Linear Slides

Linear slides are precision motion devices designed to facilitate free movement along linear planes in a wide range of automated machinery. These mechanisms enable controlled pushing, pulling, and positioning, making them essential in industrial and technological applications. The name "linear slide" or "linear motion slide" derives from the fundamental motion they provide—uninterrupted, guided linear movement.

The History of Linear Slides

The origins of linear slides can be traced back to at least 40 BC, when wooden rolling bearings were discovered in the wreckage of a Roman ship. However, historical evidence suggests that their use predates even this, as indicated by Egyptian hieroglyphs and tomb drawings. These ancient depictions illustrate early forms of linear slide principles, such as tree trunks placed beneath sleds, sledges with liquid-lubricated runners resembling plain bearings, and primitive bearings used in hand drills.

During the Renaissance, Leonardo da Vinci incorporated ball bearing designs into his conceptual sketches, including those for his helicopter. Later in the period, Agostino Ramelli, an Italian engineer, created the first detailed sketches of roller and thrust bearings. In the 1600s, Galileo refined Ramelli’s concept by proposing the containment of rollers or balls within an enclosure to reduce friction. While this innovation was not immediately applied, it became a crucial component of mechanical engineering in the following century when John Harrison integrated caged-roller slides into his H3 marine timekeeper.

The Industrial Revolution marked a significant turning point in linear slide development. One of the earliest advancements was a ball-bearing system featuring a ball running along a grooved axle assembly, patented by Philip Vaughan in 1794. Further innovations in this era included the invention of radial-style ball slides in 1869, tapered roller bearings in 1898, and a breakthrough method for grinding and milling precisely sized bearing balls in 1883. Throughout the 19th century, linear slides played a vital role in improving wheel and axle assemblies, enhancing watchmaking precision, and optimizing the functionality of water mills.

In the 20th century, linear slide technology advanced even further. In 1907, Sven Wingquist developed the self-aligning linear ball bearing, followed by Erich Franke’s invention of the wire race bearing in 1934. Bud Wisecarver introduced v-groove bearing guide wheels in 1968, securing a patent for them in 1972. By the early 1980s, Robert Schroeder of Pacific Bearings revolutionized the industry with the introduction of bi-material plain bearings, featuring a metal shell and a Teflon-based layer bonded with a thin adhesive.

Today, linear slides are more critical than ever, driven by advancements in robotic automation and high-tech industries. Their applications span a wide spectrum, from high-speed slides in dental drills to aerospace slides utilized in the Mars Rover. Flexure slides play a crucial role in optical alignment systems, demonstrating the continued evolution and indispensable nature of linear motion technology in modern engineering.

Advantages of Linear Slides

Linear slides offer numerous advantages in motion control applications. They operate with minimal friction, enabling smooth movement while simultaneously handling thousands of pounds of weight. This efficiency translates into another key benefit—the ability to move even massive loads with only a small amount of applied torque. Additionally, linear slides consume very little energy during operation, making them an efficient choice for various applications. With few moving parts, they require minimal maintenance, ensuring longevity and reliability in demanding environments.

Linear Slide Designs

Manufacturers employ various fabrication techniques to produce linear slides, including shape rolling, extrusion, forging, and shape drawing. These processes help create durable, precisely engineered components suited for diverse applications.

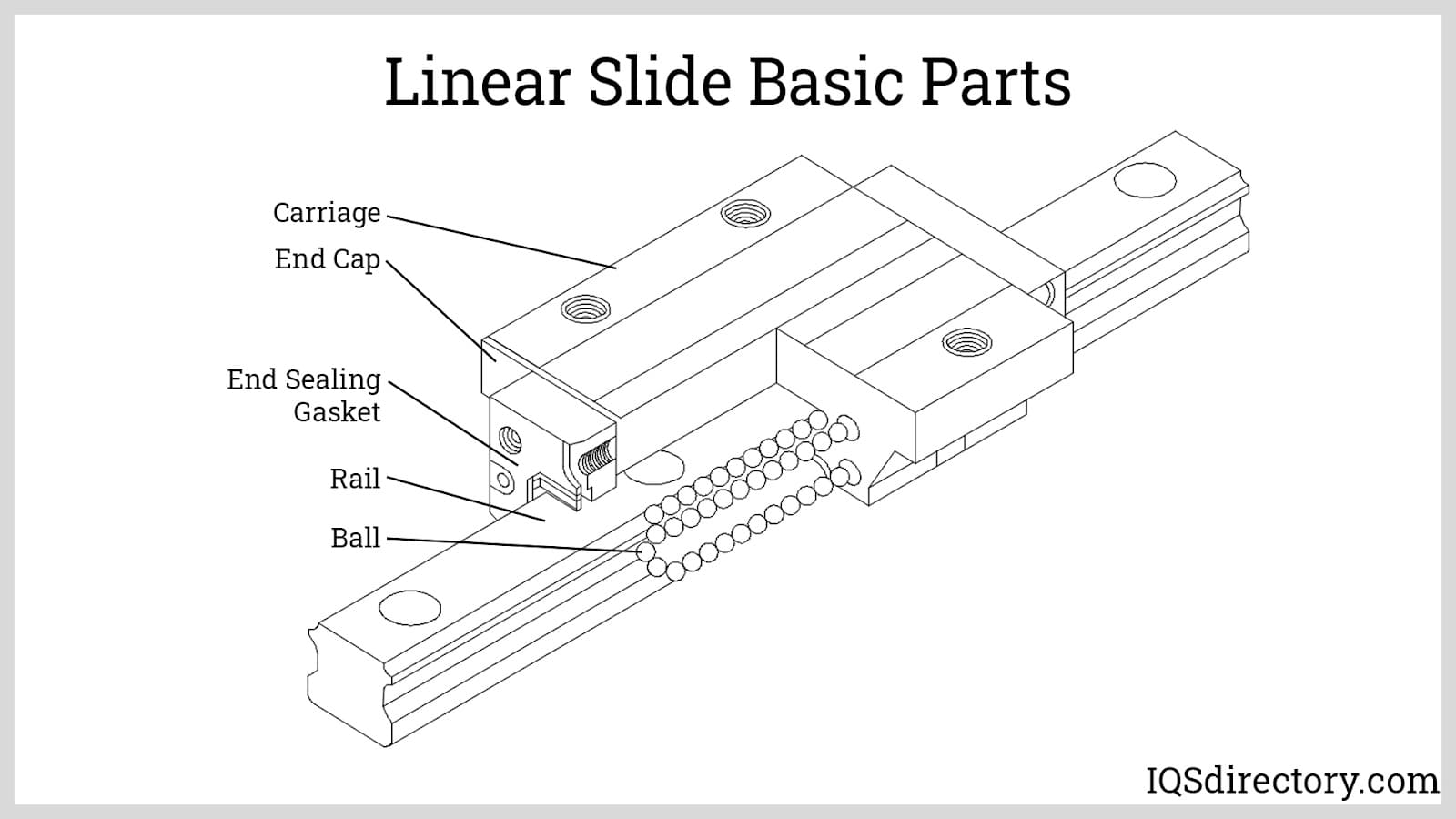

A typical linear slide consists of three primary components: a stationary base, a carriage, and a linear rail fitted with bearings. The carriage, which serves as the moving platform, is securely attached to the base and moves along the rail with minimal resistance. This precise, guided motion allows for controlled linear movement while minimizing wear and tear on the components.

Rails, also referred to as support rails, come in different designs depending on the application. In many cases, they feature a flat surface, while some designs utilize a round, polished rod for enhanced smoothness. In more specialized applications, the rail may have a more complex design, tailored to meet specific performance requirements.

When selecting materials for linear slides, manufacturers prioritize durability and strength. Cast iron is a popular choice due to its ability to withstand substantial wear and heavy loads, making it ideal for high-capacity applications. Stainless steel is another common option, particularly for environments where humidity or corrosion is a concern, as it offers excellent resistance to oxidation. Aluminum, valued for its lightweight yet sturdy properties, maintains structural integrity even under stress, making it a preferred material for certain precision applications.

Designing an effective linear slide system involves considering multiple factors, including load weight, operating speed, frequency of use, and environmental conditions. These considerations influence material selection and overall configuration, directly impacting the lifespan and performance of the mechanism. For example, in environments prone to dust and debris, manufacturers may opt to enclose the slide system in a bearing housing. Protective covers or shields prevent contaminants from interfering with the sensitive bearing components without disrupting the slide’s operation.

Another key design consideration is the method of motion control. Some linear slides rely on inertia or gravity to facilitate movement, while others incorporate linear motors for precise control. Motor-driven slides offer enhanced motion accuracy, allowing the carriage to move at precisely regulated speeds. These systems operate using a drive mechanism powered by either AC or DC electricity, and in some cases, fuel-driven power sources.

Because linear slide designs vary widely, custom configurations are readily available from suppliers. Customization options include precise adjustments to base length, rail width, saddle length, flange type, load capacity, friction level, resistive elements, shaft style, and compliance with specific industry standards. These tailored solutions ensure that linear slides meet the exact requirements of their intended applications, maximizing efficiency and performance.

Linear Slides Images, Diagrams and Visual Concepts

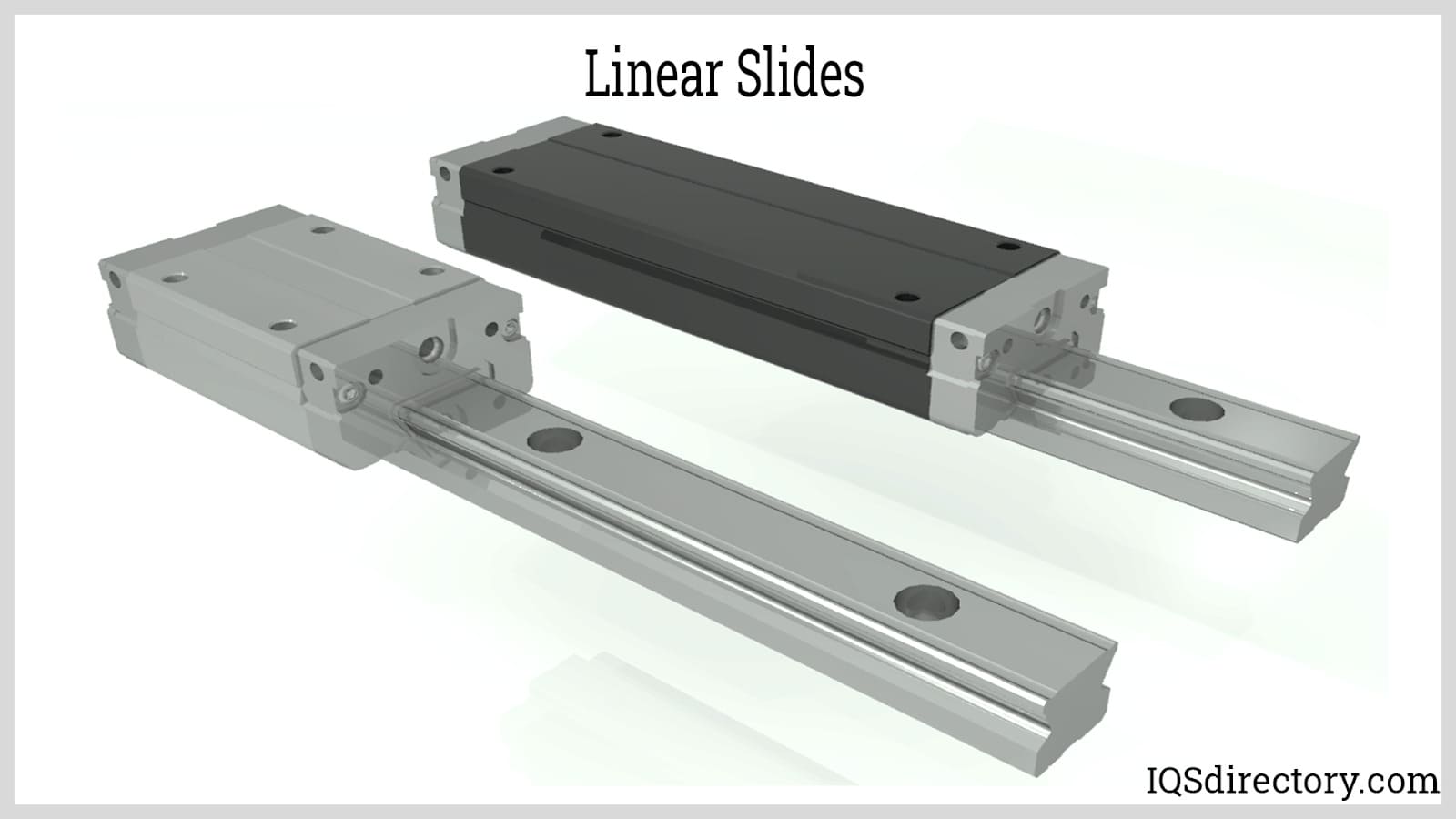

Linear slides are types of bearings that allow smooth and frictionless motion on a single axis.

Linear slides are types of bearings that allow smooth and frictionless motion on a single axis.

The basic parts of a linear slides.

The basic parts of a linear slides.

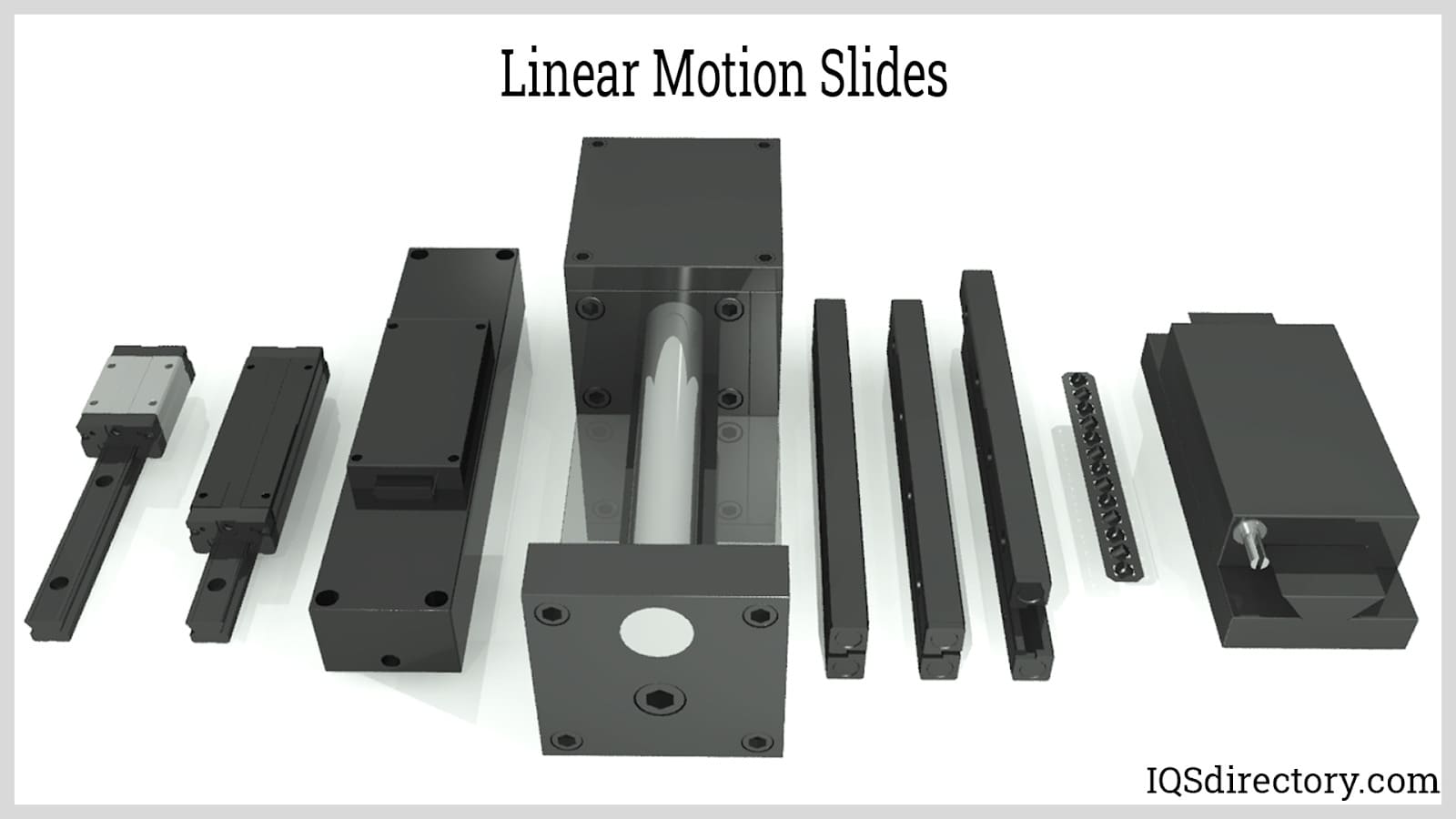

The different types of linear slides.

The different types of linear slides.

Linear Rails move items through a production process withprecision with little friction.

Linear Rails move items through a production process withprecision with little friction.

Linear slides which employ plain surface bearings that rely on a low coefficient of friction and lubrication.

Linear slides which employ plain surface bearings that rely on a low coefficient of friction and lubrication.

Types of Linear Slides

There are many different types of linear slides, each designed to meet specific application needs. While they all share the fundamental purpose of facilitating precise linear motion, their designs and capabilities vary significantly.

- Rolling Element Slide

- Rolling element slides consist of a sleeve-like outer ring with multiple rows of balls assembled in a set of cages. Early designs featured solid metal cages, but modern variations often use stamped compositions. These slides ensure smooth motion while providing durability and low friction, making them highly rigid and cost-effective due to their minimal maintenance requirements.

- Ball Slide Bearing

- Also known as ball bearing slides, these rolling element slides are designed for smooth and accurate movement along a single-axis linear path. The linear base integrates its own lubrication system, which automatically adjusts the speed of motion when needed, enhancing efficiency and precision.

- Roller Slide

- A type of roller element slide, roller slides function as non-motorized bearings. Due to their crisscrossed movement, they are often referred to as crossed roller slides. These slides are designed to support heavy loads and find applications in industries such as medical technology, telecommunications, construction, automation, vacuum systems, and cleanrooms. Their versatility makes them an integral part of many industrial processes.

- Plain Slide

- Plain slides share similarities with roller slides but lack ball bearings, limiting their industrial applications. They are less rigid than rolling element slides but can operate efficiently on steel, stainless steel, and aluminum shafts. These slides are commonly made from metal or plastic materials and provide simple, low-maintenance linear motion.

- Bushing

- Bushings are the simplest type of linear slide, consisting of thin-walled cylinders created through injection molding. Typically made from polymers and paired with lubricants, they facilitate smooth motion. Some variations feature bronze cylinders infused with oil, allowing them to rotate and slide around a polished rod while maintaining consistent performance.

- Linear Guide

- Designed to carry and support heavy loads, linear guides incorporate recirculating ball bearings affixed within a rectangular pad, sometimes replaced by slide units. Some linear motion guides feature multiple rails to ensure faster and more reliable load movement, improving efficiency in high-performance applications.

- Linear Guide Rails

- The linear guide rail serves as the fixed track to which the bearing unit is attached. Its length and position determine the total range of motion for the linear slide. Depending on the application, guide rails can range from short lengths for compact movement to several feet long for extended travel.

- Linear Slide Rails

- A specialized bearing mechanism designed for unidirectional movement, linear slide rails can operate either manually or with motorized assistance, depending on the specific application requirements.

- Ball Spline

- An advanced type of linear slide, the ball spline incorporates a cylinder that functions as the sliding unit. The cylinder typically contains three to five circuits that help recirculate the balls, ensuring controlled and effortless movement. Some manufacturers develop low-maintenance ball splines, slides, and cylinders to help reduce design and manufacturing costs.

- V Rail

- Long-length rails are sometimes designed with a "V" shape to optimize space and material management. This design reduces the risk of dust accumulation and other environmental contaminants, eliminating the need for protective bellows or covers while maintaining efficient operation.

- Advanced Linear Slide

- Precision linear motion systems, including positioning stages, XY tables, linear stages, and machine slides are categorized as advanced linear slides. These highly engineered solutions provide multi-axis precision movement, improving operational efficiency and reducing process times in automated systems.

- Machine Slide

- Machine slides use precision components positioned in front of the attached carriage to brush or wipe debris off the railing before the carriage passes over it. This self-cleaning feature minimizes wear and tear, ensuring smooth, low-friction movement while improving product transportation efficiency.

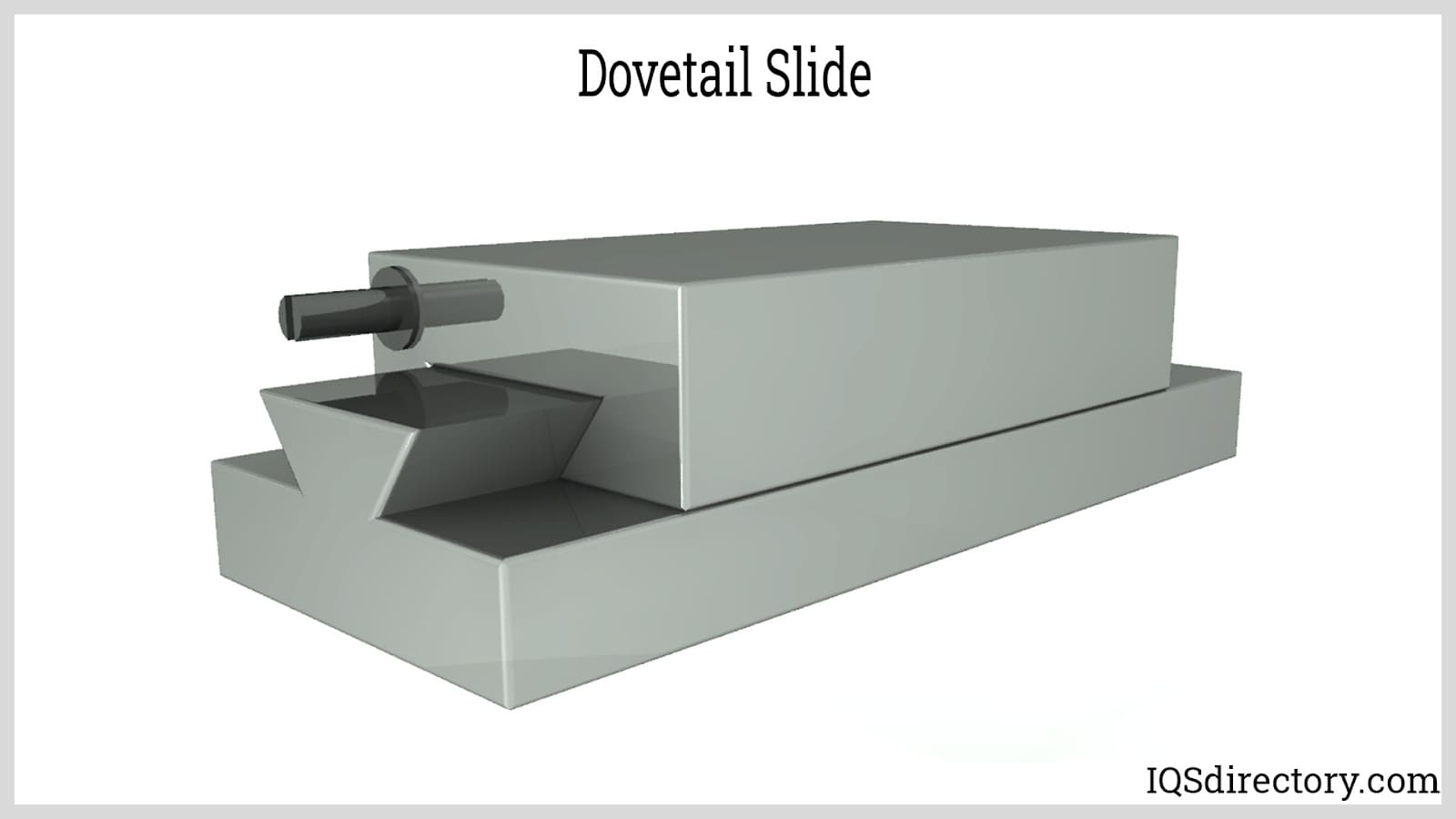

- Dovetail Slide

- While some linear slides require additional lubrication, dovetail slides are typically designed for smooth, low-friction movement with minimal maintenance. Given their role in precision-driven automated systems, proper upkeep is essential to maintaining accuracy and extending the lifespan of the equipment.

- Round Rail Bearing System

- One of two major bearing systems, round rail bearings allow for torsional misalignment while providing low friction and moderate load capacity. These bearings enable smooth movement by establishing point contact between the inner and outer race.

- Profile Rail Bearing System

- A more advanced alternative to round rail bearings, profile rail systems offer higher accuracy, greater rigidity, and improved load capacity. Their compact design makes them ideal for applications requiring high precision and efficiency in limited space.

- Ball Screw

- A linear actuator that converts rotational motion into linear movement, the ball screw minimizes friction, making it suitable for high-thrust applications. Due to its close tolerances, it is ideal for environments that demand precision and efficiency.

- Lead Screw

- Similar to the ball screw, the lead screw also functions as a linear actuator but operates differently. Instead of using ball bearings to reduce friction, lead screws rely on deep helical threads and a mating nut. They are self-locking, eliminating the need for a braking system, and are particularly effective in vertical applications.

- Drawer Slide

- As the name suggests, drawer slides enable drawers to open and close smoothly. These non-motorized linear bearings operate manually and are commonly found in cabinetry, office furniture, and storage units.

- Pillow Slide Block

- Mounted on a rotating linear shaft, pillow slide blocks provide load support while allowing for smooth, low-friction movement. Typically made from iron, they guide, constrain, or reduce friction in both rotary and linear applications.

- Linear Rails

- A fundamental component of linear slide systems, linear rails serve as smooth, flat bases that support and guide the movement of linear bearings.

- Linear Positioners

- Consisting of a drive system attached to a fixed base, linear positioners operate using extended springs that pull the slide top toward the screw end. When the screw is turned clockwise, the slide moves forward; when turned counterclockwise, the pressure from the springs allows it to retract, resulting in smooth, controlled motion.

- Precision Slides

- Designed for accuracy, precision slides consist of a carrier, base, and fitted ways that work in conjunction with gib screws to ensure smooth and exact movement. These slides facilitate the precise feeding and retraction of parts, tools, and fixtures in high-precision applications.

- Roller Tables

- Among the quietest types of bearing tables, roller tables operate with minimal noise while maintaining smooth and efficient linear motion.

- Rotary Stages

- Unlike linear slides, rotary stages enable controlled rotational movement around a central axis. These mechanisms adjust roll, pitch, and yaw for precise positioning, making them ideal for applications requiring angular motion adjustments.

- Standard Slides

- Standard slides integrate roller or ball guides, allowing for the easy engineering of complete systems with minimal assembly time.

- Telescopic Slides

- Telescopic slides consist of concentric components that allow for compact retraction and extension, making them well-suited for applications requiring space-saving, adjustable movement.

Applications of Linear Slides

Linear slides, also referred to as linear motion bearings, are critical components in machinery and mechanical systems, enabling controlled, friction-reduced movement. Designed to provide free motion while maintaining precision, they play an essential role in guiding and supporting mechanical operations with exceptional accuracy.

These motion-bearing elements ensure smooth and reliable movement by offering controlled friction and precise linear guidance. Their ability to maintain stability and consistency in motion makes them indispensable in a wide range of industrial applications.

Linear slides are integral to various precision-driven applications, including clean room operating systems, robotic welding and assembly, and precision eyeglass assembly. They also support automatic packaging equipment and play a crucial role in CNC machining processes such as drilling and grinding.

Beyond these specialized applications, linear slides find use across multiple industries, including healthcare, medical technology, aerospace, semiconductor manufacturing, chemical processing, textiles, printing, commercial manufacturing, and food production. Their versatility allows them to enhance efficiency and precision in environments requiring strict motion control.

Different Types of Loads

The load-bearing capacity of linear slides depends on the specific application and the forces exerted during operation. These loads can take various forms, including vertical loads, moment loads, dynamic equivalent loads, and horizontal loads. Additional forces such as pitch, roll, and yaw can also affect a slide’s performance. In some cases, a combination of these forces acts simultaneously, influencing both the direction and angle of movement. The intensity of these loads may vary significantly depending on the industrial process in which the linear slide is utilized.

- Linear Slides Accuracy

- The accuracy of a linear slide refers to its variation in height and length, both of which impact its ability to maintain smooth and precise movement. Achieving optimal accuracy is essential for applications requiring high-performance operation. In cases where absolute precision is not necessary, profile rail bearing systems offer a suitable alternative, providing consistent guidance while accommodating minor variations.

- Bearing Preload

- To minimize deflection and enhance stability, bearing preload can be applied to both round and profile rail bearings. This process reduces internal clearance by introducing an interference fit between the inner and outer race, fine-tuning the rolling elements for increased rigidity.

- Linear slides are available in various precision levels, tailored to specific applications. Low-precision slides, such as sleds, carts, and drawer mechanisms, are suitable for applications where fine accuracy is not a priority. Medium-precision slides, including saw guides and door guides, provide a balance of stability and performance for applications requiring moderate precision. By selecting the appropriate preload and precision level, manufacturers can optimize linear slides to meet the exact requirements of their intended applications.

Proper Care for Linear Slides

Linear slides are designed to be low-maintenance, but they are not immune to wear and tear. They are particularly susceptible to damage at the points where the weight of the load meets the linear rails. The extent of this wear depends on the type of slide in use. For instance, linear ball bearings tend to degrade faster than roller slides due to the nature of their design. To mitigate potential damage, applying lubricant to the bearings can help reduce friction and extend their lifespan. Additionally, periodic replacement of bearings, particularly ball bearings, is necessary to maintain the optimal performance of the linear rail system.

How to Find a Reliable Linear Slide Supplier

Linear slides are essential motion-bearing components used in a wide range of applications that we encounter in everyday life. Their primary function is to facilitate smooth, rapid, and quiet movement of machine parts. Available in a variety of types and sizes, linear slides can also be custom-designed to meet specific operational needs. To acquire a precisely engineered linear slide, it is crucial to work with a trusted and experienced supplier. The following sections outline a structured approach to finding the right manufacturer or supplier.

To get a perfectly fine-tuned linear slide, you will need to find a reliable and experienced linear slide manufacturer or supplier. The article in the following sections describes a step by step process to help you find one.

- Determine Your Requirements

- Before starting your search for a linear slide supplier, it is essential to define your specific needs. Create a detailed list of factors relevant to your application, including load capacity, frequency of use, machine size, and the environmental conditions in which the slide will operate. Additionally, consider the level of rigidity and speed your application demands from the linear slide. Having this comprehensive list will ensure you have all necessary details ready when discussing requirements with potential suppliers. This preparation will not only streamline negotiations but also help in identifying the most suitable slide for your application.

- Perform a Search on Google

- One of the most effective ways to find a reliable linear slide manufacturer or supplier is through a Google search. By entering relevant keywords, you can quickly generate a list of top suppliers in your region. From these results, you can explore company websites, compare their product offerings and services, and contact them with your specific requirements. Requesting quotes from at least three to four suppliers will provide insight into industry pricing and emerging trends. Once you have gathered and compared quotations, you can make an informed decision on which supplier best fits your needs. However, one drawback of using Google for research is the presence of irrelevant websites and intermediaries that may not meet your requirements.

- Use an Online Directory

- An alternative to Google searches is utilizing a reputable online directory such as IQSdirectory.com. These directories compile verified listings of suppliers, making it easier to find trusted sources for linear slides. Simply enter search terms like “linear slides” or “linear slide suppliers” to access a list of reliable manufacturers. By reviewing company profiles, comparing their products and services, and evaluating pricing, you can efficiently select a supplier that aligns with your needs. The convenience of an online directory allows for a more streamlined process, often reducing the time spent on research.

- Linear Slides for Smoothly Working Application

- Linear slides, also referred to as linear motion bearings, are engineered to facilitate unrestricted movement within an application. These motion-bearing components enable precise directional movement while ensuring accurate guidance and support for machine mechanisms. Designed to minimize friction, they provide smooth and controlled motion, enhancing the efficiency of the equipment they are integrated into. Industries such as medical, factory automation, machining, packaging, semiconductor manufacturing, aerospace, printing, automotive, and food production all rely on linear slides for various applications. Selecting the right linear slide is critical for achieving seamless performance. The following insights will help ensure that linear motion bearing slides function optimally within your system.

Things to Consider When Purchasing Linear Slides

To acquire a precisely engineered linear slide, it is essential to work with a trusted and experienced contract manufacturer or supplier. Ensuring that your linear slide is fine-tuned for optimal performance requires careful consideration of various factors. The following guidelines will help you navigate the selection process effectively.

- Determine Your Requirements

- Before initiating your search for a linear slide supplier, it is crucial to establish a clear understanding of your specific needs. Start by compiling a comprehensive list of factors related to your application. This should include the required load capacity, the frequency of use, the overall size of the machine, and the environmental conditions in which the slide will operate. Additionally, consider the necessary level of rigidity and speed that your application demands.

- Having a well-documented set of specifications will serve as a valuable reference when communicating with potential suppliers. It allows you to present a clear product description or, at the very least, a set of product parameters that suppliers can use to recommend the most suitable options. By being well-prepared, you can streamline discussions and ensure that your chosen linear slide meets all performance expectations.

- Use an Online Directory

- Once your requirements are clearly defined, the next step is to find a reliable supplier. While conducting a Google search is an option, it often results in an overwhelming flood of information, much of which is unreliable. Many manufacturers lack the credibility or quality assurance necessary for consideration, making it difficult to distinguish between reputable and subpar suppliers.

- To simplify this process, consider using an online directory. These directories have already conducted the necessary vetting to eliminate less reputable options, allowing you to focus on high-quality manufacturers. At the top of this page, you can find a curated list of recommended manufacturers.

- To identify the best supplier for your needs, browse their websites, compare their range of products and services, and evaluate their pricing. Narrow down your options and reach out to a few companies to discuss your specific requirements. Pay close attention to not just the products they offer but also the quality of customer service they provide. Reliable customer support is crucial for addressing potential concerns and ensuring a smooth procurement process.

Linear Slide Accessories

Accessories play an integral role in maintaining the efficiency and longevity of your linear guideway system. One key accessory is a wiper, which helps clear the rail of debris before the slide unit moves across it. This prevents contaminants from interfering with the performance of the linear slide.

Seals are another important accessory, serving to protect the rail from dust and dirt accumulation. Unlike standard wipers that primarily remove particulates, seals also help prevent excess lubricants from building up on the rail, ensuring smoother operation. Additional accessories you may consider include lubricants, clamps, roller tables, mounts, stopper bolts, linear locks, height-adjusting blocks, block stopper plates, and slide guide mounting hole caps. Each of these components contributes to the overall efficiency, safety, and longevity of the linear slide system. By selecting the right accessories, you can enhance the durability and precision of your linear slide, optimizing its performance for your application.

Linear Slides Terms

- Actuator

- A mechanism that controls or moves an object indirectly, rather than manually.

- Auxiliary Carrier

- An optional carrier for linear slides that enhances load capacity.

- Axial Loading

- A load that applies force along a shaft or another type of axis.

- Base Mount

- A method of attaching linear slides, either by fastening directly to "T" slot nuts located in the slide base or by utilizing the base mounting system.

- Bearing

- A device that facilitates smooth, low-friction motion between two loaded surfaces in relative movement.

- Breakaway

- The minimum amount of force or pressure required to initiate movement in a device, such as a cable, cylinder, or rotary actuator, through a full stroke.

- Carrier

- A component affixed to the linear slide, typically featuring a bearing system, responsible for supporting and transporting the load.

- Center of Gravity (COG)

- The specific point at which an object's weight is most concentrated. When supported at this point, the object remains balanced and in equilibrium.

- Coefficient of Friction

- A measurement that quantifies the resistance encountered when one object slides across another.

- Dead Length

- The portion of a linear slide or band cylinder necessary for mechanisms and mounting. The sum of the dead length and stroke length determines the total length of the linear slide or band cylinder.

- Deflection

- The degree of bending that occurs under a specific weight load.

- Gib

- A wedge-shaped component made of metal or wood that holds structural parts in place and/or provides a bearing surface.

- Inertia

- The level of resistance an object exhibits against changes in velocity. A linear slide with high inertia requires greater torque to achieve movement.

- Leadscrew

- A mechanism that converts rotary motion into linear motion.

- Proximity Sensor

- A sensing device that detects the end of a stroke on a linear slide and transmits a signal to a controller.

- Rotary Actuator

- An actuator that generates rotational movement.

- Rotor

- The shaft within a rotary actuator that rotates along its own axis.

- Shock Absorber

- A component integrated with linear slides to slow down heavy loads moving at high speeds, reducing impact and preventing damage.

- Stroke Length

- The total distance the carrier and its load travel along the linear slide.

- Tenon

- A finger-shaped projection designed to fit into a corresponding slot or hole.

- Torque

- A force that induces rotation by applying twisting or turning motion.