Leak Detectors

Leak detectors are devices engineered to detect and pinpoint the presence of leaks in liquid or gas systems, as well as to assess the volume and composition of the escaping substance. These instruments operate by employing methods such as acoustic signals, visual cues, flame ionization, or ultrasonic waves. They respond to fluctuations in pressure or flow rate, and they help identify the location of any surplus gas or fluid within a system.

The History of Leak Detectors

-

Leak Detectors in the 1800s

Concerns about gas leaks began to rise during the Industrial Revolution, as the harmful effects of certain gases on human health became better understood. However, early detection methods were quite rudimentary. One of the first notable gas detectors of the industrial era was the flame safety lamp, also known as Davey’s lamp. Invented in 1815 by Sir Humphry Davy, this device helped coal miners detect methane—then called "firedamp"—underground. The lamp used an oil flame enclosed within a glass sleeve and a mesh flame arrestor. The height of the flame served as a warning system: a steady flame meant fresh air, a rising flame signaled methane, and a lowering flame indicated diminishing oxygen. In some regions, this method remains in use even today.

In the 19th and early 20th centuries, miners also used canaries as living leak detectors. Since canaries are highly sensitive to gases like methane, carbon dioxide, and carbon monoxide, their singing was a reassuring sound. If a canary went silent or collapsed, it was an urgent sign to evacuate. Though effective, this method was eventually replaced by technological advances.

Leak Detectors in the 1900s

The development of more humane and precise leak detection began in the early 20th century. Between 1926 and 1927, Dr. Oliver Johnson, working for what would become Chevron (then Standard Oil Company), invented the catalytic combustion sensor, also known as the LEL sensor. His first prototype was dubbed "Model A," followed by "Model B," an electric vapor indicator aimed at preventing fuel tank explosions by detecting combustible air mixtures.

In 1928, Johnson partnered with Phil Williams to found Johnson-Williams Instruments, or J-W Instruments, in Palo Alto, California. This venture became Silicon Valley’s first electronics company and a pioneer in gas detection technology. Over the years, they developed many tools, including portable oxygen detectors and multifunction gas detection units.

By the 1980s and 1990s, electronic carbon monoxide detectors became standard household safety devices. Prior to this, people relied on chemically treated paper that would turn brown when exposed to the gas. Since then, advancements have led to a wide variety of digital detectors capable of identifying numerous gases in diverse settings—from healthcare and automotive applications to industrial environments.

Today’s leak detectors are not only more accurate and sensitive, but they’re also increasingly compact, affordable, and versatile. As technology continues to evolve, engineers are pushing the limits of detection accuracy and adapting these tools to serve more industries and applications than ever before.

The Benefits of Leak Detectors

Leak detectors often serve as literal lifesavers, offering an essential layer of protection in both residential and industrial settings. That’s their greatest benefit. Beyond that, they come with a host of practical advantages. Most models include built-in alarms that instantly notify users of a leak, allowing for a swift response and quick evacuation if needed. They’re also known for their high level of accuracy, reliably identifying leaks before they become dangerous. Maintenance is relatively simple—primarily involving regular sensor or sensor cable replacement and proper calibration. Additionally, their design flexibility allows for customization to detect a single gas or multiple gases simultaneously, making them incredibly adaptable across a wide range of applications.

How Leak Detectors Work

Most leak detectors are portable, hand-held instruments designed to monitor for specific conditions. Their mobility is crucial, especially when dealing with intricate and confined piping networks that transport gases or liquids. In many cases, the effectiveness of leak detection depends heavily on the operator's skill and technique. However, certain systems—such as those designed to detect water leaks—are capable of functioning autonomously, monitoring atmospheric changes and signaling alerts without requiring manual operation.

Design of Leak Detectors

Manufacturers take a number of design factors into account when developing leak detectors, such as the types of gases to be identified, whether the system will be permanent or portable, the desired level of sensitivity, and how robust the unit needs to be for its intended environment.

Gases Detected

Common targets for leak detection include refrigerants like Freon, natural gas and methane, chlorine, oxygen, sulfur dioxide, chlorine dioxide, hydrogen sulfide, and radon. Each of these gases poses specific risks, making accurate detection critical.

Environments for Detection

Designs are also tailored to match the environment in which the detector will be used. For homes, detectors are generally built to catch leaks of refrigerant gases and natural gas. Refrigerants, such as those used in cooling appliances, can be harmful to both health and the environment if they escape. Freon in particular, found in older systems, contributes to ozone depletion and may cause cardiac issues when inhaled. Natural gas, largely composed of methane, is highly flammable and potentially explosive, especially in enclosed spaces. In industrial contexts like automotive manufacturing or furnace systems, detectors often focus on identifying vacuum leaks using helium gas, which is highly effective for this purpose.

Permanent Detector Designs

In settings with continuous gas flow, such as residential heating systems fueled by natural gas, permanent leak detectors are essential. Other detectors, such as those used for periodic checks, may be portable. These often include visual or audible alarms and vary in sensitivity. Some systems are designed to detect even trace levels of methane that could ignite, while others incorporate odorants like mercaptan to help users identify leaks by smell.

Leak Detector Customization

Manufacturers can customize detectors to meet specific needs by altering the detection compounds and calibrating for particular temperature and pressure ranges. They can enhance visibility on reflective surfaces like stainless steel or aluminum, improve performance on vertical surfaces, and ensure compatibility with environmentally sensitive locations. For example, in homes located on uranium-rich land, radon detection may be added. Detector systems can also be configured for fully automated or semi-automated use, depending on the operational setting. For more detailed options and capabilities, consulting directly with your supplier is the best route.

Leak Detector Images, Diagrams and Visual Concepts

Leak detectors, a sensor used to monitor a system that contains liquids, gasses, or other substances to ensure the contained materials do not escape the system.

Leak detectors, a sensor used to monitor a system that contains liquids, gasses, or other substances to ensure the contained materials do not escape the system.

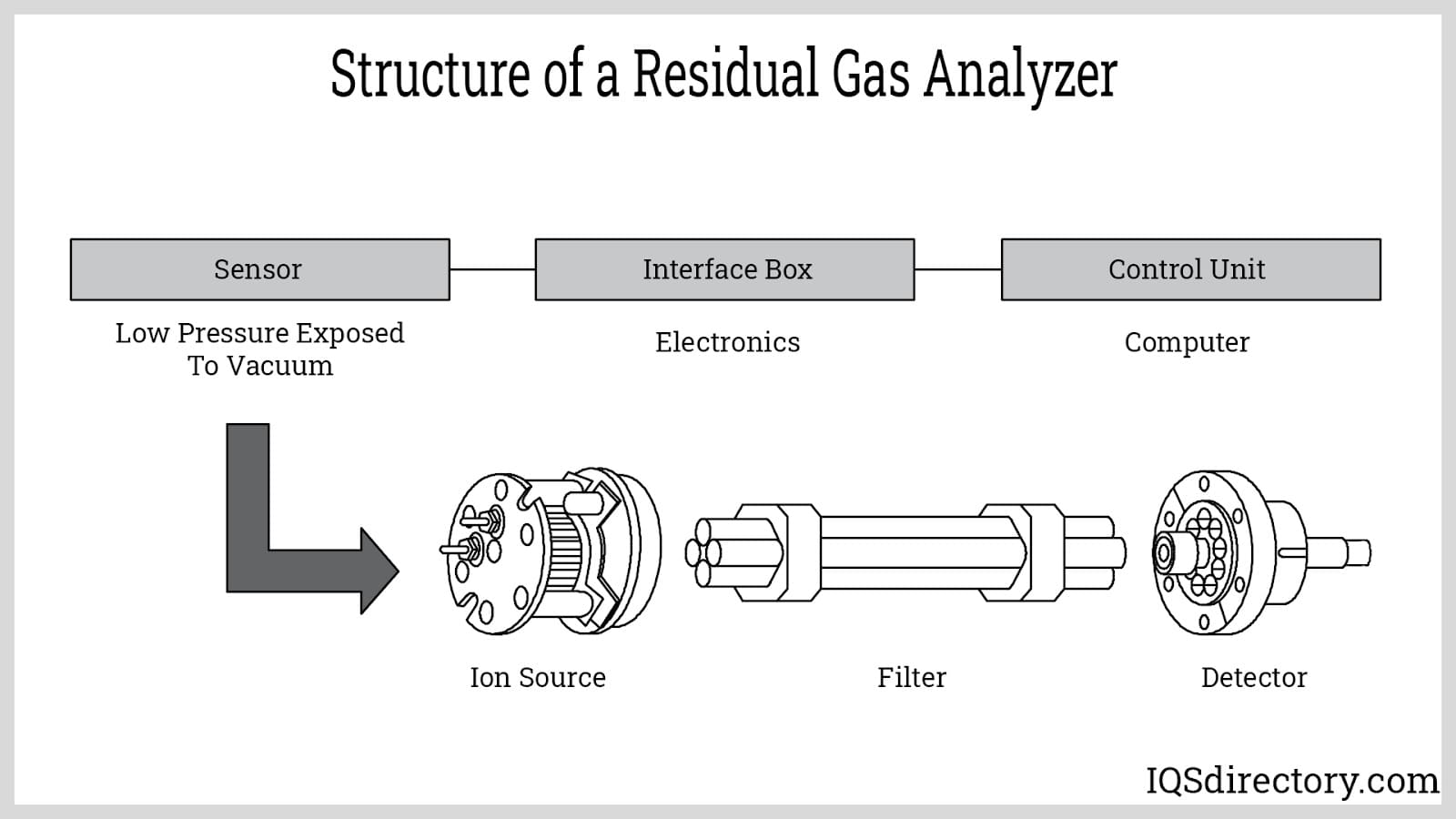

Residual gas analyzer, a small mass spectrometer designed for environmental analysis, process control, and monitoring vacuums for contamination.

Residual gas analyzer, a small mass spectrometer designed for environmental analysis, process control, and monitoring vacuums for contamination.

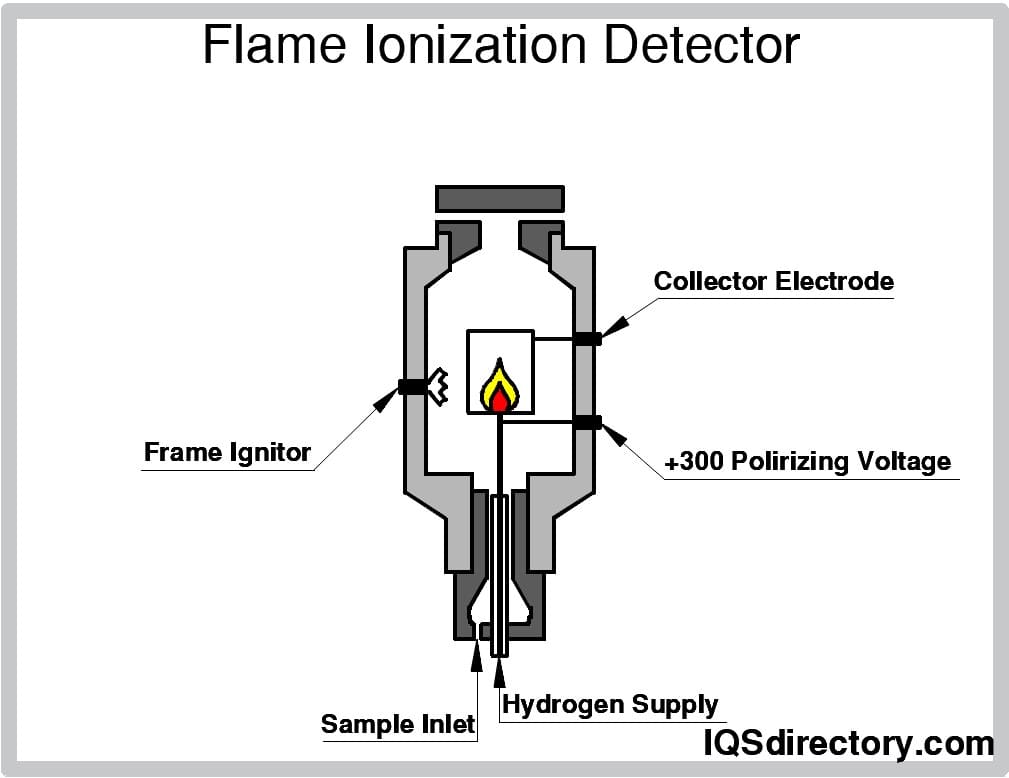

Flame ionization detector, an extremely sensitive detecting device that measures the concentrations of vapors.

Flame ionization detector, an extremely sensitive detecting device that measures the concentrations of vapors.

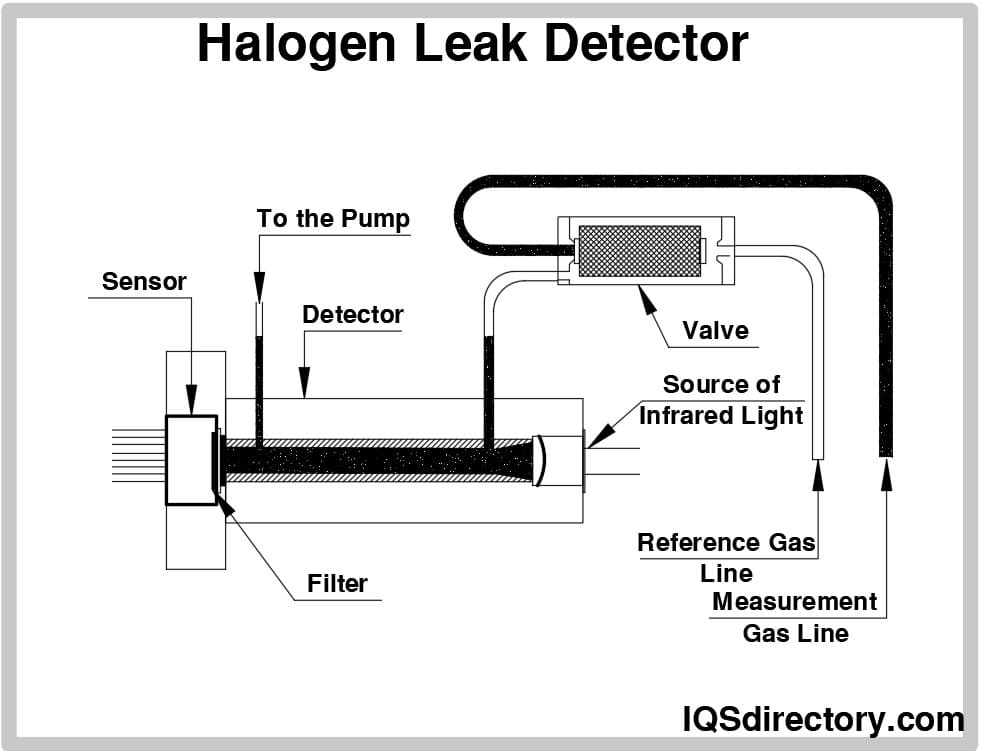

Halogen leak detectors determines the location of halogen gasses outside of the system.

Halogen leak detectors determines the location of halogen gasses outside of the system.

Helium leak detectors helium as a residual gas when testing a closed system.

Helium leak detectors helium as a residual gas when testing a closed system.

Spot leak detectors monitor leaks in a confined spaces and are used to detect liquid leaks.

Spot leak detectors monitor leaks in a confined spaces and are used to detect liquid leaks.

Ultrasonic leak detector uses sound to check for leaks since leaks produce high frequency sound

Ultrasonic leak detector uses sound to check for leaks since leaks produce high frequency sound

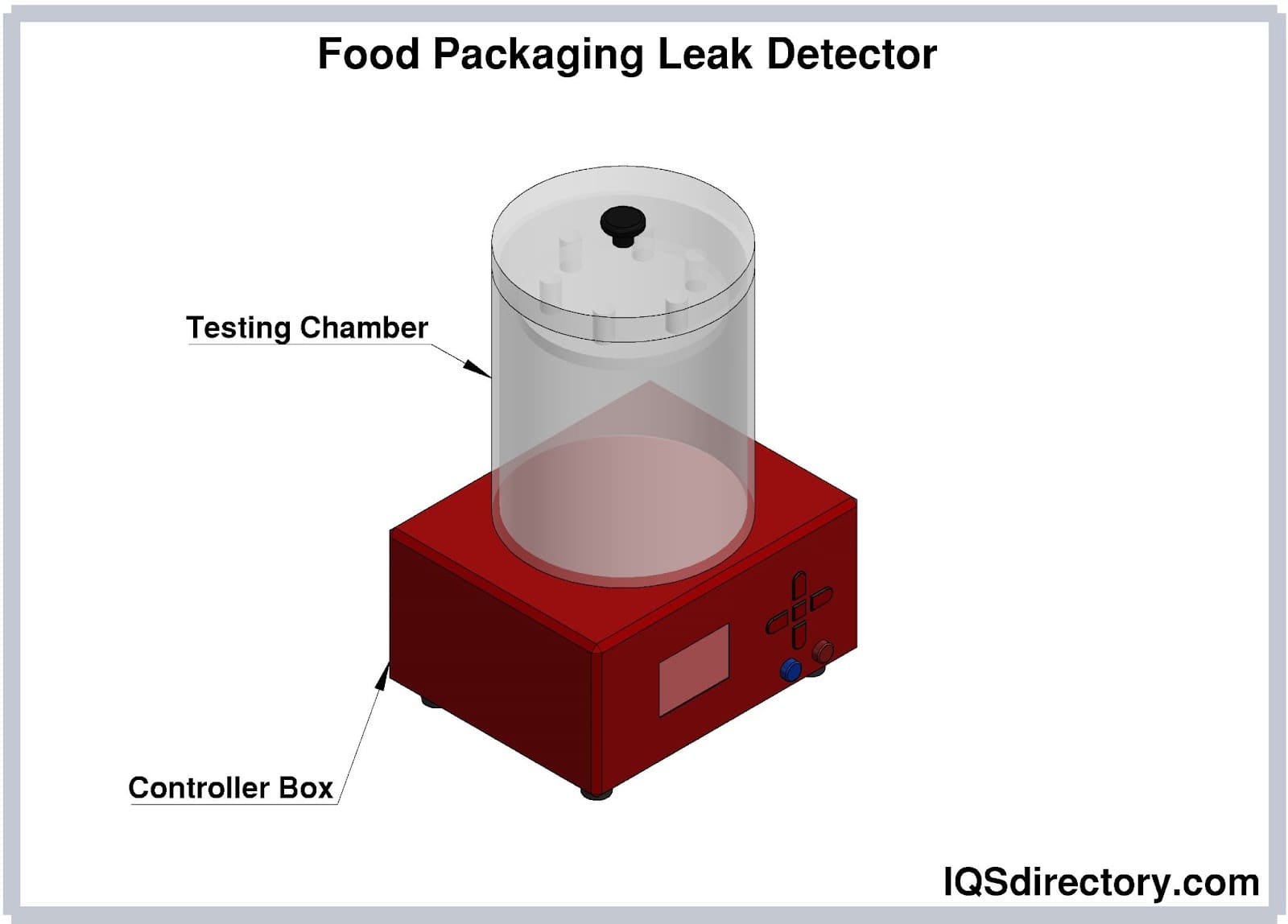

Checks for leaks in food packaging which can cause problems for food production.

Checks for leaks in food packaging which can cause problems for food production.

Leak Detector Types

Leak detection relies on several primary types of equipment, each designed to detect specific conditions and materials. Among the most widely used are electronic leak detectors, ultrasonic leak detectors, flame ionization detectors, and gas detectors like the helium leak detector.

Water Leak Detectors

Separate from gas systems, water leak detectors are designed to identify the presence of water or moisture within a structure or system. These detectors are less commonly used than gas-based systems, primarily because their application is highly specialized. They are typically installed at floor level or around the perimeter of sensitive environments such as data centers, trading floors, archives, and banking infrastructure, where even a small water leak can have major consequences.

Electronic Leak Detectors

These offer one of the quickest methods for identifying gas leaks. They typically operate using either a heated diode sensor or a corona discharge sensor. Heated diode models are preferred for their resistance to false positives, while corona discharge types can be triggered by nearby dust, solvents, or humidity.

Ultrasonic Leak Detectors

A newer addition to the industry, ultrasonic detectors are ideal for identifying larger gas leaks. They work by picking up the high-frequency sounds produced by escaping gas and converting them into lower-frequency noises that can be heard through headphones. This conversion enables human operators to pinpoint the leak by sound.

Flame Ionization Leak Detectors

These detectors work specifically with halogen refrigerants. Known as halide torch detectors, they operate on the principle of flame ionization—changing the flame color from blue to green when a halogen-based refrigerant is present. They are most commonly used for detecting chlorinated refrigerant leaks.

Gas Leak Detectors

These are tailored to identify particular gases such as natural gas, refrigerants, or halogens. Many rely on tracer gases like helium or hydrogen to help locate the leak. After the tracer is introduced into a system, the detector measures how much escapes, usually through a mass spectrometer, offering precise data about leak rate and presence.

Note: Any detection system used to find refrigerant leaks—whether electronic, flame ionization, or gas-based—is considered a refrigerant leak detector.

Gas Analyzers

While not designed to locate the exact source of a leak, gas analyzers can confirm the presence and composition of gases. These include exhaust analyzers, infrared analyzers, and residual gas analyzers. Exhaust analyzers are common in automotive diagnostics, infrared analyzers detect CO₂ levels, and residual analyzers are used heavily in semiconductor environments for contamination control.

Halogen Leak Detectors

These are used to pinpoint halogenated refrigerant leaks. Depending on the detection method—pumping or flame—environmental contaminants can cause false positives. However, ongoing improvements in sensitivity and discrimination have made these detectors increasingly reliable in both industrial and commercial settings.

Vacuum Leak Detectors

Designed for sealed systems, vacuum leak detectors use compressed air to monitor for pressure changes that would indicate a leak. These detectors are especially valued in industries like aerospace, refrigeration, medical instrumentation, and automotive manufacturing, where they verify the integrity of hermetic seals and other pressure-sensitive components.

Leak Detector Applications

Customers depend on leak detectors to both identify existing leaks and prevent future ones. This capability is essential across the industrial sector, where even minor leaks can disrupt operations, compromise safety, and pose serious health hazards depending on the material involved. Whether the issue is a gas leak or liquid seepage, reliable detection systems are critical for maintaining a safe and functional work environment.

Leaks that go unfixed represent a significant source of financial loss in both residential and industrial settings. Escaping liquids or gases can damage nearby equipment, and over time, unattended leaks become serious health risks. In workspaces or homes, water leaks can lead to mold, which often triggers allergic reactions in those exposed. In refrigeration, leak detection plays a vital role, especially in identifying older units that may still contain banned substances like chlorofluorocarbons (CFCs). As a result, a specific range of detectors has been developed just for refrigeration systems.

Numerous industries rely on precise leak detection, including medicine, scientific research, HVAC, and automotive manufacturing. In healthcare, detectors are used on pumps, fluid transfer devices, storage containers, and other essential medical tools where precision and containment are vital. Research and automotive professionals utilize detectors to inspect calibrated vessels, water pumps, cylinder heads, and hydraulic systems—anywhere that a leak could interfere with performance or data integrity.

Leak Detection Equipment Components

Different leak detection systems (LDS) are built with varying equipment components depending on their design and intended application. However, most systems include a few fundamental elements: alarms to alert personnel of leaks, sensors to detect those leaks, and displays to present system readings. The type of sensor used in a given system can differ significantly. Internally based systems rely on field instrumentation such as pressure or fluid sensors to identify leaks from within the system itself. In contrast, externally based systems monitor for leaks from the outside using tools like infrared radiometers, thermal imaging cameras, fiber optic cables, vapor sensors, or acoustic microphones.

Standards and Specifications for Leak Detectors

If your leak detection system (LDS) is intended for use with a petroleum or natural gas pipeline, it’s essential to ensure compliance with API (American Petroleum Institute) Recommended Practice 1175. This standard provides pipeline operators with a risk-based framework for managing LDS programs. It emphasizes the importance of fostering a strong leak detection

culture, developing an effective detection strategy, selecting the most appropriate system for the application, and monitoring overall program performance. It also outlines detailed procedures and training protocols for Control Center operations, clearly defining the responsibilities of Control Center personnel. Additionally, API RP 1175 offers guidance on proper testing for both equipment and alarms. Following these guidelines not only strengthens your LDS program but also helps meet federal requirements set by agencies such as the Department of Transportation (DOT) for pipeline systems.

API RP 1155 lays out the core performance expectations for LDS systems:

Sensitivity Standards

An effective LDS must minimize fluid loss by identifying small leaks and doing so rapidly. Timely detection is critical to limiting environmental and safety impacts.

Reliability Specifications

The system must be dependable. It should consistently identify real leak events while minimizing or eliminating false alarms that could undermine confidence in its performance.

Leak Detector Accuracy

If the LDS includes functions for measuring leak flow or pinpointing leak location, it must do so with a high degree of precision to support effective and timely responses.

Detector Robustness

The LDS must remain functional even when conditions aren’t ideal. For instance, if a transducer malfunctions, the system should detect the issue and continue operating—perhaps with temporarily reduced sensitivity—until the component is repaired or replaced.

Things to Consider When Purchasing Leak Detectors

Leak testing systems are essential across homes, vehicles, and industrial settings. To ensure the leak detection system you choose is safe, dependable, and precise, it’s important to partner with a reputable manufacturer or supplier. At the top of this page, you’ll find a curated list of trusted companies. While all of them offer excellent options, selecting the right one for your needs will take a bit of research. Start by exploring their websites to learn more about their offerings. From there, choose a few that align with your goals and reach out to discuss your specific requirements. Be sure to inquire about customization options, certification standards, pricing, delivery timelines, and available support services. After gathering this information, compare your conversations to identify the supplier that not only provides high-performing systems but also demonstrates a commitment to personalized customer service. Because leak detection plays such a vital role in safety and system integrity, working with a supplier who understands your application and collaborates closely with you can make all the difference. Once you’ve found that partner, take the next step and get your project underway.

Leak Detector Terms

-

Adsorption

The condensation of gas or vapor onto a surface.

Aerosol

A suspension of tiny solid or liquid particles dispersed in the air.

Analyzer

An instrument used to identify and measure the components present in a mixture, both qualitatively and quantitatively.

Blocking

A condition that causes leak detectors to fail, often due to a lack of oxygen in the environment.

Calibration

The process of adjusting an instrument to ensure it responds accurately to known standards.

Combustion

The rapid chemical reaction of a substance with oxygen that releases heat and light.

Explosive/Flammable Range

The concentration range of a vapor or gas in air that can ignite or explode, defined by its upper and lower flammable limits.

Gas

A physical state of matter with low density that expands to fill any enclosed space.

Interference

A substance other than the target gas that causes a false signal or reading on a detector.

Leak Tight

A condition in which leakage occurs at a rate deemed acceptable for a specific component or system.

Non-destructive Testing (NDT)

The assessment of a material or object using methods that do not impair its future usability.

Permeation Leak

Leakage that occurs through a material's surface without a visible hole or distinct path.

Quantitative

A measurement that reflects the total amount of leakage from a system or component.

Sensor

A component that translates the presence of a gas or vapor into an electrical signal; it is central to the function of gas monitors and may also detect moisture or other variables.

Toxic Gas or Vapor

Any airborne substance that poses a health risk or is potentially fatal when inhaled or absorbed.

Tracer Gas

A gas introduced into a system to help identify leaks; it aids specific detectors in locating escaping substances.

Vapor

A material in its gaseous state when below its boiling point.

Zero Gas

Clean, uncontaminated air used to confirm no residual gases are present near the sensor during calibration, ensuring accurate adjustments.