Latches

Latches serve as essential mechanical devices designed to secure doors, windows, cabinets, and various other objects that require opening and closing functionality.

The History of Latches

Latches have been a fundamental component of hardware for centuries, undergoing advancements while maintaining their original principles. Some of the earliest known latch designs include the Suffolk latch and the Norfolk latch, both of which originated in England during the 16th century and remain in use today. However, historical evidence suggests that iron latches date back even further, with examples found in China and Europe as early as the 13th century.

Traditionally, latches functioned solely to keep doors closed rather than to lock them, while bolts served the purpose of securing them. Bolt latches, however, sometimes function as mere fasteners. In modern applications, latches have evolved to incorporate both locking and fastening capabilities. Many contemporary latch designs integrate mechanical and electrical components, enhancing security and reliability through advanced locking mechanisms.

Latch Design

Manufacturers typically produce latches through processes such as die casting, stamping, or forging, with additional components assembled or spot-welded as necessary. The design of standard or custom latches depends on key factors, including material selection, mounting style, and latching position. These elements are determined based on the intended application, accounting for variables such as applied force, operational frequency, and exposure to environmental conditions.

- Material Design

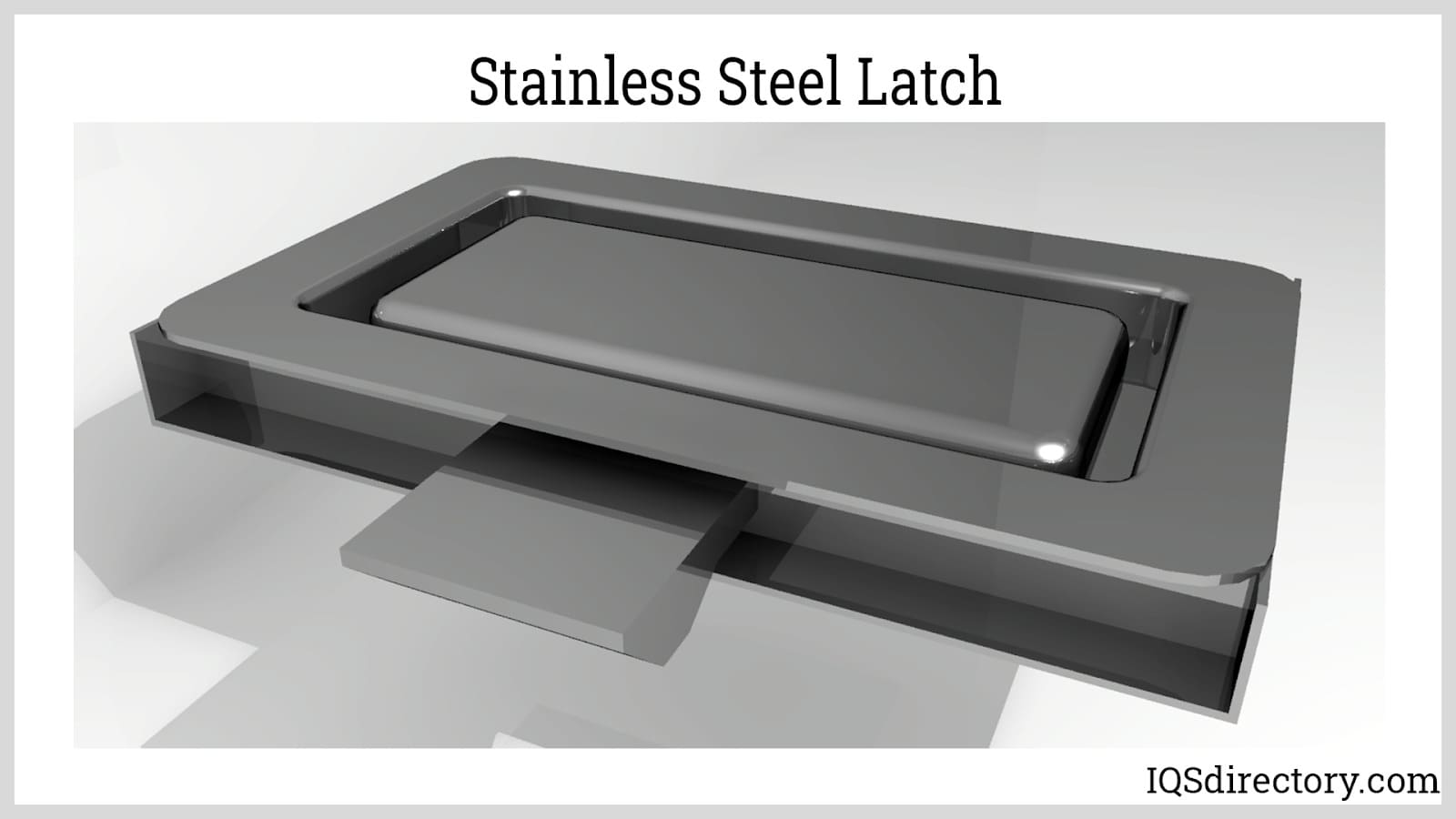

- Latches are commonly constructed from metals such as stainless steel, steel, aluminum alloy, cast iron, and brass due to their durability and resistance to wear under frequent and high-stress use. Among these, stainless steel latches provide the highest strength and corrosion resistance.

- In some cases, manufacturers opt for thermoplastics and thermoplastic elastomers as alternative materials. Plastic latches and rubber-based latches offer advantages such as reduced weight and superior vibration absorption compared to metal. Additionally, thermoplastic latches provide enhanced flexibility, improved impact resistance, and ease of fabrication, making them ideal for custom designs and specialized applications.

- Mount Design

- The choice of mounting configuration depends on the available space, intended function, and performance requirements of the latch. Several common mounting options exist, including concealed mounting, edge mounting, side mounting, and single-hole mounting.

- Most latches feature plates or brackets positioned on adjacent surfaces, with one bracket containing a pin or post and the other featuring a corresponding notch, groove, or seal to receive it. Once engaged, the pin secures the latch, preventing the door, cabinet, gate, or lid from opening.

- Concealed mounting ensures that the latch and its hardware remain hidden behind the panel, while edge mounting installs latch components along the mating panel edges. Face mounting, by contrast, places the latch directly on the front surface of the panel. Side mounting positions both the latch and the keeper at the back of the connecting panels, rendering them invisible from the cabinet or door front. Single-hole mounting involves securing the latch through a single hole in the panel face. For non-single-hole mounting configurations, manufacturers can modify hole spacing to accommodate custom specifications.

- Latching Position

- The latching position plays a crucial role in latch functionality. A primary latching position ensures that the door remains securely closed, whereas a secondary latching position allows the door to remain partially closed without full engagement. Manufacturers select the appropriate latching position based on the specific needs of the application, ensuring optimal performance and security.

Latch Images, Diagrams and Visual Concepts

Latches, mechanical components that allows for the temporary joining of moving parts relative to each other.

Latches, mechanical components that allows for the temporary joining of moving parts relative to each other.

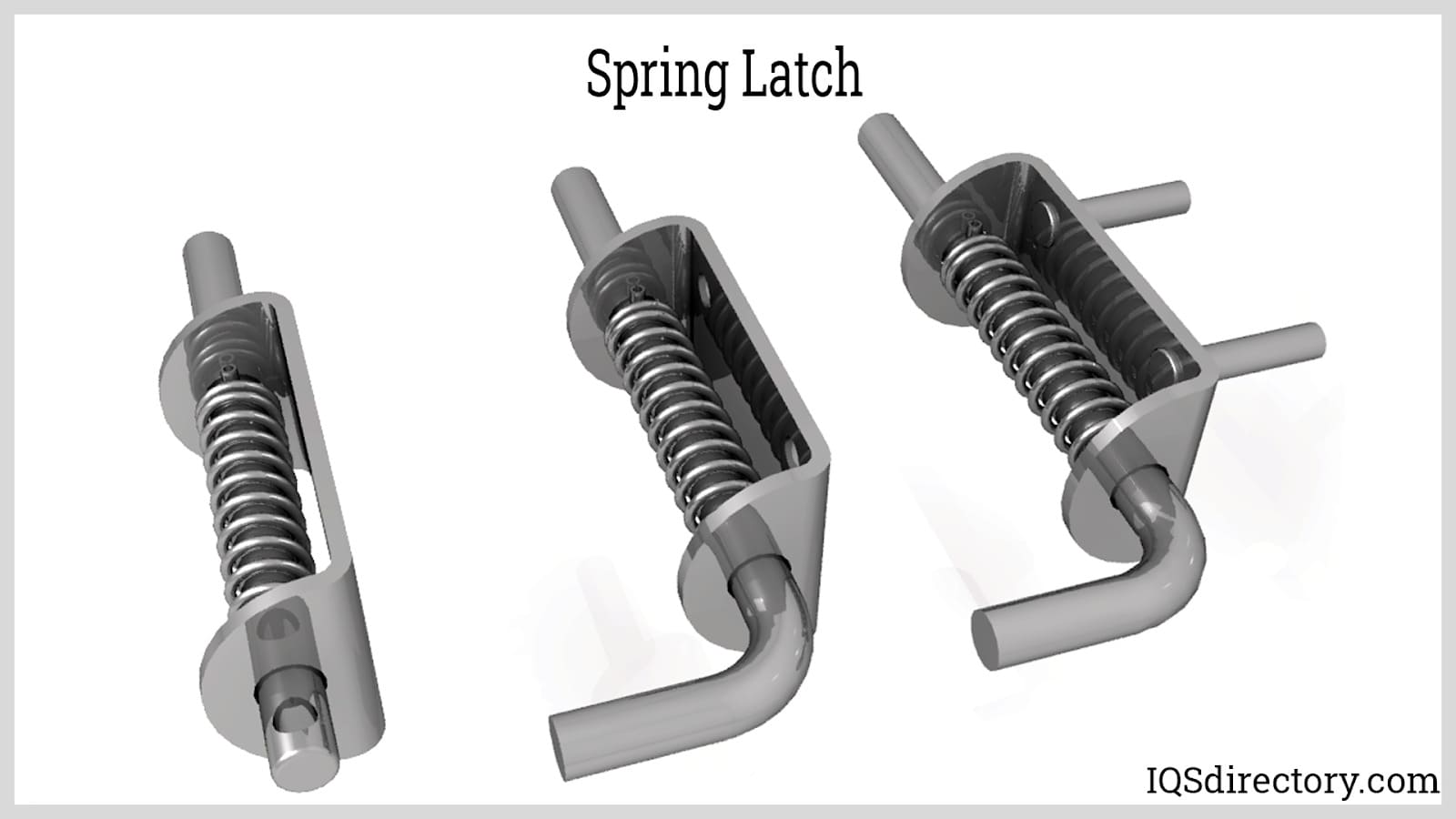

Spring latchs join two separate components to prevent movement or opening.

Spring latchs join two separate components to prevent movement or opening.

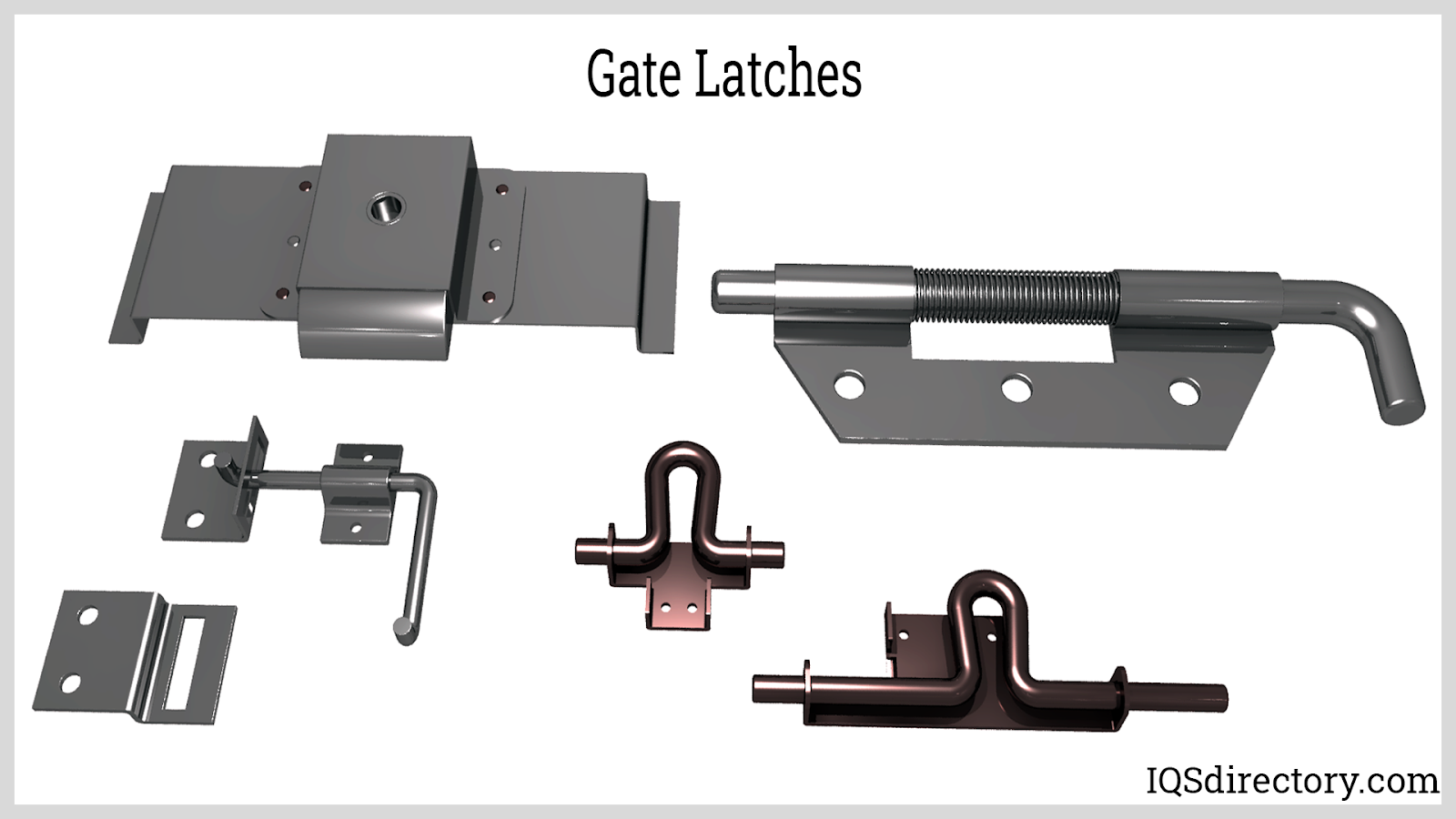

Gate latches are made from highly durable materials, come in several different styles, and with right or left hand orientation.

Gate latches are made from highly durable materials, come in several different styles, and with right or left hand orientation.

Band Clamps is an example of the different methods of design and style of latches

Band Clamps is an example of the different methods of design and style of latches

Latches can have different design features and be made from different materials based on the application.

Latches can have different design features and be made from different materials based on the application.

Swinging latches are push-to-close which automatically activate once the door is closed.

Swinging latches are push-to-close which automatically activate once the door is closed.

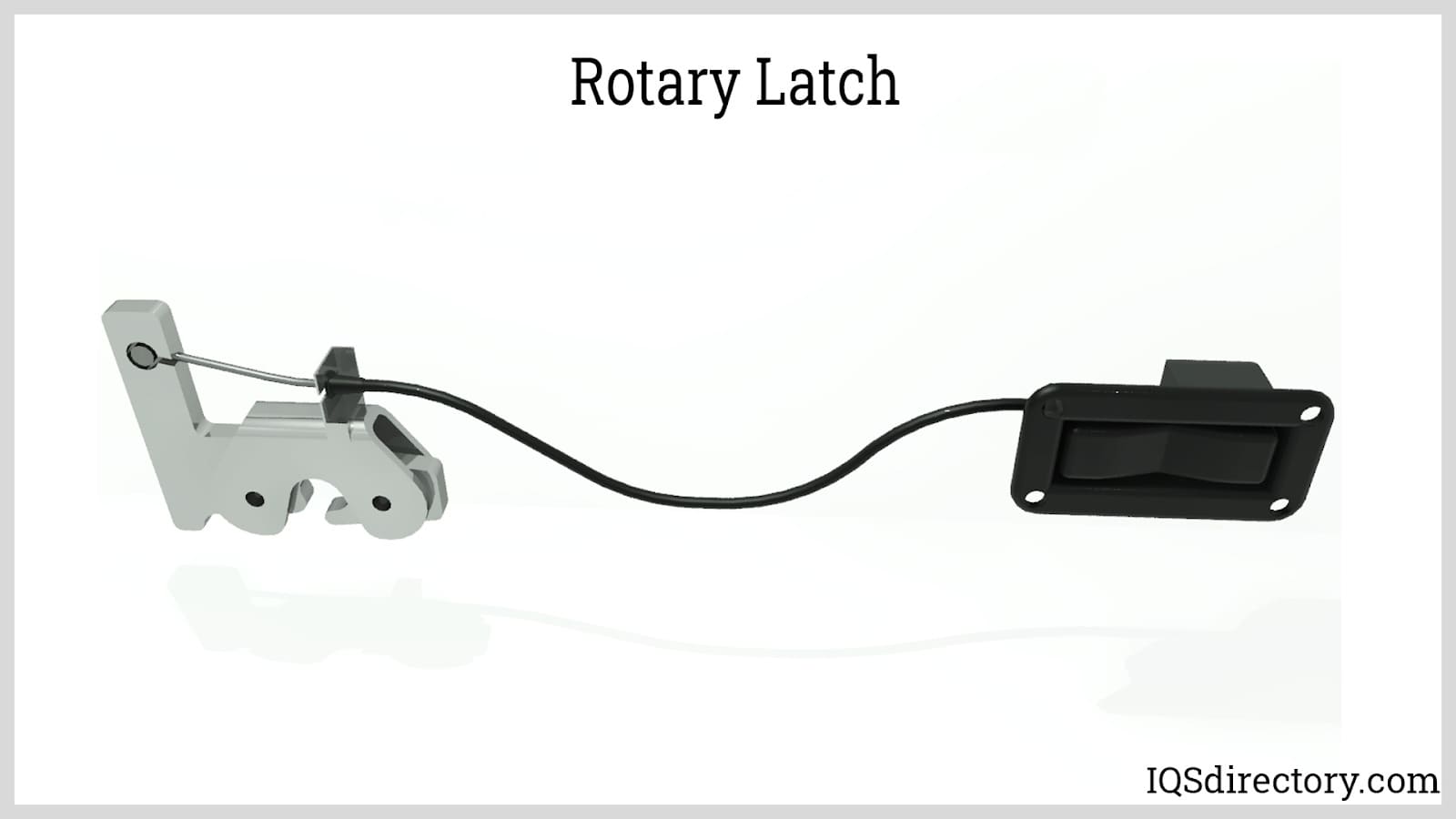

Rotary latchs uses a spring loaded mechanism which enables a push to close function.

Rotary latchs uses a spring loaded mechanism which enables a push to close function.

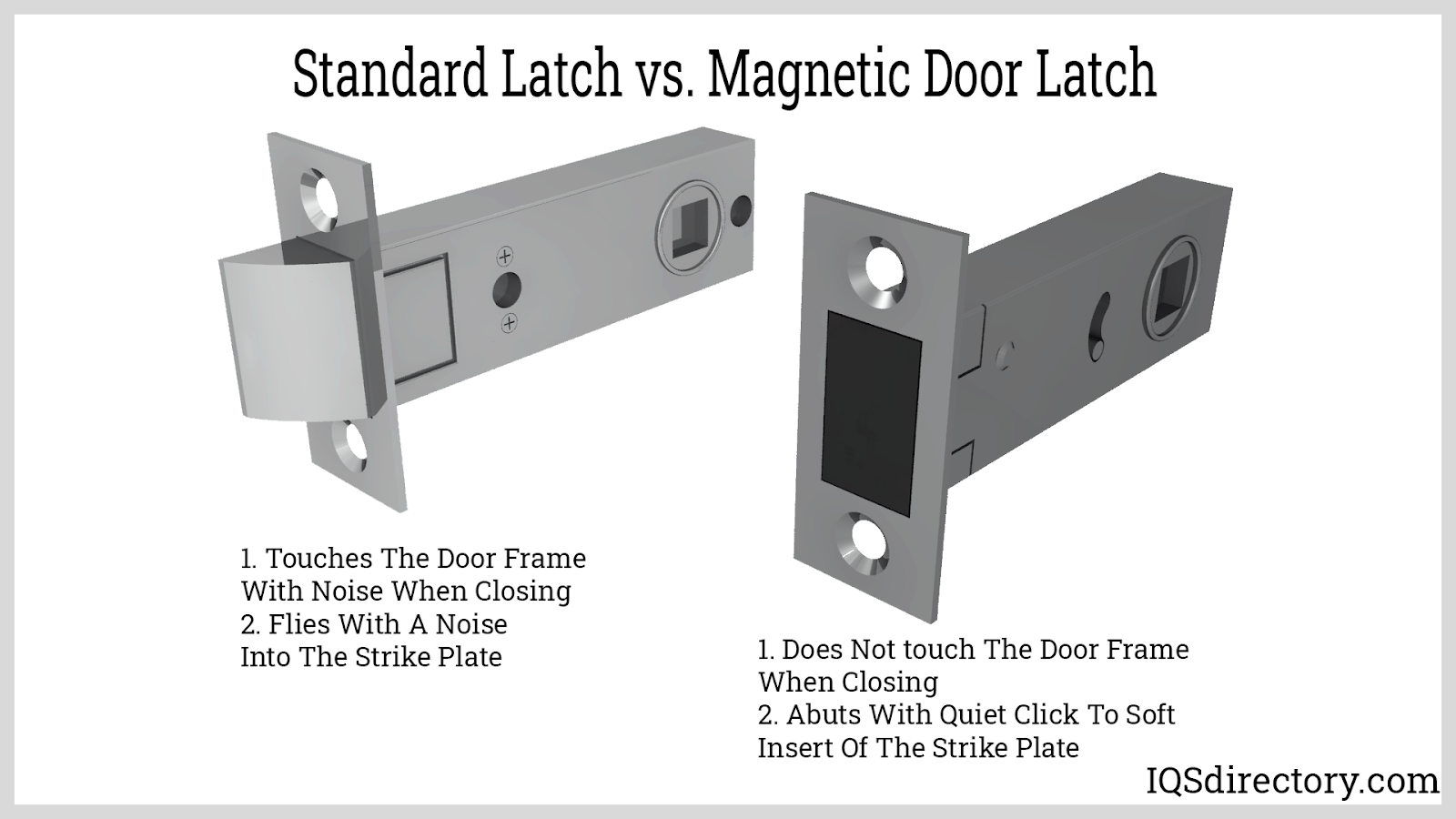

A magnetic door latch consists of a striking pad and a magnet to lock versus using a a standard latch.

A magnetic door latch consists of a striking pad and a magnet to lock versus using a a standard latch.

Types of Latches

- Bolt Latch

- Bolt latches are available in single-bolt and double-bolt configurations, primarily used to secure doors and gates. These latches provide a simple yet effective means of fastening by sliding a bolt into a corresponding strike plate or bracket.

- Spring Latch

- Spring latches incorporate an angled bolt edge that compresses a spring when the door is closed, securing it in place. To disengage the latch, turning a handle retracts the spring latch assembly, allowing the door to open smoothly. This mechanism ensures easy operation while maintaining a secure closure.

- Draw Latch

- Also known as tension or toggle latches, draw latches are designed to pull two surfaces together and lock them securely. These latches consist of two plates connected by a joining strap or pin, making them highly versatile. They are commonly found in household and office applications, including suitcases, briefcases, trunks, toolboxes, and jewelry boxes. Their utility extends to corners and hinges, where a firm hold is required.

- Compression Latch

- Similar to draw latches, compression latches create a tight and secure connection between adjacent surfaces. In addition to providing a firm hold, they are often employed in applications that require a seal along the edges of the connected components, ensuring airtight or watertight protection when necessary.

- Door Latch

- Door latches function as securing mechanisms that keep doors closed. All door latches consist of two plates, a bar, and either a hook or a pin to ensure the door remains in position until intentionally released.

- Ring Latch

- Commonly referred to as a ring gate latch, this latch features a large ring handle that must be lifted and twisted to unlock. Frequently used in low-security applications such as garden gates, ring latches offer both practicality and a rustic aesthetic, adding a touch of charm to outdoor spaces.

- Latch Bolt

- Latch bolts incorporate a spring-loaded bolt with an angled top edge. When the door is closed, the angled side makes contact with the strike plate, causing the bolt to retract momentarily. Once it reaches the proper position, the bolt extends fully and locks into place within the strike plate, effectively securing the door.

- Rim Latch

- Rim latches are an old-fashioned style of latch with roots in Colonial times. They feature a surface-mounted box and a latch that hooks into a keeper on the doorframe. While rim latches provide basic security, they are not effective as locking mechanisms unless combined with a hinge and lock assembly.

- Lever Latch

- Lever latches offer reliable access control for overhead bins in buses and RVs, as well as compartments in various vehicles. These latches can be customized with different trigger actuation styles and key or tool access features. Sometimes referred to as push-button latches, they provide convenience and security in transportation and storage applications.

- Slam Latch

- As the name suggests, slam latches engage automatically when a door is shut. These latches require no manual locking action, making them ideal for quick and effortless closure.

- Thumb Latch

- Thumb latches are a traditional style of latch featuring a liftable bolt mechanism. They are commonly used to secure gates and residential doors, maintaining a vintage aesthetic while offering functional security.

- Cabinet Latch

- Cabinet latches are specifically designed to secure cabinet doors, ensuring that storage compartments remain closed. These latches can also be used for cupboards, drawers, and similar storage solutions.

- Gate Latch

- Gate latches keep fencing entrances and exits securely shut. Available in various designs, they provide a simple yet reliable means of securing gates in residential, commercial, and agricultural settings.

- Paddle Latch

- Paddle latches incorporate a unique flip-out latch handle mechanism, allowing the operator to securely close the latch and open it when necessary. These latches provide a firm hold while offering an intuitive means of operation.

- SR Latch

- Also known as a set-reset latch, an SR latch is a type of flip-flop circuit with two stable states, both of which store state information. In digital electronic systems, latches and flip-flops function interchangeably, using signals and outputs to control locking and unlocking mechanisms.

- Touch Latch

- Touch latches operate without visible hardware, relying instead on a push-to-open mechanism. Rather than using a handle, they allow users to open and close cabinets or cupboards with a gentle push. These latches often feature spring-loaded components with either magnetic or mechanical elements, providing a sleek, modern aesthetic while ensuring convenient access.

- Industrial Latch

- Industrial latches are designed for heavy-duty applications, offering durability and reliability in demanding environments. Their robust construction makes them suitable for transportation industries, including aerospace, automotive, recreational vehicles, railway, marine, and off-highway applications. These latches are engineered to withstand high levels of stress while maintaining secure and consistent performance.

Applications of Latches

Latches are particularly effective in applications requiring controlled closure and release between two adjacent surfaces. While their primary function is to secure doors, panels, and enclosures, their versatility extends across a broad range of industries, from simple fastening solutions to highly complex mechanical and electronic systems.

Latches are commonly utilized in the transportation, home, building and construction, and furniture industries. In transportation, they provide secure fastening for vehicle compartments, aircraft panels, and marine enclosures. In home applications, they ensure the reliable operation of cabinets, doors, and gates. Within the construction sector, they play a crucial role in structural security, while in furniture manufacturing, they enable smooth and secure operation of drawers, storage units, and office enclosures.

Installation of Latches

Each type of latch requires a specific installation method tailored to its design and function. However, the general procedure for installing a mortise latch follows these steps:

Position the latch on the edge of the door, ensuring proper alignment with the intended strike plate or receiving mechanism. Using a chisel, carefully carve out the center section to create a recess for the latch assembly. Gradually work around the interior perimeter to refine the space, ensuring a precise fit. Verify the depth to ensure the latch sits flush with the door surface, making any necessary adjustments. Once properly aligned and recessed, secure the latch in place, fastening it according to the manufacturer’s specifications.

For exact installation instructions based on the specific latch type, it is best to consult the manufacturer. Many manufacturers also offer installation kits that include specialized tools and components to simplify the process and ensure proper functionality.

Proper Care for Latches

Maintaining the appearance and functionality of latches requires only a few simple cleaning techniques. For latches with a clear-coat finish, occasional washing with a mild, non-abrasive soap and a soft buffing cloth will help preserve their shine. To enhance their luster further, applying a protective, non-abrasive car wax can provide an added layer of protection.

Latches with a bronze finish require extra care, as this material is more delicate than many other metal coatings. To maintain its integrity, gently wipe the surface with a small amount of vegetable oil or a mild household detergent, taking care not to oversaturate the metal.

For chrome-finished latches, routine maintenance is even simpler—wiping them down with a damp cloth will keep them looking clean and polished.

Latch Standards and Specifications

The highest-quality latches and locksets adhere to stringent industry standards, ensuring durability, reliability, and safety. The American National Standards Institute (ANSI) and the Builders Hardware Manufacturers Association (BHMA) certify latches that meet rigorous testing criteria. These certifications help guarantee overall performance and security.

Depending on the intended application, additional compliance standards may be necessary. For example, latches used on handicap-accessible doors must meet the accessibility requirements set by the Americans with Disabilities Act (ADA). Ensuring compliance with the appropriate standards helps maintain safety, accessibility, and regulatory adherence for a variety of latch applications.

Things to Consider When Purchasing Latches

When selecting a latch, several factors should be taken into account to ensure it meets your specific needs. Consider the number of latches required, the expected intensity of use, and the environment in which the latch will be installed—whether indoors, outdoors, or in a high-moisture setting such as a coastal area. Additionally, assess the available mounting surface to determine the most suitable latch type for your application. These factors will help guide your decision toward a latch that provides optimal performance and durability.

For the best results, consulting a reputable latch or hinge manufacturer is highly recommended. Experienced manufacturers possess specialized knowledge that the average customer may not, allowing them to identify potential compatibility issues with latch types and configurations before a purchase is made. Furthermore, working directly with a manufacturer offers the advantage of customization, ensuring that the latch you choose aligns precisely with your specifications. To find a trusted supplier, refer to the list of manufacturers we have provided. We are confident that the right manufacturer for your needs is among them. Explore their websites to learn more about their offerings, and when you identify a few that seem like a good fit, reach out with your questions to discuss your specific requirements.

Latch Accessories

Latches can be enhanced with various accessories designed to improve functionality and ease of use. Common latch accessories include handles, such as charge handles, as well as anchors, springs—including gas springs—strike plates, and hinges. To determine the best accessories for your specific latch application, consulting with your latch and hinge manufacturer will provide the most informed recommendations.

Latches Terms

- Actuation

- The movement of the handle or latch portion initiates the latch or unlatch function, allowing controlled access.

- Alike Change

- A configuration in which multiple latches or locks are designed to operate with the same key for convenience and efficiency.

- Anti-Friction Latch Bolt

- A specially designed latch bolt that minimizes friction, ensuring smoother operation and reduced wear.

- Architectural Hardware

- Components used in construction for movable elements such as doors, windows, and cabinets, enhancing functionality and durability.

- Axle

- A key structural element that provides the bearing surface for the rotating rotor and secures the latch mounting on a rotary latch.

- Back Plate

- A protective plate mounted on the door, serving as the attachment point for the moving parts of the latch.

- Bevel

- A term describing the angle or inclination of the latch bolt, which affects how it engages with the strike.

- Cam

- A rotating tongue located at the end of the latch plug, playing a crucial role in latch operation.

- Case

- The housing that encloses the internal mechanism of the latch, providing structure and protection.

- Catch

- A component designed to facilitate pawl retention, ensuring secure latching functionality.

- Clamping Force

- The pressure exerted by the latch to pull and secure two panels together, enhancing closure strength.

- Coaxial Mount

- A structural enhancement for rotary latches, combining a standard mount with a secondary pivot on the back plate’s bottom for added strength.

- Deadlocking Latch Bolt

- A latch bolt featuring a plunger mechanism that prevents retraction due to external pressure when the door is closed.

- Direct Release Actuation

- A mechanism where the latch is disengaged by directly moving the handle or latch without intermediary steps.

- Dogging Device

- A specialized feature that secures the crossbar in a depressed position, keeping the latch bolt retracted and allowing free door movement from both sides.

- Drop Ring

- A ring-shaped handle connected to a spindle, used to operate a latch. When not engaged, the ring naturally falls into a resting position.

- Four-Point Actuation

- An unlocking method that requires movement at multiple points on the handle or latch portion for added security.

- Front

- The visible section of the latch assembly through which the latch bolt extends.

- Hinged/Swinging Latch Bolt

- A latch bolt affixed with a hinge, retracting through a swinging motion to engage or disengage.

- Hook

- A component designed to enable slam-action functionality, ensuring quick and secure latching.

- Latch Bolt

- A spring-loaded bolt with a beveled edge, activated via a handle, knob, or turn mechanism to secure or release the latch.

- Lip

- A protruding element that serves as the contact point for the latch bolt when the door is shut.

- Mortise

- A recessed cavity within the door designed to house a mortise latch, ensuring a flush installation.

- Plate

- The main body of the latch assembly, providing critical structural support and durability.

- Plunger

- A movable latch component that ensures retention when engaging with a strike for secure closure.

- Roller Strike

- A strike variant equipped with a rolling mechanism that reduces friction when making contact with the latch bolt.

- Snib

- A small switch commonly found on nightlatches, preventing latch operation when engaged.

- Springbolt

- A self-retracting bolt that can be pressed into the lock case and automatically returns to its original position without manual assistance.

- Stop

- A button mechanism that controls the locking or unlocking of the latch bolt, often in relation to an exterior knob.

- Strike

- A protective metal plate installed in the doorjamb to receive the latch bolt when the door closes, typically "T"-shaped with a designated hole.

- Template Hardware

- Hardware precisely manufactured to template specifications, ensuring exact hole spacing and dimensions for seamless installation.

- Throw

- The full range of extension at which the bolt projects when fully engaged.

- Transom Catch

- A fastening device designed for transoms, featuring a ring mechanism to retract the latch bolt when operated.

- Universal

- A latch or hardware piece designed for compatibility with a wide range of door types, ensuring versatile application.