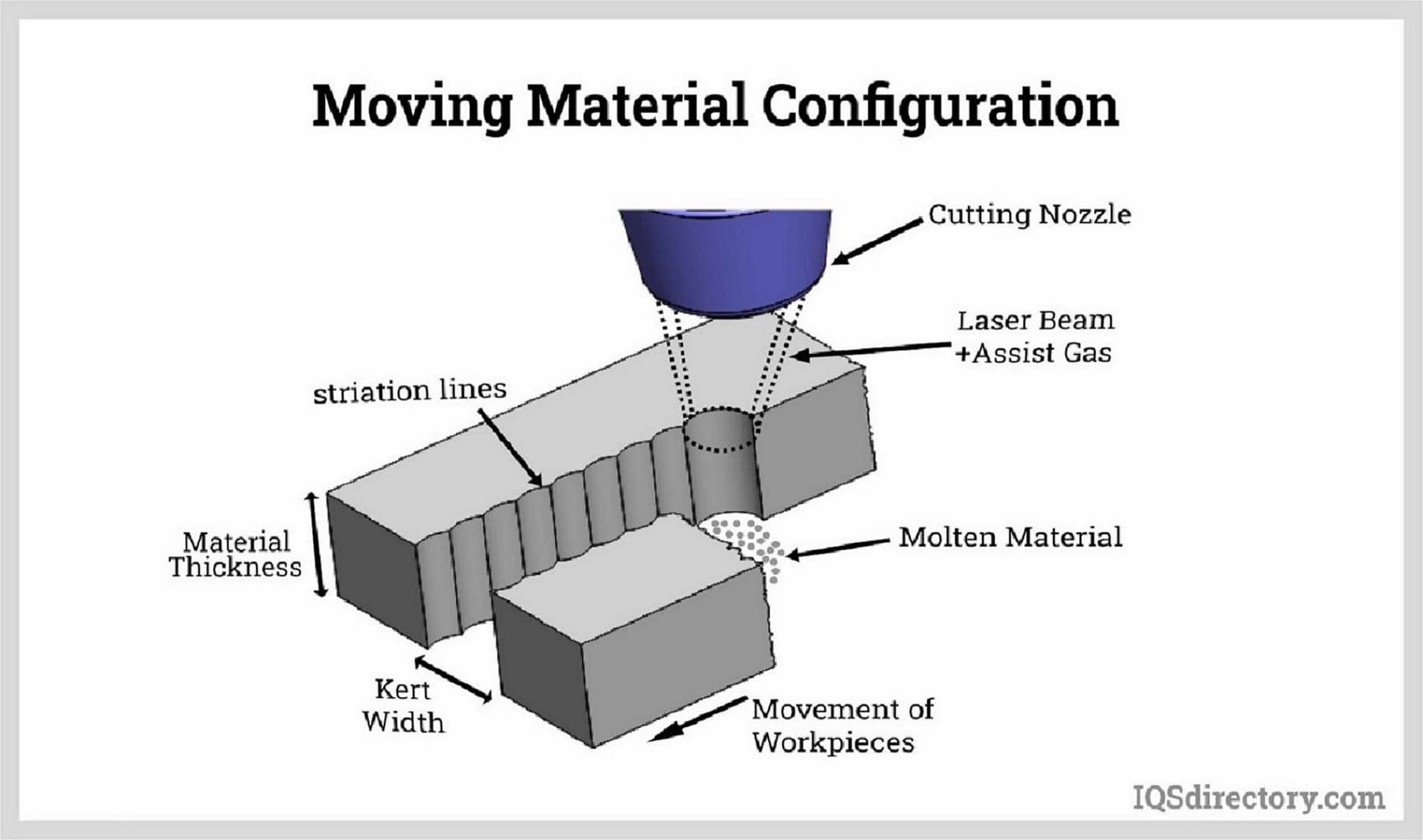

The laser cutter is stationary while the material surface moves.

The laser cutter is stationary while the material surface moves.

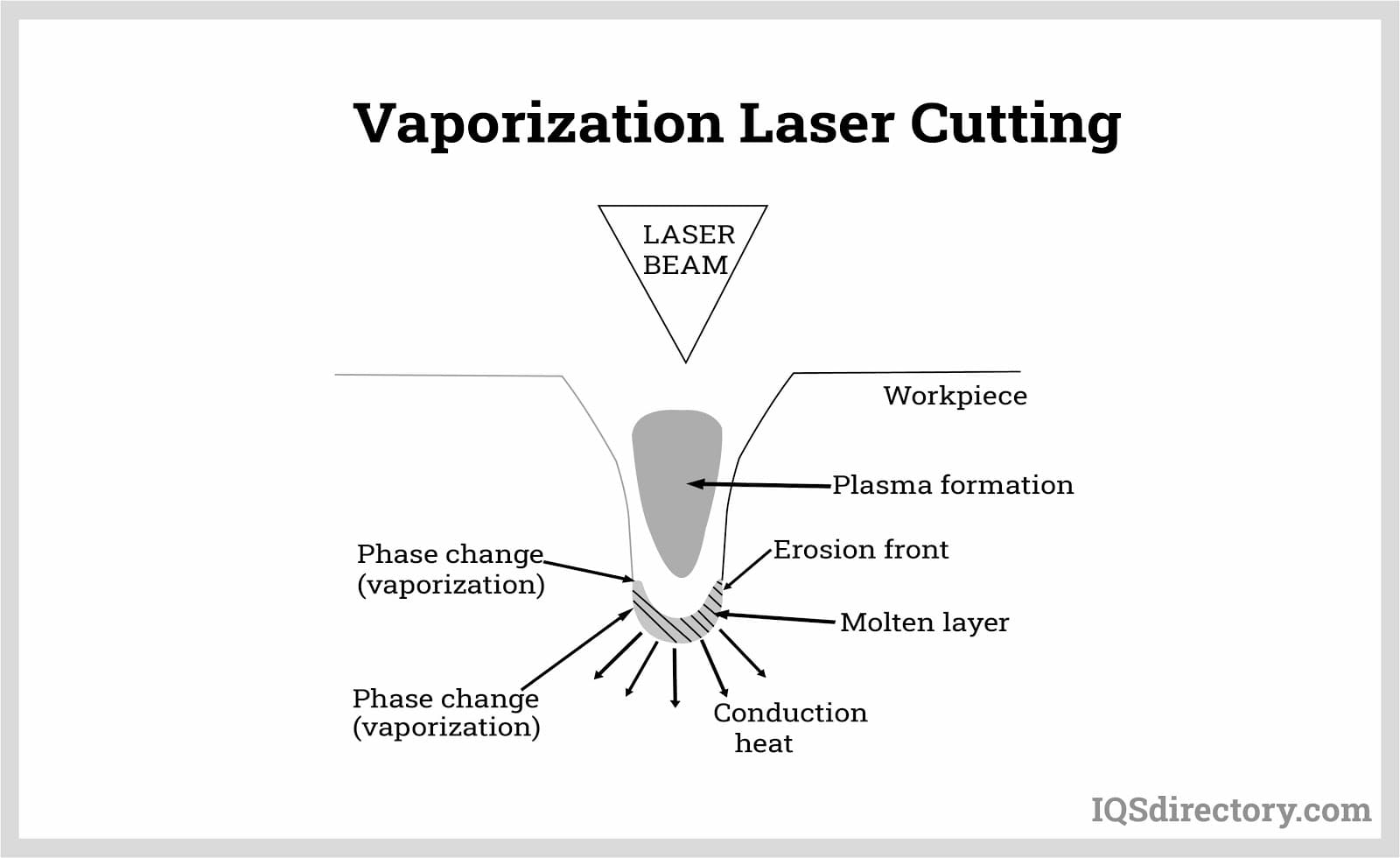

Vaporizing laser cutting changes the state of the material to a gaseous state.

Vaporizing laser cutting changes the state of the material to a gaseous state.

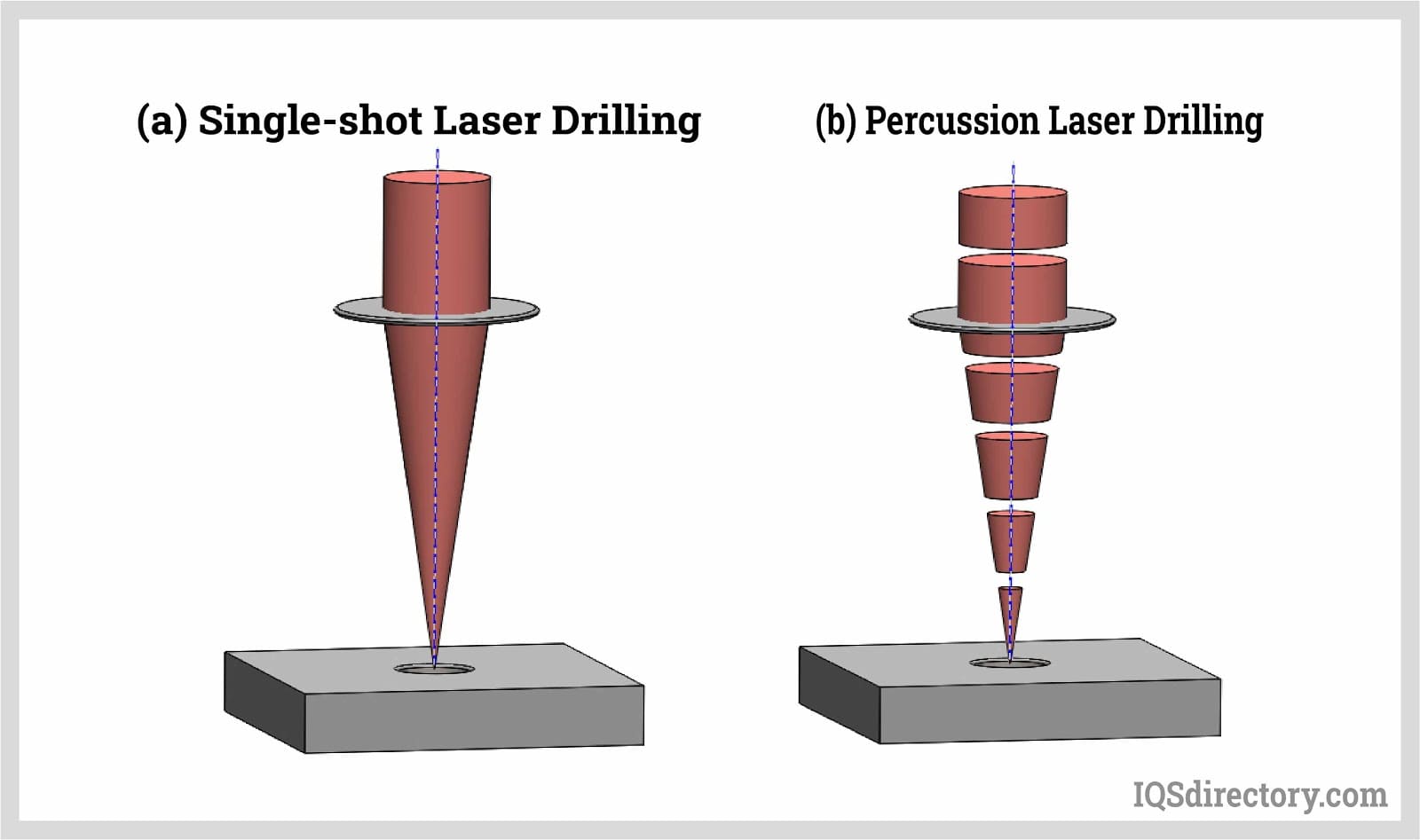

Percussion drilling allows the laser beam diameter to be the same as the hole diameter.

Percussion drilling allows the laser beam diameter to be the same as the hole diameter.

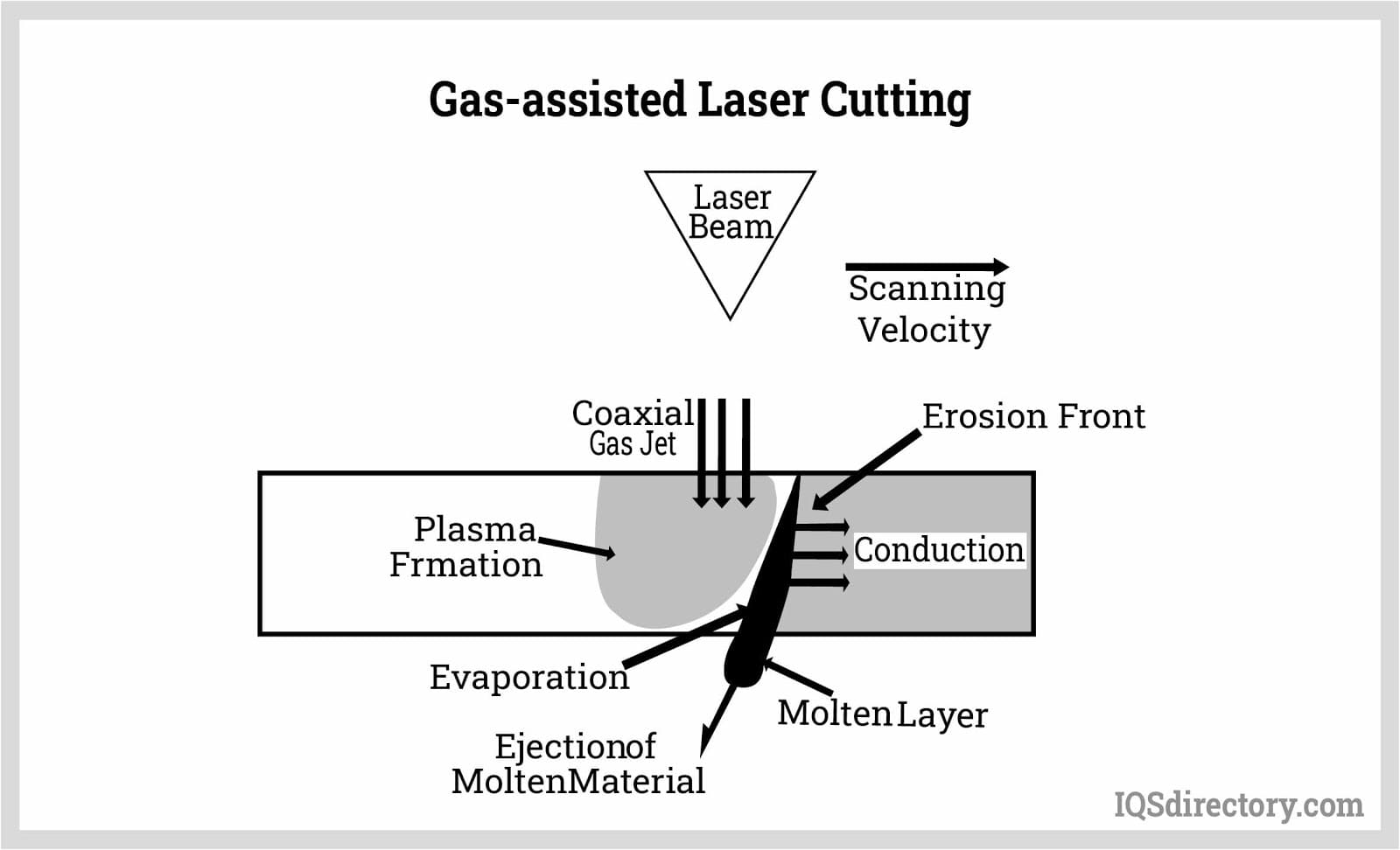

Using a jet of gas with the laser beam expels the material from the cut.

Using a jet of gas with the laser beam expels the material from the cut.

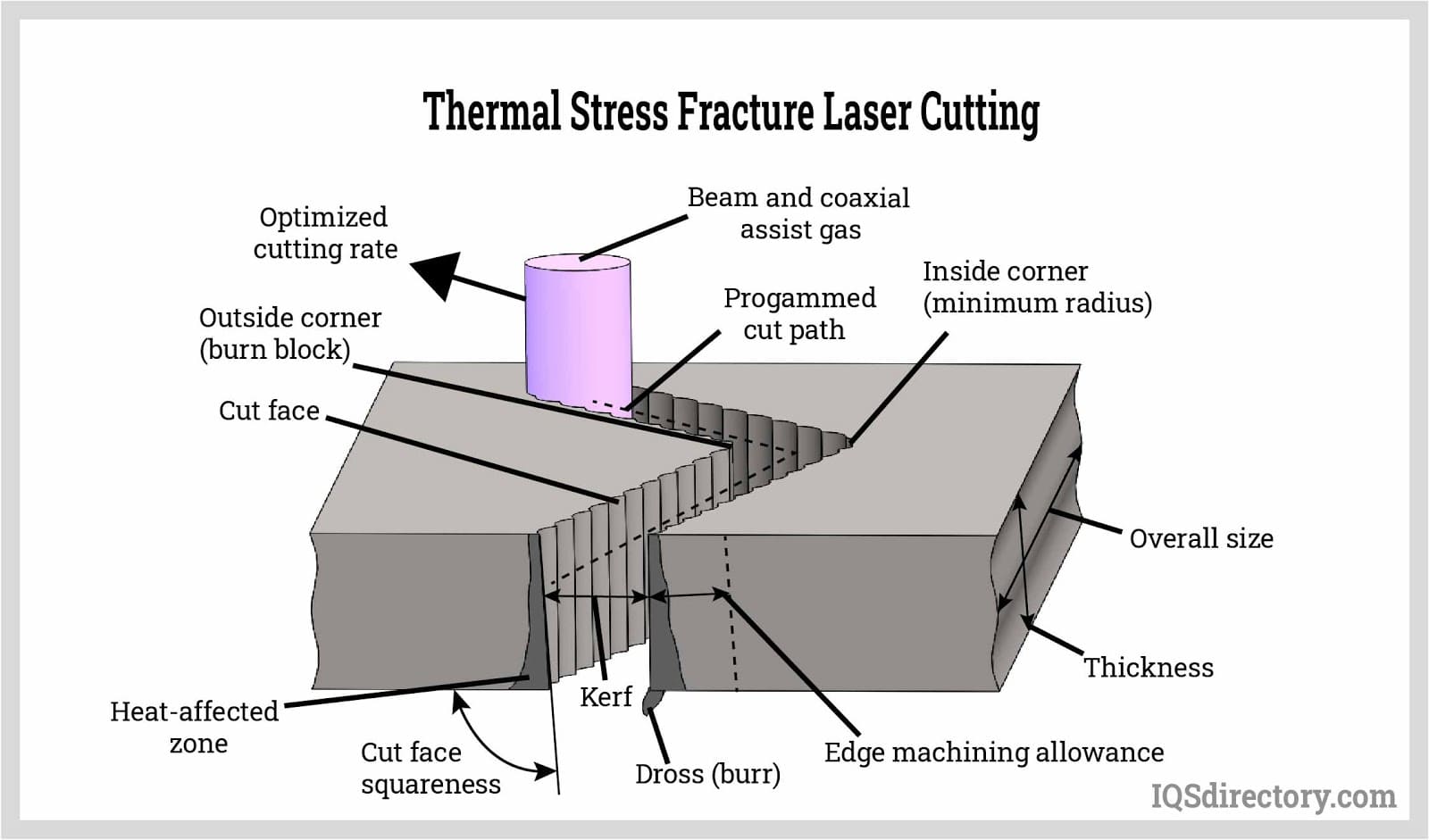

A process that involves introducing a small kerf at about one-third the thickness of the material using a laser.

A process that involves introducing a small kerf at about one-third the thickness of the material using a laser.

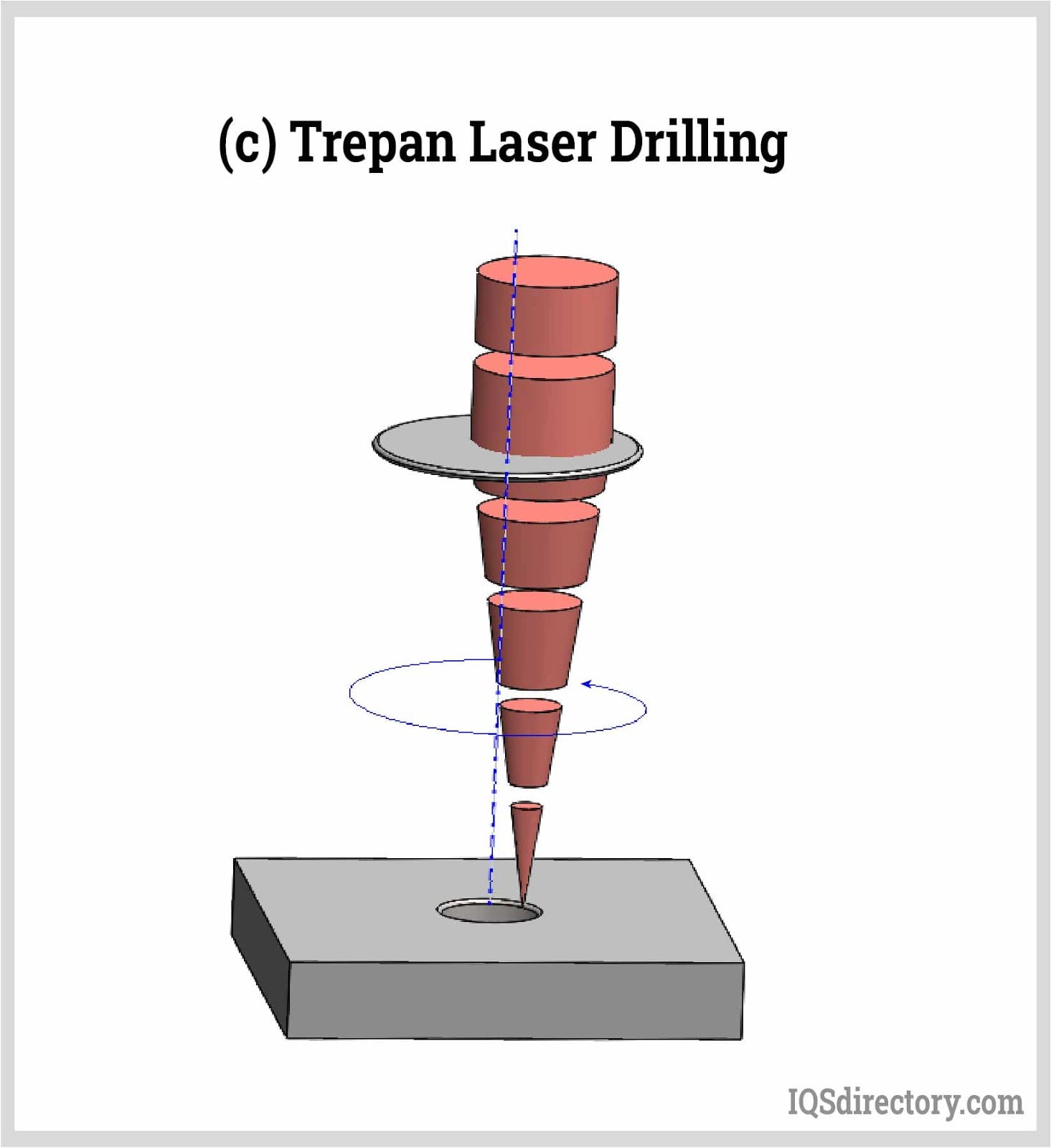

Trepan laser drilling, the laser spot size is significantly smaller than the hole size then traverses around the hole, expanding the drilled hole to the desired diameter.

Trepan laser drilling, the laser spot size is significantly smaller than the hole size then traverses around the hole, expanding the drilled hole to the desired diameter.

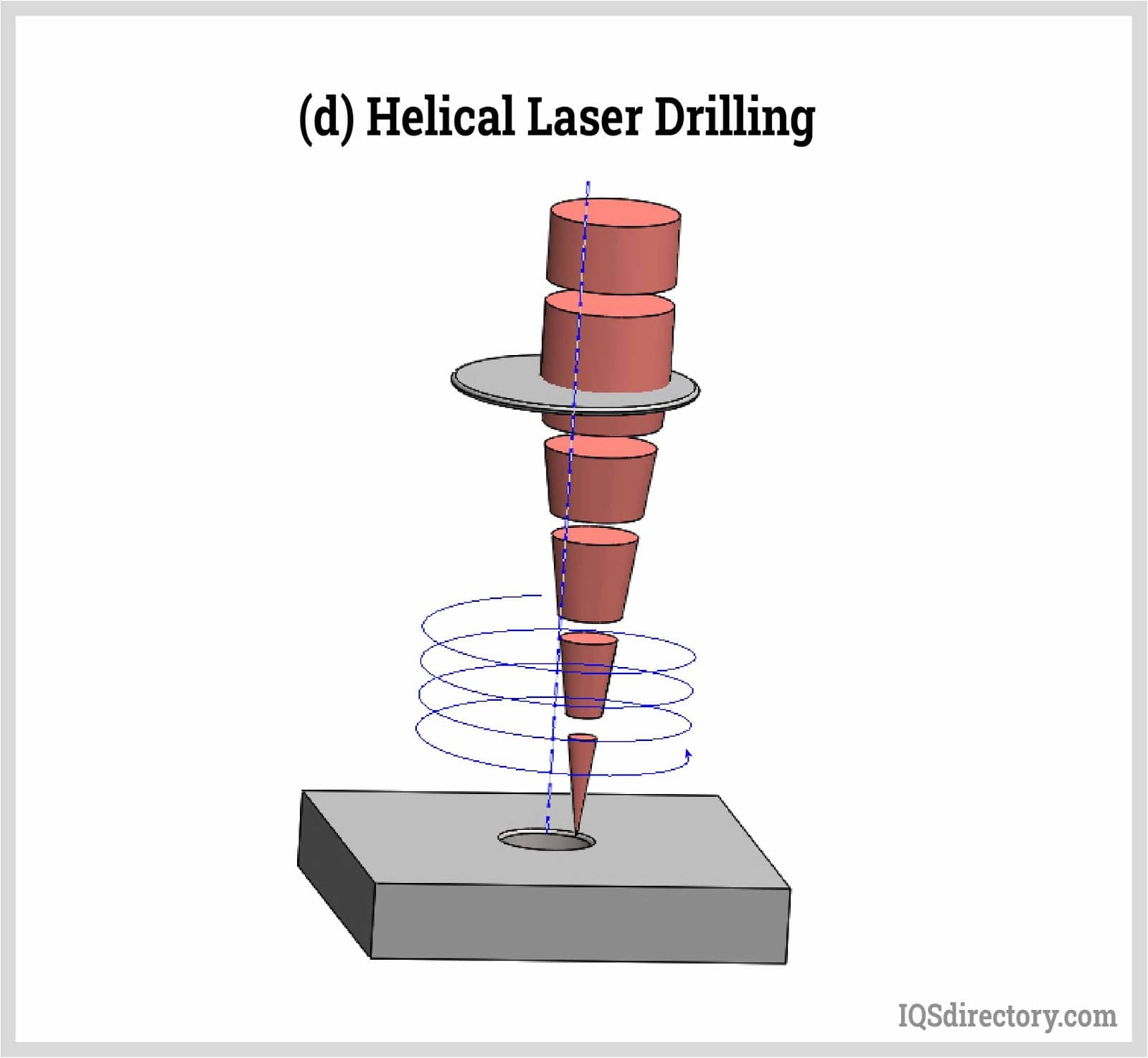

Helical laser uses a moving laser that rotates relative to the workpiece like a conventional drill bit.

Helical laser uses a moving laser that rotates relative to the workpiece like a conventional drill bit.

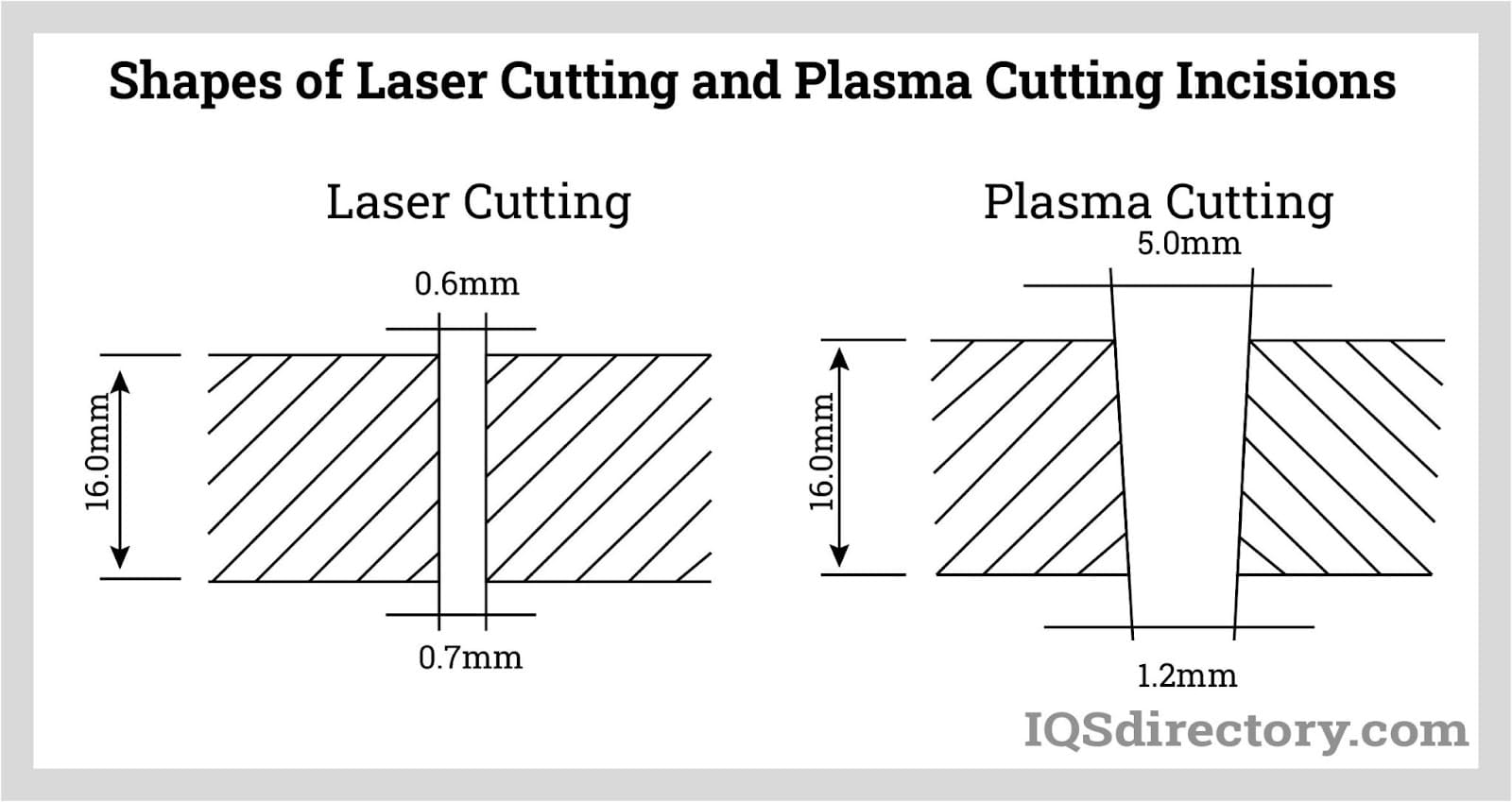

The difference between the two processes is the fuel to power the cutting process with plasma cutting using a plasma gas, while laser cutting involves a beam of light.

The difference between the two processes is the fuel to power the cutting process with plasma cutting using a plasma gas, while laser cutting involves a beam of light.

Laser Cutting Types

- CNC Laser Cutting

- This process utilizes an intense laser beam to cut part shapes from sheet material with remarkable precision. The minimal heat distortion ensures that the parts remain flat, preserving their structural integrity throughout the cutting process.

- CO2 Laser Cutting

-

A laser cutting method that employs carbon dioxide as the primary lasing medium, CO₂ lasers function by using a gas mixture—including helium, nitrogen, and predominantly CO₂—to generate a powerful beam. These lasers produce a cut quality comparable to milled edges on mild steels and can operate in either continuous wave (CW) mode or pulses, depending on the material and application.

- Custom Laser Cutting

- A highly specialized form of laser cutting, this process involves CNC machining programs that are custom-programmed to create unique designs tailored to the buyer’s exact specifications. Every aspect of the cut is meticulously controlled to ensure the final product matches the intended design.

- Evaporative Laser Cutting

- This method involves the direct vaporization of target materials, typically those with low vaporization temperatures and low thermal conductivity. It effectively removes material without causing excessive heat buildup, making it ideal for precision applications.

- Excimer Laser Cutting

- Utilizing noble gas compounds as the lasing medium, excimer lasers generate light in the ultraviolet to near-ultraviolet spectra. Their short wavelengths allow for highly detailed and precise cutting, making them well-suited for intricate microfabrication tasks.

- Gas Laser Cutting

- A technique in which gas acts as the activating agent for the laser beam. The choice of gas influences the cutting speed, edge quality, and overall efficiency of the process.

- Nitrogen Cutting

- Also known as inert gas cutting, this method covers cut edges with melted and resolidified metal composed of the same material mixture. Because of its ability to prevent oxidation, nitrogen cutting is particularly useful for applications in food processing, chemical plants, and sign production, where corrosion resistance is essential.

- Laser Cutters

- These highly specialized machines perform all laser-based cutting, drilling, and engraving processes. They are designed to precisely cut metals and other materials, ensuring superior edge quality and intricate detailing in manufactured parts.

- Laser Drilling

- A process in which a laser beam is used to create precise holes in materials. This method is widely employed in aerospace, electronics, and medical applications where micro-perforation and high-precision drilling are required.

- Laser Engraving

- By using lasers to etch designs or text onto a surface, laser engraving enables permanent markings on a variety of materials, from metal and plastic to wood and glass. It is commonly used for branding, identification, and decorative purposes.

- Laser Etching

- A variation of laser engraving, laser etching marks the surface of a material without cutting all the way through. This is achieved by using a reduced power setting to create subtle yet durable markings.

- Laser Machining

- An umbrella term for material removal processes utilizing laser beams, laser machining includes cutting, drilling, grooving, marking, and scribing. This technology offers exceptional precision and is used for intricate shaping and fabrication across multiple industries.

- Laser Marking

- This process creates permanent marks on materials at extremely high speeds, sometimes within milliseconds per character. It is programmable, highly flexible, and environmentally clean, making it ideal for product labeling and traceability applications.

- Laser Metal Cutting

- One of the most widely used laser applications, this process involves cutting metals—the most common material in machining and manufacturing. The precision and efficiency of laser metal cutting make it indispensable in industries such as automotive, aerospace, and construction.

- Laser Micromachining

- A specialized process designed to achieve extreme detail and high precision, laser micromachining is used for manufacturing tiny components that require close tolerances, such as microelectronics and medical devices.

- Laser Welding

- This technique uses a concentrated laser beam to join two or more metal pieces by melting the contact areas and allowing them to resolidify. Laser welding is known for producing strong, high-quality joints with minimal heat-affected zones.

- Liquid Laser Cutting

- In this process, large organic dye molecules serve as the active lasing medium. Liquid laser cutting is used in applications requiring tunable wavelengths and high-energy beam generation.

- Melt Shearing

- Also referred to as “fusion cutting,” this laser process melts the material at the cut zone, while a high-speed gas jet blows the molten material away. This results in a high-quality cut edge that features microscopic ripples, often seen in applications requiring clean and smooth cuts.

- Moving Optics Laser Cutting

- A technique in which mirrors reflect the laser beam toward the cutting head while keeping the workpiece stationary. This setup is ideal for applications where material movement is impractical or where extremely precise control of the cutting path is required.

- Multi-Axis Laser Cutting

- Unlike conventional single-axis laser cutting, multi-axis laser cutting allows for three-dimensional cuts. While this technology provides greater versatility for complex shapes, it also involves higher costs, longer setup times, and additional safety considerations.

- Oxygen Assist Cutting

- A process where oxygen serves as the primary cutting agent, while the laser beam sustains the reaction. This method is particularly useful for cutting thick steel plates, as the oxygen actively reacts with the metal to accelerate the cutting process.

- Pulsed Laser Cutting

- Instead of using a continuous beam, pulsed laser cutting employs short bursts or a sequence of pulses to concentrate power at specific intervals. This approach enables higher peak power delivery, which is especially effective for cutting materials with high thermal resistance.

- SemiConductor Laser Cutting

- A process that utilizes semiconductor materials as the active lasing medium. Semiconductor lasers are compact, energy-efficient, and widely used in electronics, fiber optics, and medical device manufacturing.

- Solid State Laser Cutting

- In this technique, the lasing medium is in a solid state rather than a gas or liquid. Solid-state lasers, such as Nd:YAG (neodymium-doped yttrium aluminum garnet) lasers, are known for their high efficiency and are commonly used for precision cutting in industrial and medical applications.

Laser Cutting Process

The laser cutting process is controlled using laser optics and a computerized or computer-controlled system that directs the beam onto the material being cut. CNC laser systems rely on CAD designs, which input all necessary machining details into a program that fully automates the cutting process. These advanced systems require minimal human intervention, with technicians primarily overseeing production and maintaining the machines.

During cutting, either the laser beam or the workpiece moves to achieve the desired pattern. As this movement occurs, the focused beam melts material in a localized area. To guide the laser light, manufacturers utilize mirrors or fiber optics to direct the beam through a lens, which focuses it with extreme precision. The laser cutter is programmed to stimulate the lasing material through electrical discharges or lamps inside a sealed chamber. The beam reflects internally against a partial mirror until it gains sufficient energy to be emitted as a coherent, monochromatic stream of light.

Assist gases such as nitrogen or carbon dioxide are often used in conjunction with laser cutting to prepare freshly cut surfaces for painting or corrosion resistance. In tube laser cutting, gas is injected inside the laser tube to enhance the cutting quality. A well-known example of this technique is CO2 laser cutting, which remains one of the most powerful and widely used laser cutting methods.

For large-scale and high-precision applications, manufacturers integrate speed control systems with laser emission devices to ensure consistent performance and safe operation. These advancements make laser cutting one of the most reliable, efficient, and precise fabrication technologies in modern industry.

Laser Cutting Applications

Laser cutting is a value-added service that enables precise cutting, slicing, melting, vaporizing, and chipping of a wide variety of materials. Many industrial processes rely on this technology to achieve high precision and efficiency in material fabrication. Without laser cutting, several manufacturing operations would be incomplete, as it plays a critical role in producing complex components with microscopic tolerances and superior accuracy.

Industries that depend on laser cutting include microtechnology, electronics, medical device manufacturing, automotive production, aerospace engineering, military and defense applications, communications, plumbing, and HVAC systems. The ability of laser cutters to fabricate small, intricate parts makes them indispensable in these sectors, ensuring reliability, durability, and high-performance functionality.

Products Produced Through Laser Cutting

Laser cutting technology is widely used to manufacture a broad range of products and components. These include catheters, hypo-tubes, gas flow orifices, filtering devices, nozzles, solar cells, and gaskets. The aerospace industry relies on laser-cut circuit boards, while cell phone manufacturers use the process for producing intricate mobile device components. Additionally, laser cutting is crucial in the production of computer microchips, transducers, water piping systems, refrigeration components, and various military and communication devices. Its versatility and precision make it a fundamental process in modern manufacturing.

Machinery Used in Laser Cutting

Achieving the high-quality results for which precision laser cutters are known requires the use of specialized machinery. Different laser types offer unique advantages depending on the material being processed and the specific requirements of the application. Among the most commonly used laser cutting machines are fiber lasers, high-power lasers, and metal lasers.

- Fiber Laser

- Fiber lasers operate using an optical fiber that has been treated with rare earth elements such as thulium, holmium, erbium, or ytterbium. These lasers are highly efficient due to their lack of moving parts, which minimizes maintenance needs and reduces operating costs. Their energy efficiency and longevity make them an ideal choice for many industrial applications requiring precision cutting.

- High-Power Laser

- High-power lasers are used for cutting through stronger and thicker materials such as mild steel, carbon steel, stainless steel, and titanium. This classification applies to several laser types, including fiber lasers and solid-state lasers, which generate intense power levels necessary for processing dense and heat-resistant metals.

- Metal Laser

- Designed specifically for cutting metal materials, metal lasers provide optimal performance when working with materials such as mild steel, stainless steel, titanium, and other specialized metals used in industrial applications. These lasers ensure clean, precise cuts that meet the high standards required in metal fabrication.

Things to Consider When Choosing Laser Cutting

Despite its many advantages, laser cutting has some limitations, most of which are related to the thermal effects of hot cutting. The intense heat generated during the process can lead to thermal expansion and warping, particularly in narrow sections of a workpiece. Oxygen, often used as an assist gas, can introduce stress into the cut edges of certain materials, potentially causing distortion and oxidation. This issue is particularly noticeable in materials with dense hole patterns.

Additionally, laser cutting requires significant amounts of energy, which can make operational costs higher than some alternative cutting methods. Metals such as aluminum and copper alloys present further challenges due to their high reflectivity and excellent heat conduction properties, which reduce laser efficiency. Furthermore, laser cutting is not suitable for processing materials such as crystal, glass, or other non-metals that do not respond well to laser interaction.

Despite these drawbacks, laser cutting remains an outstanding choice for precision cutting and industrial fabrication. If you are considering laser cutting for your application, it is essential to work with a reputable service provider to ensure you receive the highest quality results. Not all laser cutting services are equal, so carefully evaluate different manufacturers to find one that meets your specific needs. Browse their websites, review their capabilities, and contact them directly to discuss your project specifications. By asking questions and voicing any concerns, you can make an informed decision and select the provider that offers the best combination of expertise, customer service, and product quality.

Laser Cutting Variations and Similar Processes

In addition to laser cutting, several related processes are widely used for marking, laser engraving, drilling, and shaping materials. Other common laser marking techniques include laser engraving, laser drilling, and waterjet cutting. Many manufacturers that specialize in laser-cut products also provide custom laser cutting services, which are particularly useful for intricate or highly detailed designs that cannot be effectively cut by hand.

- Laser Engraving

- Also referred to as laser etching, this process utilizes laser technology to create permanent marks on a surface. Unlike traditional engraving methods, which rely on mechanical tools, laser engraving achieves precision by using a focused laser beam to etch the material. The most efficient way to perform laser engraving is with a dedicated laser engraver, a CNC-controlled machine that operates based on CAD-generated inputs. Human operators oversee the process, adjusting the speed, beam spread, and intensity to achieve the desired results.

- A key distinction between a laser cutter and a laser engraver lies in how they interact with materials. While a laser cutter melts or burns through the surface to create precise cuts, a laser engraver instead fractures or vaporizes the material, leaving behind a permanent imprint without completely penetrating the workpiece. This makes laser engraving an ideal method for creating serial numbers, branding, decorative designs, and other fine details on metal, glass, wood, and plastic surfaces.

- Laser Drilling

- For applications requiring precise holes with tight tolerances, manufacturers turn to laser drilling. As the name implies, this technique employs a high-powered laser beam to create holes in a material, ensuring clean edges and minimal distortion. Laser drilling is commonly used in aerospace, electronics, and medical industries, where accuracy is paramount.

- Because it does not require direct contact with the material, laser drilling is advantageous for delicate components that might be damaged by mechanical drilling methods. The process is particularly effective for creating micro-holes in metals, ceramics, and composites, allowing for enhanced performance in specialized applications.

- Waterjet Cutting

- Waterjet cutting is a non-thermal process that uses highly pressurized streams of water to cut and shape materials. Unlike laser cutting, which relies on intense heat, waterjet cutting removes material through pure force, making it an excellent option for materials sensitive to high temperatures.

- One of the main advantages of waterjet cutting is its ability to save energy and resources compared to laser-based methods. Additionally, because it does not generate heat, it eliminates the risk of thermal distortion or warping, making it suitable for heat-sensitive materials. However, waterjet cutting has its limitations. While it is effective for many materials, it cannot be used to cut extremely hard substances like diamonds. Similarly, brittle materials such as certain glass compositions may be prone to breakage under the high-pressure water streams.

- Despite these constraints, waterjet cutting remains a valuable alternative to laser cutting, offering a clean and precise cutting method for a wide range of applications, from industrial manufacturing to artistic design.

Laser Cutting Terms

- Ablation

- The removal of material using an industrial laser through evaporation, vaporization, or melting.

- Alloy Steels

- Steel alloys composed primarily of iron, excluding the additional metals required to produce stainless steel.

- Articulated Arm

- A system made up of hollow tubes and mirrors used to deliver the beam in a CO₂ laser.

- Assist Gas

- A gas that facilitates the cutting process by blowing melted material through the cut zone. Oxygen is typically used for cutting ferrous metals, while inert gases help produce oxide-free cut edges.

- Attenuation

- The reduction in power or energy of radiation as the laser beam passes through a scattering or absorbing medium.

- Beam

- A concentrated group of rays that may be convergent, divergent, or parallel.

- Beam Diameter

- The width of a circular laser beam at a specific point, where its intensity decreases to a fraction of its peak value.

- Beam Divergence

- The rate at which a laser beam spreads, measured in milliradians. One radian equals approximately 3.4 minutes of arc, or nearly 1 mil.

- Computer Numerical Control (CNC)

- A computerized system that directs the movement of the machine. CNC technology controls motion tables or positions the workpiece beneath the focused laser beam.

- Coated Steels

- Carbon or mild steel that has been treated with coatings such as zinc plating, mill scale, paint, rust, or identification markings. These coatings typically result in reduced cutting speeds and increased dross accumulation on the bottom edges of the cut.

- Collimation

- The ability of a laser beam to maintain a narrow, low-divergence profile over a distance.

- Collimator

- An optical device made up of two lenses, spaced apart by the sum of their focal lengths, used to adjust the beam diameter to meet specific delivery requirements.

- Continuous Wave (CW)

- A laser operating mode in which the beam is continuously emitted, as opposed to pulsed operation.

- Copper/Copper Alloys

- Metals that exhibit high reflectivity to laser light and possess excellent thermal conductivity. These properties reduce cutting efficiency by lowering the maximum thickness that can be effectively processed.

- Crystal

- A solid crystalline material with a structured atomic arrangement used as a lasing medium.

- Cut Initiation

- Also known as "piercing," this process uses the laser in pulsed mode to drill an entry hole in the material, often with air or oxygen as the assist gas.

- Cutting Bed Size

- The dimensions of the work area in a laser cutting machine, determining the maximum material size that can be processed. Standard sizes include 4' x 8', with some machines featuring beds as large as 5' x 10'.

- Cut Width

- The width of a laser-cut slot, determined by factors such as material properties, lens focal length, and the type of assist gas used. Typical laser cut widths range between 0.1 mm and 0.4 mm.

- Cycle Time

- The total time required to complete a laser cutting process from start to finish.

- Depth Of Field (DOF)

- The range in which the focused laser beam remains effective, influenced by the focal length of the lens, the laser wavelength, and the diameter of the unfocused beam. A shorter focal length results in a smaller depth of field.

- Drift

- Unintended fluctuations in laser output, including variations in amplitude or frequency.

- Dross

- Solidified material that accumulates on the lower edge of a laser cut. Factors such as surface rust, poor-quality steel, and incorrect process parameters contribute to dross formation. Higher oxygen pressure and pulsed laser cutting can help reduce dross buildup.

- Duty Cycle

- The percentage of time the laser beam is actively cutting, drilling, welding, or heat-treating compared to the total cycle time.

- Enclosed Laser Device

- A laser system housed within a protective enclosure to prevent hazardous optical radiation from escaping.

- Feed Rate

- The speed at which the cutting head moves relative to the workpiece.

- Focal Point

- The location where a focused laser beam has maximum energy concentration. The focal point is determined by identifying where the beam reaches its smallest diameter and where refracted light rays converge.

- Gas Jet Assist

- A coaxial assist gas used to achieve the high power levels necessary for cutting specific metals, typically involving nitrogen, oxygen, or argon.

- Gas Jet

- A device that directs gas into the cutting zone to remove molten material and enhance cutting performance. In some cases, the gas reacts chemically with the workpiece to generate heat and increase cutting speed.

- Heat Affected Zone (HAZ)

- The area adjacent to the cut zone that undergoes changes in material properties due to heat conduction from the cutting process.

- Hologram

- An interference pattern recorded on a plate or film that can store large amounts of data and generate three-dimensional images.

- Kerf

- The notch or groove produced by a laser cutter. The width of the kerf depends on factors such as material thickness, material properties, lens focal length, and the type of cutting gas used.

- Laser Cutting Grade Steels

- Steels specifically manufactured for laser cutting applications. These materials maintain the strength of standard steels but have lower impurity levels, such as reduced sulfur and silicon content, allowing for faster and thicker cuts.

- Laser Resonator

- Also known as a "laser cavity," this component consists of optical mirrors, a pumping system, and an active lasing medium. Laser resonators can be classified as stable or unstable, depending on whether the oscillating beam converges into or spreads outward from the cavity.

- Laser Product

- A legal classification referring to a laser, laser system, or any product that incorporates a laser as an integral component.

- Lens

- An optical element that focuses or reflects light rays to a specific point. Variations in laser beam diameter influence the lens's depth of focus and power density.

- Melting Point

- The temperature at which a material transitions from solid to liquid. Materials with higher melting points require slower laser cutting speeds due to the increased energy required to melt them.

- Mode Locking

- A technique used to generate extremely short laser pulses by synchronizing the phase differences of multiple modes or frequencies within the laser cavity.

- Neodymium Solid-State Glass (Nd:Glass) Lasers

- Lasers that produce high-power, short pulses for specialized industrial applications.

- Neodymium:Yttrium-Aluminum Garnet Solid-State Lasers (Nd:YAG Lasers)

- Lasers similar to Nd:Glass types but offering superior beam transmission via fiber optics. Nd:YAG lasers are preferred for applications requiring fine detail work and outperform CO₂ lasers when processing highly reflective materials.

- Nozzle

- A component of the gas jet system in laser cutting that narrows the assist gas flow and directs it into a controlled column.

- Power Density

- The intensity of laser output per unit area, measured in watts per square centimeter (W/cm²).

- Pulse

- A single, short burst of laser energy, distinct from a continuous beam. Pulsed lasers can achieve higher peak power levels than continuous wave lasers.

- Pulse Frequency

- The rate at which laser pulses are emitted, measured in pulses per second.

- Reflectivity

- A material’s ability to reflect laser light. High-reflectivity materials, such as aluminum and copper alloys, are more challenging to cut and require adjustments to work speeds and laser parameters.

- Substrate

- A base material sheet that may or may not contain a pre-existing interconnection pattern.

- Ultrashort Pulsed Laser

- A laser capable of emitting pulses with durations shorter than one nanosecond.

- Vaporization

- The phase transition of a material from solid or liquid to vapor. Laser cutting works by vaporizing metal or other materials to create precise cuts.