Marking Machinery

Marking machinery refers to an extensive array of machines and equipment designed to produce precise markings on a diverse range of products and components. These markings, once carefully designed and manufactured, are seamlessly applied to packaging through the use of specialized labeling machinery

The History of Marking Machinery

-

Early History of Marking

The practice of marking stretches back thousands of years, with some of the earliest evidence of engraving dating between 540,000 and 430,000 years ago. This discovery, a chiseled shell, was found in Trinil, Java, Indonesia—the same location where the first Homo erectus remains were uncovered. The next oldest engravings date to the Middle Stone Age, around 60,000 BC. These consist of hatched ostrich shells adorned with decorative banding, discovered in South Africa's Diepkloof Rock Shelter. These shells, likely used as water containers, provide insight into early human artistry. Moving forward in time, the Upper Paleolithic period presents numerous examples of engraved bone and ivory, while prehistoric cultures worldwide left behind engraved petroglyphs.

By antiquity, beginning in the 1st Millennium BC, metal engraving had emerged as a practiced art. Artisans employed techniques such as chasing or a combination of lost-wax casting and chasing to create shallow grooves on metal jewelry. Engraved gemstones also became highly prized and remained a popular art form until the 19th century AD. Around the 1st century AD, people began engraving glass, typically using a wheel to etch decorative figures and elaborate scenes onto glass vessels. Many of these designs depicted Greek mythology, hunting, entertainment, and biblical stories from both the Old and New Testaments. This practice flourished in major cities such as Rome but appears to have faded out by the 5th century. Artisans also used engraving techniques to attach embellishments such as gold leaves, enhancing the perceived value of glassware.

Middle Ages and Marking

During the Middle Ages, European goldsmiths expanded their use of engraving, not only to decorate metalwork but also to inscribe detailed designs. Around this time, they began taking print impressions to replicate their artwork, leading to the development of printing plates. By 1430, German artisans had pioneered this technique, quickly followed by their Italian counterparts. From 1470 to 1530, engraving flourished, with artists such as Albrecht Dürer, Lucas van Leiden, and Martin Schongauer achieving renown for their meticulous craftsmanship.

However, engraving’s dominance began to wane with the rise of etching, a process that emerged in Europe in the late 1400s. Across the Atlantic, even earlier evidence of acid etching has been found in present-day Arizona, where the Hohokam culture used the technique to decorate marine shells before 1100 AD. In 15th-century Germany, artisans began etching iron plates, applying the technique to metal cups, plates, armor, and firearms. The method’s transition into printmaking is credited to Daniel Hopfer of Augsburg, Germany (c. 1470–1536), whose decorated shield and sword remain preserved in the Real Armería of Madrid and the Germanisches Nationalmuseum of Nuremberg, respectively. The increasing use of the copper plate further accelerated the decline of traditional engraving, as etching provided a more accessible and efficient means of creating intricate designs.

During the mid-Renaissance, Jacques Callot of Nancy, Lorraine (modern-day France), revolutionized etching with the development of the échoppe, a specialized etching needle. The échoppe featured a slanted oval section at the tip, allowing artists to replicate the swelling lines characteristic of engraving. This advancement ensured that etching remained a dominant technique in art for centuries.

Modern Marking Systems

Today, engraving and etching persist but are primarily executed using CNC-controlled machinery. Modern marking systems serve a wide range of applications, including artisan crafts, industrial manufacturing, electrical component labeling, and high-precision printing. These advanced systems offer exceptional speed, efficiency, precision, repeatability, and versatility, ensuring that the art of marking continues to evolve in the digital age.

Benefits of Marking Machinery

While traditional marking methods such as hand stamping may come at a lower cost, they fall far short in terms of performance. These older techniques require significant manual labor and often result in inconsistent markings, making them less reliable for high-quality production. In contrast, marking machinery provides unmatched advantages, including programmability, precision, repeatability, speed, efficiency, and the ability to make quick adjustments. Additionally, with the vast array of marking machinery available and the diverse range of design options that manufacturers can implement, there is always a solution tailored to meet specific needs.

Marking Machinery Design

When selecting marking machinery for a customer, manufacturers consider several key factors to ensure the best fit for the application. These factors include the type of material being marked, the lifespan of the material, the volume of production and machine capacity, the intended use of the marked material, the level of detail required, and the environmental impact of the marking process.

In industries such as aerospace and medical equipment manufacturing, marking equipment must apply sufficient pressure to alter the surface of a component while maintaining extreme precision. These fields demand markings that are not only permanent but also highly accurate to ensure compliance with strict design specifications. Any compromise in marking quality could impact performance and safety. In contrast, applications involving more durable and less delicate materials may require robust marking methods such as embossing or engraving, which can withstand harsh conditions and provide long-lasting identification.

How Marking Machines Work

Different marking machines operate in distinct ways, but generally, they function by removing specific areas of a material to create a visible mark. This can be achieved through direct contact using a marking tool, indirect contact with a laser beam, or the application of strong chemicals, such as an acid bath, that etch away the material.

For large-scale projects, manufacturers can program the desired marking pattern’s depth, size, and location into a computer, ensuring precise and repeatable results. They can also digitize an image and upload it to an automated CNC system, allowing the machine to interpret and recreate the design with accuracy and efficiency.

Marking Machinery Images, Diagrams and Visual Concepts

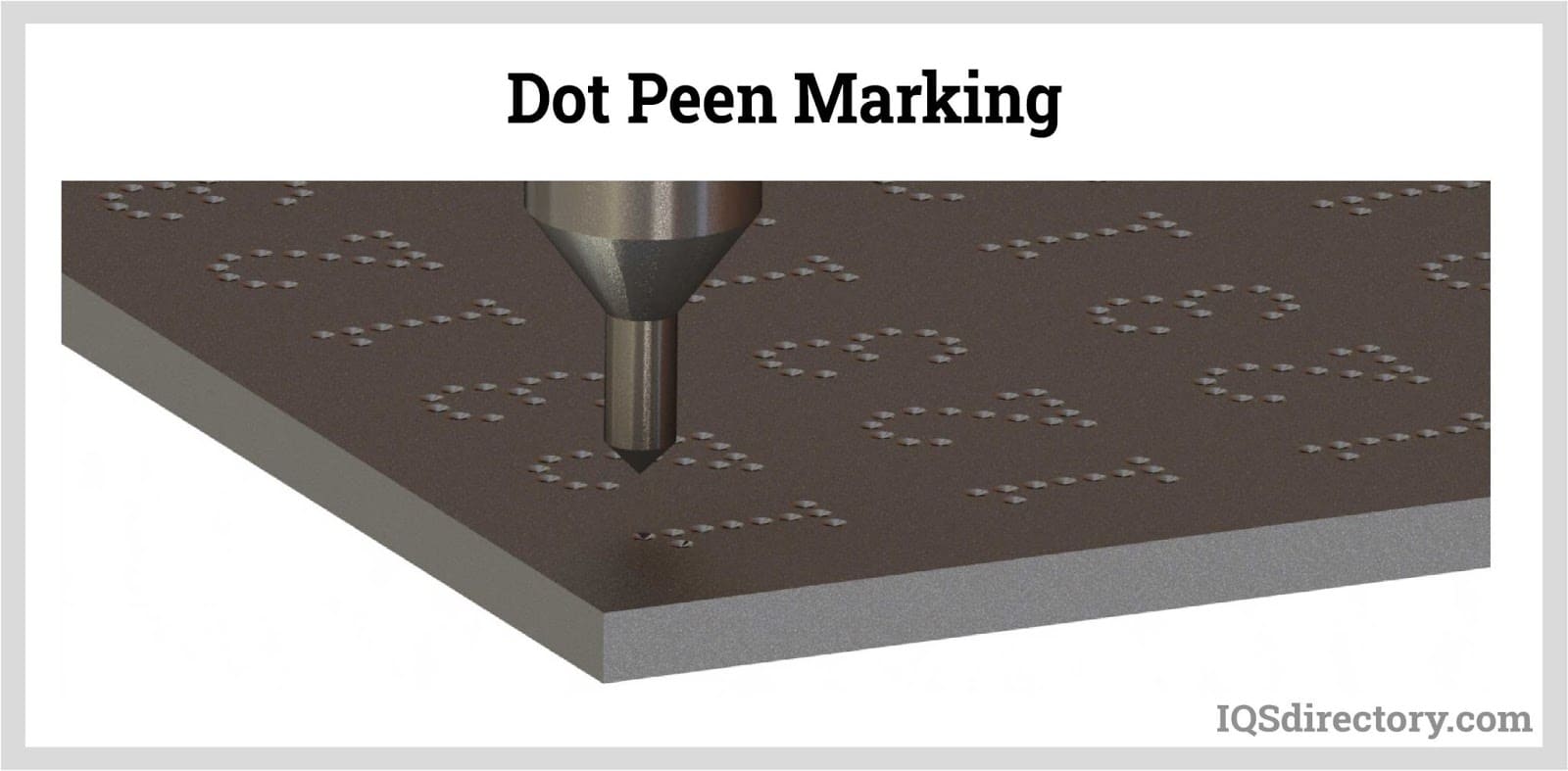

Dot peen marking machine uses a marking pin made of rigid material to engrave a series of small dots closely spaced to one another to form straight or curved lines.

Dot peen marking machine uses a marking pin made of rigid material to engrave a series of small dots closely spaced to one another to form straight or curved lines.

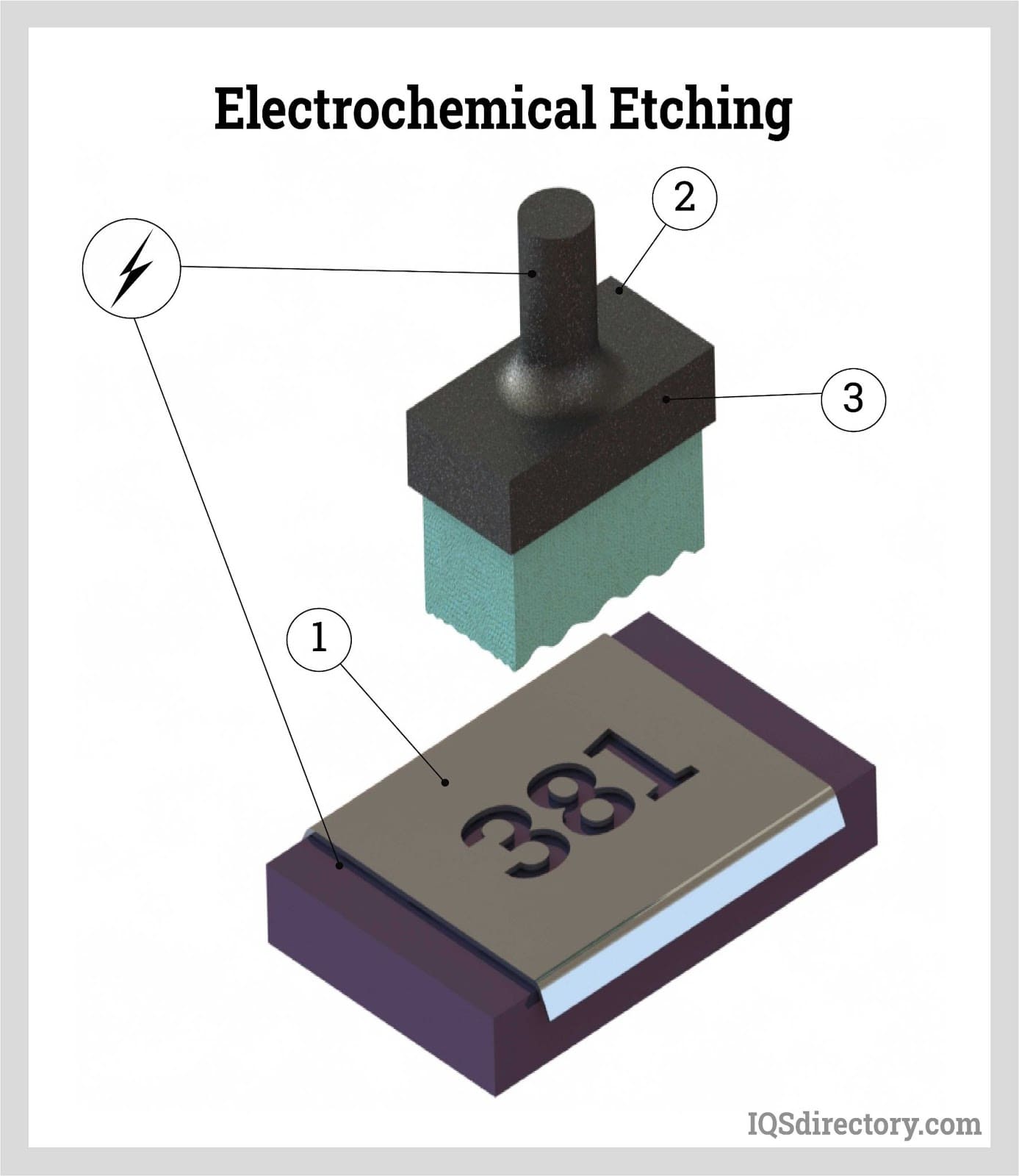

Electrochemical etching, the process of transferring a marking pattern from a stencil to an electrically conductive substrate through an electrolytic reaction.

Electrochemical etching, the process of transferring a marking pattern from a stencil to an electrically conductive substrate through an electrolytic reaction.

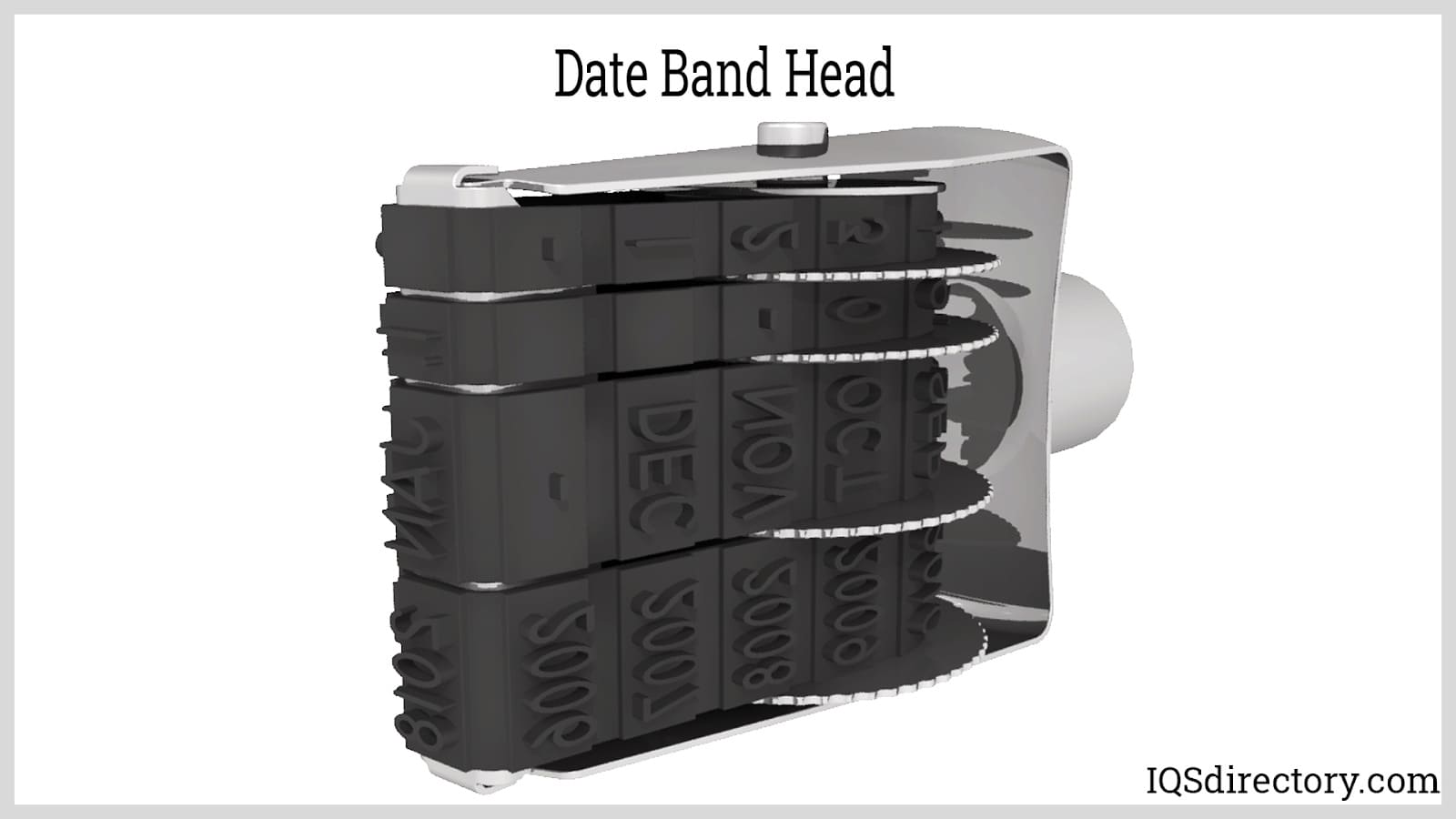

An example of the ink-based die marking which is usually made of rubber, making it ideal for marking brittle substrates.

An example of the ink-based die marking which is usually made of rubber, making it ideal for marking brittle substrates.

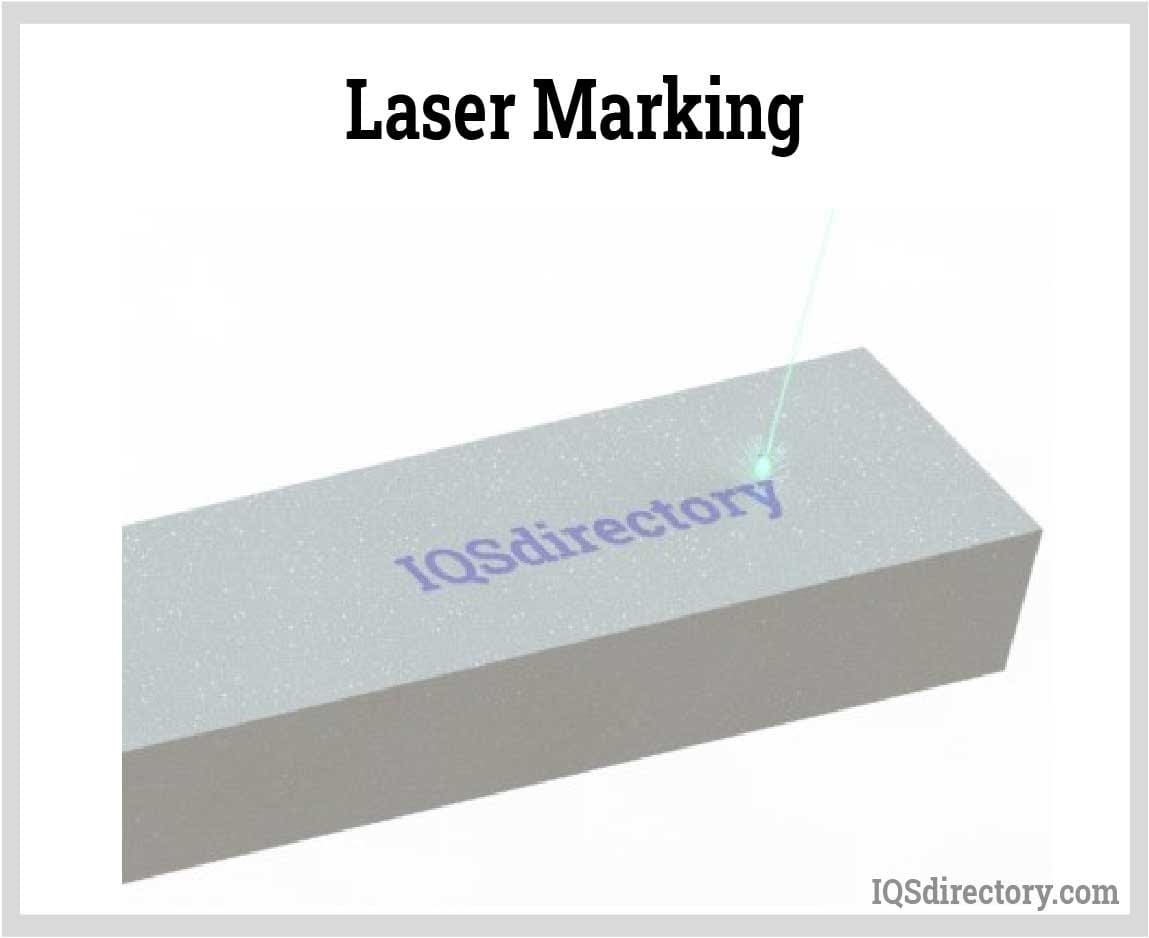

Laser marking, a marking process that incorporates laser technology to mark workpieces.

Laser marking, a marking process that incorporates laser technology to mark workpieces.

Scribe marking machine uses a stylus made from a hard material to produce a mark by piercing the substrate and is dragged along the surface to create lines or curves.

Scribe marking machine uses a stylus made from a hard material to produce a mark by piercing the substrate and is dragged along the surface to create lines or curves.

Hot stamping, the process of transferring ink from a carrier foil by pressing a heated die onto the surface.

Hot stamping, the process of transferring ink from a carrier foil by pressing a heated die onto the surface.

Laser marking machines make use of focused, high-energy laser beams that strike the surface of the material to print the marking pattern.

Laser marking machines make use of focused, high-energy laser beams that strike the surface of the material to print the marking pattern.

Types of Marking Machinery

Marking Systems

Marking systems consist of tools and machines designed to stamp, print, etch, and emboss a variety of surfaces with precision and durability.

Dot Peen Machines

Also referred to as pin marking machines, these systems use a pneumatically driven marking pin to stamp workpieces with a series of small, closely spaced dots. These dots form straight or curved lines, creating clear and legible markings. With independent X and Y marking axes, dot peening ensures precise placement while maintaining speed and accuracy without applying excessive stress to the surface. This technology is ideal for producing text, logos, and 2D data matrix codes.

Embossing Machine

Designed to work with ductile materials such as leather and plastic, embossing machines apply heat and pressure to create permanent deformations that form raised 3D images. These machines are commonly used in credit card production, where they imprint numbers and letters onto the card surface for long-lasting identification.

Engraving Machine

For applications requiring markings on harder materials like stainless steel, engraving machines provide deep, durable grooves. Using a process similar to embossing, these machines carve into rigid surfaces, making them a popular choice for jewelry processing. Several types of engraving machines exist, with laser engraving being one of the most precise and widely used.

Laser Engrave Machine

Laser engraving machines use highly focused laser radiation to remove material from an object’s surface without direct contact. This makes them particularly advantageous for sensitive materials such as glass. Most laser engravers use fiber lasers, which are cost-effective and simple compared to alternatives like CO₂ lasers. Common applications include direct photopolymer laser imaging, direct flexographic plate and cylinder engraving, subsurface laser engraving, and intricate jewelry engraving.

Laser Cut Machine

Similar to laser engraving machines, laser cutting machines also use fiber lasers but feature a distinct machine laser lens with a longer focal point. This reduces taper along the cut edge, making them ideal for thicker materials where minimizing slope angles is crucial. Laser cutting is frequently used in jewelry design and other precision applications.

Pad Printing Machine

Designed to print 2D markings onto 3D objects, pad printing machines use silicone pads to transfer images from a printing plate onto a product’s surface. They are commonly used in industries such as toys, electronics, and medical equipment manufacturing, where detailed and durable markings are required.

Plasma Etch Machine

Using gases or vacuum pressure, plasma etching modifies surfaces with exceptional effectiveness. However, this process can only be performed in batches, making it time-intensive. If the process extends too long, it may cause deterioration of the material’s moldings, limiting its use in high-speed production environments.

Chemical Etching Machine

Chemical etching offers an affordable marking solution but yields inconsistent results. While it is useful for applications where precision is not a priority, its limitations prevent it from being used in industries requiring highly accurate and repeatable markings.

Steel Stamp Press

For low-volume marking, steel stamps offer a simple yet effective solution. These stamps create indentations by pressing or striking the material with significant force. Options include stamp marking kits, hand stamps, and press stamps, each suitable for different production needs.

Numbering Machine

Used for legal documentation and administrative purposes, numbering machines consecutively print numbers onto pages, ensuring organized and sequential identification.

Press Marker

Capable of leaving permanent markings at high speed, press markers are effective but come with drawbacks. They require time-consuming assembly, are not suitable for fragile or hard parts, lack flexibility, and pose potential safety risks during operation.

Etching Machines

Etching machines use acids, bases, or other chemically abrasive substances to engrave or mark materials. This process, also known as chemical milling, is often employed to create master prints or dies from metal pieces, which can then be used to replicate a design across multiple imprints.

Additional marking machinery includes roll marking devices, stylus marking devices, hot stamping machines, and nameplate markers, each offering unique capabilities for specialized marking applications.

Marking Machinery Applications

Marking machinery creates a wide range of marks, including identification codes, images, designs, labels, and logos. Customers rely on these machines to fulfill various objectives, such as enhancing brand recognition, pricing retail products, streamlining product returns, preventing counterfeiting, and enabling efficient tracking of parts and inventory.

These machines operate on a diverse array of materials, including fabric, glass, leather, paper, plastic, textiles, and wood. The marks they produce are applied to an extensive range of products and components, such as cables and wiring, consumer goods, credit and debit cards, greeting cards, glass sculptures, electronic components, jewelry, packaging, storage boxes, wood trim, and writing utensils.

Marking machinery serves a broad spectrum of industries, including electronics, finance, shipping, fine arts, textiles, crafts, communications, quality control, and furniture manufacturing.

Marking Equipment Components

Marking machinery typically comprises specialized marking tools and secondary equipment, each playing a crucial role in the marking process. Specialized marking tools include scribers—thinly shaped machine components that engrain marks onto materials—along with printing plates, laser markers, and steel stamps. Secondary equipment, such as industrial inkjet printers and printing machines, is used to apply ink-based markings onto flat surfaces with precision. These machines are powered by dedicated energy sources and guided by programmed instructions, ensuring accurate and efficient marking across a variety of applications.

Standards and Specifications for Marking Machinery

Marking machinery must be maintained to the highest quality standards to ensure precision, safety, and reliability.

The primary certification for marking machinery is the CE mark (French: Conformité Européenne), which verifies that a product has been tested and complies with the European Union’s health, safety, and environmental regulations. If you plan to use marking equipment in Europe or manufacture marked products for European markets, it is essential to ensure that the machinery you purchase carries CE production identification.

In addition to CE certification, marking machinery must also meet OSHA compliance standards to guarantee safe operation in workplaces. Ensuring that marking equipment adheres to these safety regulations helps prevent workplace hazards and ensures compliance with occupational health requirements.

Things to Consider When Choosing Marking Machinery

Navigating the complexities of marking machinery can feel overwhelming, but with the right manufacturer by your side, finding the best equipment for your needs becomes much easier. A reliable marking machinery manufacturer will guide you in selecting the ideal machinery and tools based on critical factors such as product volume, material type, industrial application, and how seamlessly the new equipment will integrate into your existing system.

To find the right manufacturer or supplier, explore the comprehensive list provided at the top of this page. Each partner has been thoroughly vetted for experience and reliability. Review their information and websites, identify the most promising options, and reach out with your specifications and questions. As you compare their responses, pay close attention to pricing, delivery policies, available certifications, lead times, and overall customer service. The supplier that excels in all these areas is the one best suited to meet your marking needs.

Marking Machinery Terms

-

Bar Code

A product identification code that utilizes a sequence of parallel lines of varying widths and spacing. It is scanned electronically to retrieve product information efficiently.

Bevel

The slanted surface from the engraved character to the background. The first bevel, or character bevel, defines the shape of the engraved mark, while the second bevel, also known as the clearance taper or sighting angle, is typically set at 45 degrees on each side of the hand stamp.

Bottoming

The process of impressing a stamp or die deeply into a material to ensure the characters or design reach the background. It also refers to smoothing out metal that has been displaced by a stamping die.

Character

An individual letter, number, or symbol marked onto an object. The style and shape of characters vary depending on the marking system used.

Chase

A metal frame in a hot stamping press that securely holds the die in place during the stamping process.

Chemical Etching

A process in which a mark is permanently burned onto a product by applying an acid through a screen, resulting in a precise, long-lasting mark.

Die

A metal plate with an etched or engraved design or image, used in marking machines to stamp, roll, or print markings onto a product.

Dot Marking

Also known as dot peening, this micro-percussion marking method uses sequences of dots to create an engraved design on an object according to specific marking requirements.

Etching

A process in which a metal plate is coated with wax, through which lines are cut. A corrosive acid is then applied, dissolving the metal beneath the exposed lines to create an engraved design.

Foil

A thin, flexible material used in hot stamping, where a coat of color transfers from the foil to the stamped product during the marking process.

Hand Stamp

A steel stamp that engraves a design onto an object when struck with a hammer. This method is commonly used for low-volume production.

Impregnation Printing

A specialized printing process that transfers sublimating dye-based ink into the interior of molded parts, providing superior wear resistance.

Ink Jet Marking

A non-contact marking method that uses a fine mist of ink to create precise markings on an object based on design specifications.

Insert

A stamp or type placed within marking equipment, such as a die, to produce a specific design or image on a surface.

Intaglio

An engraving technique where a design is etched into a metal plate, filled with ink, and transferred onto damp paper using a roller press to create a reverse image.

Mortise

A recessed cavity or depression in a die designed to hold an insert securely in place.

Numbering Head

A marking device that imprints multiple characters simultaneously, allowing for fast and consistent product identification.

Pad Printing

A process that transfers ink to molded parts by filling engraved characters in a plate with ink, transferring the ink to a pad, and pressing the pad onto the surface. The ink is then cured using heat, ultraviolet light, or another curing method.

Part Marking

The process of engraving, etching, stamping, or otherwise applying an identification code, logo, or design onto a product or part for tracking, branding, or regulatory purposes.

Steel Branding Die

A heated die used to burn characters or designs into materials such as wood and leather, ensuring a permanent mark.

Steel Stamp

A marking device that creates an impression by being pressed or struck against a material. Steel stamps come in various forms, including hand stamps, press stamps, and stamp marking kits.

UPC (Universal Product Code) Number

A 14-digit numerical code found beneath a barcode, used for product identification and tracking.

VIN (Vehicle Identification Number)

A unique sequence of letters and numbers assigned by vehicle manufacturers to ensure accurate identification of a specific vehicle.