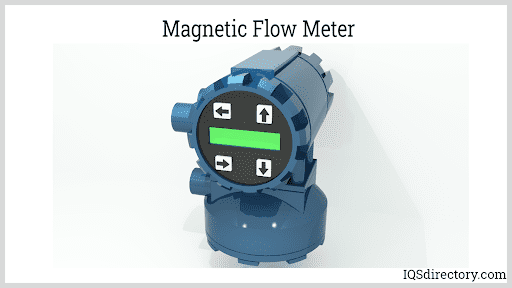

Magnetic Flow Meters

A magnetic flow meter (Figure 1) is a volumetric flow meter that has the potential to measure liquids or sludge that have a conductivity of at least 5 µS/cm. It is also known as a magmeter or magnetic meter. Both are derived from its original terminology.

The magnetic flow meter does not have any movable parts. It creates a magnetic field with the help of electromagnets. It also has a flow tube which is not magnetic in nature, electrodes to create an electric field and a liner. It is ideal for environments where low pressure and low maintenance is needed.

Figure 1

Figure 1

Quick links to Magnetic Flow Meters Information

Operational Principle of Magnetic Flow Meters

Magnetic flow meters infamously operate on Faraday’s Law of Electromagnetic Induction. It states that the velocity of the liquid, the magnetic field’s strength, and the length of the conductor is directly proportional to the voltage generated. This principle is used to measure the velocity of the liquids involved in the process. The fluid involved in this process must be conductive otherwise, this operating principle won’t work.

Magnetic flow meters cause a magnetic field that helps the conductive liquid or liquid slurry flow in the pipe. The flow of the liquid generates a signal voltage. The intensity of the voltage signal is directly related to the speed of the flow. The greater the flow, the stronger the voltage signal generated. The electrodes then detect these voltage signals in the magmeter. The electrodes in turn transmit the signal to the electronic transmitter installed. The strength of the signal then interprets the flow of liquid.

Three Main Types of Magmeters

Usually consumers choose among the following three types of magnetic flow meters based on their application:

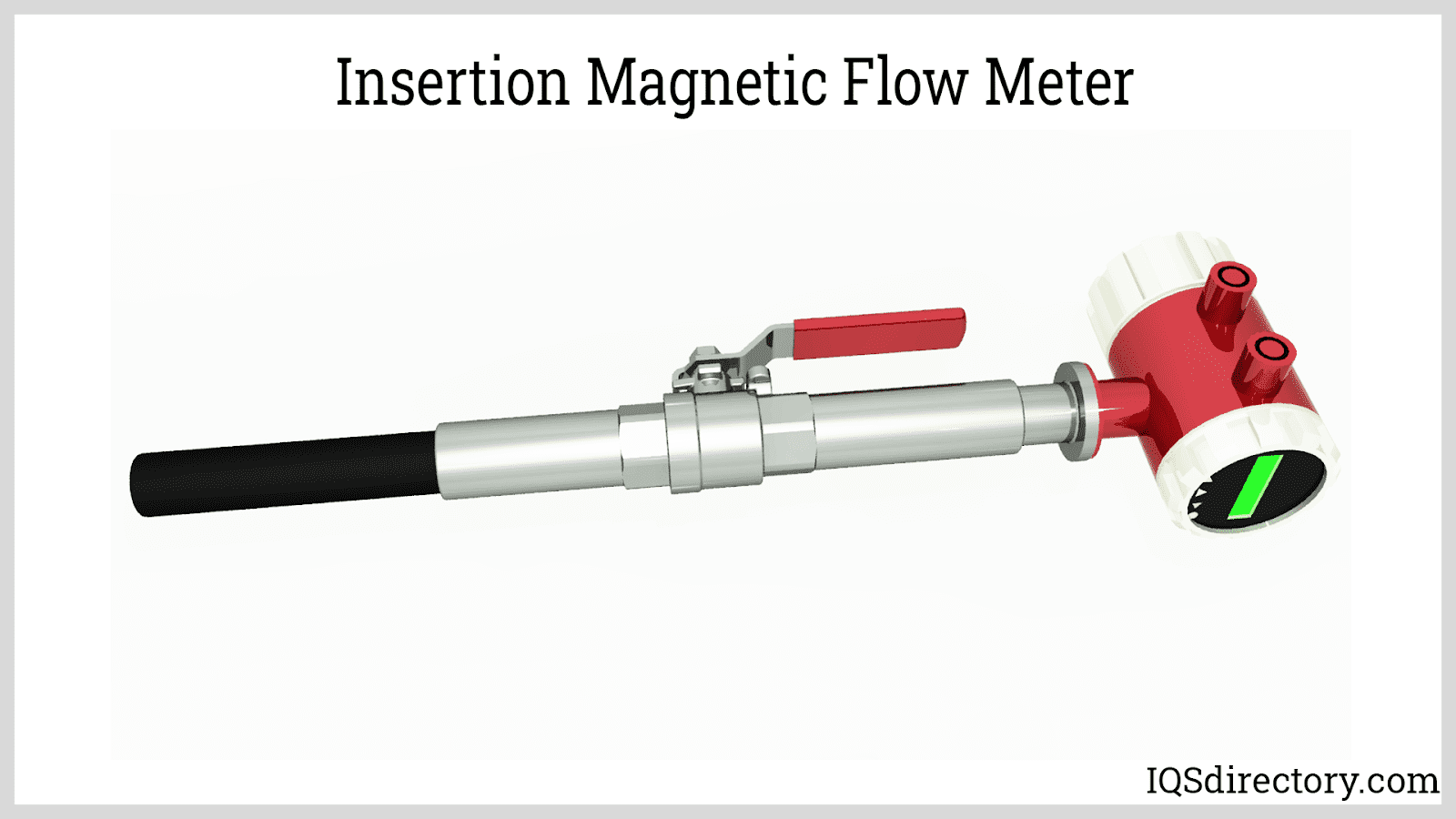

- Insertion Magnetic Flow Meter

- This type of magnetic flow meter can be used in a diverse range of pipe sizes. Usually, it measures the flow best in large size pipes up to 8 inches wide. Figure 2.

-

Figure 2

Figure 2

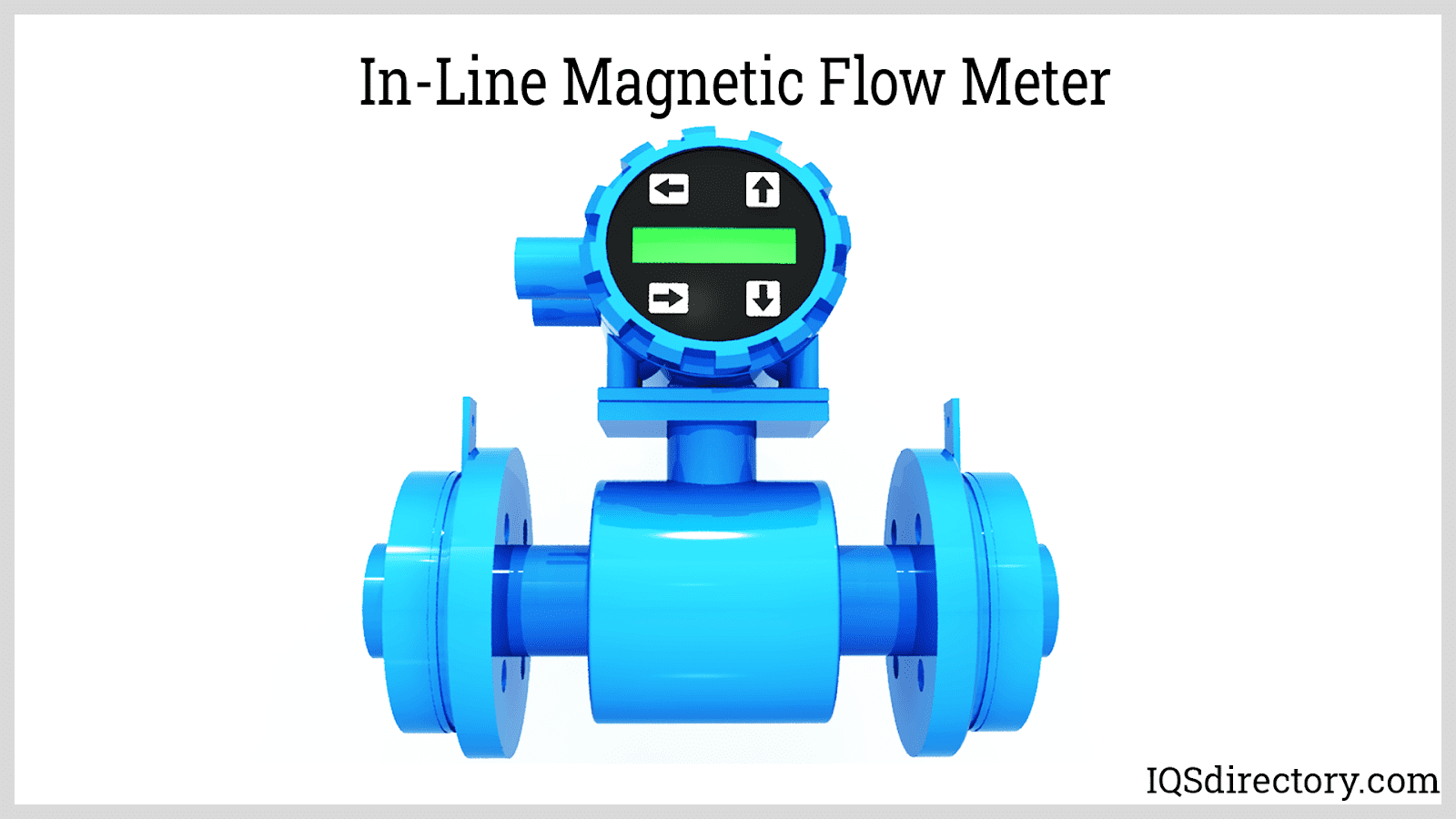

- In-Line Magnetic Flow Meter

- These types of flow meters bring the best results in situations where higher flow rates need to be measured accurately. For example in wastewater, or food/pulp, etc applications. Figure 3.

-

Figure 3

Figure 3

- Low-Flow Magnetic Meters

- As the name suggests it is best for applications with a low flow of liquid. Unlike other magnetic flow meters, it requires almost no maintenance as it is less affected by mechanical debris Figure 4.

-

Figure 4

Figure 4

Selection of Magnetic Flow Meter

Selection of a mag meter largely depends on one’s use. Key aspects that need to be taken into consideration are as follows:

- Type of fluid being measured.

- The abrasion capacity of the liquid/sludge being processed.

- The least and most of the flow required.

- The amount of pressure generated by the process i.e. both minimum and maximum.

- The temperature and friction as a result of the flow.

- Size of the pipe being used.

- What kind of display is required? Does one need an integral display, or a remote display will do.

- If the user requires an analog or digital display.

Pros of Using Magnetic Flow Meters

Magnetic flow meters are very easy to use and are fuss free. These require very little maintenance and have no parts that move. This is the reason there is a much reduced chance of blockages. These predict the flow rate accurately for a wide range of pipe sizes and liquid velocities. These can be as accurate as ±0.5%.

These are widely used in wastewater disposals and are preferred where the liquids carry any kind of charge. What makes these stand out is their ability to monitor both low and high flow rates accurately.

Industrial Applications of Magnetic Flow Meters

Magnetic flow meters are used in multiple industries. The most common usage is in wastewater treatment plants to treat and purify dirty water. Other than that, magnetic flow meters are excessively used in the metals and mining industry. Other uses include the food and alcohol industry.