Linear Actuators

While many modern linear actuators maintain a familiar form and function to their earliest predecessors, the precision of their construction and the evolution of their power sources have undergone significant advancements since the earliest versions were produced.

Determining the exact origins of the first linear actuators is challenging, but tools resembling those found in contemporary machine shops likely emerged during the Industrial Revolution. By the 1800s, machinists, manufacturers, and industrialists in both England and America were utilizing an array of tools dependent on linear actuators.

Throughout the 19th century, fundamental types of linear actuators were either invented or standardized alongside the rapid evolution of machining techniques, hydraulic systems, and pneumatic technologies. These advancements laid the foundation for more sophisticated applications and innovations in the field.

In the latter half of the 20th century, the trajectory of linear actuators took a transformative turn when Bent Johnson developed the first electric linear actuator in 1979 to enhance a friend's wheelchair. Within just a few years, the electric actuator had expanded into agriculture and other industries, revolutionizing automation across multiple sectors.

Today, continuous advancements in engineering, materials science, and physics have enabled the creation of numerous variations of linear actuators while refining the technologies used in their production. Even the most compact micro linear actuator designed in 2017 embodies centuries of progress in machining, standardization, and material manufacturing, reflecting the long and ongoing evolution of this essential technology.

Linear Actuators FAQ

What is the basic function of a linear actuator?

A linear actuator converts energy into straight-line motion, allowing controlled movement in mechanical systems. It’s used across industrial, automotive, and automation settings where precise linear displacement is needed.

How do electric linear actuators differ from hydraulic or pneumatic types?

Electric actuators use motors to generate motion, offering higher accuracy, energy efficiency, and easier installation than hydraulic or pneumatic systems, which rely on fluid or air pressure for movement.

What factors should be considered when selecting a linear actuator?

Key considerations include load capacity, speed, voltage, size, environmental conditions, material strength, and IP rating. Ensuring compatibility with system requirements prevents inefficiency and premature wear.

Why is lubrication important for linear actuators?

Proper lubrication reduces friction, increases efficiency, and extends actuator lifespan. For example, well-lubricated ball screw actuators can achieve efficiencies above 90%, while neglecting lubrication may drop performance significantly.

How should linear actuators be stored before installation?

Actuators should remain in factory packaging to protect them from dust and contaminants. Periodic oil redistribution helps prevent wear from inactivity, especially for actuators stored for extended periods.

What are the main types of linear actuators used in industry?

Common types include mechanical, hydraulic, piezoelectric, electro-mechanical, and telescoping actuators. Each design serves specific applications depending on precision, force, and space requirements.

What qualities define a reliable linear actuator manufacturer?

A dependable manufacturer offers customization, transparent pricing, responsive support, and proven experience. They should align with your logistics and production needs to ensure consistent quality and timely delivery.

Designing and Engineering Linear Actuators

When designing a linear actuator or a system that incorporates multiple actuators, numerous factors must be considered to ensure optimal performance. One of the first decisions to make is whether a standard linear actuator design will meet the specific needs of your project. If a standard option cannot be adapted to function efficiently, then exploring custom solutions becomes necessary.

Key requirements to consider when selecting or ordering a linear actuator:

- Size – Ensuring the actuator's dimensions fit within the available space and align with system constraints.

- Input Voltage – Matching the actuator's power requirements with the existing electrical system to avoid inefficiencies.

- Load Speed – Determining the necessary movement speed for proper operation in dynamic applications.

- Load Capacity in Lbs – Ensuring the actuator can support the required force without overloading or premature wear.

- Environment – Considering factors such as temperature, humidity, exposure to chemicals, and operating conditions.

- IP Rate – Selecting the appropriate level of protection against dust, water, and other environmental elements.

- Production – Factoring in manufacturing lead times, scalability, and long-term availability.

- Material – Choosing the right materials for durability, weight, corrosion resistance, and longevity.

Linear Actuators Images, Diagrams and Visual Concepts

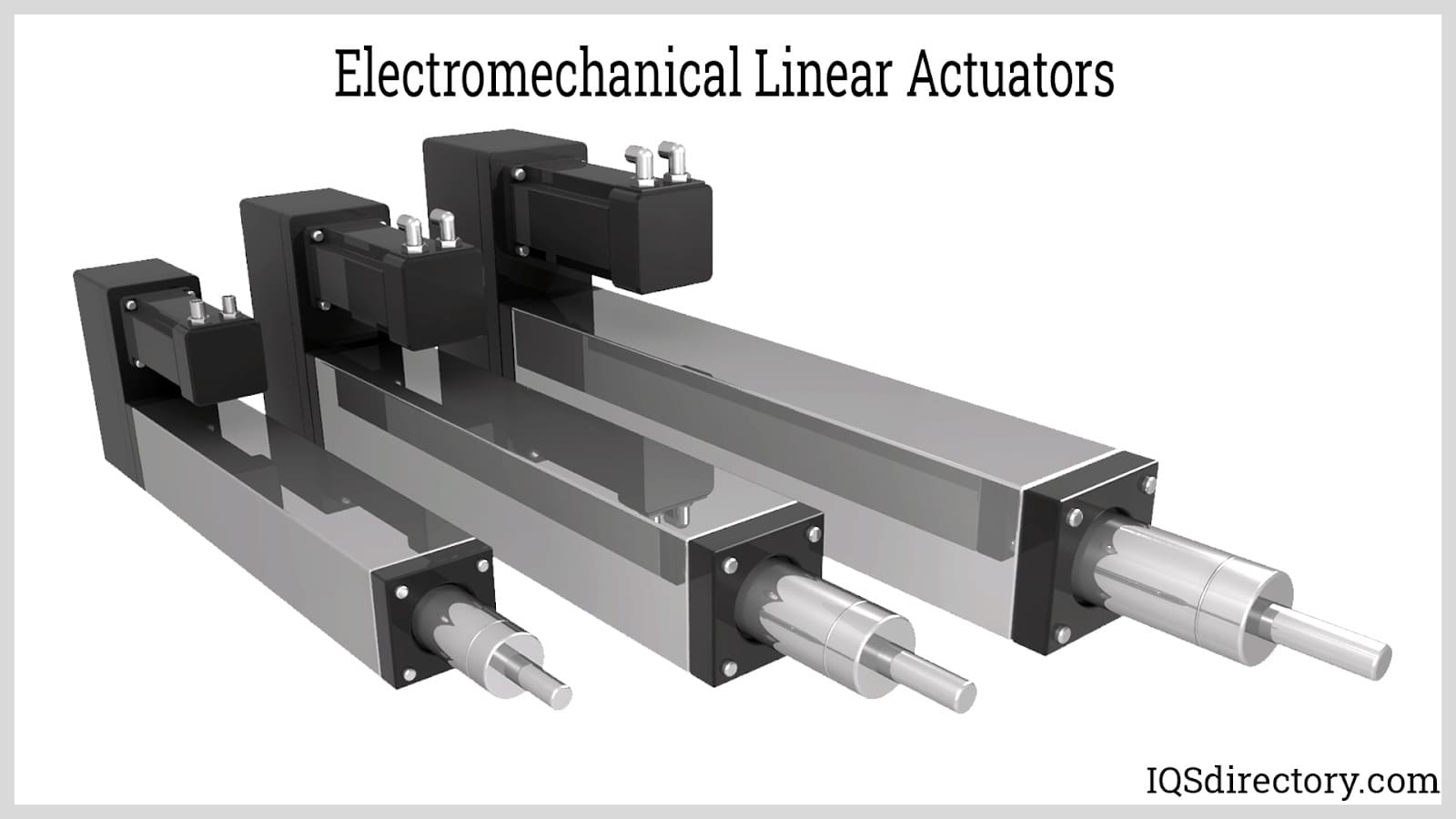

An example of a linear actuator that uses a motor and a series of gears for motion.

An example of a linear actuator that uses a motor and a series of gears for motion.

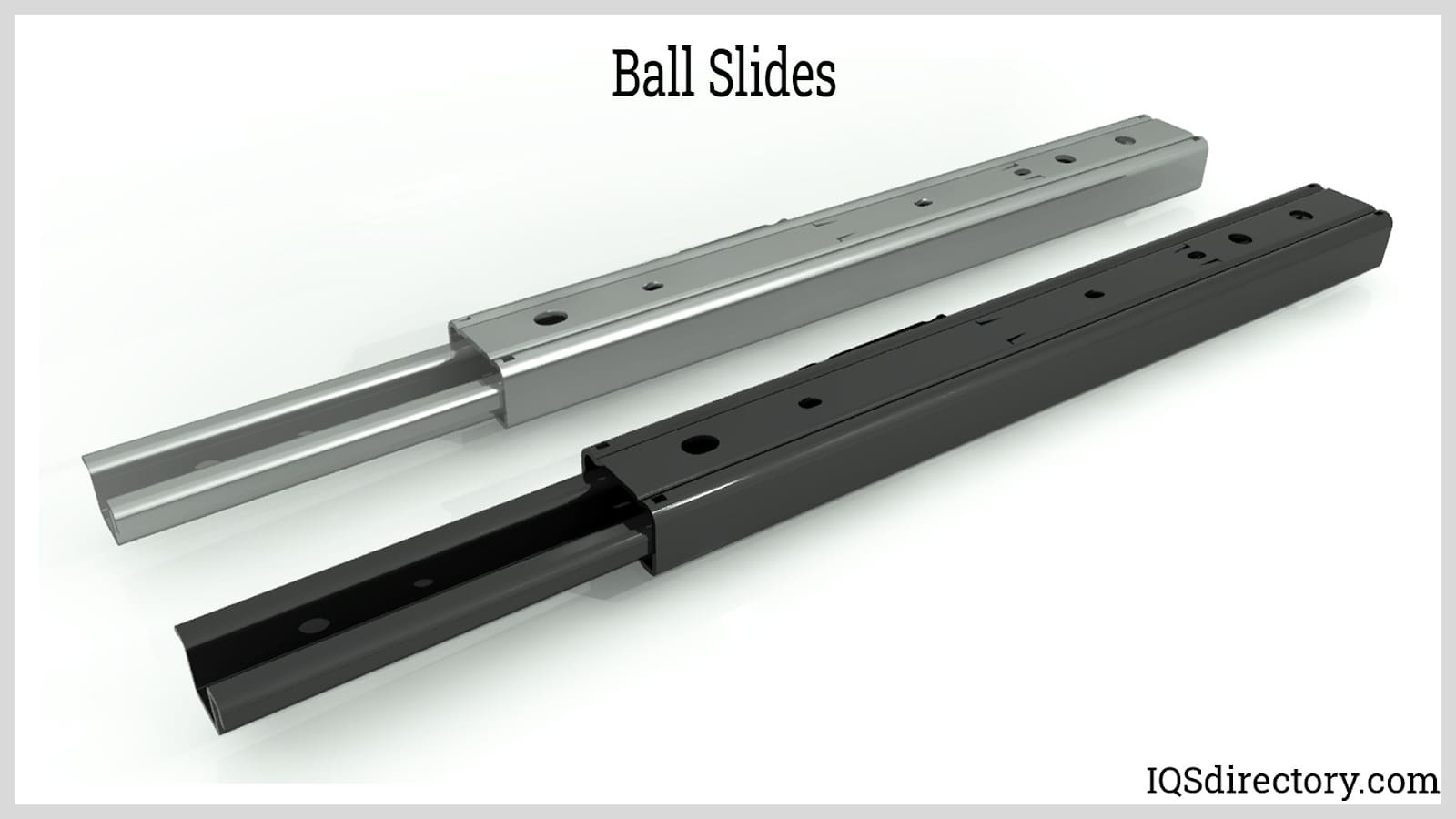

Ball-guided positioning linear slides that have precision accuracy and sturdy.

Ball-guided positioning linear slides that have precision accuracy and sturdy.

The motion of a linear actuator when supplied with enough force or energy.

The motion of a linear actuator when supplied with enough force or energy.

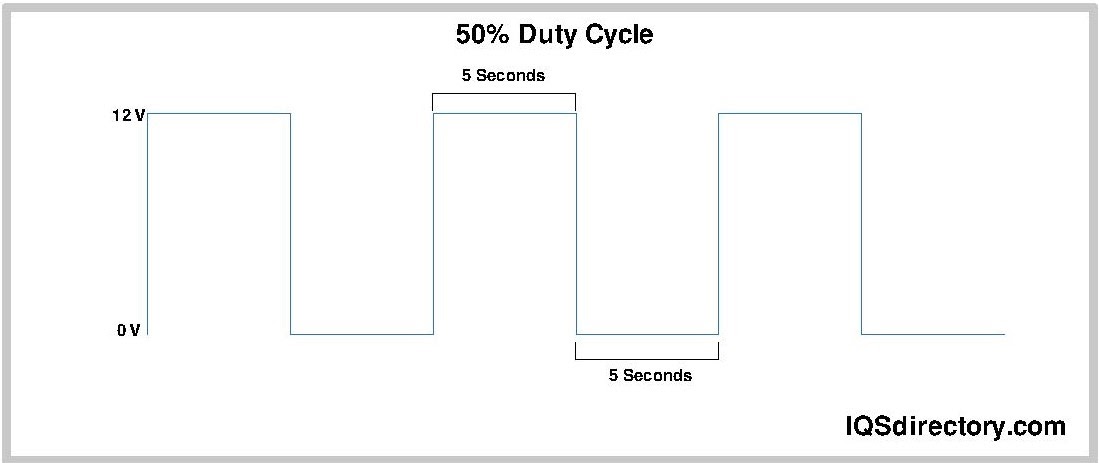

The duty life cycle of a linear actuator when the cycle is set at 50 percent.

The duty life cycle of a linear actuator when the cycle is set at 50 percent.

Notable Types of Linear Actuators

- Mechanical

- Simple linear actuator models typically function by converting rotary motion into linear motion. This category encompasses ball screw actuators, leadscrews, rack and pinion systems, belt drive actuators, and cam-driven actuators. These designs rely on fundamental mechanical principles to produce controlled, precise movement in a variety of applications.

- Hydraulic

- Often referred to as hydraulic cylinders, these actuators consist of a hollow cylinder with a piston inserted within. The incompressibility of liquids enables unbalanced pressure on the piston to create linear displacement. This principle is commonly seen in hydraulic car jacks and other force-intensive applications, though the term "hydraulic actuator" generally refers to devices that incorporate a hydraulic pump for power, providing substantial force capabilities for industrial, automotive, and heavy machinery applications.

- Piezoelectric

- These linear actuators utilize the piezoelectric effect, a property of certain materials that expand when voltage is applied. Often discussed as ultrasonic actuators, they are primarily used in manipulating fluid films and applications requiring extremely precise positioning within short ranges of motion. While they provide exceptional accuracy, the relative weakness of the effect can limit their force output, and repeatability in some applications may be a concern.

- Electro-Mechanical

- Operating on the same fundamental principles as mechanical actuators, electro-mechanical actuators utilize an electric servo motor to generate rotary motion instead of manual operation via a knob or handle. This category includes numerous variations tailored to different applications, including but not limited to:

- Simplified Design – Streamlined configurations optimized for basic motion control applications.

- Standard Design – Versatile actuators balancing efficiency and adaptability for various industries.

- Compact Designs – Space-efficient versions suited for confined installation areas.

- Linear Motors

- Similar in principle to a rotary electric motor, a linear motor generates motion through repeated magnetic field structures distributed along the actuator’s length. Unlike traditional designs, it does not require a lead screw for motion conversion. Although its load capacity is relatively low due to material limitations, its durability and adaptability make it a viable choice for environments that are typically hostile to standard motors and actuators.

- Telescoping Linear Actuator

- Designed for applications where space constraints necessitate a compact yet extendable motion solution, these actuators employ specialized mechanisms to maximize efficiency in limited spaces. Variants include but are not limited to:

- Telescopic Cylinder Actuator – Utilizes multiple nested segments to extend and retract efficiently.

- Rigid Belt Actuator – Features a reinforced belt system for smooth, controlled movement.

- Segmented Spindle – Composed of interlocking spindle sections that extend linearly.

- Rigid Chain Actuator – Employs a segmented chain that locks into position as it extends.

- Helical Band Actuator – Utilizes a coiled band that unrolls to create a stable linear motion.

Linear Actuator Accessories

The specific application and type of linear actuator you are utilizing may necessitate or benefit from the integration of various additional components, tools, and accessories to enhance functionality, performance, and ease of use.

For instance, when working with electro-mechanical linear actuators, the inclusion of speed controllers, digital timers, fuses, monitoring tools, and other electrical accessories may be essential for precise control and efficient operation. These components help regulate motion, ensure safety, and optimize power distribution, ultimately extending the actuator’s longevity and improving its performance within the system.

Beyond standard enhancements, some manufacturers provide customized accessories designed to modify standardized actuators for specialized tasks or to increase user convenience. These tailored solutions allow for seamless integration into unique applications, whether for automation, industrial processes, or specialized machinery.

To achieve the best results with your linear actuator, it is crucial to consult with your manufacturer regarding recommended or available accessories. Their expertise can guide you in selecting the most suitable enhancements to maximize efficiency, reliability, and overall system performance.

Linear Actuator Maintenance and Storage

The vast range of applications and the many intricate details involved in using linear actuators make it difficult to provide universal guidelines for their implementation. To ensure optimal efficiency, effectiveness, and safety, it is essential to follow the manufacturer’s instructions and consult with your mechanics and engineers throughout the process.

- Installation of Linear Actuators

- While all linear actuator installations will be different, these are a few key suggestions you'll want to keep in mind regardless of any specifics:

- Know your goals and expectations in advance. Before installation begins, have a clear understanding of the actuator’s function and performance requirements.

- Familiarize yourself with instructions before assembly. Reviewing the manufacturer’s guidelines beforehand helps prevent costly mistakes.

- Adhere strictly to manufacturer instructions. This applies to all components and systems involved to ensure proper functionality and avoid damage.

- Individually inspect components before system assembly. Checking each part before installation can help identify issues early.

- Pay attention to anything unusual. If something looks, feels, or sounds off during setup, stop immediately and verify with the manufacturer before proceeding.

- Linear Actuator Maintenance

- A linear actuator should be inspected regularly by someone familiar with its design and function. If an actuator begins to operate incorrectly—whether it looks, sounds, or feels different—it should be addressed immediately, even if it has not yet caused a system failure.

- A malfunctioning actuator can lead to significant damage within a system, creating costly repairs and downtime. Identifying and resolving issues early prevents larger problems in the future. When troubleshooting actuator problems, the manufacturer remains the best resource for accurate diagnostics and solutions, as linear actuators can have highly specific operational requirements that may not be readily apparent to a general mechanic or engineer.

- Actuator Lubrication Increases Efficiency

- Different actuators and applications require specific lubrication types and maintenance schedules. Always consult the manufacturer and engineering team to ensure proper lubrication, as this directly impacts performance and longevity.

- For instance, in ball screw actuators, achieving 90% efficiency or higher requires proper lubrication. Neglecting this can cause efficiency to drop by as much as 85%, reducing performance to a level worse than a naturally less efficient actuator. Keeping actuators properly lubricated is especially critical in finely tuned systems where even small inefficiencies can lead to performance degradation.

- Linear Actuator Storage

- Linear actuators should remain in their factory packaging until they are ready for installation or use. This protects the unit from dust, dirt, and other environmental contaminants that could affect performance.

- The specific type of actuator determines how long it can be safely stored and what maintenance steps are required to preserve its condition. Many actuators benefit from periodic adjustments—typically every few months—to redistribute oil evenly and prevent issues from prolonged inactivity.

- Compliance Issues

- Compliance for linear actuators varies on a case-by-case basis, influenced by industry standards, environmental conditions, labor laws, and various federal, local, and industrial regulations. While industry-wide hard standards may be limited due to the degree of customization involved in actuator applications, it is important to consider general safety and compliance best practices to minimize risk and liability.

- Other Considerations

- Beyond installation, maintenance, and compliance, additional factors should be considered when selecting linear actuators—especially if future purchases will be necessary for maintenance, system expansion, or ongoing manufacturing requirements.

- Compatibility – Ensuring the actuator aligns with the system’s design, power requirements, and load specifications.

- Repeatability – Verifying that the actuator can consistently perform within required tolerances.

- Sourcing – Identifying reliable suppliers to maintain consistency in quality and availability.

- Repairs – Understanding repair options and availability of replacement parts to minimize downtime in case of failure.

Choosing a Linear Actuator Manufacturer

Evaluating the quality of a linear actuator manufacturer involves two distinct considerations: their general capabilities as a manufacturer and their ability to meet your specific needs. A manufacturer may excel in one area but fall short in the other, so identifying a partner who balances both ensures the best long-term outcome for your business.

Qualities of a Good Manufacturer

- Versatility

- An excellent manufacturer prioritizes producing the product you need rather than forcing your requirements into an ill-fitting standardized offering. While standard designs may save time and money, they are not always the most efficient or effective solution. A manufacturer that demonstrates adaptability and a willingness to customize solutions is far more valuable in the long run.

- Reliability

- Assessing reliability without first committing to a manufacturer may seem difficult, but there are clear indicators to consider. Pay close attention to how their support staff communicates with you—do they provide prompt and informative responses, or do you find yourself waiting on their schedule? Examining references, customer testimonials, and any complaints filed with regulatory or industry organizations can also reveal patterns of reliability—or lack thereof—before you enter into a contract.

- Experience

- Experience is a key factor in manufacturing linear actuators, given the vast range of applications and custom requirements involved. A manufacturer with a proven track record in the industry will be better equipped to quickly and effectively adapt to your project’s specifications. Choosing a manufacturer with deep expertise in actuator production ensures that you won’t become an experiment in their learning curve.

- Transparency

- A trustworthy manufacturer ensures that you always know exactly what you’re getting and how much you’re paying. There should be no hidden fees tacked on after the initial estimate, and all costs, including shipping and handling, should be clearly outlined from the start. Warranty terms, guarantees, and support agreements should be well-defined, with no ambiguity. If delays or issues arise, a reliable manufacturer will inform you promptly, rather than trying to obscure or minimize the problem until it becomes unavoidable.

- Support

- A high-quality manufacturer should serve as your primary resource for all maintenance and repair concerns related to your linear actuators. Observing how their customer service team handles inquiries, service requests, and troubleshooting can provide valuable insight into the overall quality of their operations. If customer support is lacking, it is often a reflection of deeper issues within the company’s manufacturing processes.

Qualities of a Suitable Manufacturer

- Specific Application

- A suitable manufacturer for your needs should have experience with your specific application or a closely related one. Their familiarity with the type of linear actuator required for your project will help prevent missteps, inefficiencies, and errors throughout production, installation, and operation. When reviewing references, prioritize manufacturers whose previous work aligns with your industry’s needs and expectations.

- Logistics

- The logistical side of working with a manufacturer plays a crucial role in ensuring seamless procurement and delivery. Shipping times, handling processes, sourcing methods, and inventory management should align with your business needs. If a manufacturer cannot reliably meet your logistics expectations, it could lead to costly delays and disruptions in your workflow.

- Scheduling

- Manufacturers operate within set production schedules and do not always have unlimited flexibility. It is essential to confirm that their availability aligns with your current and future requirements. If a manufacturer consistently prioritizes higher-volume clients, you may find yourself deprioritized, leading to delays in production and fulfillment. Ensuring that they can accommodate your timeline before committing is crucial to avoiding unexpected setbacks.

- Volume

- The ideal manufacturer should be capable of meeting your volume demands while aligning with your purchasing strategy. If they cannot consistently fulfill your order quantities, they may not be a viable partner. Conversely, some manufacturers impose minimum volume commitments that may exceed your needs. While bulk purchasing can sometimes be an option for maintaining spare units, it is generally more efficient to work with a manufacturer whose production scale naturally aligns with your requirements.

- By carefully weighing these factors, you can identify a manufacturer that not only delivers high-quality linear actuators but also aligns with your specific operational and logistical needs, ensuring a productive and sustainable partnership for the future.

Linear Actuator Terms

- 12 Volt Linear Actuator

- A 12-volt linear actuator converts direct current (DC) electrical energy into linear mechanical motion. While the motion generated does not operate at exceptionally high speeds, these actuators provide several key advantages. Their high power output, durability, and reliability make them a preferred choice in numerous applications, particularly in automotive, robotics, and automation systems where stable and efficient linear motion is required.

- Electric Cylinders

- Also known as electric linear actuators, these devices transform electrical energy into mechanical motion, allowing for precise and controlled linear movement. Compared to pneumatic and hydraulic actuators, electric cylinders offer superior accuracy, higher energy efficiency, and easier installation. They also boast an extended service life, making them a cost-effective and dependable choice for industrial automation, manufacturing, and other precision-driven applications.

- Miniature Linear Actuators

- Miniature linear actuators, also referred to as micro or mini linear actuators, function similarly to standard actuators but are designed on a much smaller scale. These actuators generate mechanical linear motion by converting various forms of energy into mechanical energy. Their compact size makes them ideal for applications requiring fine control in limited spaces, such as medical devices, aerospace systems, and precision robotics.

- Rotary Actuators

- Rotary actuators are compact, efficient, and simple mechanisms that rotate an output shaft through a fixed arc, generating oscillating motion. They occupy minimal space, require simple mounting, and can produce high instant torque in both rotational directions. Their versatility makes them suitable for lifting, lowering, opening, closing, indexing, and transferring tasks across industries, including automation, material handling, and assembly operations.

- Servo Actuators

- Servo actuators provide precise position control by utilizing linear motion to maintain the correct operation of another mechanism or equipment component. At their core, servos operate based on error-sensing feedback, allowing them to make real-time adjustments to achieve accurate positioning. These actuators are essential in applications that demand high precision, such as robotics, CNC machinery, and automated manufacturing systems.

- Valve Actuators

- Valve actuators generate linear motion to control valves using various screw assemblies. This movement is crucial for positioning, opening, and closing valves in industrial, commercial, and process automation systems. Depending on the specific application, valve actuators ensure fluid or gas flow is regulated efficiently, contributing to safety and precision in industries such as oil and gas, water treatment, and power generation.