Paper Tubes

Paper tubes are defined as cylindrical containers made from cardboard that vary in thickness and size. These containers are used by a multitude of industries for countless applications because of their versatility and cost-effectiveness. For items that can either be rolled into a cylindrical shape or folded up to fit into a cylindrical container, paper tubes are useful containers for distributing, manufacturing, and shipping. Industries that use paper and cardboard for their applications include food, electronics, and automotive. They can be used in any department from distribution, insulation, parts protection, or storage.

Quick links to Paper Tubes Information

Advantages of Paper Tubes

Numerous industries recognize the wide range of uses for paper and cardboard tubes. Paper tubes have many advantageous properties, such as their strength, evaporation potential, non-toxicity, energy efficiency, cost efficiency, recycling potential, cold resistance, water resistance, and simple storage capabilities. It would benefit the industry even further if more consumers were just as aware of all of these beneficial properties. Thanks to extensive research, uses for paper and cardboard tubes have expanded. Today, they are used as a material for children’s toys, for the protection of pipes, the storage of frozen items, and protection of sensitive items as they are shipped from place to place.

Materials Used in Paper Tubes

Paper and cardboard tubes come in a variety of types to suit numerous applications. Some of the wood pulp bases that make up paper or cardboard tubes include kraft paper, paperboard, fiberboard, and paper-adhesive composites. The more rigid types of material can be classified as cardboard. The first step in making paper and cardboard tubes is forming the wood pulp material into ribbons and spiral winding them in order to add layers and increase their tensile strength. Manufacturers may improve the tube’s structural strength further by mixing the material with an adhesive solution which dries hard and adds a rigid coating to the cardboard. Other coatings that can be added include foil or kraft paper on the exterior for decoration or labeling; or wax, which helps protect the tubes from humidity, moisture and extreme temperatures. Tubes that are made to preserve food feature a foil covering to prevent contamination, and paper tubes that are used in military applications have a wax coating to make them resistant to heat. Paper tubes that are used as an insulator for electrical connector wires are made to resist moisture. For holidays and other special occasions, paper tubes can be covered with patterned or colored paper for gifting purposes.

Paper Tube Images, Diagrams and Visual Concepts

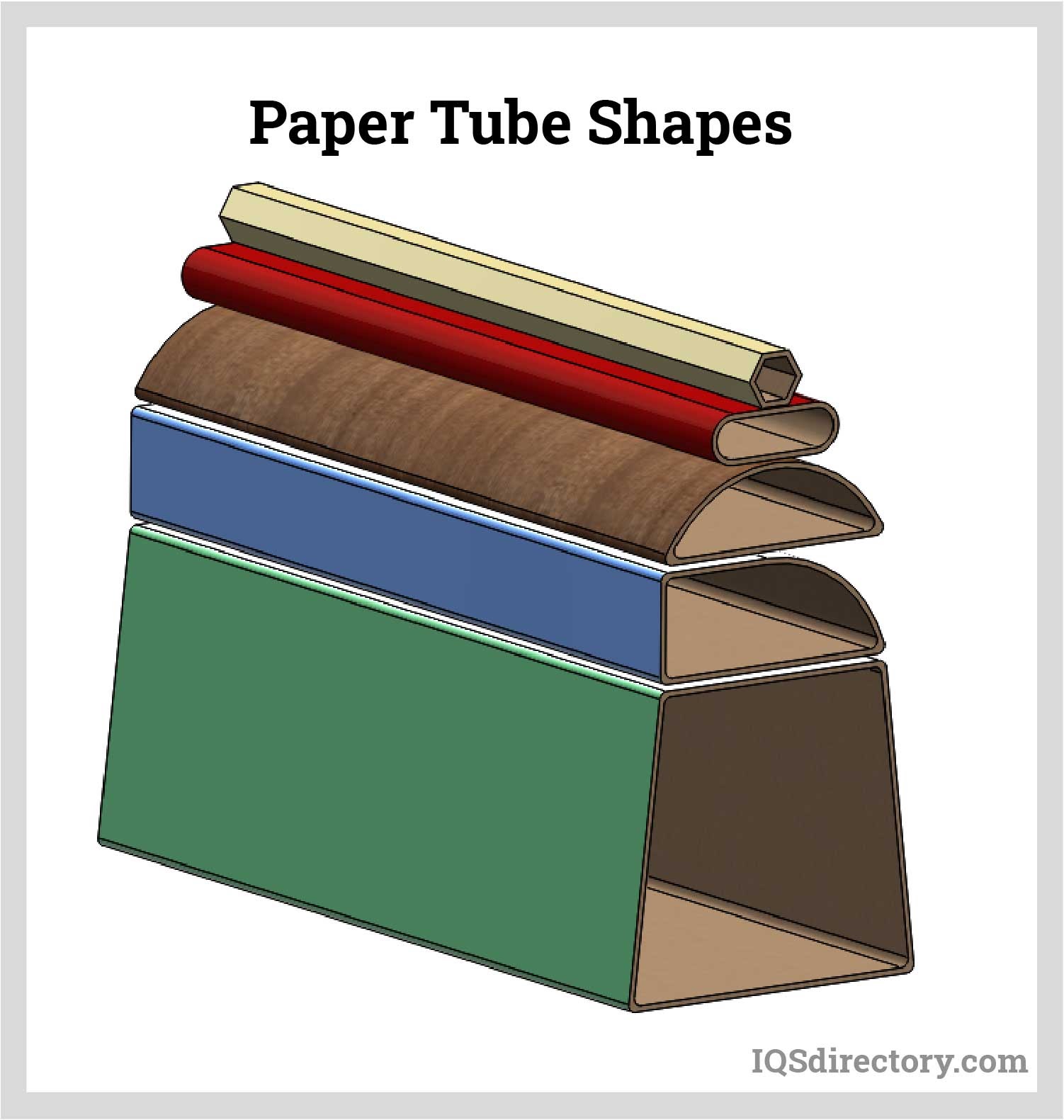

Custom shapes for fitting specific products or parts while eliminating wasted space and other types of packing material.

Narrower width ribbons are wound to form a spiral tube for giant rolls of paper material.

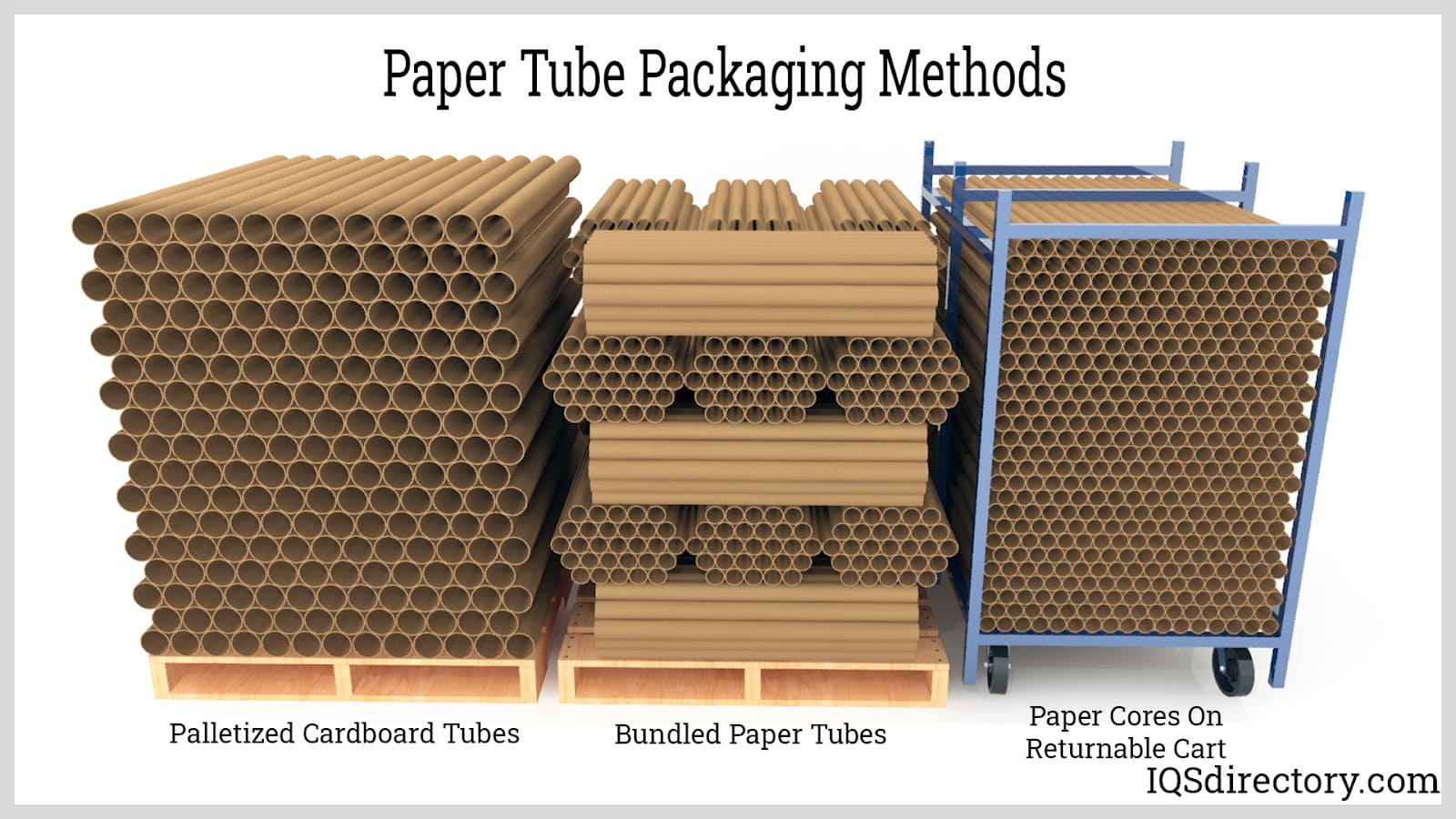

Methods packing the tubes for shipment or storage depending on the customer requirements.

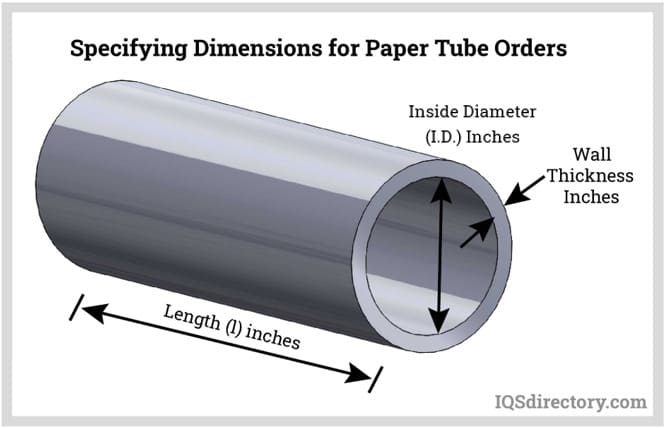

The tubes are measured according to the product length and diameter while providing enough clearance between the product and the tube.

Applications of Paper Tubes

The packaging industry has recently made the use of telescope tubes. A telescope tube consists of two pieces: the container itself, and a second piece that fits tightly over the first, acting as the lid. Telescope tubes are often used to package sensitive materials such as delicate items, important documents, cosmetic items, and artwork. The retail industry uses these tubes extensively in packaging some of their items for sale. Telescope tubes are highly recommended for their beneficial properties. They are user-friendly, environmentally-friendly, waterproof, and insulated and cushioned on the inside for extra protection.

Other industries and applications that utilize paper tubes include:

Fireworks

For rocket bodies, canisters, and other items that have been pre-packaged with a fuse.

Posters

For print containers.

Consumer

For point of purchase displays.

Coin Banks

For purposes such as nonprofit fundraising.

Paper Cores

For winding paper, adhesive, fabric, and electrical products.

Contractor and Construction

Use the exceptionally strong Sonotubes® to construct concrete pillars and supports. You can find companies who make Sonotubes here on IQS Directory.

Regardless of the intended application, the length, diameter, and the wall thickness can vary. The flexibility of paper and cardboard enables manufacturers to easily modify the fabrication processes.

Educating Consumers on Paper Tubes

As new uses for paper products are being discovered, it is highly recommended for manufacturers of paper tubes to educate consumers and inform them of the variety of ways in which paper tubes can be used. For instance, cardboard tubes can be used to make molds for the fabrication of numerous products. The construction industry forms concrete tubes using cardboard. Therefore, many other industries could benefit from applying the same concept to their own applications. There are several ways to recycle and reuse paper tubes right at home. Aside from using it to mail and package materials, cardboard can be wrapped in an adhesive material and used as fly paper. A tube can be cut in half and placed in boots when not in use to help them retain their shape. Educating the public on new ways to use cardboard and paper tubes can save time, money, and energy for customers and boost sales and improve the reputation of a business.

More Paper Tubes Information

Paper Tubes Informational Video