Mezzanines

Mezzanines are elevated structures designed to maximize space efficiency within a facility. Constructed from a variety of materials, these raised platforms offer a practical solution for businesses facing space limitations, allowing them to expand usable areas without the need for extensive building construction or structural expansion. Often open and un-walled, mezzanines provide additional storage, workspace, or operational areas while maintaining the flexibility to adapt to changing business needs.

Note: An industrial mezzanine should not be confused with a mezzanine card, which is a type of printed circuit board assembly used in electronic systems.

Mezzanines FAQ

What is a mezzanine and how is it used in industrial facilities?

A mezzanine is an elevated platform built within a building to increase usable space without major construction. In industrial facilities, mezzanines are used for storage, offices, or production areas, helping businesses maximize vertical space efficiently.

What materials are commonly used to construct mezzanines?

Mezzanines are typically constructed from steel, aluminum, fiberglass, or wood composites. Steel is preferred for heavy loads, while aluminum and fiberglass are used for lighter or corrosive environments. Particle board is often used for economical decking in dry settings.

What are the advantages of installing a mezzanine in a warehouse?

Installing a mezzanine doubles usable space without requiring new construction. It offers flexibility for storage, offices, or operations, and modular systems can be reconfigured or relocated, making them ideal for warehouses and manufacturing facilities with limited floor space.

What safety features are required for mezzanine structures?

All mezzanines must include guardrails, treaded stairs, and reflective markings to prevent falls and slips. OSHA, IBC, and ADA standards govern safety, accessibility, and design to ensure mezzanines remain stable and compliant in industrial and commercial environments.

How does a prefabricated mezzanine differ from a custom-built one?

Prefabricated mezzanines are modular, cost-effective, and quick to install but offer limited customization. Custom mezzanines are tailored to fit specific layouts and load requirements, ideal for facilities with tight space or specialized operational needs.

What factors determine the load capacity of a mezzanine?

Load capacity depends on materials, column size, and deck design. Engineers calculate both live and dead loads to ensure structural integrity. Typical mezzanines support 50–250 pounds per square foot, depending on use and building conditions.

Are used mezzanines a good option for expanding workspace?

Used mezzanines offer cost savings and quick installation for businesses expanding storage or office areas. However, they may show wear or require modifications for fit and safety, making inspection and proper refurbishment essential before reuse.

Applications of Mezzanines

Mezzanines serve a wide range of functions, from storage solutions to operational and structural enhancements. They can be used to store unused materials, provide elevated work platforms for equipment, create designated walking space for facility guests, or accommodate seating in auditoriums. Additionally, mezzanines offer adaptable floor space that can serve as either a ceiling or a floor for office areas.

For instance, a small in-plant office can be built beneath a mezzanine, where the mezzanine floor simultaneously acts as the office ceiling and a storage platform. Conversely, an office can be constructed at mezzanine level, freeing up the space below for storage, workspace, or other operational needs. This versatility makes mezzanines an ideal solution for maximizing efficiency in facilities with limited space.

Mezzanines are widely utilized by manufacturers, suppliers, distributors, and service companies across various industries. Common sectors benefiting from mezzanine installations include food service, storage, manufacturing, agriculture, aerospace, retail, education, transportation, healthcare, and outdoor recreation.

History of Mezzanines

The word mezzanine comes from French, which in turn derives from the Italian mezzanino, a diminutive of mezzano, meaning middle. This etymology reflects the mezzanine’s function as an intermediate level within a structure.

Mezzanine platforms have been used in various forms for centuries. Before the Industrial Revolution, they were most commonly found in theaters, providing additional seating or viewing areas. By the mid-1800s, as department stores emerged, mezzanines became a popular way to create additional retail space, maximizing floor usage without requiring full-scale expansion.

Following the Industrial Revolution, mezzanines became an essential component of manufacturing and warehousing. Structures such as warehouse mezzanines and storage mezzanines were introduced to support industrial operations, allowing for more efficient use of vertical space.

Today, mezzanines continue to be widely used across multiple industries. Advancements in materials and construction techniques have made them more affordable, easier to install, and highly adaptable to various applications, reinforcing their relevance as a cost-effective space optimization solution.

Mezzanine Design Considerations

- Steel plates are used for decks that must withstand heavy loads. However, steel is both heavy and expensive, leading to higher construction costs.

- Aluminum plates are an alternative for lighter load applications, as they are easier to maintain and significantly lighter than steel.

- Fiberglass decks are ideal for corrosive environments where moisture or chemicals may compromise traditional materials.

- Particle board is the most commonly used decking material due to its cost-effectiveness. It is made by bonding multiple layers of board together and is suitable for dry environments where decks do not need to support heavy point loads.

- Structural Design

- Base Plates

- Base plates are fundamental to the stability of a mezzanine structure. If you are new to mezzanines, you may not realize that all mezzanines experience some degree of movement, as they are not completely rigid structures. This movement occurs in two ways: lateral movement and deflection, which refers to the motion of the deck when weight is applied. Poorly designed mezzanines with inadequate or offset base plates experience excessive movement, making the size and orientation of base plates critical. Standard mezzanines typically require base plates measuring 12 inches in length and width, with a thickness of three-fourths of an inch. Anchor bolts are equally important, as they provide the necessary seismic connection for structural stability.

- Columns

- Columns provide support for horizontal, twisting, and vertical loads. When comparing mezzanine designs, it is essential to evaluate the size of the columns, as some manufacturers may cut costs by using undersized columns, compromising structural integrity. Familiarizing yourself with column sizes ensures that you receive a stable and reliable mezzanine. A commonly recommended column size is a 5" x 3/16" tube, which effectively supports varying loads.

- Braces and Other Hardware

- Braces are commonly used to enhance structural strength and reduce lateral movement. Cross braces and knee braces are especially useful in fabricating lighter structures, ensuring stability. If undersized columns are used, braces must be incorporated to compensate for reduced structural strength. Some fabricators may attempt to cut costs by using low-quality nuts and bolts, which can compromise the mezzanine's durability and safety. For reliable construction, high-grade fasteners, such as A325 bolts and nuts, should be used to secure the structure properly.

- Material Design

- Mezzanine structures are typically constructed using hot-rolled steel, cold rolled steel, or stainless steel for industrial applications. Aluminum and fiberglass may also be used but are generally reserved for lighter structures that are not subjected to heavy loads.

- Non-industrial mezzanines can be made from various materials, including wood. However, composite lumber is often preferred for mezzanine flooring, offering a lightweight yet reliable solution. In industrial settings, mezzanines with wood flooring are commonly used for storage purposes. If the mezzanine is intended for other uses, additional structural support may be required, as wood does not provide the same load-bearing capacity as metal components.

- The load-bearing structures of industrial mezzanines are typically made from steel columns and elements, ensuring high structural strength. Shelving or racks may be incorporated for additional storage. The deck surface can be made from a variety of materials, including steel plates, aluminum plates, fiberglass, and particle board, each chosen based on the specific application and environment.

- The load-bearing structures of industrial mezzanines are typically made from steel columns and elements, ensuring high structural strength. Shelving or racks may be incorporated for additional storage. The deck surface can be made from a variety of materials, including steel plates, aluminum plates, fiberglass, and particle board, each chosen based on the specific application and environment.

- Worker Safety

- No matter their function or configuration, all mezzanines must be designed with worker safety as a top priority. Mezzanine access stairs are typically designed with treaded steps and marked with brightly colored or reflective tape to prevent slipping or tripping hazards. Additionally, perimeter railings are installed to reduce the risk of falls and enhance overall workplace safety.

- Customization

- Mezzanine structures can be customized in numerous ways to meet specific operational needs. Features such as lifts, conveyors, and pallet rack systems can be integrated to streamline storage and retrieval tasks, improving efficiency. Other customization options include the addition of stairs, roof decks, or railings, ensuring that the mezzanine is tailored to its intended use and the facility's requirements.

Advantages of Mezzanines

There are numerous advantages to investing in mezzanines, making them a valuable addition to any facility.

One of the most significant benefits is the ability to maximize space efficiency. Installing a mezzanine effectively doubles the capacity of the area in which it is placed. For businesses requiring even more space, manufacturers can install three-tier or triple-deck mezzanines, allowing operations to continue seamlessly without the constraints of limited floor space.

Mezzanines are also highly versatile, offering solutions for storage, office space, and work areas. Their only real requirement is a high ceiling, which is a common feature in most industrial facilities. This adaptability makes them an ideal choice for businesses seeking flexible space solutions that can be customized to meet specific operational needs.

For companies looking to expand working and storage areas without the high costs of traditional construction, mezzanines provide an ideal alternative. Unlike permanent structural modifications, mezzanines are installed rather than constructed, meaning they can be integrated into a warehouse or industrial building within a matter of days.

The modularity, versatility, and wide range of configurations available for mezzanines make them an excellent space management solution. Many mezzanine systems are designed to be highly modular, allowing them to be disassembled, expanded, reduced, or relocated as needed. This flexibility ensures that businesses can continue optimizing their space efficiently, adapting to changes without the need for extensive renovations.

Used Mezzanines

Used mezzanines may show signs of wear and tear from previous use, but they are typically structurally sound and can be refurbished or modified to meet specific needs. Whether for expanding storage capacity in a warehouse or creating additional office space, used mezzanines provide a practical and budget-friendly alternative for businesses looking to maximize space efficiently. However, while they offer cost savings, there are also drawbacks to consider when deciding between a used or new mezzanine.

Advantages of Used Mezzanines:

- Cost Savings: One of the biggest advantages of used mezzanines is the significant cost savings they provide. Purchasing a used mezzanine is typically much more affordable than buying a new one, making it a great option for businesses operating on a tight budget or seeking cost-effective expansion solutions.

- Quick Installation: Used mezzanines are often already assembled or partially disassembled, allowing for a faster and more efficient installation process. This can help businesses save time and minimize disruptions compared to the extended construction timeline required for a new steel mezzanine.

- Versatility: Available in a variety of sizes and configurations, used mezzanines offer flexibility to meet different space requirements. They can be modified or adapted to fit unique layouts, allowing businesses to customize the mezzanine to their specific needs.

- Sustainability: Choosing a used steel mezzanine promotes environmental sustainability by repurposing existing structures that would otherwise go to waste. This supports circular economy practices by reducing material waste and extending the lifespan of industrial mezzanine systems.

Disadvantages of Used Mezzanines:

- Limited Availability: Finding a used mezzanine that matches exact specifications can be challenging. The availability of used mezzanines varies depending on market conditions and specific size and feature requirements, making it difficult to secure one in a timely manner.

- Wear and Tear: Since used mezzanines have already been in service, they may show signs of wear and tear. While most used warehouse mezzanines remain structurally sound, some may require repairs or refurbishments to ensure safety and longevity. These additional modifications could increase overall costs and delay installation.

- Potential Incompatibility: A used warehouse mezzanine may not be precisely tailored to a business’s space or operational needs, leading to compatibility issues. Adjustments or modifications may be necessary to fit the mezzanine into the existing layout, which can add complexity and unforeseen expenses.

- Limited Warranty: Unlike new mezzanines, used mezzanines often come with limited or no warranty coverage. If issues arise after purchase, the buyer may be responsible for all repairs or replacements, such as fixing a worn-out non-slip coating or addressing other metal fabrication concerns.

When weighing the advantages and disadvantages of a used mezzanine, businesses should carefully evaluate their specific needs, budget, timeline, and long-term growth plans. Deciding whether to search for a used mezzanine or invest in a new one depends on factors such as availability, customization requirements, and overall cost-effectiveness.

Mezzanine Accessories

Various accessories can enhance the functionality, safety, and accessibility of a mezzanine. Some examples include OSHA-compliant stairs, ADA-certified railings, public access railings, bar gates, bar joists, specialized decking, and additional shelving. These components can improve structural integrity, provide safer access, or increase storage capacity, depending on the specific needs of the facility.

The suitability of any accessory depends entirely on the intended application. To determine the best options for your mezzanine, consult with your manufacturer to discuss your specifications, operational requirements, and compliance needs. This ensures that your mezzanine is customized to maximize efficiency, safety, and usability within your workspace.

Mezzanine Installation

Mezzanine installation varies depending on the specific needs of the application. Some mezzanines are designed as semi-permanent platforms, meaning they have their own load-bearing piers and do not place additional stress on the existing structure. These standalone mezzanines provide independent support, making them a versatile option for various facilities.

Alternatively, some mezzanine designs rely on the original structure’s load-bearing points for support. In these cases, the mezzanine is typically installed as an extension from the floor, integrating with the building’s existing framework to provide stability.

Mezzanines can be assembled on-site, allowing for customization and adjustments during installation. However, prefabricated mezzanines are constructed at the factory and then delivered in sections for final installation at the facility. This prefabrication process can reduce installation time and minimize disruption to ongoing operations.

Mezzanine Standards and Compliance

Strict guidelines govern the design and construction of mezzanines to ensure worker safety, as improperly built structures can pose significant hazards. These regulations are primarily established by the Occupational Safety and Health Administration (OSHA) to protect employees from workplace accidents. Failure to comply with these standards not only endangers workers but can also result in substantial fines and legal consequences.

Mezzanine systems must be designed, constructed, and maintained in accordance with OSHA standards, as well as regulations set by the International Building Code (IBC) and the American Institute of Steel Construction (AISC). Additionally, depending on the facility’s location and the mezzanine’s intended use, compliance with other codes may be required, such as the Uniform Building Code (UBC) and the Americans with Disabilities Act (ADA). Ensuring adherence to these regulations helps maintain a safe, accessible, and legally compliant mezzanine structure.

Points to Consider When Selecting a Mezzanine

To ensure a suitable and long-lasting mezzanine, several key factors must be considered before making a final decision.

The first step is conducting a thorough evaluation of your requirements and the available space for installation. You must determine whether the mezzanine will serve as storage space, office space, or equipment support. Additionally, you need to assess the ceiling height, exact placement within the facility, overall available space, and whether a single or multi-story structure is required.

- If You Have Enough Space

- Prefabricated mezzanines are the best option for facilities with ample space. These mezzanines are cost-effective, as they are mass-produced in standard modules, typically 10x10 ft. Depending on your needs, two or three modules can be installed to create the desired layout. Prefabricated mezzanines include framing, columns, and deck surfaces, while additional components such as electrical conduit, railings, staircases, gates, and kick plates can be selected individually and installed by a contractor.

- However, prefabricated mezzanines offer limited customization. Since they are pre-designed, users cannot modify critical structural elements such as column placement or load capacity, which can impact overall performance.

- If You Do Not Have Enough Space

- A custom-made mezzanine is the ideal solution when space is limited or specific design requirements must be met. Custom mezzanines start with on-site field measurements and detailed drawings, allowing for complete control over design, column placement, deck materials, railings, and additional structural features. While these decisions can be complex, they ensure that the mezzanine is optimized for the facility’s exact needs.

- One of the most important factors in custom mezzanine construction is evaluating the facility’s slab to determine whether it can support the mezzanine or if additional footings are required. If the mezzanine will support heavy equipment, concrete footings are typically recommended for added stability. However, for storage and light-duty applications, base plates with additional bracing provide sufficient support.

- Once all requirements are determined, partnering with the right manufacturer ensures that your research and planning translate into a high-quality mezzanine system. A reliable manufacturer will collaborate with you from start to finish, tailoring the mezzanine to meet your specifications while maintaining durability and efficiency. To find a reputable manufacturer, consider those listed at the top of this page—each has a proven track record of expertise, professionalism, and customer-focused service.

Mezzanine Images and Illustrations

Free standing mezzanines are not connected to the main structure of the buildingand supported by columns bolted to the floor to take up the minimal amount of space as possible.

Free standing mezzanines are not connected to the main structure of the buildingand supported by columns bolted to the floor to take up the minimal amount of space as possible.

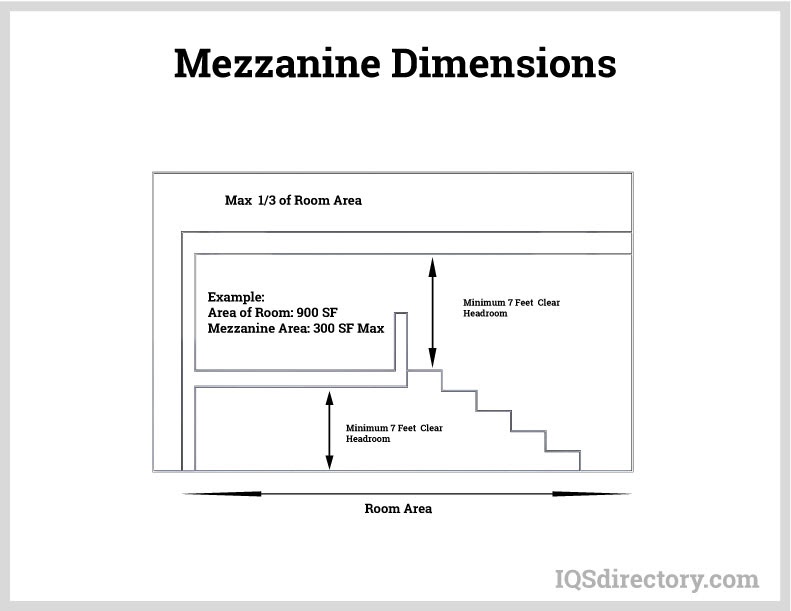

The clearance height above and below the mezzanine cannot be less than 7 feet, while the total area of a mezzanine cannot be greater than 1/3 the floor area of the location.

The clearance height above and below the mezzanine cannot be less than 7 feet, while the total area of a mezzanine cannot be greater than 1/3 the floor area of the location.

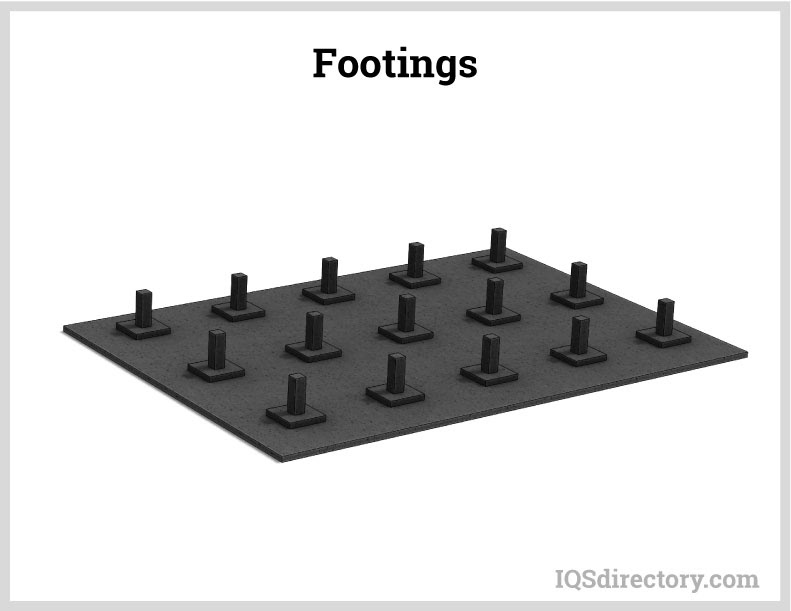

Necessary to determined that the building's concrete slab will not be able to handle the load.

Necessary to determined that the building's concrete slab will not be able to handle the load.

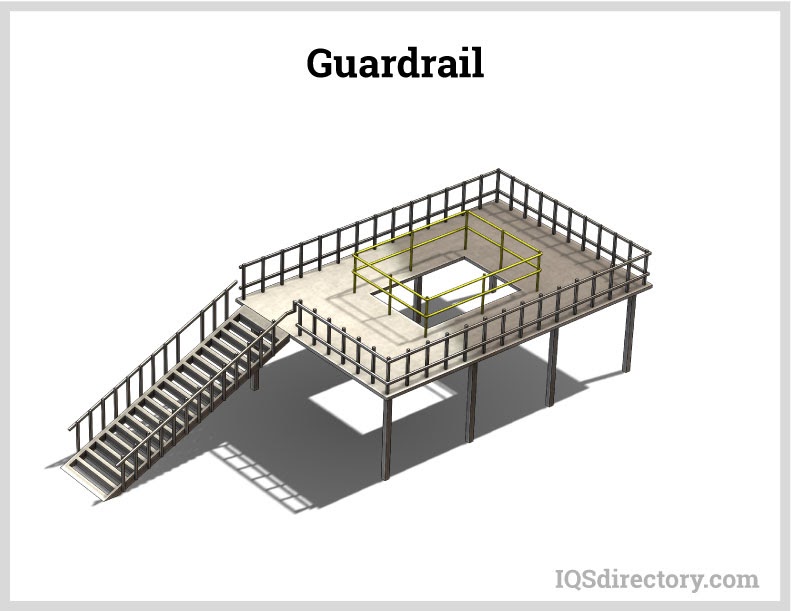

Mezzanines are required to have guardrail at a height of 42 inches.

Mezzanines are required to have guardrail at a height of 42 inches.

With exposed sides handrails are required must be welded, have a smooth, and have a continuous finish.

With exposed sides handrails are required must be welded, have a smooth, and have a continuous finish.

A gate set at a opening in guard rails to allow for better access to the top section of the mezzanine.

A gate set at a opening in guard rails to allow for better access to the top section of the mezzanine.

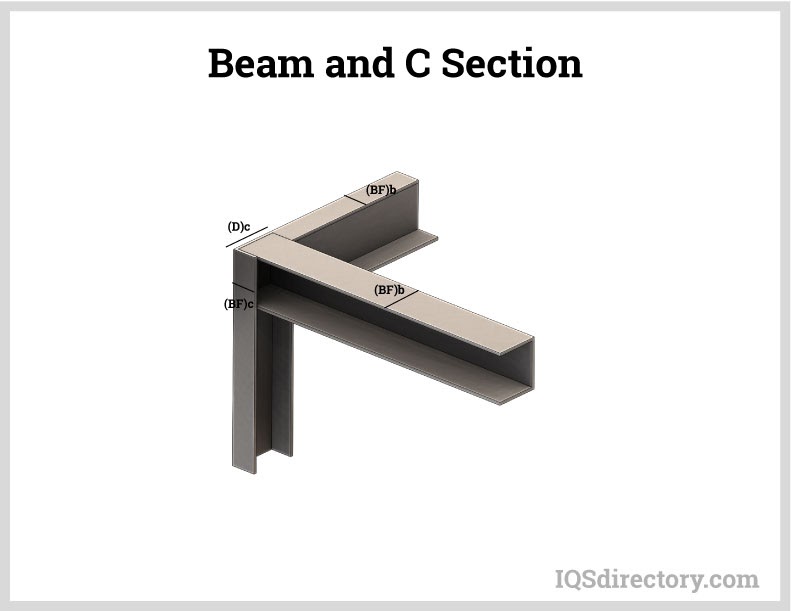

Beam and C-Section keeps the mezzanine to a minimum depth.

Beam and C-Section keeps the mezzanine to a minimum depth.

Bar Joist and Girder Joist are open-web supports floors or ceilings of a mezzanine to allow for higher capicity.

Bar Joist and Girder Joist are open-web supports floors or ceilings of a mezzanine to allow for higher capicity.

Mezzanine Types

- Aluminum Mezzanines

- A great choice for light-duty applications, as they are resistant to corrosion and easily washed. However, they cannot withstand heavy loads. The understructure of aluminum mezzanines is constructed from extruded aluminum, which is light as well as sturdy. For this purpose, aluminum is specially extruded in the form of I-beams, C channels, and tubular columns. To complement the understructure, the deck is also made from light materials like aluminum grating and fiberglass.

- Cold Rolled Steel Mezzanines

- Constructed with sheet metal that is cold rolled below the recrystallization temperature of steel by break press into a C-channel instead of an I-beam. They are lighter, offer a significant reduction in investment, and tend to be more aesthetically appealing than hot rolled steel mezzanines, making them suitable for public buildings. The columns used are either tubular or tapered. The handrail and gates are similar to those of hot rolled mezzanines.

- Custom Mezzanines

- Mezzanines configured to consumer specifications. Custom mezzanines consist of parts that are not "off the shelf" and often require custom fabrication.

- Free Standing Mezzanines

- Raised platforms that can stand without leaning on, hanging from, or otherwise using the support of another structure. Free standing mezzanines, many of which are prefabricated, usually perform less demanding tasks, such as the temporary storage of lighter-weight materials. Neither structural nor free standing mezzanines impede the operation of workers or machinery on lower levels. Their supports can be placed in a way that minimizes interference with the movement of personnel and equipment.

- Hot Rolled Structural Steel Mezzanines

- Have many elements, including the understructure, which is made from open web bar joists, and structural I-beams and columns made from hot rolling—a milling process in which steel is rolled at a temperature above its recrystallization point. Additional elements like handrails can either be horizontal, baluster, or solid panel handrails. The gates of a structural steel mezzanine may be fabricated as lift-out gates, swing gates, or sliding gates. They may have any kind of decking, including resin particle board, plywood, B-deck, bar grating, plank, steel, and concrete.

- Structural Steel Mezzanines

- Offer greater column spacing, easy electrical conduit access, water pipes, and more open space. However, they are heavier than other mezzanines and have rougher finishes. Additionally, they have a high floor and a dead load.

- Industrial Mezzanines

- Heavy-duty mezzanines designed to endure the heavier and shiftier loads that industries are accustomed to handling.

- In-Plant Mezzanines

- Mezzanines constructed inside a plant or building. An in-plant mezzanine is typically shipped unassembled and then put together once inside the designated location.

- Metal Mezzanines

- Raised platforms that can be used in warehouses, factories, stores, and other industrial or commercial settings for storage or office space.

- Mezzanine Construction

- The construction of structures within pre-existing buildings between the ceiling and the floor, essentially providing another story within the facility.

- Mezzanine Design

- The process of selecting building materials, schematics, and other elements of mezzanine construction before the installation of a mezzanine in a workspace.

- Mezzanine Floors

- Serve as the base for the entire upstairs area. They are placed over the supporting purlins. Common floorboard materials include plywood, diamond treaded steel, welded bar and metal plank gratings, various poly texture panels, and concrete.

- Mezzanine Manufacturers

- Produce structures that serve as intermediate floors between the main stories of a building.

- Mezzanine Systems

- All of the elements used to create an intermediate story within a building that sits between two main levels.

- Modular Mezzanines

- Mezzanines that are prefabricated in standard-size offerings. Modular mezzanines are usually limited to a lighter PSF capability, but they are shipped and installed quickly and generally cost less.

- Office Mezzanines

- Raised platforms above or beneath which office space can be created.

- Perimeter Mezzanines

- Used in factories, warehouses, and other large buildings for observing floor operations and providing easy transportation from one end of a facility to another. They can also accommodate visitors or guests during tours. Perimeter mezzanines are an excellent choice for short-term product storage.

- Prefabricated Mezzanines

- Mezzanine systems designed and partially assembled in a factory before full assembly by the end-user. They often come as a small, simple platform for storing supplies or products. However, when a mezzanine serves a more specialized purpose, manufacturers can create a custom design that includes precise specifications such as floor perforation size, shape, square footage, shelving design, or layout.

- Plant Mezzanines

- Transitional floors located within industrial plants.

- Stainless Steel Mezzanines

- A great choice for food service and medical applications, as they are resistant to moisture and chemicals and feature FDA-approved surfaces. They also have a clean and professional appearance. Tubular stainless steel columns and I-beams form the understructure of stainless steel mezzanines. Decking materials can range from bar gratings to stainless diamond plates and planks. Since stainless steel is highly resistant to corrosion, these mezzanines do not require finishing products such as paints and primers.

- Steel Mezzanines

- Semi-permanent steel structures built within pre-existing buildings between the ceiling and the floor.

- Storage Mezzanines

- Platforms designed for the storage of products and equipment.

- Storage Platforms

- Semi-permanent structures built between the ceiling and floor of a building to maximize usable storage space.

- Structural Mezzanines

- Use inherent members such as racks or shelving units to support loads placed on the upper level. Structural mezzanines relocate floor-level work areas to an upstairs platform. They are suspended by a combination of the building's own load-bearing elements along with columns and supports. Structural mezzanines are often integrated into a building during its construction, designed with specific uses in mind, such as providing work surfaces for machinery or storing heavy materials.

- Warehouse Mezzanines

- Raised platforms used to create additional space within warehouses.

Mezzanine Terms

- Column Footing

- A support base for the mezzanine’s load-bearing columns, ensuring structural stability. Column footings are typically made of concrete or metal to provide a solid foundation for heavy loads and prevent shifting or settling over time.

- Collateral Load

- Additional dead loads beyond the weight of the mezzanine structure and decking materials. These include elements such as sprinkler systems, ceilings, electrical components, and mechanical systems, all of which contribute to the overall load capacity.

- Dead Load

- The built-in allowance within a mezzanine’s load capacity that accounts for the weight of the actual mezzanine structure itself, including beams, decking, and support components.

- Equipment Platform

- A broad term referring to any elevated platform used in industrial settings such as manufacturing, material handling, and processing facilities. Equipment platforms are often referred to by different names, including mezzanines, steel structures, and process platforms.

- Grating

- An open grid of metal bars, typically made from steel or aluminum, used for flooring in mezzanine structures. Grid bars are connected to cross bars running perpendicular to them or to bent connecting bars that extend between them, creating a strong, ventilated surface.

- High Density Storage

- A space-saving storage method where unitized loads are stocked more than one unit high and/or deep, allowing for maximum use of available space while maintaining easy access to stored materials.

- Industrial Platform

- A raised platform designed to enhance worker efficiency by providing safe access to elevated workspaces. Industrial platforms are commonly used in factories, warehouses, and other industrial environments to support workstations, machinery, and storage.

- Landing

- A platform positioned at the end of stair flights, commonly found in mezzanine structures. Landings improve accessibility, safety, and functionality, particularly in multi-level mezzanine installations.

- Lateral Deflection (Drift)

- The degree to which a mezzanine will sway due to lateral forces acting upon it. Controlled lateral deflection ensures stability and structural integrity under varying load conditions.

- Lateral Load

- The horizontal force exerted on a mezzanine that causes it to sway. Mezzanine structures are engineered to withstand specific lateral loading conditions, ensuring safety and stability in industrial and commercial settings.

- Lift Truck

- A powered vehicle used to lift, stack, rack, or transport loads within a facility. The term lift truck is synonymous with forklift and is essential for moving materials efficiently in warehouses, manufacturing plants, and distribution centers.

- Live Load

- The maximum weight capacity a mezzanine is designed to support while in use. Typical live loads range from 50 to 250 pounds per square foot (PSF), depending on the intended application and structural design.

- Metal Catwalks

- A specialized type of elevated walkway often integrated with mezzanine structures. Metal catwalks provide safe and efficient access between areas that are otherwise difficult to reach, commonly used in warehouses, industrial facilities, and commercial buildings.

- Office Platform

- A modular office space created using mezzanine platforms. Office platforms feature raised floors supported by structural elements, such as columns, beams, and fasteners, providing an efficient way to create elevated workspaces within a facility.

- Observation Tower

- A tall, freestanding structure designed to allow for long-range observation of landscapes, operations, or events. Observation towers offer 360-degree visibility, making them valuable in industrial, security, and commercial applications.

- Pounds Per Square Foot (PSF)

- A unit of measurement that quantifies the amount of pressure exerted within a one-square-foot area. PSF is a critical factor in determining load capacities and structural requirements for mezzanine systems.

- Purlin

- A horizontal structural component attached to the primary frames of a mezzanine. Purlins reinforce flooring support, distribute loads, and ensure overall structural stability.

- Stair Tower

- A sturdy and stable stair structure used to access multi-level mezzanines. Stair towers are designed with safety features such as slip-resistant steps and guardrails, preventing falls and ensuring compliance with OSHA and building code regulations.