Metal Fabrication

Metal fabrication is a broad term encompassing all metalworking processes. Common metal fabrication methods include metal bending, welding, stamping, punching, and various other forming techniques used to shape and assemble metal parts.

Quick links to Metal Fabrication Information

The History of Metal Fabrication

The use of metals for tools and decorative items has been integral to human civilization since ancient times. Archaeological evidence shows the earliest known metalworking is a copper pendant from northern Iraq dating back to around 8700 BC. In the Great Lakes region between 5000 and 4000 BC, early peoples processed copper using hammers and heat. Early metal fabrication included techniques such as bending and cutting with tools made from stone, wood, bone, and sinew.

Ancient societies were familiar with seven primary metals: iron, tin, lead, copper, mercury, silver, and gold. During the Bronze Age and Iron Age, people worldwide used heat and force to fabricate metal tools, weapons, and jewelry from these materials.

In ancient Egypt, metalworkers developed advanced skills, crafting weapons, adornments, religious artifacts, and trade items. These techniques spread through imitation by artisans, blacksmiths, alchemists, and others in different cultures.

Many fundamental metalworking methods, such as bending, stamping, and engraving, have been used since antiquity and remain in practice today, though modern technology has made these processes more efficient and precise.

Looking ahead, innovations like lasers and advanced machinery now enable precise metal cutting without physical contact. Computer-assisted manufacturing, including CNC machining, allows for highly accurate fabrication with minimal errors. Complex parts can be designed using CAD software and produced seamlessly by automated equipment.

Despite advances in metal fabrication technology, some experts are cautious about the future. As automation and new methods emerge, traditional techniques and jobs may be replaced by machines. The continued evolution of metalworking remains uncertain, with ongoing changes expected.

Metal fabrication provides numerous advantages over alternatives like plastic fabrication. Metal products deliver excellent heat resistance due to higher melting points, making them suitable for high-temperature applications. Metal fabrication is also highly versatile, enabling manufacturers to create a wide variety of parts and products. In addition, metal components are known for their strength, durability, and hardness compared to plastic parts. Metal fabrication is often cost-effective, especially for large production runs or high-volume orders, allowing companies to benefit from competitive pricing and efficient production processes.

Manufacturers determine the best fabrication approach for parts and products by analyzing their intended applications and specific requirements. Considerations include shape, size, tolerances, metal thickness, complexity, and similar factors.

With the wide range of metal fabrication processes available, fabricators can tailor products to meet virtually any specification. This customization covers not only basic factors like size and shape but also properties such as color, surface texture, and corrosion resistance. When unique material properties are necessary, manufacturers can request special alloys from their suppliers to achieve the desired results.

- Before Fabrication

- Before metal reaches the fabricator, it is processed into usable forms. Raw metals are rarely fabricated directly; instead, they undergo primary forming processes like extrusion to become solid stock metal parts. This stage also includes applications such as sheet metal fabrication.

- This stage, known as primary metal forming, typically involves processes such as alloying, shaping, casting, extruding, and forging to prepare the metal for fabrication.

- During Fabrication

- Once metals are available in stock forms, such as sheet metal, tubes, or pipes, fabricators use them to create products of various shapes and sizes. Common fabrication operations include welding, machining, roll forming, shearing, press braking, laser cutting, punching, stamping, and other specialized techniques.

- Some products require multiple fabrication methods to complete. For example, pipe elbows may involve both mandrel bending and swaging processes.

- Finishing the Fabrication Process

- After the main fabrication is complete, manufacturers can enhance the finished part with secondary processing or finishing. This can improve properties such as corrosion resistance, durability, or appearance through processes like powder coating, sanding, deburring, annealing, and polishing.

Metal fabrication begins with sheet metal typically no thicker than a quarter inch, which must be ductile enough to be shaped into different forms.

Metal fabrication begins with sheet metal typically no thicker than a quarter inch, which must be ductile enough to be shaped into different forms.

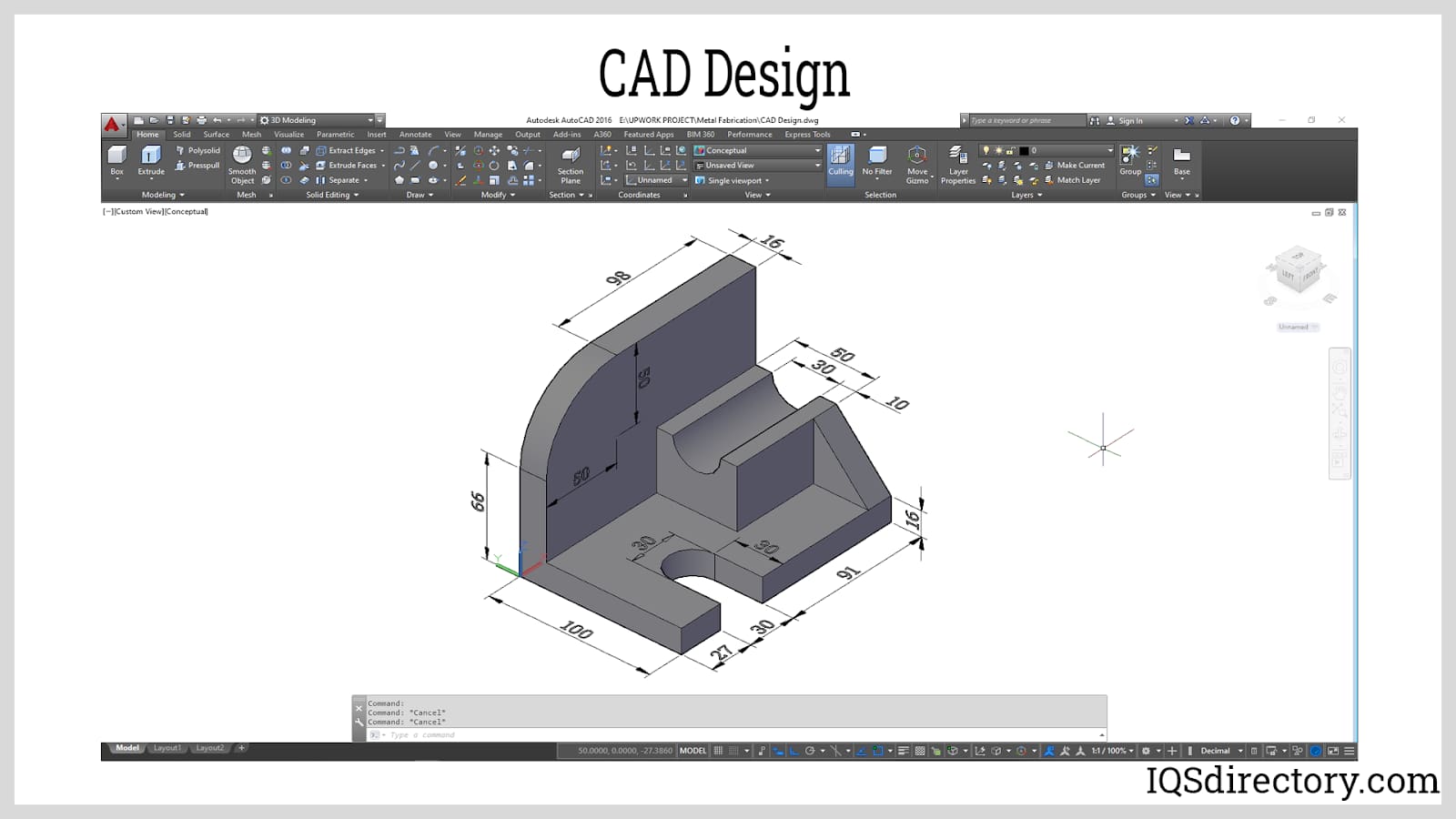

CAD drawings are utilized to define project requirements, identify improvements, and plan fabrication strategies during the design phase.

CAD drawings are utilized to define project requirements, identify improvements, and plan fabrication strategies during the design phase.

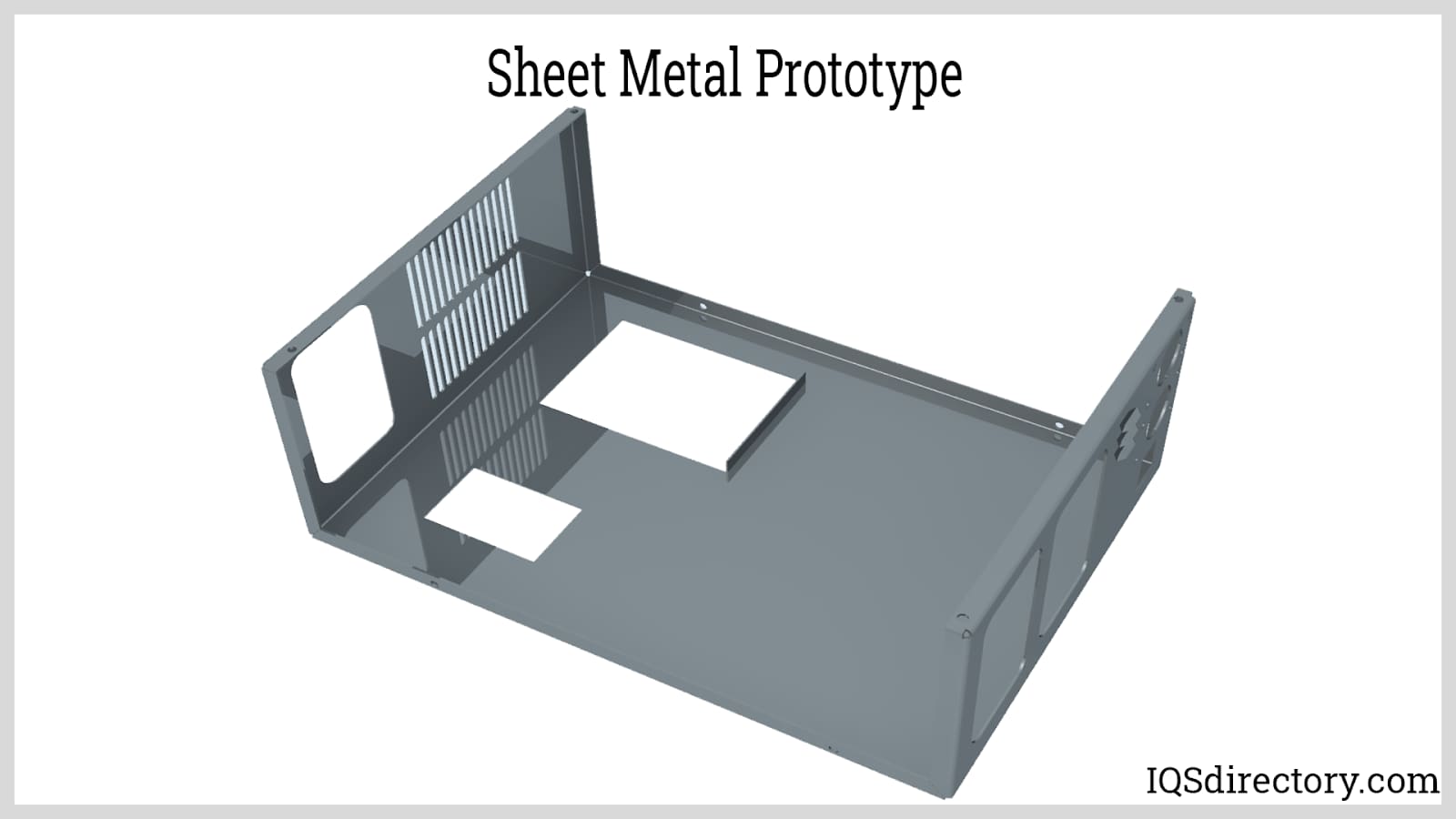

Prototyping enables manufacturers to evaluate and refine the design before moving on to production.

Prototyping enables manufacturers to evaluate and refine the design before moving on to production.

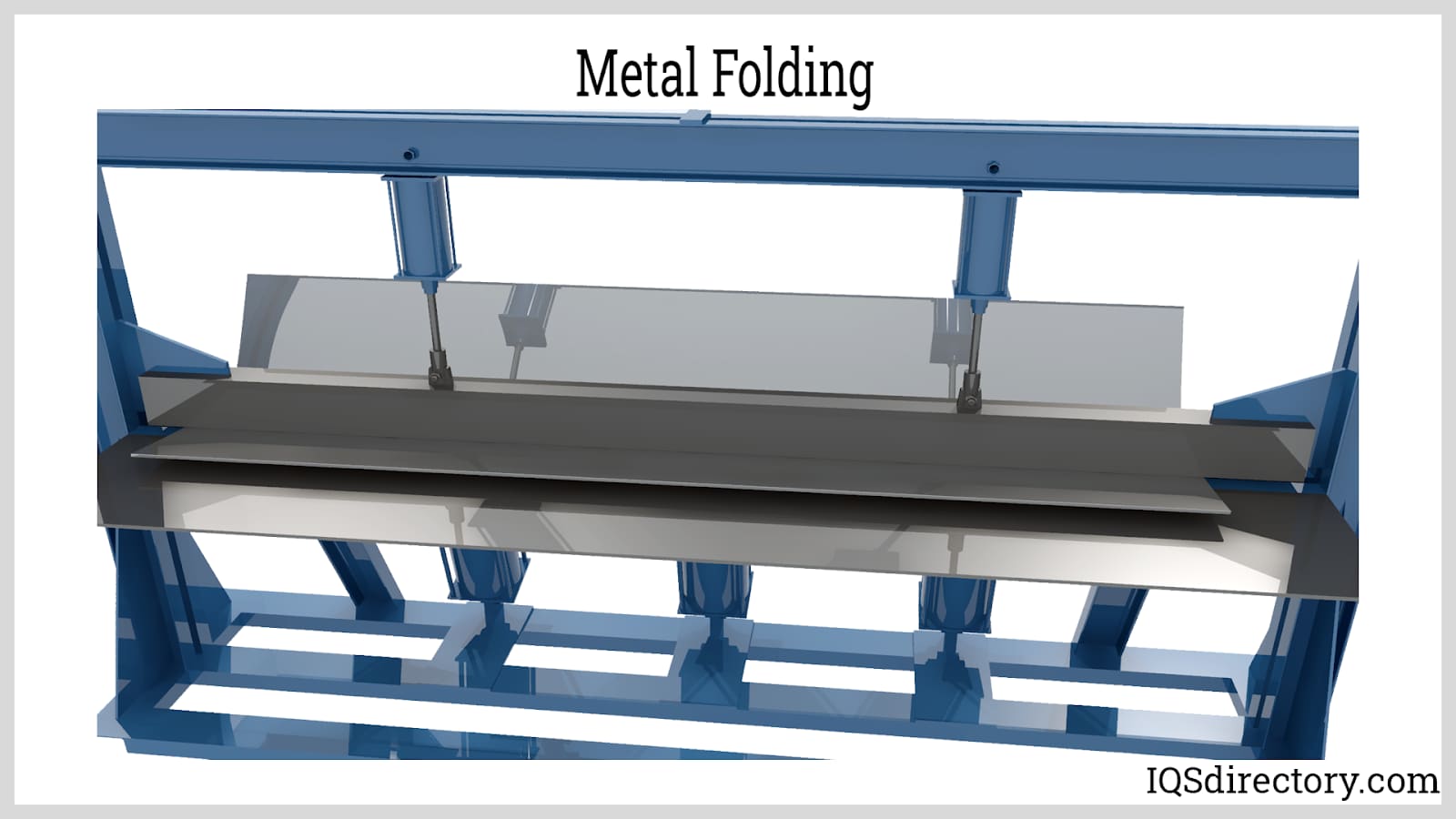

Folding shapes the metal to achieve the specific form needed for manufacturing.

Folding shapes the metal to achieve the specific form needed for manufacturing.

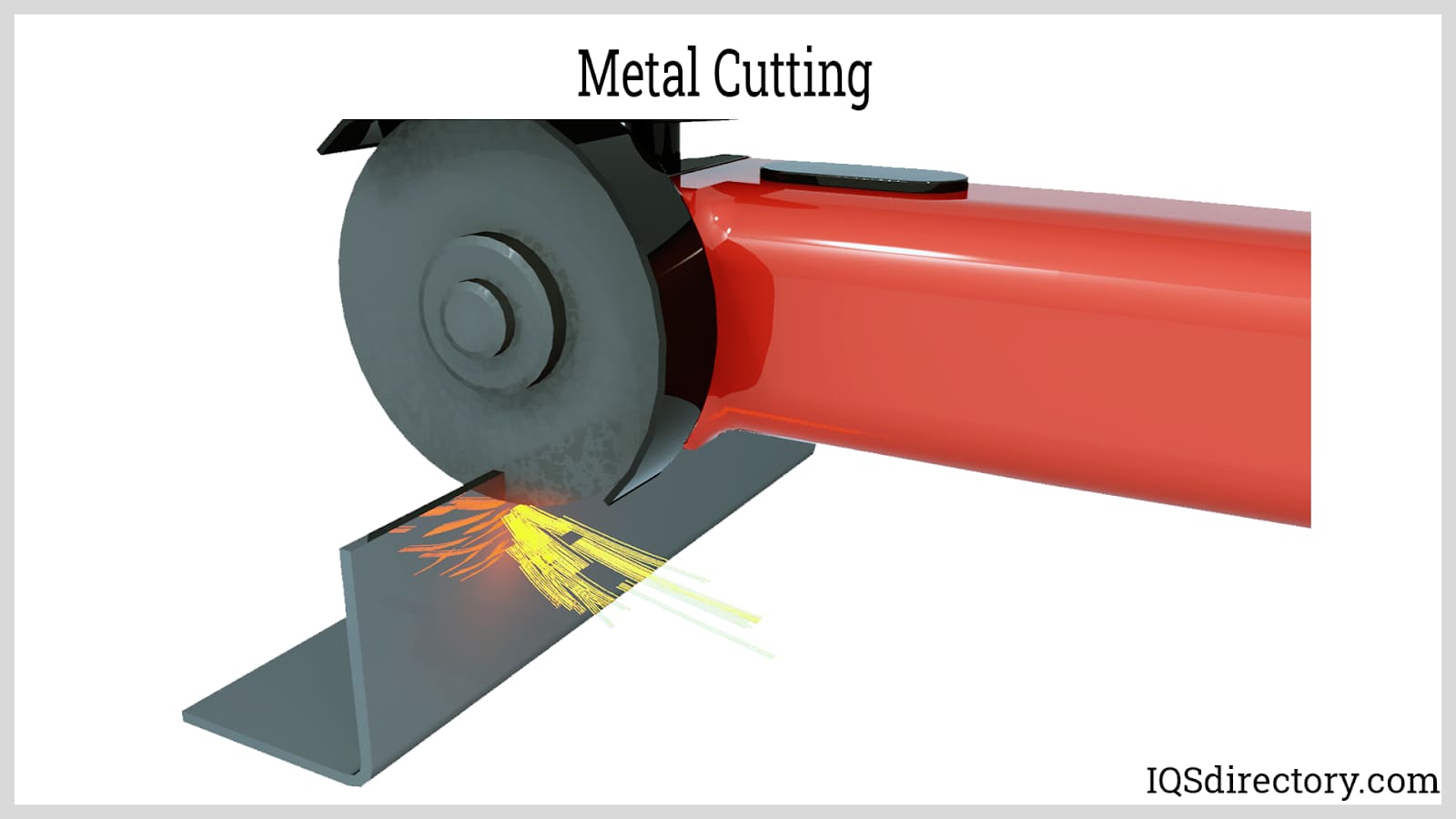

Cutting divides a workpiece into smaller sections, a common step in metal part production.

Cutting divides a workpiece into smaller sections, a common step in metal part production.

Metal smoothing completes the part by refining surfaces and edges, often using powder coating for a quality finish.

Metal smoothing completes the part by refining surfaces and edges, often using powder coating for a quality finish.

Final assembly of the product may involve welding or making electrical connections as needed.

Final assembly of the product may involve welding or making electrical connections as needed.

- Aluminum Fabricators

- Produce components for industrial machinery and various other products.

- Custom Metal Fabrication

- Services offering metal part assembly, stamping, welding, or any type of fabrication customized to customer requirements.

- Fabricated Metal Products

- Fully assembled metal products that have undergone processes such as stamping, punching, welding, or other fabrication methods.

- Heavy Fabrication

- Operations involving the production of very large or complex fabricated metal products.

- Laser Fabrication

- Uses an intense, focused light beam. Depending on its power and beam size, the laser can cut, mark, or weld metals with precision.

- Metal Bending

- A forming method where metal is plastically deformed to achieve a new shape by applying force.

- Metal Fabricating

- Refers to making or altering a metal product. Examples include welding, bending, and laser cutting among other processes.

- Metal Forming

- Includes a range of manufacturing processes applied to metal parts to create fabricated components.

- Metal Welding

- The process of joining two metals by melting them together until they fuse as one.

- Metalworking Process

- Any fabrication activity involving assembling, stamping, punching, or otherwise working with metal.

- Robotic Welding

- Welding operations performed by automated robotic equipment.

- Sheet Metal Fabricators

- Specialize in creating custom-shaped or molded products from sheet metal, such as auto body panels, aerospace parts, and more.

- Stainless Steel Fabrication

- The process of manufacturing custom parts from various stainless steel grades, which are valued for corrosion resistance, strength, and aesthetics.

- Steel Fabricators

- Produce or modify steel products, including services such as steel bending, welding, and cutting.

- Structural Steel Fabricators

- Manufacture steel parts and assemblies for construction industry applications.

Nearly any type of metal or metal alloy can be fabricated by manufacturers. The most common materials include aluminum, carbon steel, mild steel, stainless steel, brass, bronze, copper, and titanium.

- Aluminum Metal

- A naturally occurring, recyclable metal found in minerals. Aluminum is lightweight, ductile, durable, and resists corrosion and oxidation. Aluminum and its alloys are widely used in aerospace. Source them from manufacturers on IQS Directory.

- Carbon Steel

- Can refer to non-stainless steel in general, or specifically to steel with no more than 2.1% carbon and specific proportions of copper, manganese, and silicon. Higher carbon content lowers ductility.

- Mild Steel

- Also called low-carbon or plain-carbon steel, this affordable material offers low tensile strength but is ductile and malleable, making it suitable for many uses. It contains about .05% to .25% carbon and is widely used in fabrication today.

- Stainless Steel

- Highly durable, strong, hypoallergenic, and resistant to corrosion, oxidation, and acids. Stainless steel contains at least 10.5% chromium. Stainless steel fabricators often serve medical and food processing markets.

- Structural Steel

- A specialized steel used in construction for buildings, bridges, and other structures. Regional standards for safety and quality often require custom fabrication.

- Note: There are many steel types. For structural steel or other special projects, your manufacturer can coordinate with primary steel or sheet metal fabricators for custom fabrication.

- Brass Alloy

- Primarily composed of copper and zinc, brass is easily cast due to its low melting point and malleability. It is used decoratively for its color and also for its antimicrobial qualities. Brass metal formers can adjust composition for different properties such as strength or corrosion resistance.

- Bronze Metal

- A copper alloy mainly with tin, bronze is resistant to fatigue and corrosion (especially seawater), has good electrical and heat conductivity, and is ductile and durable.

- Copper Metal

- A naturally occurring element often found in usable metallic form. Copper is the base for brass and bronze and is known for its electrical and thermal conductivity, ductility, malleability, and softness.

- Titanium Metal

- A strong yet lightweight transition metal. Titanium resists corrosion from chlorine, seawater, and aqua regia, and conducts heat and electricity well.

Metal fabrication is essential across all industries, commercial sectors, and consumer markets. Industries that rely on metal fabrication include construction, architecture, furniture, HVAC, office supplies, home appliances, manufacturing, electronics, aerospace, automotive, transportation, and recreation.

Both simple hand tools and complex electronics rely on fabricated metal components. In office buildings, examples include metal furniture, shelving, HVAC ductwork, grates, and desk accessories. Industrial uses involve stamped metal storage racks, bent hoods for lighting, and welded railings. Household items such as kitchen utensils, scissors, animal cages, bed frames, and appliances are often fabricated from metal.

Heavy fabrication processes and robotic welding are used for assembling building structures and airplane frames. Metal fabricators also build bridge skeletons and perform precision engraving on electronic components with laser fabrication. Custom metal fabrication meets specialized requirements for unique or irregular parts.

Manufacturers use a mix of traditional and advanced equipment to deliver precise metal fabrication. Typical machinery includes CNC machines, roll formers, laser cutters, hydraulic press brakes, and welding equipment.

Metal fabrication machines can be customized for specific jobs. For instance, cutting patterns can be modified by reprogramming laser cutters, often integrated with CNC systems. Machine settings like speed, pressure, and force angles can also be manually adjusted to achieve desired results.

If you’re unsure whether metal fabrication is the right solution, consider questions such as your product’s function, desired appearance, necessary properties, and budget. Metal fabrication differs from plastic fabrication in several ways. For example, while metal parts can be finished for chemical resistance, plastic naturally resists chemicals. If chemical resistance is your priority, plastic fabrication may be better. For wear resistance and durability, metal fabrication is usually preferred. Carefully evaluate your needs before deciding.

Once you decide to use metal fabrication, the next step is finding a custom metal fabricator. We recommend reviewing our list of top providers at the top of this page. Visit their websites to learn about their services, certifications, and lead times. Select several companies of interest and contact them with your requirements. Evaluate not only their technical capabilities but also their customer service—do they communicate well, work within your budget, and ensure product quality? Choose the company that best meets your fabrication and service needs.

Below are several common variations and related processes in metal fabrication.

- Cutting Process

- Cutting removes excess material from a workpiece to achieve the specified shape and size.

- Forming Process

- Forming involves pressing or bending metal at specified angles using equipment such as hydraulic brakes. Methods include roll forming and press braking.

- Roll Forming

- A high-volume, continuous bending process. Roll formers can shape various metals into products like channels and trim, essential for sheet metal and panel production.

- Press Braking

- Press braking bends metal in lower volumes than roll forming. The process uses a flat surface with a specially shaped indentation and a matching pressing tool. The metal sheet is placed between them, and the press forms the bend by forcing the metal into the indentation.

- Welding Process

- Welding is a key fabrication method used to join metal parts in many industries, including construction, manufacturing, and maintenance. Specialized welding techniques exist for diverse applications, including underwater and space environments.

- Common welding variations include TIG welding, arc welding, solid-state welding, resistance welding, and oxy-fuel welding.

- Alloy Steel

- Steel that contains one or more alloying elements—other than carbon and the usual amounts of manganese, silicon, sulfur, and phosphorus—to achieve specific properties. Common alloys include chromium, nickel, and molybdenum.

- Aluminum

- A nonferrous metal frequently used to create lightweight, strong, and corrosion-resistant alloys. Aluminum is primarily found in bauxite ore.

- Annealing

- A heat treatment process where a cold-rolled substrate is heated and cooled to increase softness and improve formability.

- Bending

- The process of reshaping sheet metal by passing it through pairs of forming rollers. Bending slightly thins the metal at the bend radius.

- Brazing

- A high-temperature joining method that bonds two metals with a filler that melts just below the metals' melting points.

- Chemical Treatment

- Chemicals applied to metals to prevent corrosion and protect surfaces.

- Computer Numeric Control CNC Machining

- An automated manufacturing process that precisely shapes or forms metal parts using specialized software and CAD/CAM systems to control tooling movements.

- Cold-Rolled Product

- A metal sheet that achieves its final thickness by being rolled at room temperature.

- Conversion Coating

- A chemical film applied to metal surfaces before painting to improve adhesion and corrosion resistance.

- Corrosion

- The gradual degradation of metal due to chemical reactions or oxidation. Rust is a common example of corrosion.

- Cutting

- A process where metal is separated or opened using a sharp edge. Metal sheets are typically cut from larger stock before fabrication.

- Die Cutting

- Applies a powerful die to a metal blank, often using a mechanical or hydraulic press, to cut or shape the material.

- Ductility

- The ability of metal to undergo deformation without breaking. Ductility is largely determined by a metal’s hardness and tensile strength.

- Forming

- A general term for processes that shape or mold metal into specific configurations.

- Hot Rolled Sheet

- A metal sheet processed to its final thickness by rolling at elevated temperatures using a hot-rolling mill.

- Leveling

- Flattening a rolled metal sheet to eliminate distortion and achieve uniform thickness.

- Powder Coating

- Applying a solid powder to a metal surface and heating it above the melting point to form a smooth, uniform film.

- Roll Forming

- A continuous process that shapes sheet metal by passing it through multiple sets of rolls.

- Stainless Steel

- A group of corrosion-resistant steels containing at least 10% chromium, often alloyed with elements like nickel, molybdenum, titanium, and niobium for enhanced properties.

- Tensile Strength

- Also called "ultimate strength," this is the maximum stress a material can withstand before breaking.