Metal Spinning

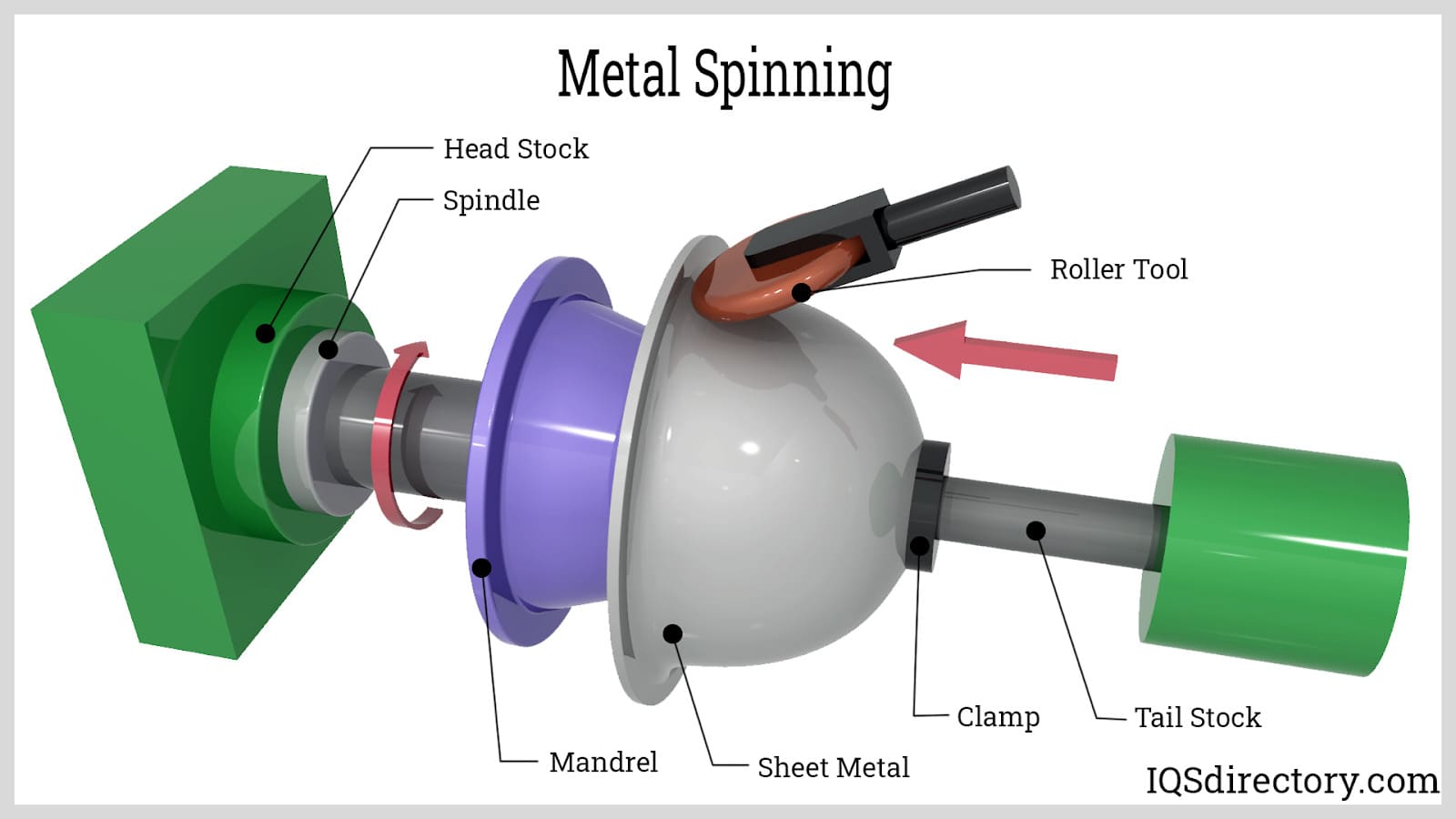

Metal spinning, also known as spin forming, is a cold metalworking technique where a flat metal disc, mounted on a lathe mandrel, rotates at high speed and is shaped by various forming tools.

Sheet metal spinning produces high-quality components used across multiple industries, such as aerospace, food processing, healthcare, defense, pharmaceuticals, paper manufacturing, music, architecture, interior design, and home appliances.

Quick Links to Metal Spinning Information

The History of Metal Spinning

- The Beginning of Metal Spinning

- Metal spinning is an ancient metal forming process, with evidence suggesting that early Egyptians were among the first practitioners. Artwork in the tomb of Petosiris, a 4th-century high priest at Tuna el-Gebel, shows two individuals operating a lathe. Additional Egyptian texts from before Petosiris’ era reference hand bows for spinning metal, wood, and stone. Similarly, historical records and archaeological finds from ancient India and China indicate that metal spinning was known in those cultures as well. These discoveries demonstrate that metal spinning was practiced by various civilizations worldwide, each using their own set of tools.

- Later, Viking craftspeople developed intermittent pedal-powered lathes, resetting the treadle with pole tools. These designs were basic and easy to construct, though somewhat limited in use.

- In the Middle Ages, Western metalworkers improved upon bow-driven lathes by inventing a continuous pedal-powered lathe, replacing the bow with a pedal and flywheel. This innovation allowed for continuous rotation and better control during spinning, resulting in products with more precise dimensions and complex shapes. Lathes also became smaller during this period, making them more manageable for metalworkers.

- The introduction of iron lathes marked a significant advancement in metal spinning. Previous lathes were made of copper or wood, but iron lathes enabled the formation of thicker, denser, and more accurately dimensioned metal components. This increase in precision allowed for the manufacture of intricate items like watch and clock parts.

- Metal Spinning in the 1800s and Beyond

- During the Industrial Revolution, manufacturers introduced steam-powered and later electric motor-driven lathes. These machines enabled higher production rates, primarily using soft, nonferrous metals. Products made included cups, pewterware, appliances, machine components, and building parts. Around 1920, spinning of harder metals such as steel began to be explored.

- Motorized lathes brought about mass production in metal spinning. However, manual oversight and involvement were still required until the development of CNC technology. CNC-controlled lathes now operate autonomously based on digital programming, producing more precise, complex, and rapidly manufactured products. This automation also increases worker safety by reducing close contact with machinery. With ongoing technological improvements, metal spinning has become an essential process for many industries, supporting everything from large-scale manufacturing to detailed custom applications.

Metal spinning provides several key benefits. The finished parts are free of wrinkles and warping. The process is efficient, typically forming a metal piece in just five to ten minutes. Metal spinning generates minimal scrap, reducing material waste. It is often more affordable than other metal forming methods, particularly for small production runs. Additionally, the spinning process can work-harden the metal, resulting in stronger finished components.

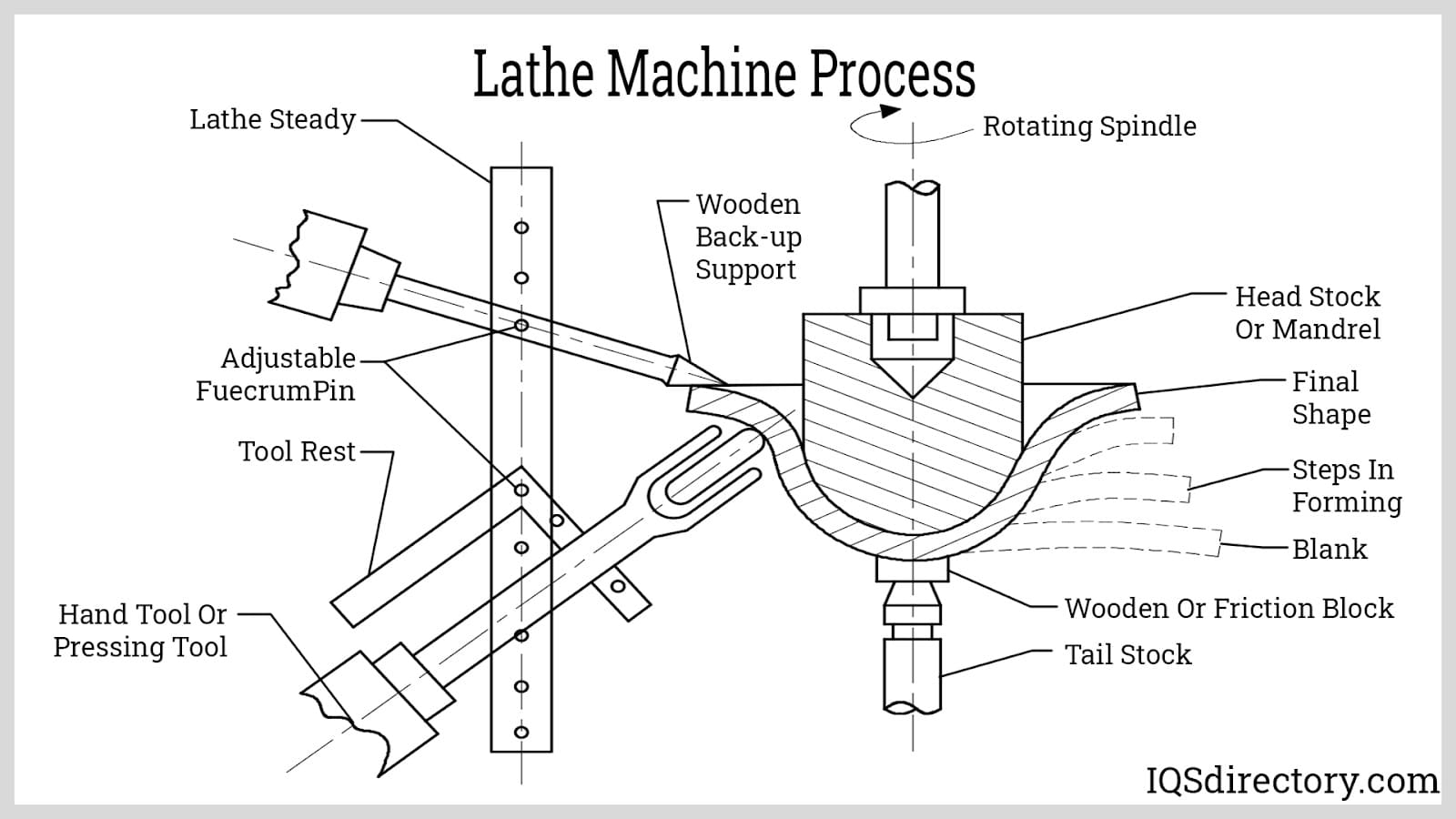

The metal spinning process is simple and consists of the following steps:

The metal spinner uses a tool or multiple tools, known as spoons, to apply pressure to a rotating metal disc, or blank, shaping it over a mandrel. Sometimes, manufacturers pre-form the metal using deep drawing before spinning. Rollers attached to levers are also commonly used to smooth and shape the material prior to reaching the mandrel. Generally, a larger roller diameter results in a smoother surface on the finished product.

Metal spinning is suitable for a variety of ductile metals and alloys, such as aluminum, titanium, stainless steel, and copper.

- Aluminum Metal

- Known for being cost-effective and highly malleable, aluminum is selected for its ease of forming, strong corrosion resistance, and low weight. It is a preferred choice for aerospace, construction, and transportation applications.

- Titanium Metal

- Titanium is exceptionally strong and durable, featuring excellent corrosion and heat resistance, low density, and a high strength-to-weight ratio. These qualities make it especially valuable in the aerospace industry.

- Stainless Steel

- Stainless steel is widely used in metal spinning for its outstanding strength-to-weight ratio, ease of fabrication, and competitive cost. Its durability, attractive finish, heat resistance, and corrosion resistance make it ideal for products like cutlery, automotive parts, and more.

- Copper Metal

- Copper is a non-magnetic metal valued for its appearance, corrosion resistance, ductility, and workability. It is recyclable, antimicrobial, and both electrically and thermally conductive. Common spun copper items include pipes, sinks, architectural elements, jewelry, and medical devices.

Metal spinning is a metalworking operation that transforms a flat, circular blank into symmetric, round shapes.

Metal spinning is a metalworking operation that transforms a flat, circular blank into symmetric, round shapes.

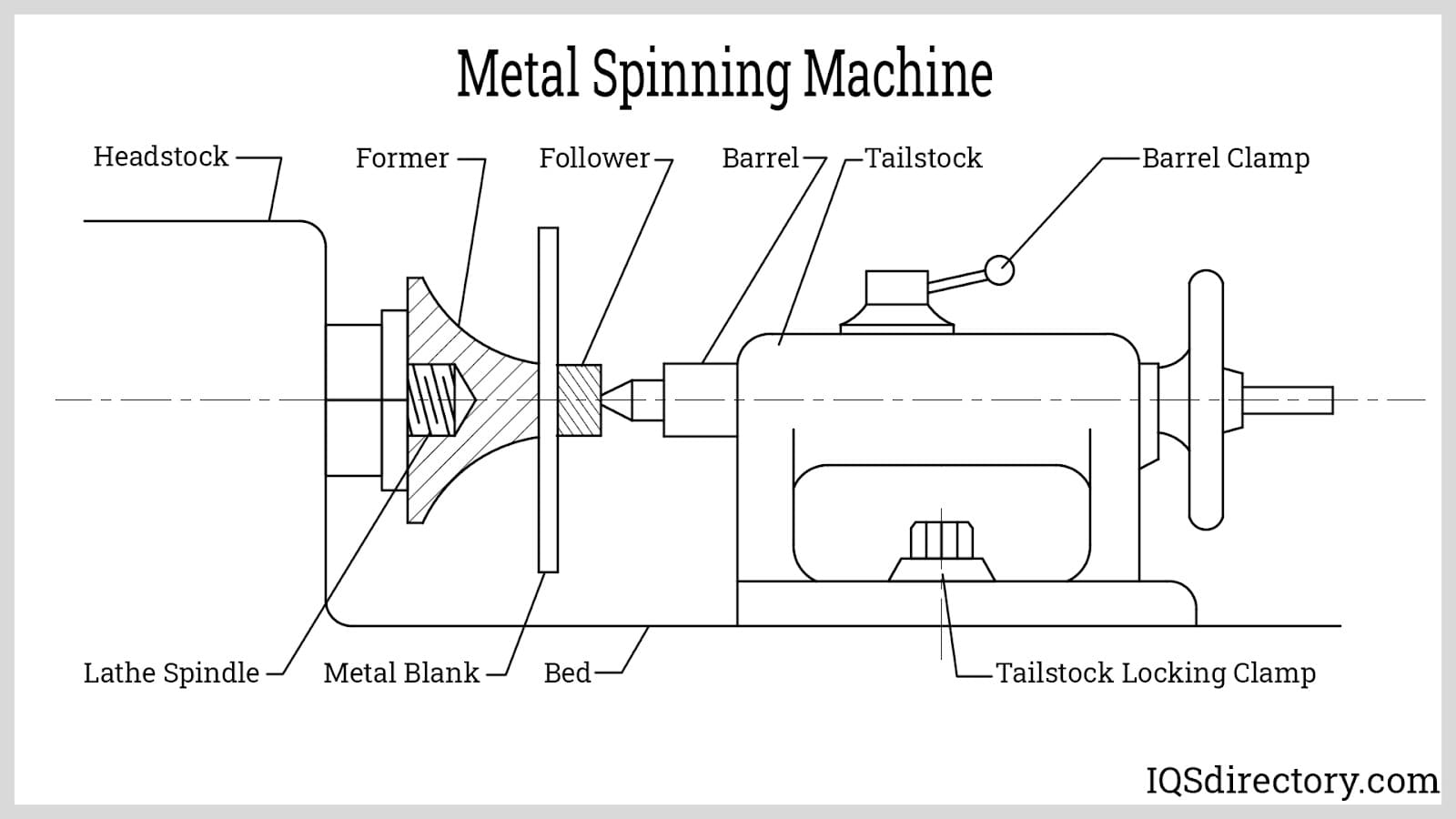

Metal spinning machines rotate the workpiece quickly on an axis and can also be used for cutting, drilling, and sanding operations.

Metal spinning machines rotate the workpiece quickly on an axis and can also be used for cutting, drilling, and sanding operations.

Lathe beds support the headstock, tailstock, and other components of the machine.

Lathe beds support the headstock, tailstock, and other components of the machine.

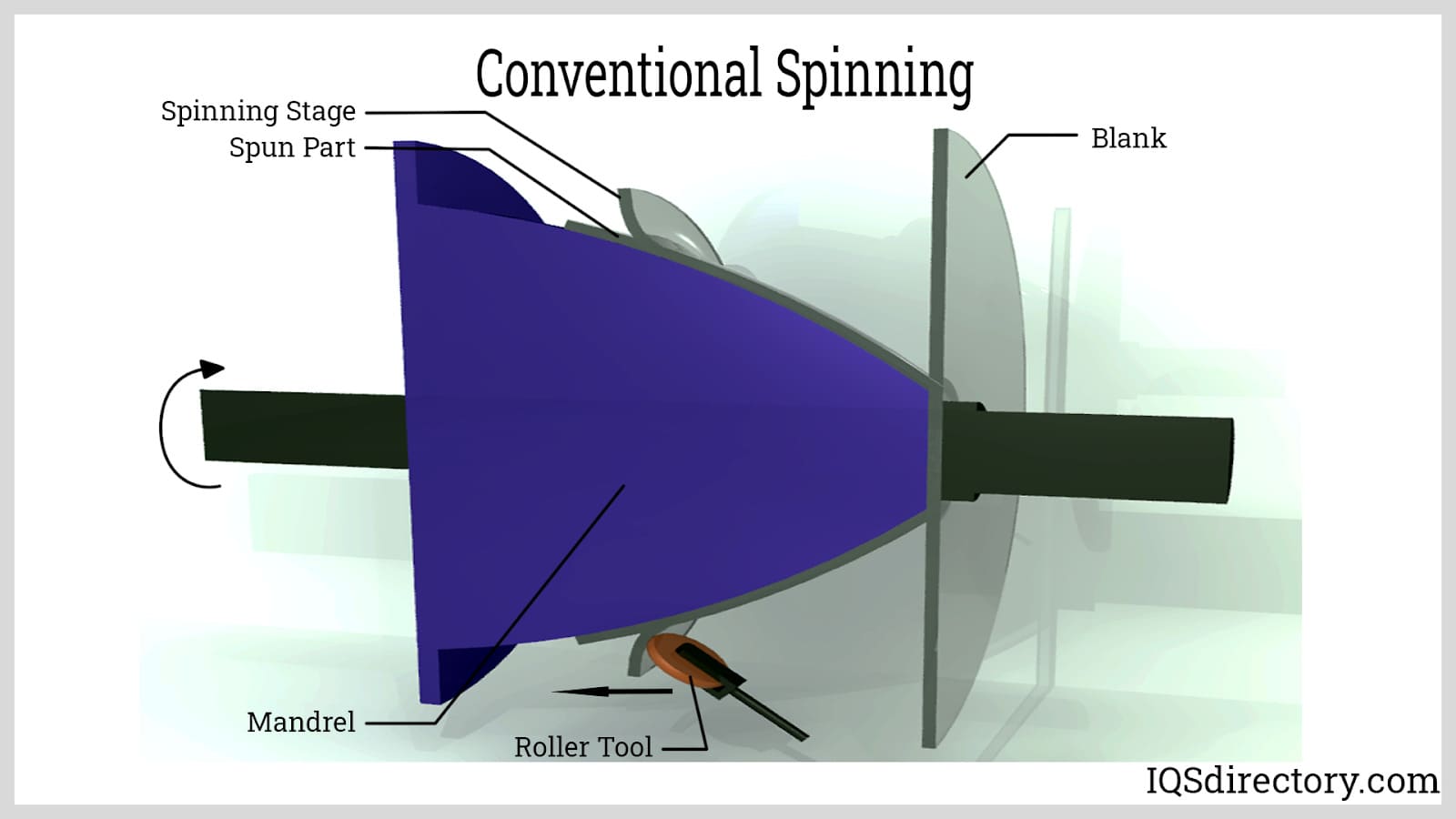

In conventional spinning, the roller shapes the workpiece by pressing it over the mandrel's contour.

In conventional spinning, the roller shapes the workpiece by pressing it over the mandrel's contour.

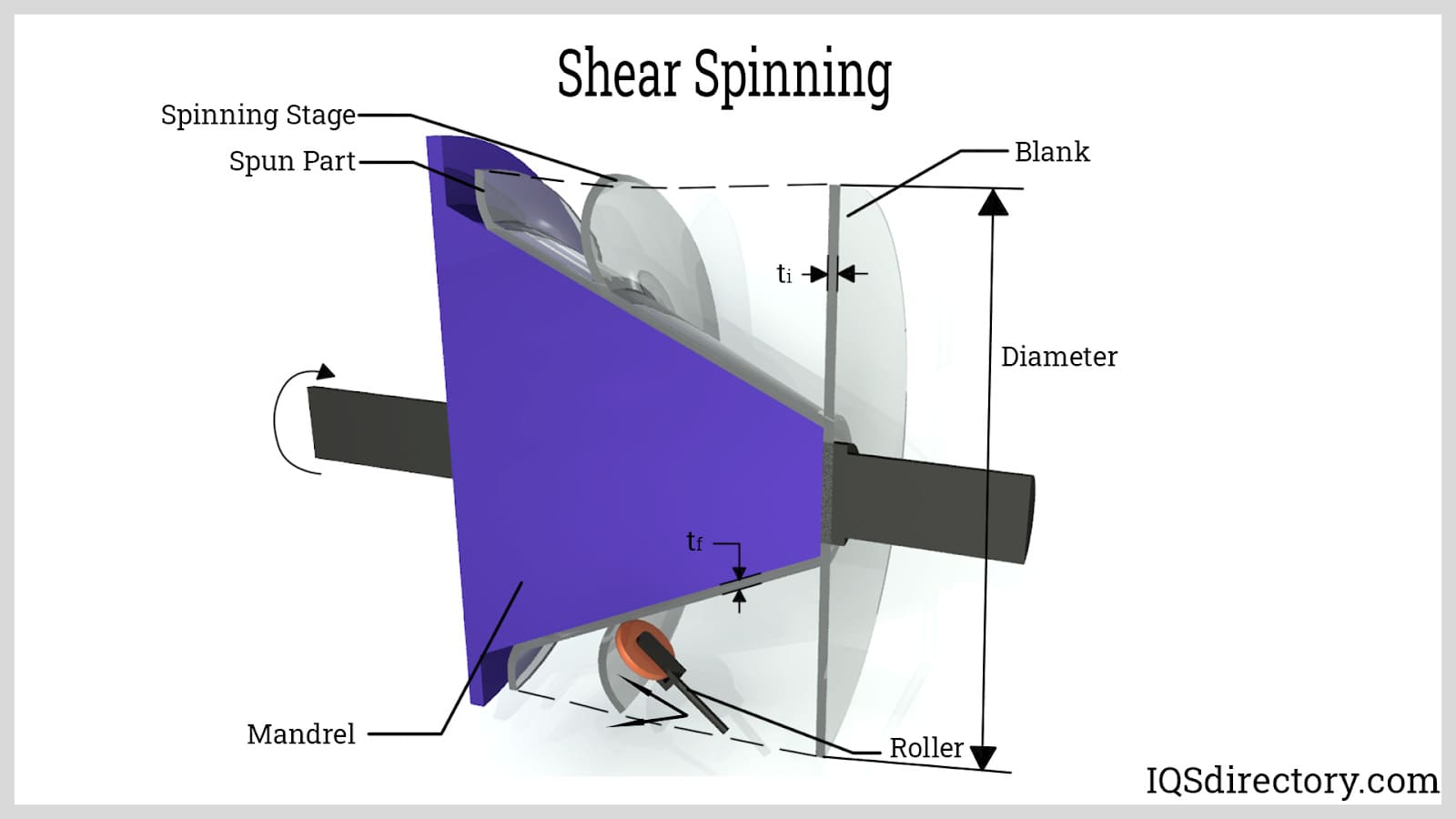

Shear spinning uses rollers to apply downward force as the workpiece moves along the mandrel's profile.

Shear spinning uses rollers to apply downward force as the workpiece moves along the mandrel's profile.

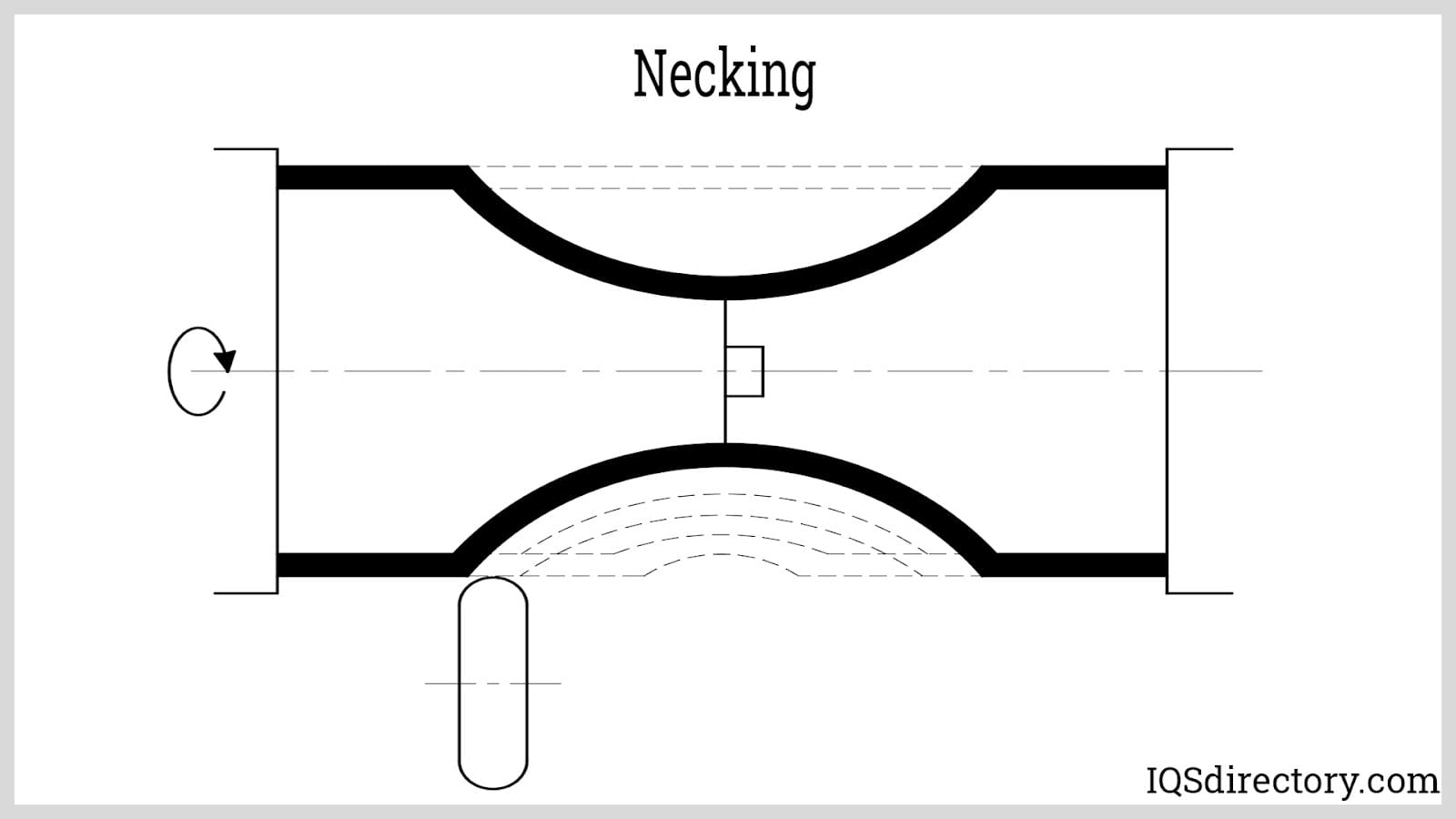

Necking is the gradual reduction of diameter in a specific section of the part.

Necking is the gradual reduction of diameter in a specific section of the part.

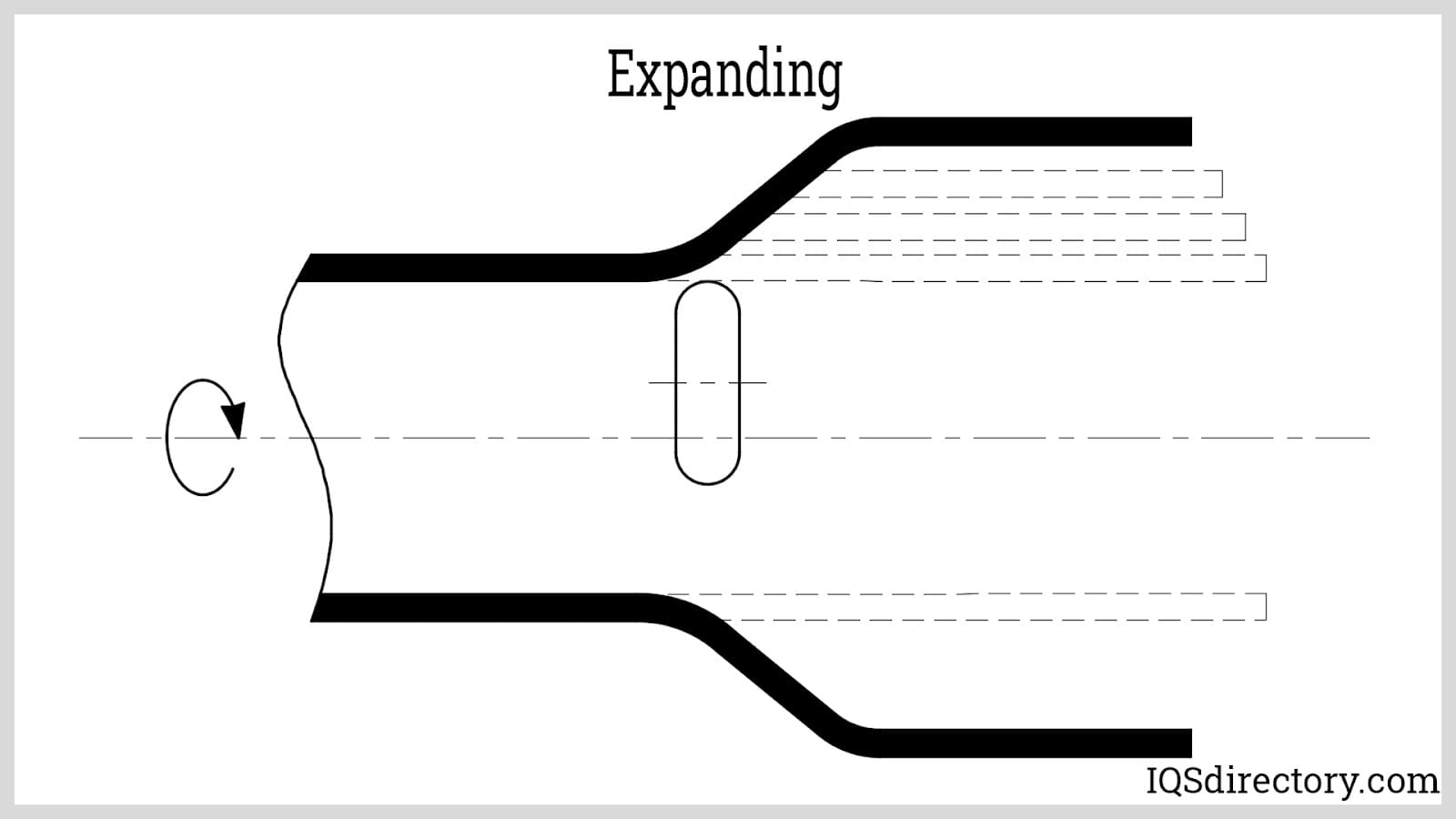

Expanding increases the diameter in a designated area of the part.

Expanding increases the diameter in a designated area of the part.

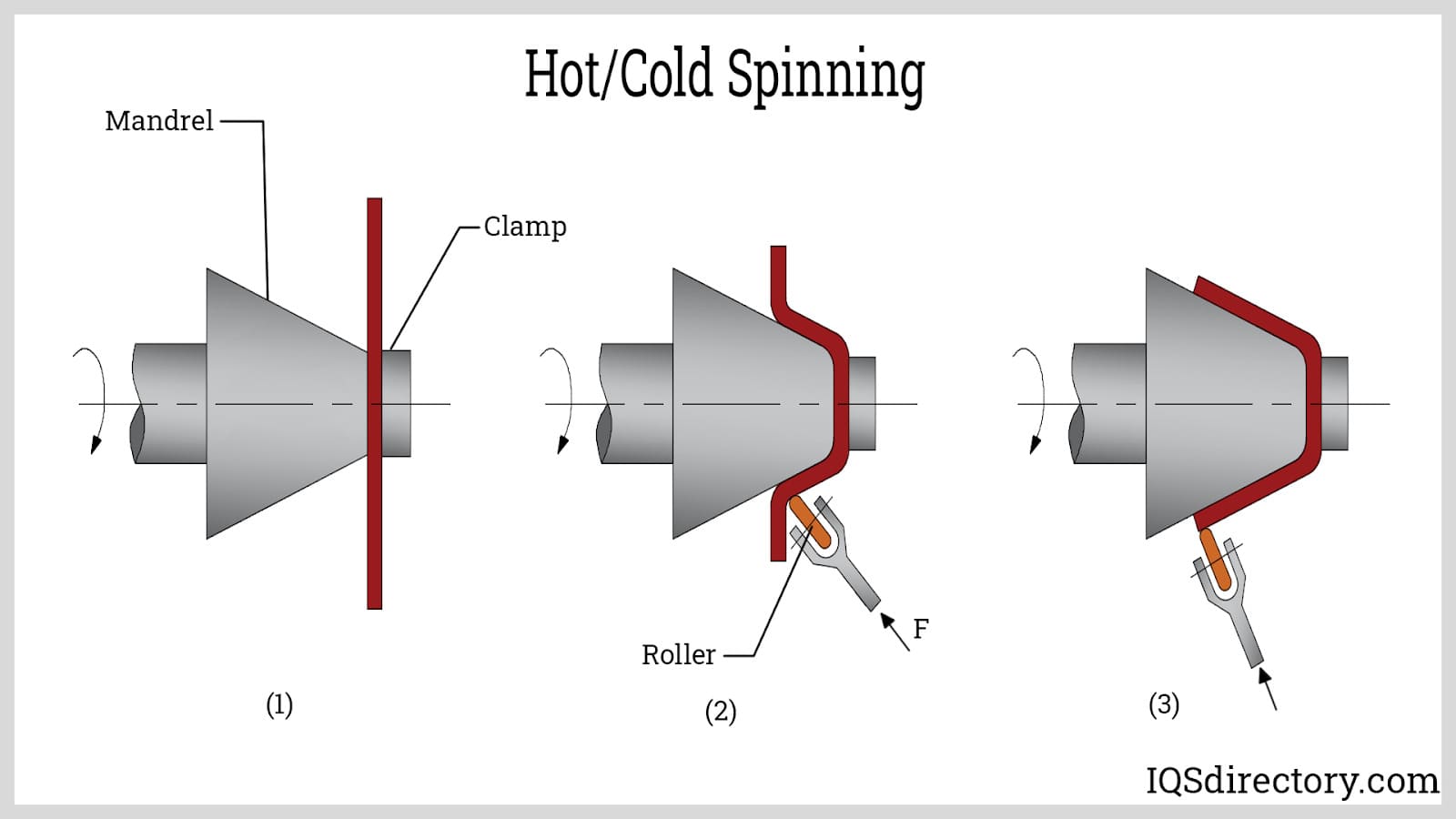

Hot spinning heats the workpiece to forging temperatures, while cold spinning is performed at room temperature.

Hot spinning heats the workpiece to forging temperatures, while cold spinning is performed at room temperature.

Metal spinning is ideal for low or medium production volumes, especially when the cost of metal stamping dies is too high.

Metal spinning is ideal for low or medium production volumes, especially when the cost of metal stamping dies is too high.

Any metal that can be formed by metal stamping can also be processed using metal spinning.

Any metal that can be formed by metal stamping can also be processed using metal spinning.

Although metal spinning can be performed by hand, most modern metal spun products are made using CNC metal spinning machines—computer numerically controlled equipment.

Some manufacturers still use hand metal spinners, but these are increasingly uncommon. While the machine controls the spinning, the pressure is applied manually, making the process labor-intensive and potentially resulting in less consistent parts.

CNC metal spinners (computer numerically controlled spinning) and associated equipment are now the primary tools for metal spinning. Modern CNC technology allows for rapid, high-volume production of precision, concentric metal parts with tight tolerances. CNC spin machines are also employed in fabricating other sheet metal parts.

Most metal spinning shops use custom metal spinners. This approach offers lower costs due to fast setup times and flexible tooling, making custom metal spinning more cost-effective than many other metal fabrication methods.

Precision metal spinning enables the creation of products such as engine components, gas cylinders, nozzles, tank heads, rocket nose cones, brass instrument bells, decorative items, specialty lighting, public waste bins, funnels, freezer parts, mixing bowls, cookware, filter housings, pressure vessels, and cartridges.

Metal spinning has various adaptations and related processes, including hot spinning, reducing, flow forming (with tube forming, forward flow forming, reverse flow forming, and shear spinning), and hydroforming (with tube hydroforming, panel hydroforming, low pressure hydroforming, and high pressure hydroforming).

- Hot Spinning

- This variation uses heat to make the workpiece more pliable, allowing for the creation of smaller diameters with seamless shoulders. The application of heat reduces the force required for shaping the metal.

- Reducing Method

- This method allows metal spinners to form parts with inward angles and smaller diameters. For parts where precise angles or surface finishes are less important, spinning is done without a mandrel—called "spinning on air." For critical forms and finishes, the workpiece is spun on an eccentrically mounted mandrel.

- Flow Forming

- Flow forming is an advanced alternative to spin forming, used for designs that require variable wall thickness and higher complexity. It creates seamless, flexible components with greater tensile strength.

- In flow forming, rollers extrude a pre-formed metal blank or perform over a mandrel, producing hollow, symmetrical shapes. Wall thickness is controlled by the gap between the mandrel and rollers, which can be adjusted for variable or uniform thickness.

- The resulting parts are round in cross-section and can be straight-sided cones or contoured shapes. The blank may be welded or made from sheet metal. Materials like stainless steel are ideal due to their ductility and strength, making them suited for cold extrusion.

- Tube Forming

- A type of flow forming that produces cylindrical shapes by cold working tubular preforms using rollers and a mandrel.

- Forward Flow Forming

- This tube forming process is used to create shapes with one closed end, such as vessels. The material moves in the same direction as the rollers, with the preform's bottom resting against the mandrel face.

- Reverse Flow Forming

- This flow forming method produces parts with two open ends, like tubes. Rollers apply force against a serrated mandrel ring, compressing and extruding the material.

- Shear Spinning

- Shear spinning, a main type of flow forming, creates cone-shaped or contoured metal parts by using rollers to shear a flat blank over a rotating mandrel. The blank's diameter remains the same, but the wall thickness is reduced based on the mandrel angle. No material is lost during this process.

- Hydroforming as an Alternative

- Hydroforming is used when traditional spinning or flow forming are not suitable. It uses high-pressure hydraulics to force metal around a punch, resulting in parts with uniform thickness. Hydroforming includes tube hydroforming, panel hydroforming, low pressure hydroforming, and high pressure hydroforming.

- Tube Hydroforming

- The most common hydroforming process, typically performed at low pressure, creates tubular parts with excellent structural integrity.

- Panel Hydroforming

- This high-pressure process is used to manufacture parts for the automotive and aerospace sectors.

- Low Pressure Hydroforming

- Used for reshaping tubes where strict cross-sectional definition is not required.

- High Pressure Hydroforming

- This method achieves greater reshaping of tubing, allowing the length-to-circumference ratio to change by up to 50 percent.

- Application Specifications

- When selecting a metal spinning manufacturer, review your project requirements, including budget, standards, order quantity, delivery needs, and timeline. Preparing these details in advance will help you communicate effectively with potential suppliers.

- Supplier Output Capability

- Evaluate the supplier’s production capabilities. Some metal spinning companies may not accommodate small batches or could have limits on product diameter and thickness. Many suppliers offer a wide size range—from fractions of an inch up to over six feet in diameter. Some shops may specialize in certain metals, like stainless steel or aluminum. Metal spinning often means lower tooling costs due to simpler die designs, and many shops can fabricate tooling in-house for faster turnaround. Be sure to ask about these factors when discussing your needs with manufacturers.

- To help you choose the best partner, we provide a curated list of leading metal spinning companies. Browse their profiles near the top of this page. Remember, the ideal manufacturer is one that offers the right services and expertise for your specific application, not just the lowest price.

- Alloy

- A substance with metallic properties composed of two or more chemical elements, with at least one being a metal.

- Buckling

- A deformation that occurs perpendicular to the surface of a sheet due to compressive stress.

- CNC

- Computer Numeric Controlled.

- Camber

- The tendency of sheet metal to shear due to bending along the same plane.

- Cold Working

- The process of reshaping metal, typically at room temperature (but not always), also known as cold forming or cold forging. Contrast with hot working.

- Concentric

- Sharing the same center or axis, such as concentric circles or cylinders.

- Deep Drawing

- A process for forming deeply recessed parts from sheet metal by plastic deformation, where the depth is equal to or greater than the part’s minimum width.

- Die

- A tool, often with a cavity, that shapes solid, molten, or powdered metal primarily by its own form.

- Draw Plate

- A circular plate with a central hole, contoured for a forming punch, used to support the blank during forming.

- Elongation

- The extent to which a material stretches permanently before breaking.

- Hemming

- Bending a part 180°, usually in two steps after spinning: first making a sharp angle, then flattening it with a punch and die.

- Hold Down

- A device used to secure the workpiece during processing.

- Lathe

- A machine tool for shaping metal or wood, turning the workpiece about a horizontal axis against a fixed tool.

- Mandrel

- A tapered steel support used during forming, also called a chuck.

- Necking

- Reducing the cross-sectional area of metal in a specific area by stretching or tension.

- Orange Peel

- A surface texture on steel resembling an orange peel, either from the mill or after forming.

- Overbending

- Bending metal beyond the desired final angle to compensate for springback.

- Reset

- Adjusting or realigning dies or tools during production, not to be confused with the initial setup before a run.

- Stamp

- A general term for most press working operations.

- Support Plate

- Typically used as a spacer within the spinning machine.

- Tooling

- The form or shape used to mold sheet metal into the desired configuration.