Multistage Blowers

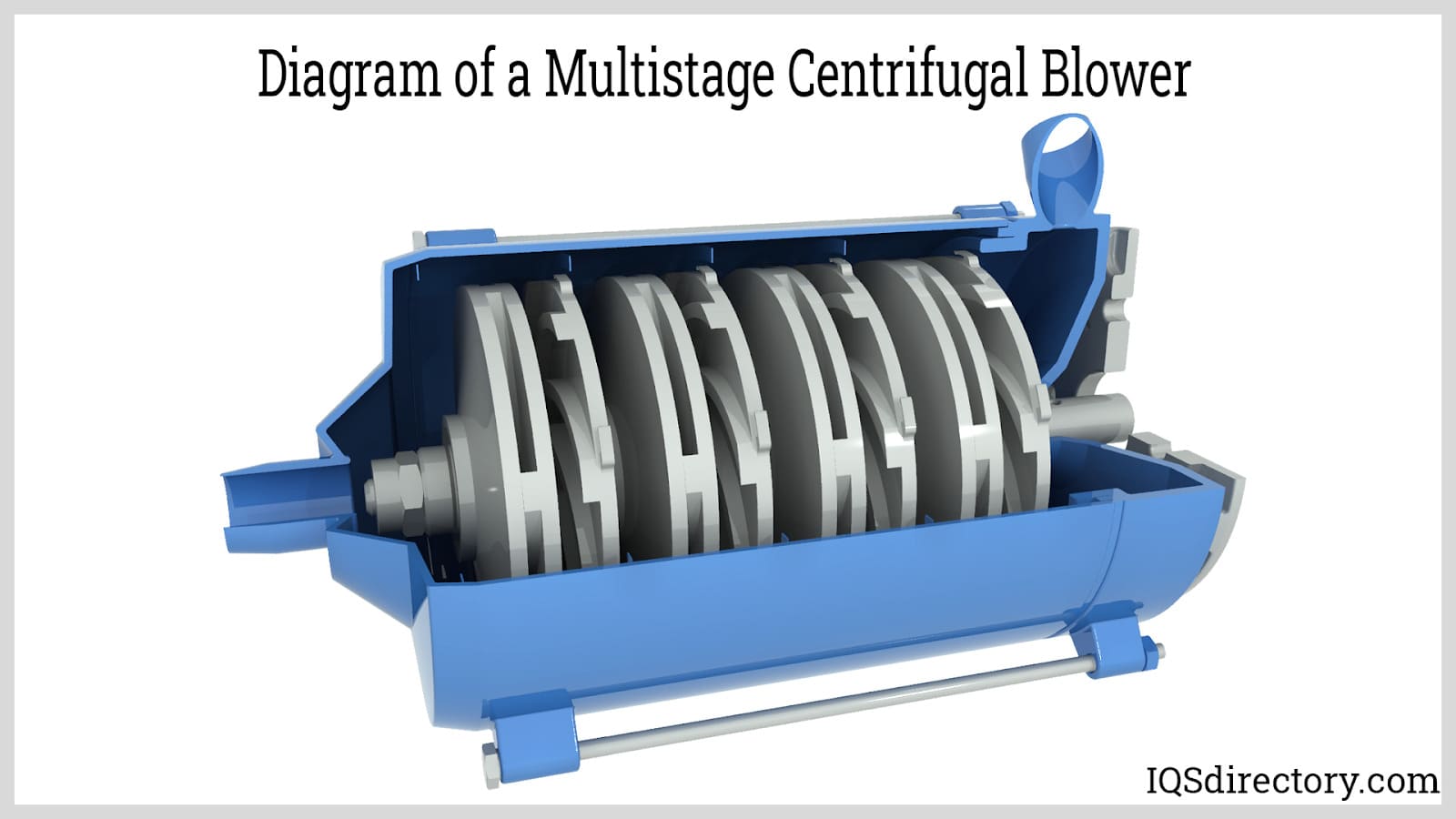

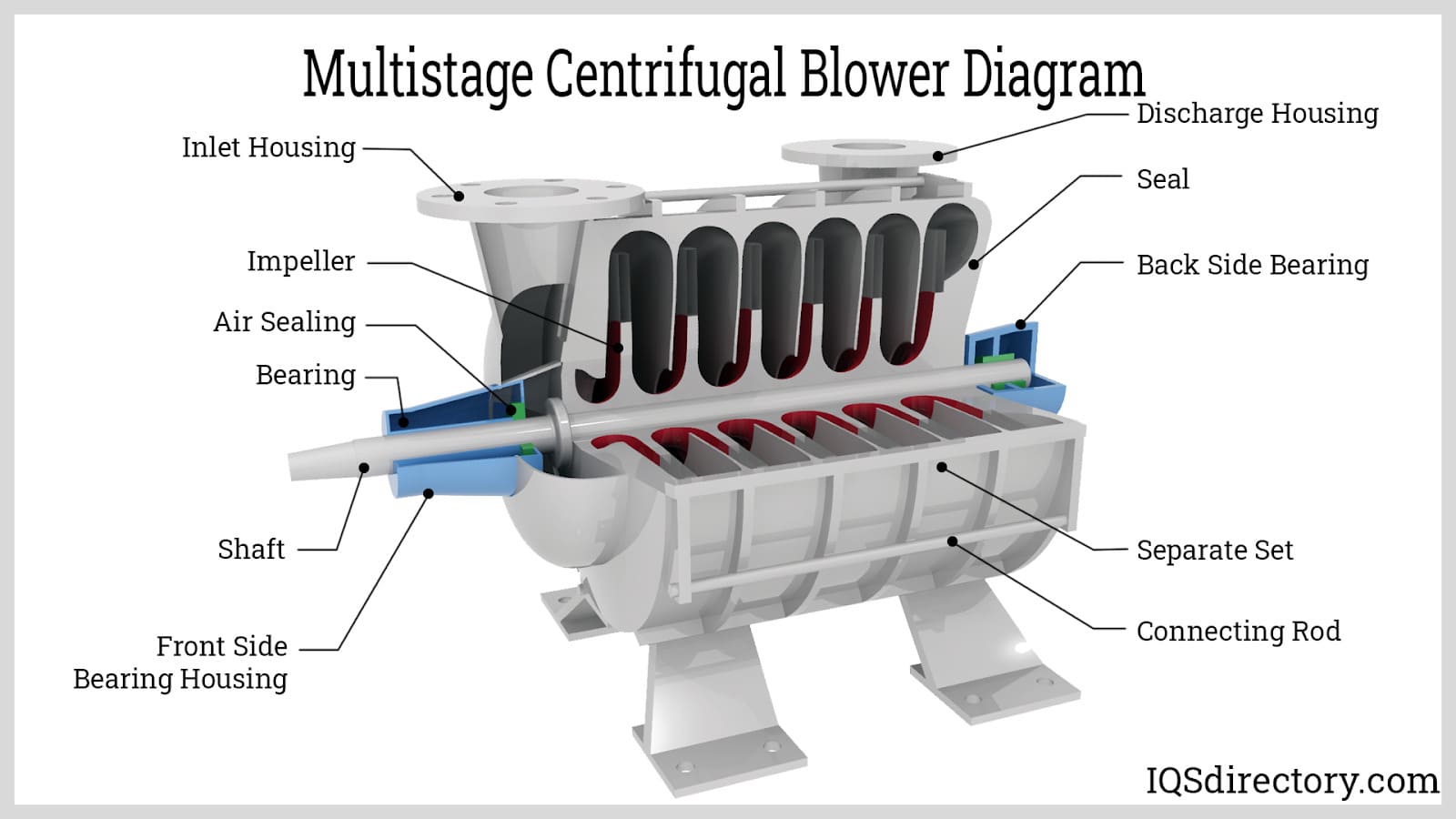

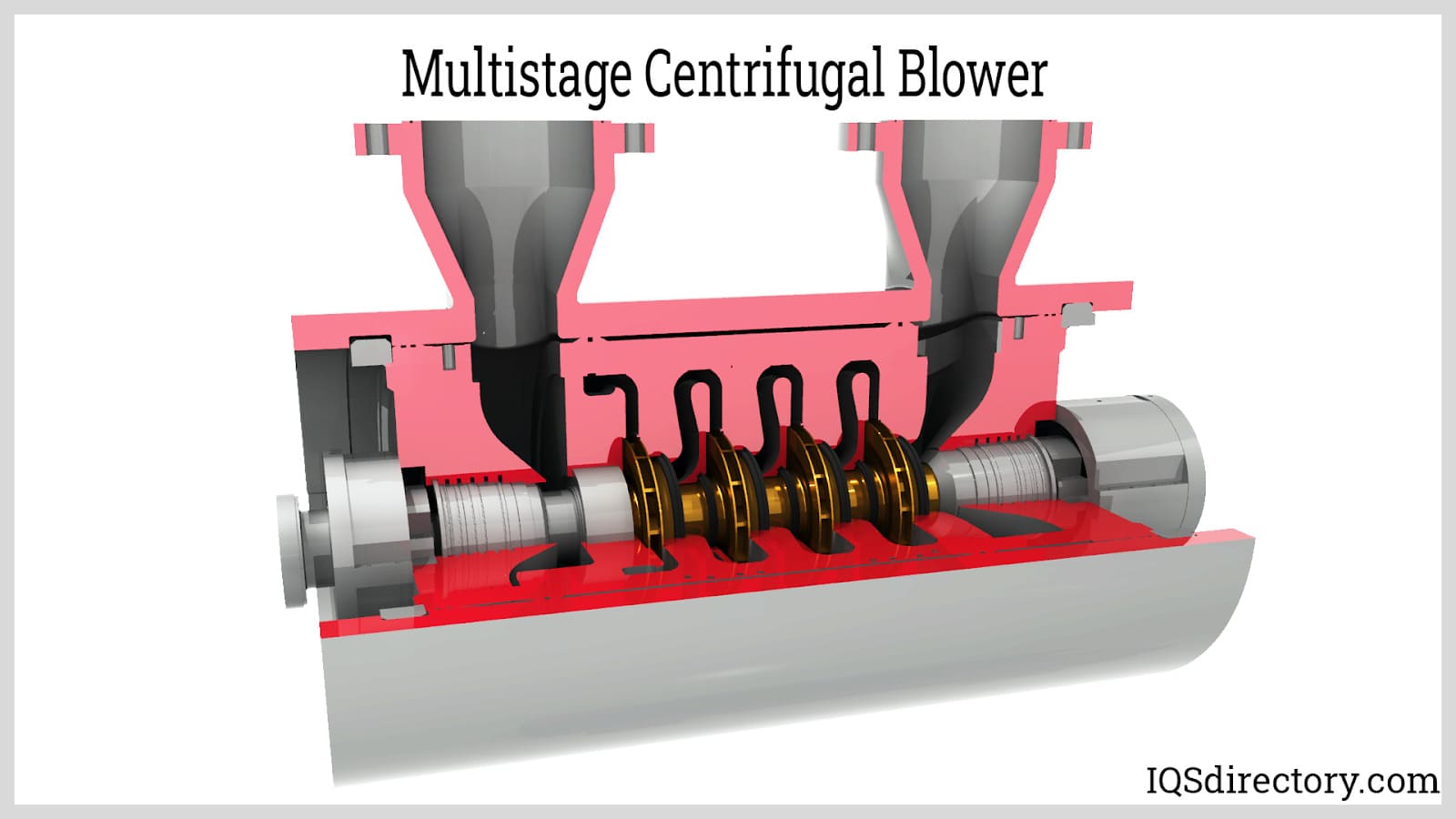

Multistage centrifugal blowers create a variable flow using power at a constant speed. They are constructed with multiple impellers mounted on a single extended shaft, which is coupled to a motor shaft that is belt- or direct-drive-driven. The extended shaft is supported on both ends by self-aligning ball bearings connected to the motor shaft.

The reliable operation of multistage centrifugal blowers makes them ideal for rugged, tough, and high-risk environments. They are suited for pressure and vacuum applications for air and gasses. The design of multistage blowers makes it possible to choose the number of compression stages and the impeller design for each stage.

Multistage blowers use the kinetic energy of the impellers to increase the volume of the air or gas and move it against the resistance of ducts, piping, and dampers. They displace the air radially, changing the direction of the airflow. Air or gas is sucked into the blower through an inlet volute to the first stage impeller. Every impeller is linked through a return channel.

Quick links to Multistage Blowers Information

How Multistage Blowers Work

Multistage blowers use electric motors to increase the speed of air or gas and move the air or gas along the impellers until the discharge pressure is reached. As air or gas passes through each stage of the blower, pressure increases until it is at the desired discharge level. The pressure buildup is caused by accelerating the air or gas using the set of impellers, which is decelerated by long radius and high-efficiency diffusers.

The drive mechanism of a multistage blower rotates the impellers using a direct or indirect motor configuration. The rapid rotation of the impellers pulls in air or gas through the inlet. The centrifugal force of the impellers increases the kinetic energy of the air or gas particles, causing them to leave the blower at a higher speed than when they entered.

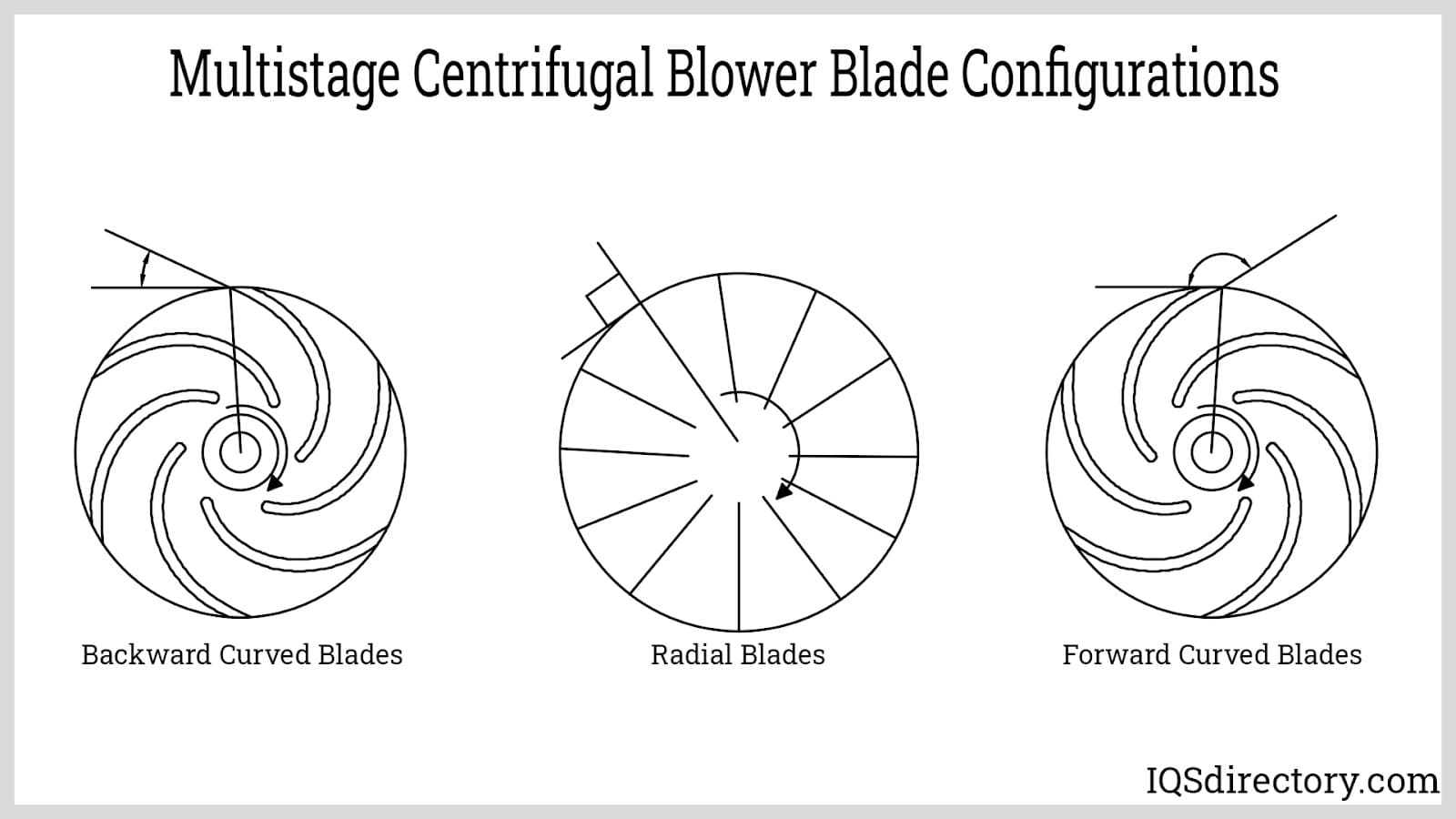

As the air or gas progresses through the various stages of the blower, its elements move faster and faster. This increase in speed results in an increase in pressure. The speed of the movement of the air or gas depends on the shape of the impellers, which can be forward curved or backward inclined and radial. The various types of impeller configurations are designed to adapt to the needs of different applications.

Multistage centrifugal blowers offer superior-quality design, materials, and manufacturing. They require minimal maintenance with exceptional efficiency.

Components of a Multistage Centrifugal Blower

Multistage centrifugal blowers come in different designs depending on the configuration of the impellers, the number of impellers, and whether they are being used to increase pressure or create a vacuum. The key feature of multistage blowers is their strength, which is due to the high quality of their components. Regardless of the many different designs, certain components of multistage blowers are found in all types and varieties.

Key components of multistage blowers:

Baffle Rings

Baffle rings guide airflow into the impellers to reduce inlet passage loss. Combined with impeller design, baffle rings increase blower efficiency and pressure or vacuum capabilities.

Balance Piston

The balance piston limits axial force and reduces pressure on drive bearings, increases rotor life, and prevents gas leakage.

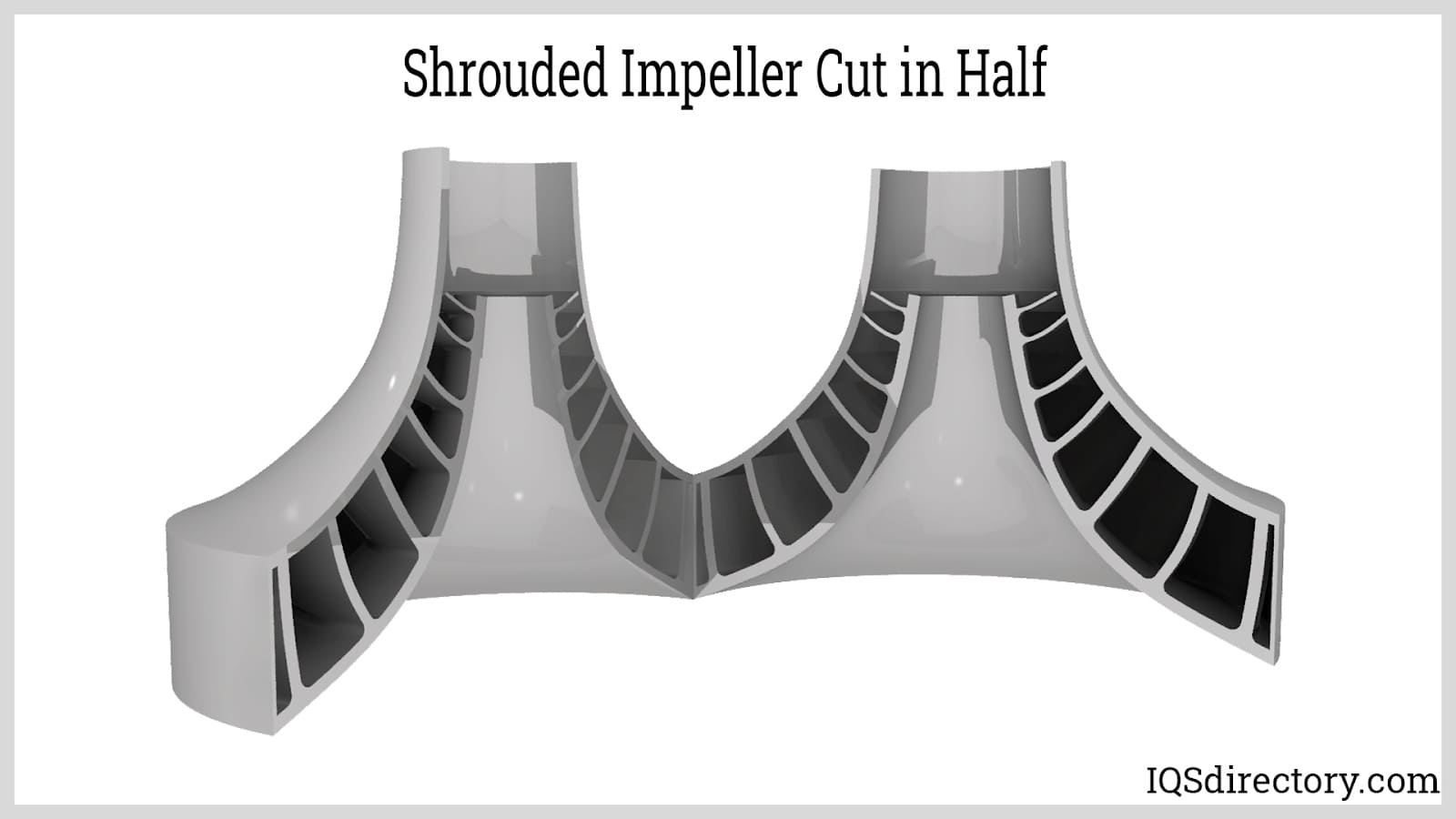

Shrouded Impellers

Shrouded impellers offer higher efficiency and are balanced to achieve smooth operation with the least amount of vibration. They are less sensitive to axial positioning.

Unshrouded Impellers

Unshrouded impellers operate at high rotational speeds and high volume flow rates. They have to be properly positioned with respect to the sides of the casing.

Flexible Coupling

The flexible coupling is connected directly to the power source for optimum power transfer and minimization of bearing loads.

Cast Housing

The housing for a multistage blower is made of cast iron for large blowers and aluminum for smaller ones. The aluminum or cast iron sections are assembled using high-strength steel rods. The blower and its driver are mounted together on a single steel baseplate, assuring long-lasting performance and durability.

Shaft Sealing

Shaft sealing can be labyrinth, mechanical, or purgeable nitrogen.

- Labyrinth Seals are mechanical seals that use a multiple-chamber mechanism to prevent leaks. They are composed of several grooves to present a difficult path for air or gas to escape.

- Mechanical Seals form a seal between the rotating and stationary parts. One portion of the seal rotates with the shaft, while the other sits stationary with the blower housing.

- Purgeable Nitrogen Seals use a purge line that applies gas at constant pressure against the gas stream, keeping it from leaking out. This is normally applied at the shaft entry and exit from the blower housing.

These generic components are arranged, designed, and engineered in different configurations by each manufacturer. The inlet, outlet, impellers, and housing can be found in all forms of multistage blowers.

Benefits of Using Multistage Blowers

The accurate and efficient movement of air and gasses is necessary for several applications. Multistage centrifugal blowers are a crucial part of the process. Regardless of their power and excellent performance, they are one of the easiest pieces of equipment to operate.

- Versatility – Multistage blowers are ideal for multiple applications. They can be adjusted from grade one to five to meet specific needs.

- Efficiency – Efficiency is the most outstanding attribute of multistage blowers. They economically use energy to reach precise pressure needs.

- Noise – Although multistage blowers are extremely powerful, they are very quiet and operate at under 80 db.

- Maintenance – Multistage blowers are powerful, efficient, and strong equipment that require very little maintenance. The various parts of a blower are easy to maintain and replace.

- Drive – Multistage blowers make it possible to choose the type of drive required to meet the needs of an application. They are available with direct and v-belt drives.