Level Switches

Level switches, also known as level control switches, are devices used to monitor material levels within storage tanks or conveying systems. These instruments provide an electrical switching response when a particular level is reached, allowing operators to track and manage material quantities effectively. While level switches can sometimes serve a dual purpose—both indicating and controlling levels—some are strictly dedicated to measurement or alert functions. Devices that strictly measure without controlling are typically referred to as level sensors or level indicators , which differ from switches in that they do not initiate a control response.

The History of Level Switches

The development of level switches is closely linked to the evolution of fluid dynamics—the study of fluids in motion and the forces acting upon them. This field has roots reaching back to antiquity, with its earliest known written exploration credited to Archimedes of ancient Greece. In his work On Floating Bodies (circa 250 BC), Archimedes formulated the principle that a body submerged in a fluid experiences an upward buoyant force equal to the weight of the displaced fluid. He also noted that, at equilibrium, each particle within a fluid is subjected to equal pressure from all directions.

Notably, early advances in level control technology were pioneered by Islamicate engineers and scientists. In the 9th century, the Banu Musa brothers described a float valve and float chamber, foundational components of modern level control systems. Centuries later, prominent thinkers such as Abu Rayhan Biruni and Al-Khazini brought further clarity to fluid mechanics. Biruni determined how to measure the weight of objects in air and in displaced water, documenting differences in density between liquids such as saline and freshwater. His work illuminated the relationship between an object’s specific gravity and the volume of fluid it displaced. Al-Khazini, building on these foundations, introduced the hydrostatic balance, which he outlined in his 1121 treatise The Book of the Balance of Wisdom.

The 19th century marked a turning point, as inventors began securing patents for early level switch designs. One example featured a magnetic float that, when affected by changes in liquid level, triggered the movement of a needle to indicate status. As industrial machinery advanced through the 20th century, level switches followed suit, evolving into highly precise and dependable devices. Modern switches now offer a range of capabilities with improved safety, accuracy, and adaptability across countless applications.

Applications of Level Switches

Level switches are essential tools across numerous industries, where they support critical processes by monitoring and managing material levels. In pharmaceutical production, they are used to measure bulk quantities of drug ingredients with precision, ensuring consistency in formulation. The food and beverage industry relies on level switches to track both liquid and powdered food materials throughout production and packaging stages, maintaining quality and efficiency. In HVAC system design, these switches help regulate and monitor oil and refrigerant levels in heating and cooling systems—boiler systems, in particular, often incorporate chambered level switches for accurate fluid control. In industrial manufacturing, they play a crucial role in safely managing hazardous chemicals involved in a variety of processing applications. Municipal and industrial water treatment facilities also depend on level switches to monitor wastewater levels, helping to maintain compliance and protect surrounding environments.

Advantages of Level Switches

One of the key advantages of a level switch is its straightforward design. Many models operate with few or no mechanical moving parts, making them exceptionally user-friendly and durable. Their minimal complexity not only reduces the likelihood of failure but also makes them simple to repair if issues do arise. In addition to their reliability and safety, level switches are highly adaptable, offering easy customization to suit a wide variety of applications and system requirements.

Level Switch Design

-

Materials Used in Level Switches

Level switch manufacturers typically construct their products using durable materials like stainless steel, brass, and a variety of plastics. Among the most commonly used plastics are polypropylene and polysulfone, which come in different colors and are particularly well-suited for use in acidic environments such as electroplating and metal cleaning. These plastics are also appropriate for low-temperature food processing and for general applications in commercial or consumer appliances. Brass, on the other hand, is compatible with petroleum-based liquids and is often found in vehicle storage tanks, generators, hydraulic systems, and in equipment used for lubrication, recovery, fuel refining, and processing.

Considerations and Customization in Level Switches

Level switch construction generally involves a switching mechanism, a tube, and connection points. However, manufacturers tailor their designs based on several factors, including the target application, the type of material being measured, the size of the container, and more. Level switches can be designed with varying complexity and triggered by different operational cues such as buoyancy, temperature, or pressure. Additional features that may be included in a switch design are thermal, vibrating, or optical sensors. These enhancements can be fine-tuned to detect specific substances or conditions related to viscosity, density, opacity, or thermal conductivity. Suppliers frequently develop custom solutions to meet the demands of particular industries or processes.

Switch Features and Configurations

Level switches are available in a wide array of configurations. In the simplest liquid level designs, a float or buoy responds to the rise or fall of the material it is monitoring. As the float rises with the material level, it eventually activates an electrical circuit, sending a signal to a connected control system or indicator. This principle applies to many solid-level switch designs as well.

For granular solids, spinning rotary switches are often used. These consist of paddles or blades rotating around an axis and placed at specific heights inside a container. When the rotating motion is interrupted by solid material, the system registers the obstruction as an indication that the material has reached the height of the switch.

More advanced level switches use technologies such as ultrasonic wave transmission and reflection, infrared beam projection, or radio wave signaling. Selecting the right switch type for a given application is essential for achieving accurate and reliable material level measurement.

Level Switch Images, Diagrams and Visual Concepts

Level switch, an electrical or mechanical method for measuring the level of a liquid, powder, or granule material by activating an alarm if the material level passes a certain height or depth.

Level switch, an electrical or mechanical method for measuring the level of a liquid, powder, or granule material by activating an alarm if the material level passes a certain height or depth.

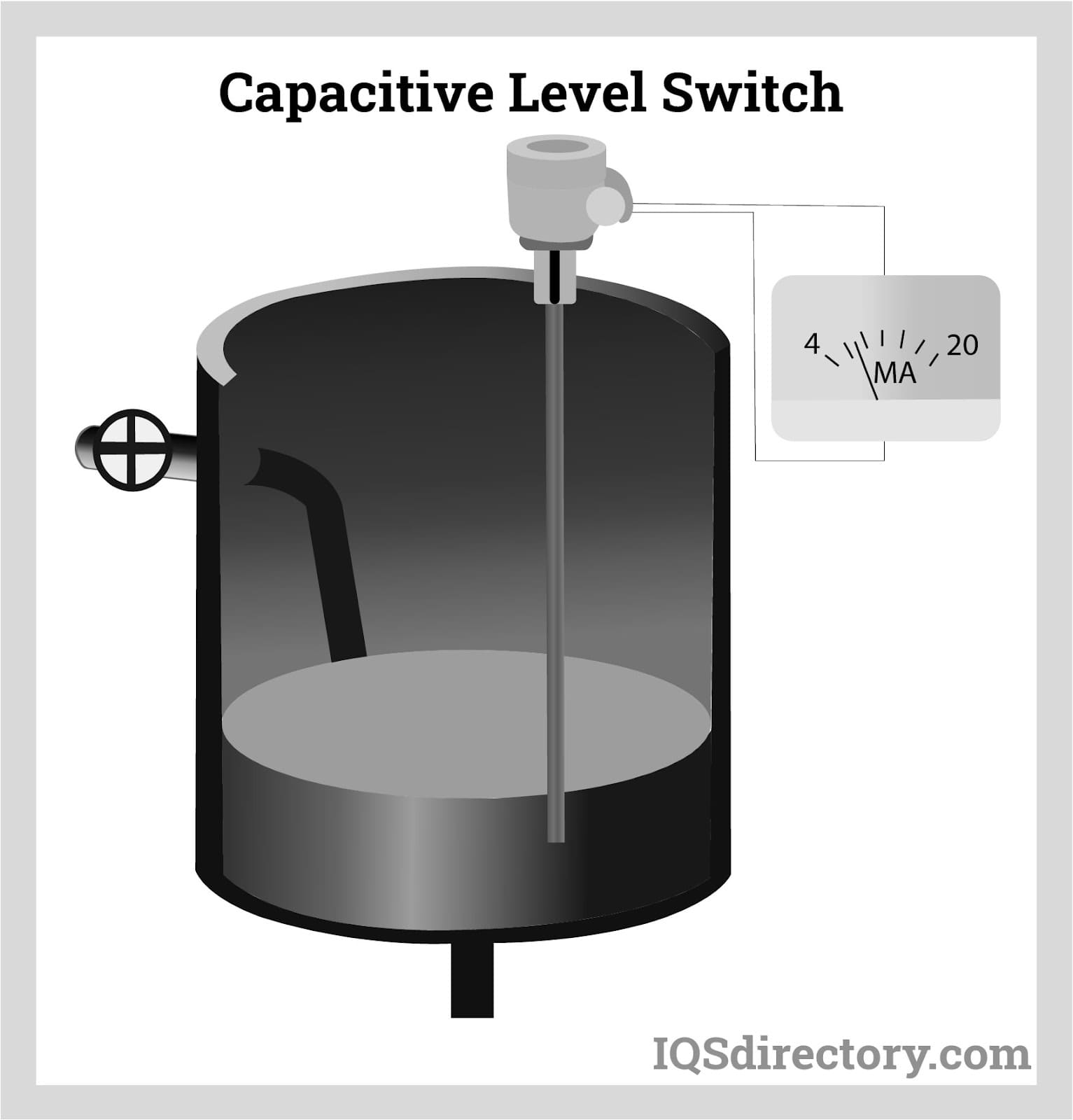

Capacitive level switches are designed for measuring corrosive liquids, high temperatures, and liquid levels in sealed containers.

Capacitive level switches are designed for measuring corrosive liquids, high temperatures, and liquid levels in sealed containers.

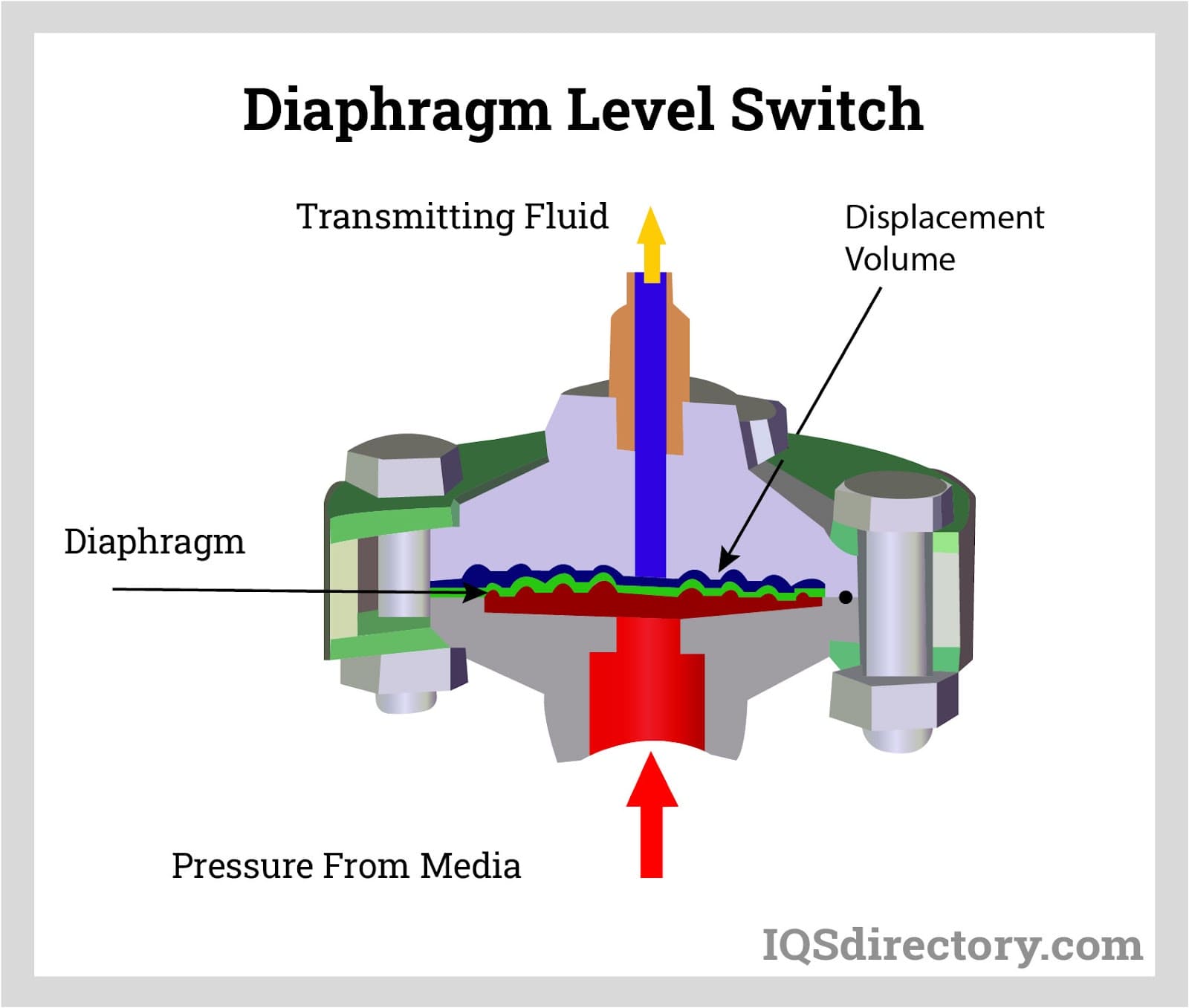

Diaphragm level switch measures pressure changes caused by the increase or decrease of the air pressure.

Diaphragm level switch measures pressure changes caused by the increase or decrease of the air pressure.

Displacer level switches are designed to work under high temperatures and pressure.

Displacer level switches are designed to work under high temperatures and pressure.

Float level switch, a mechanical switch that floats on the surface of a media.

Float level switch, a mechanical switch that floats on the surface of a media.

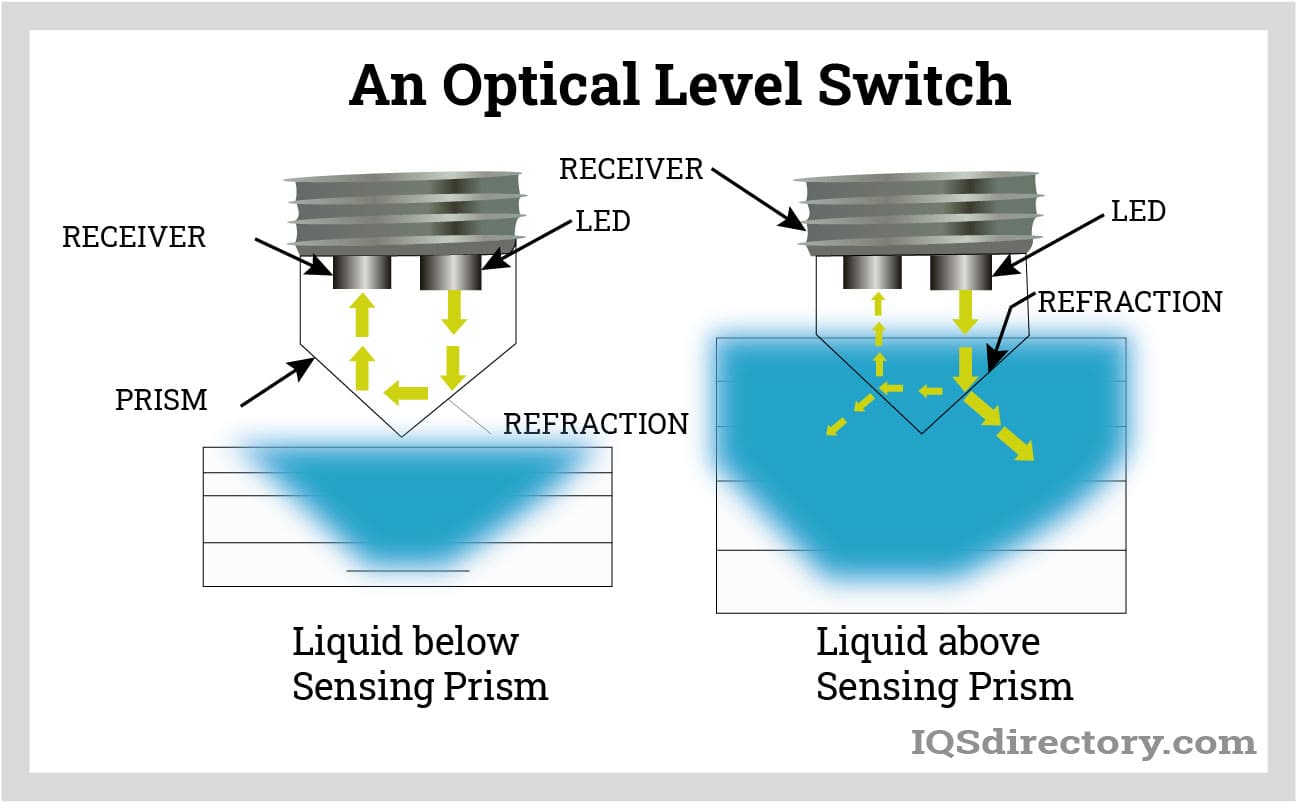

Optical level switches uses a level sensor and light receiver to sense the changes in the liquid level.

Optical level switches uses a level sensor and light receiver to sense the changes in the liquid level.

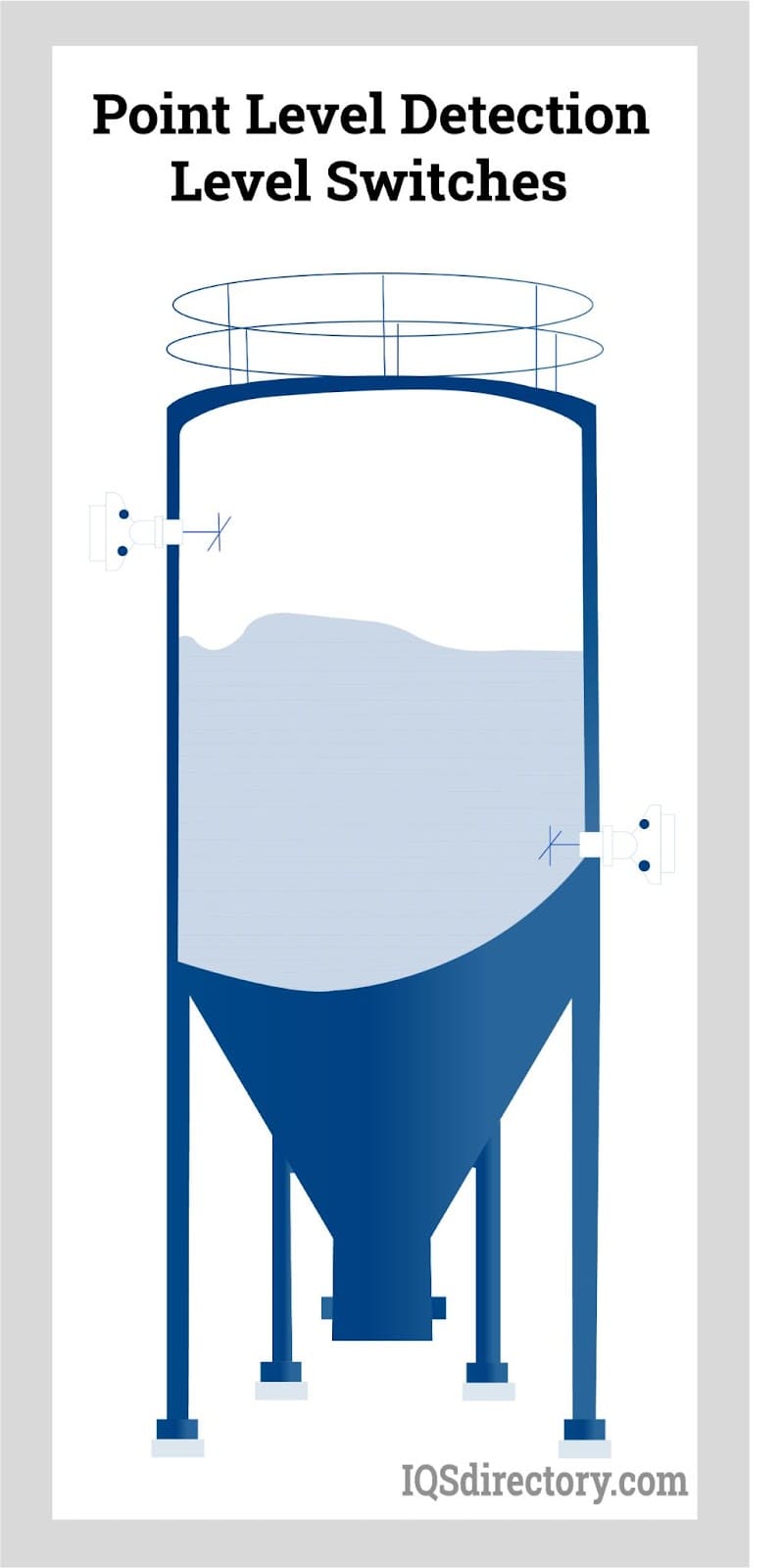

Point level detection switiches are programmed with a predefined level and is activated when the level is reached.

Point level detection switiches are programmed with a predefined level and is activated when the level is reached.

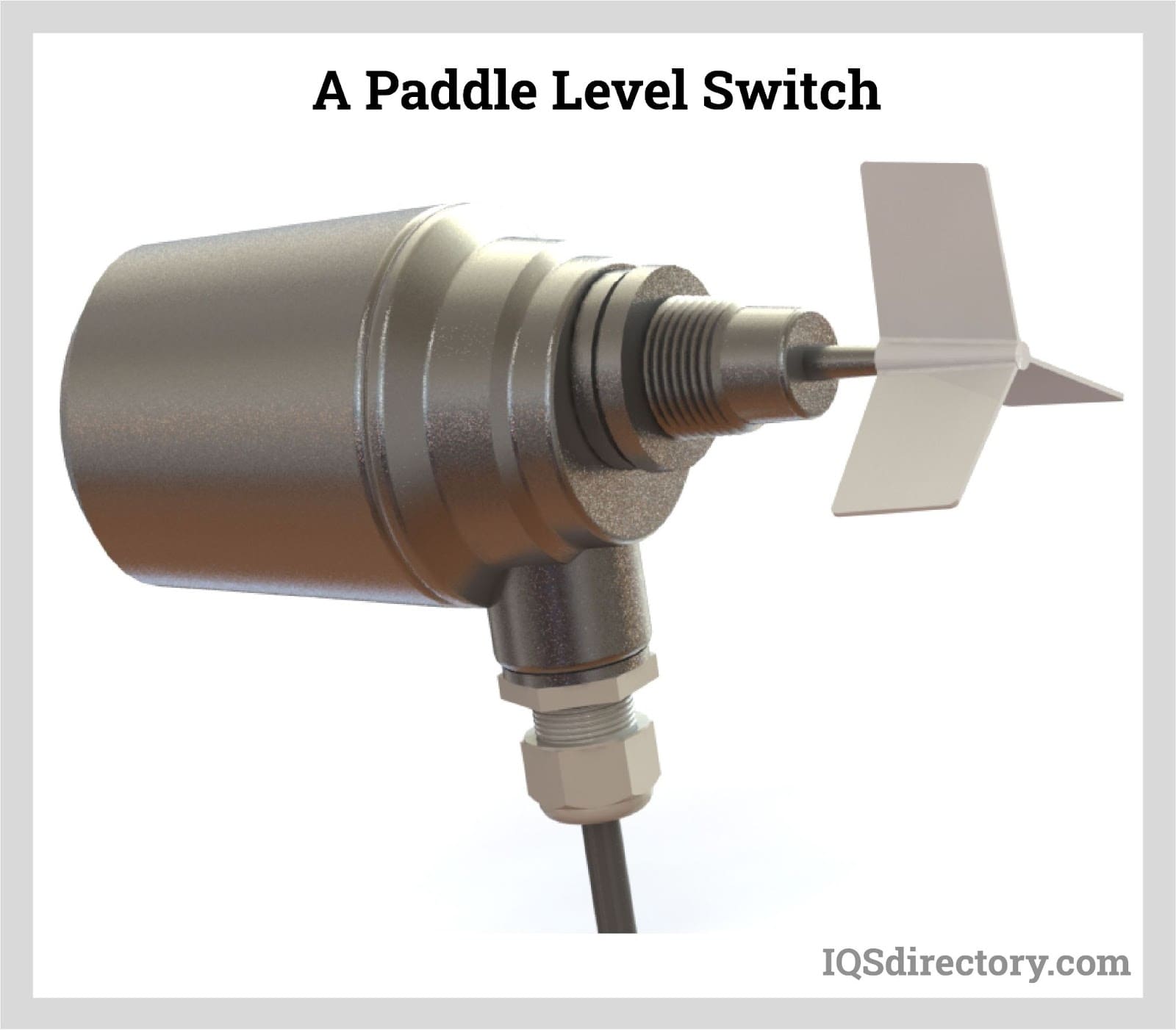

Paddle level switch have an electric motor that slowly rotates a metal paddle when the material reaches a certain level.

Paddle level switch have an electric motor that slowly rotates a metal paddle when the material reaches a certain level.

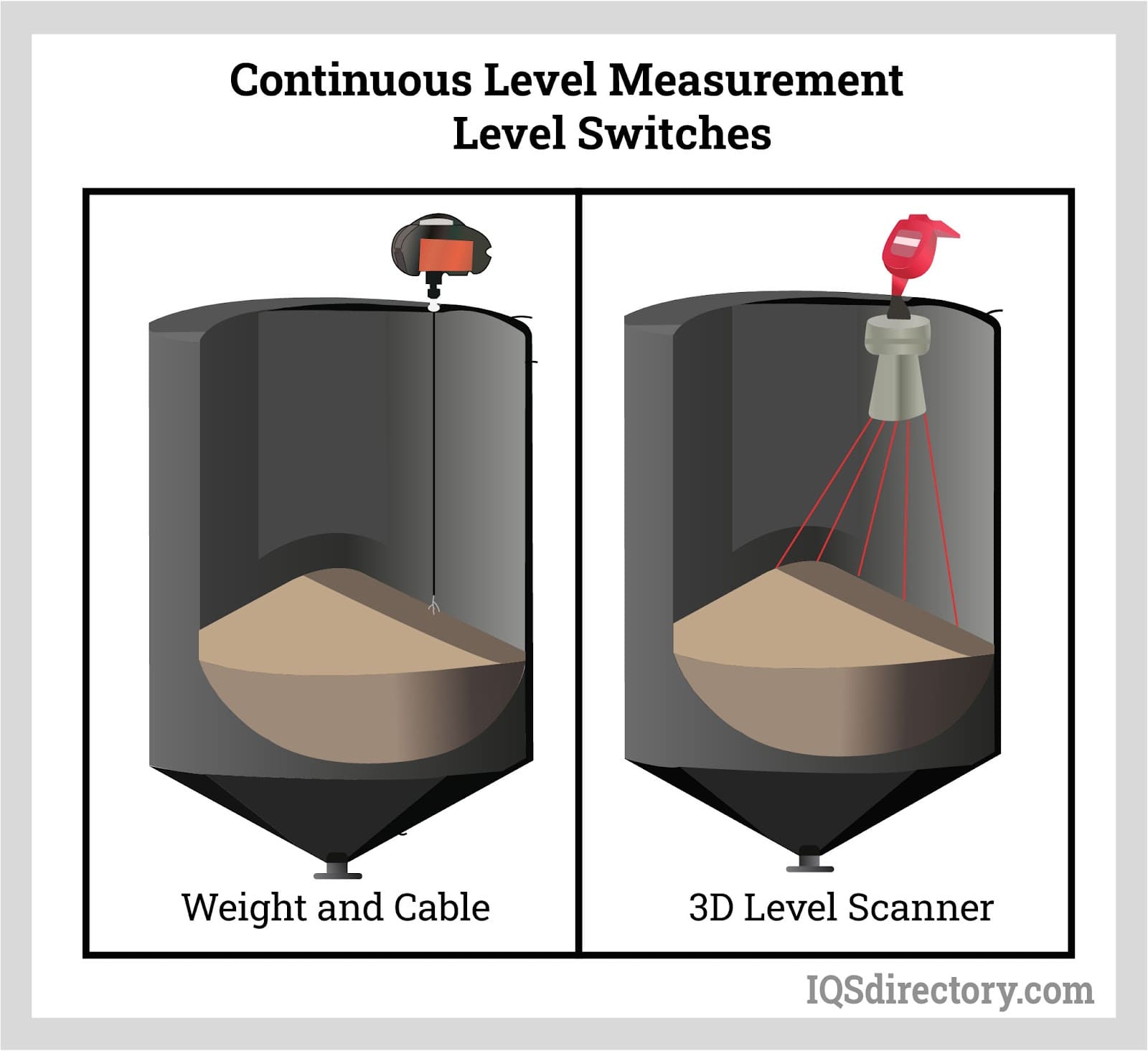

Continuous level measurement level switches have two different methods for installation being horizontal and vertical.

Continuous level measurement level switches have two different methods for installation being horizontal and vertical.

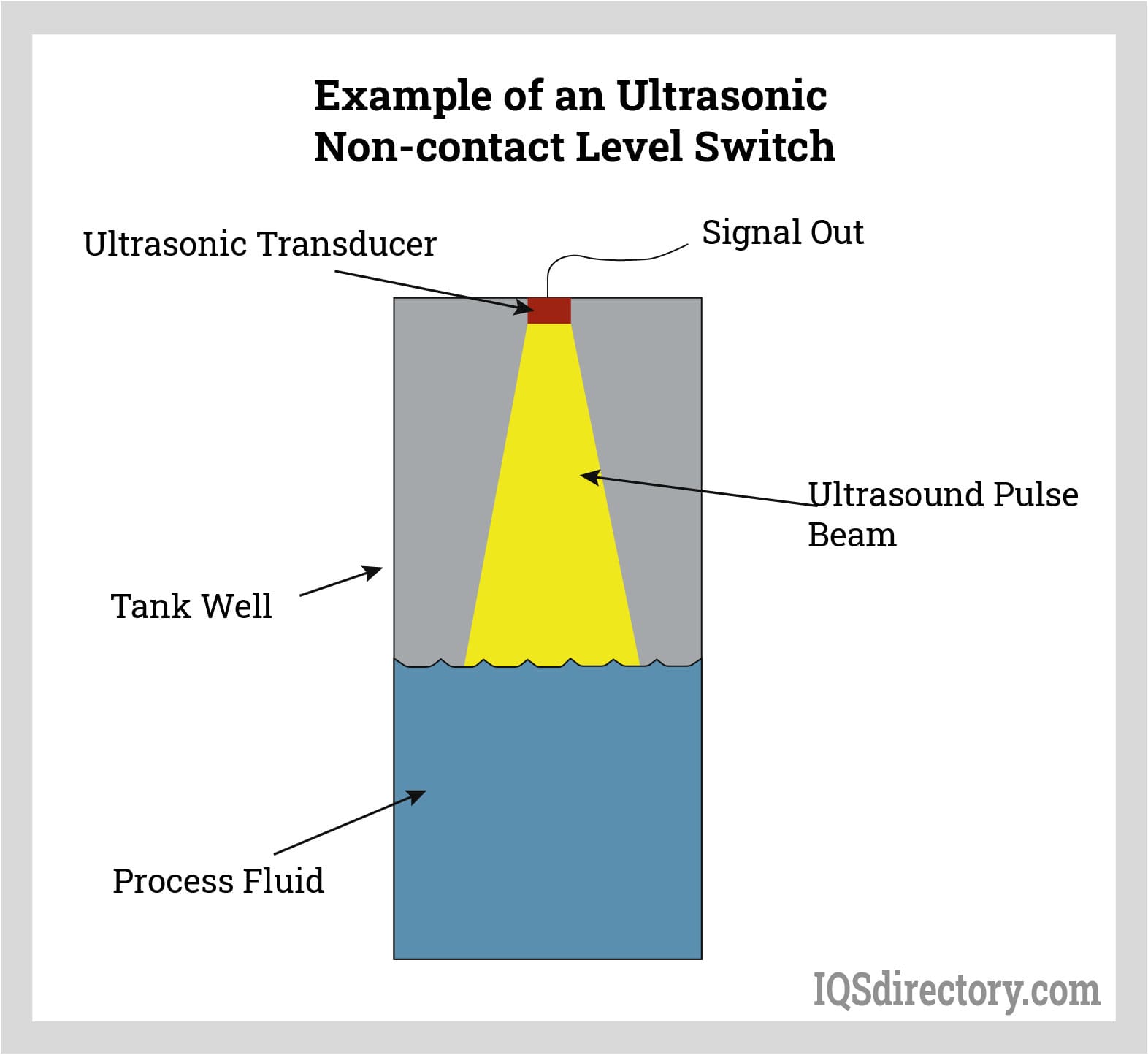

Non-contact level switches measure the time it takes for waves to travel from the transducer to the media.

Non-contact level switches measure the time it takes for waves to travel from the transducer to the media.

Level Switch Types

While there are many types of devices categorized as level switches, certain varieties are more prevalent in industrial applications. Among the most widely used are capacitance level sensors, chambered level switches, displacer level switches, float level switches, optical level switches, and ultrasonic level sensors.

Mechanical Level Switches

These switches directly contact the material they monitor and are suitable for both solid and liquid applications. They are known for their rugged construction and adaptability to industrial settings. Their operation often involves buoyancy and may utilize floats, displacers, springs, attraction sleeves, chambers, or magnetic fields that trigger a switching response. Common examples include float level switches, displacer level switches, and rotary tank level indicators.

Non-mechanical Level Switches

Unlike mechanical types, these switches detect material levels without direct contact. Popular examples include capacitance level sensors, ultrasonic sensors, and optical switches.

Capacitive Level Sensors

These sensors detect material presence by collecting or channeling electrical charge. They are used to monitor levels of aqueous and organic liquids, solids, and slurries, particularly when detecting contact at a defined level.

Chambered Level Switches

Enclosed in protective casings, these switches may be sealed or flanged for airtight performance. Used mainly for monitoring material levels in containers, they also play a role in regulating flow into or out of these enclosures.

Displacer Level Switch Devices

These measure buoyant force changes on a weight (displacer) heavier than the liquid it’s monitoring. As the level changes, the displacer’s position shifts a spring-loaded attraction sleeve in or out of a magnetic field, triggering the switch.

Electric Level Switches

Operate by opening or closing electrical contacts to indicate the presence or absence of a liquid.

Electromechanical Level Switches

Combine electrical and mechanical components for monitoring and control, often used in systems requiring more complex feedback or actuation.

Float Level Switches

Use buoyant mechanisms such as rods or floats that rise with liquid levels. When they reach a designated point, they activate connected devices like pumps, alarms, or indicators. Variants include mercury float switches and bobber-style designs with magnetic sensors.

Float Sensors

These provide liquid level detection only, with no switching action, and are generally used for measurement alone.

Hydrostatic Level Switches

Rely on static pressure from a liquid to determine level changes, making them ideal for applications involving consistent pressure environments.

Level Control Switches

Specifically designed to maintain material levels within a set range, preventing overflow or depletion.

Level Indicators

These devices give readouts of the material quantity within a container, offering real-time monitoring.

Level Sensors

Used to measure levels of various substances including liquids, powders, slurries, and granules, often in conjunction with control equipment.

Liquid Level Switches

Monitor the volume of liquid in a vessel. Ultra-low level switches are available to detect even trace amounts of fluid, useful when dealing with expensive or limited liquids.

Microwave Level Switches

Comprised of a transmitter and a receiver, these switches send microwave pulses back and forth. An interruption in the beam signals material presence and activates the switch.

Multi-Point Switches

Designed with the ability to register multiple actuation levels, these are ideal for applications with several control points within a single tank or container.

Optical Level Switches

Compact and cost-effective, these switches use infrared LEDs to detect translucent liquids. Light reflections change when a liquid is present, altering the switch response.

Pneumatic Level Switches

Triggered by air pressure via internal valves or amplifiers, often used in hazardous environments where electrical components are limited.

Pressure Sensors

Detect changes in pressure exerted by liquids, often used to infer material levels within closed containers.

Proximity Switches

Operate without physical contact, relying on a sensing field to detect nearby material. When an object enters this field, the switch is activated.

Thermal Level Switches

Use temperature sensors to detect heat variations caused by the presence of a fluid. Some can differentiate between air and liquid based on thermal conductivity differences.

Tilt Switches

Trigger a response when tilted to a specified angle. These are especially useful in mobile equipment or bulk solid level detection.

Two-Stage Level Switches

Equipped with a secondary fail-safe trigger, these switches deactivate pumps or sound alarms when liquid surpasses the primary limit, helping prevent overflow or flooding.

Ultrasonic Level Sensors

Use high-frequency sound waves to detect the level of a material without contact. They are well-suited for applications involving delicate or aggressive substances.

Vibrating Level Switches

Utilize reed, probe, or tuning fork sensors driven by vibration. A change in the vibration pattern caused by surrounding material is used to signal level presence or change.

Level Switch Standards and Specifications

Level switch standard requirements vary based on the specific industry and application. For instance, in the food processing sector, switches must comply with FDA regulations to ensure sanitary and safe contact with consumables. In military applications, they must meet Mil-Spec certification to satisfy stringent defense standards. To determine the exact certifications your switches need, it’s best to consult with regulatory authorities and industry experts familiar with your operational environment.

Switch Purchase Considerations

If you're searching for level switches, it's wise to partner with an experienced manufacturer—like those featured on this page. The right supplier will help you secure level switches and sensors that meet both your technical requirements and your budget. Take a moment to explore the offerings of the manufacturers listed here. Choose three or four that seem like a good fit and reach out to start a detailed conversation. Be sure to cover topics such as compliance standards, budget constraints, project timelines, and delivery needs. Once you've gathered the necessary insights, select the manufacturer that aligns best with your goals and move forward with your project.

Accessories for Level Switches

Common level switch accessories include alarms, remote gauges, float balls, float rods, pressure switch mounting brackets, counter flanges, shut-off valves, and similar components.

Level Switch Terms

-

Aperture

The distance between adjacent parallel wires, typically measured in millimeters.

Buoyancy

The upward force exerted on an object by the fluid in which it is partially or fully submerged.

Mercury Switch

A sealed glass tube containing a small amount of liquid mercury and two separate electrodes; when tilted to a certain angle, the mercury pools to complete the circuit and allow current to flow. The circuit breaks when returned to the original position.

Opacity

The degree to which a material blocks the passage of light; the opposite of transparency.

Polypropylene or Polypropene (PP)

A tough thermoplastic polymer known for its exceptional resistance to many chemical solvents, acids, and bases.

Polysulfone or PSU

A high-performance thermoplastic polymer recognized for its strength, rigidity, and clarity, and its ability to maintain those properties between -100°C and 150°C.

Sluice

A gated channel for controlling water levels and flow, often used in waterways, wastewater facilities, and mineral recovery during mining.

Viscosity

The measure of a fluid’s resistance to flow; in simpler terms, its thickness.