Parts Washers

Parts washers play a critical role in the parts manufacturing process, handling one of the final steps—cleaning, degreasing, and drying parts in preparation for surface treatment and distribution. After products are machined, forged, or fabricated, they often have residual oils, chemicals, burrs, abrasive dust, paint, and other debris from the fabrication process. These contaminants can interfere with finishing coatings like zinc and electroplating, as they are ineffective on dirty surfaces. Parts washers address this issue by providing precise and thorough cleaning, ensuring the surface is properly prepared for further treatment.

Frequently Asked Questions About Parts Washers

What is the main purpose of a parts washer in manufacturing?

A parts washer cleans, degreases, and dries components after machining, forging, or fabrication. It removes contaminants such as oils, carbon, and metal shavings to prepare parts for coatings, plating, or final assembly.

What types of parts washers are commonly used in industrial settings?

Common types include solvent and aqueous parts washers, as well as ultrasonic, cabinet-style, rotary drum, and conveyor systems. Each is selected based on the part size, material, and level of automation required.

How do aqueous parts washers differ from solvent-based systems?

Aqueous washers use water-based or pH-neutral solutions combined with heat and mechanical energy to remove contaminants. Solvent-based systems rely on petroleum solvents but are less eco-friendly and now less common due to environmental regulations.

What industries rely most on parts washers?

Parts washers are essential in automotive, aerospace, electronics, and medical manufacturing. They are also used across Midwest and Southern U.S. facilities for cleaning components before painting, electroplating, or coating applications.

What are the benefits of using modern parts washing systems?

Modern systems offer energy efficiency, low maintenance, and environmentally friendly cleaning using biomatic or aqueous processes. They reduce labor time, enhance safety, and deliver consistent cleaning quality across high-volume production.

How should industrial parts washers be maintained for long-term efficiency?

Operators should avoid overloading, remove burrs before cleaning, use the correct cleaning solution, and maintain filtration systems. Following these steps helps ensure optimal performance and extends equipment lifespan.

Are there safety or quality standards for parts washers?

Yes. Parts washers should comply with OSHA safety standards and may be certified to ISO or ASME specifications. Systems used in military or aerospace manufacturing must also meet Mil-Spec requirements for quality assurance.

Applications of Parts Washers

Industrial parts washers are widely used to remove contaminants like carbon, grease, metal chips, and cutting fluids from various metal parts. Their applications span a wide range, from cleaning small metal pieces like nuts, fasteners, and screws to larger components such as automotive assemblies, rail bearings, diesel engine blocks, and even wind turbine gearboxes.

Beyond manufacturing, industries like electronics, automotive, and medical fields also rely on industrial cleaning equipment. These washers are essential for cleaning items that require surface treatments like painting, powder coatings, zinc coating, lubricants, electroplating, and more—processes that cannot be performed effectively without thorough cleaning beforehand.

Advantages of Parts Washers

There are many advantages to parts washing. These include:

- Low Maintenance Costs

- Low Power Requirements

- Energy Efficiency

- Ease of Use

- Diversity of Method Choice

- Abundance of Eco-Friendly Process and Solvent Options

The History of Parts Washers

Parts cleaning technology was initially developed in the mid-20th century for use in automotive transmission and engine repair shops, where it dramatically improved upon the previous "soak tanks." These simple vats filled with detergent and water allowed mechanics to soak parts for hours, but parts washers provided a much faster, easier, and more effective way to clean soiled parts.

The early parts cleaning systems used solvents such as mineral spirits, naphtha, trichloroethylene, xylenes, and benzene. The cleaning process involved a low amp, flame-tight electric liquid pump that skimmed dirty metal pieces with solvents in drum washers or rotary drum parts washers until they were clean.

By the late 1960s, manufacturers started refining their methods to reduce environmental impact and improve safety. During this time, the industry transitioned from using harsh degreasers like gasoline, diesel fuel, and kerosene to milder cleaners, such as vapor degreasers and chlorinated solvents. However, in the 1980s, chlorinated solvents were banned. This led to the widespread adoption of aqueous-based cleaning systems, first developed in 1971 by Gary Minkin. These aqueous systems revolutionized parts cleaning by introducing hydraulic impact pressure, which significantly enhanced cleaning power.

Today, many parts cleaning systems are designed to be environmentally friendly. Early water-based solutions were less effective than chemical cleaners, but advancements in technology have made them far more efficient. Modern parts washers use a biomatic process, which involves a heater washer with a pH-neutral cleaning solution combined with a microbe colony that breaks down grease, oil, and other contaminants. This method provides an effective, environmentally safe cleaning solution. Additionally, the integration of CNC programming has improved the efficiency of the process, reducing labor time and effort.

Looking ahead, the future of parts washing is promising. Engineers are likely to continue developing systems that are even more efficient, thorough, environmentally friendly, and cost-effective, further improving the industry’s sustainability and effectiveness.

Design of Parts Washers

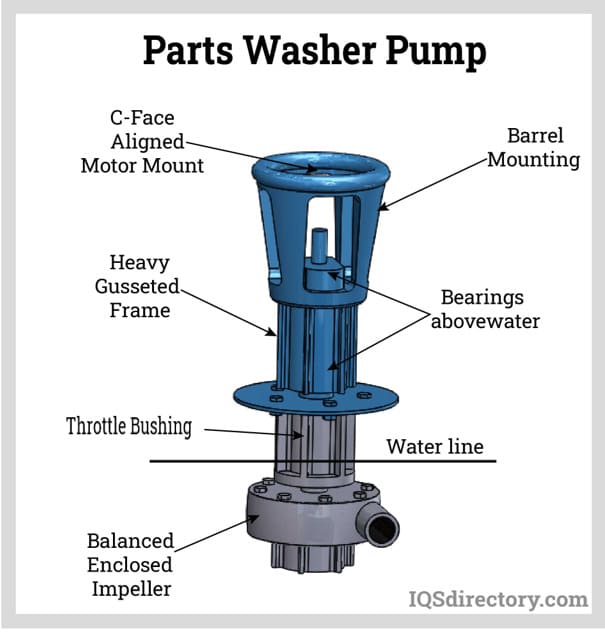

Parts cleaning equipment generally includes a water heater, filtration system, pumps, scrubbers, brushes, nozzles, and a cabinet.

Water heaters in parts washers can be powered by gas, electricity, or steam. The filtration system is responsible for capturing waste and debris produced during the cleaning process. Pumps increase the pressure of sprayers, while scrubbers and brushes work together to dislodge contaminants from the parts. To break down contaminants, various solutions are used, including hot water, detergents, solvents, vapors, acids, and alkaline solutions, some of which are synthetic and others natural. Cabinets, also called enclosures or housings, are typically made from stainless steel, though some models may feature glass or plastic components.

Design options for parts washers and systems are abundant. For example, some washers are fully automated, with CNC machines adjusting settings, while others require manual loading. Depending on the design, parts may be front or back loaded and cleaned in a basket, tray, rack system, by a robotic arm, on a rotary table, or via a conveyor belt. Most parts washers are aqueous, utilizing water combined with a chemical or natural solvent to boil, blast, or soak the dirty parts until they are clean. Some solvents include inhibitors, which prevent harmful chemical reactions between the cleaner and non-ferrous metal substrates.

Given the wide variety of unfinished parts across different industrial sectors, parts washer manufacturers often offer custom designs. These cleaners can range from simple stand-alone basket immersion parts to complex machines that combine deburring, aqueous tumbling, rinsing, drying, and paint coating in a single system. Advances in industrial technology have made it possible to integrate multiple steps of the finishing process into one specialized machine.

Accessories for Parts Washers

To simplify your parts washing tasks, several accessories are available that can improve efficiency. Consider investing in cleaning brushes, oil-absorbing pads, washer heaters, washer filters, turntables, and parts baskets. To determine which accessories are best suited for your specific needs, it's a good idea to consult with your supplier for expert advice.

Installation of Parts Washers

Each industrial parts washer has its own installation requirements. To ensure proper setup, make sure to follow the installation instructions provided by your supplier.

Proper Care of Parts Washers

To ensure your metal parts washers function at their best over the long term, consider the following expert tips for maintaining efficiency:

Here are some expert tips for running your parts washers efficiently for many years.

- Avoid Storage of to-be-Cleaned Metal Pieces

- Parts should move directly from the production line to the washer. Storing parts with oil and grease allows additional dirt to accumulate, which puts extra strain on the parts cleaning machinery. This leads to longer cycle times and increased maintenance and repair costs.

- Remove Burrs Before Cleaning

- Burrs on metal parts can complicate the cleaning process by preventing cleaning detergents or solvents from effectively reaching all surfaces. Additionally, burrs may detach during the cleaning, which could disrupt the filtration system. Removing burrs beforehand will improve the cleaning process.

- Don't Put Too Many Parts in a Batch

- Overloading the parts washer basket limits the space needed for effective cleaning, which may result in unsatisfactory results. While reducing the load size might decrease output, it will allow for better cleaning, as more solvent will be able to reach each part.

- Choose the Right Cleansing Solution

- Select the appropriate cleaning solution based on the type of contaminants. For oil-based contaminants like cutting fluids, hydrocarbon cleaning methods provide the best results. For water-based contaminants like grinding or lapping compounds, aqueous parts washers are more effective.

- Make Sure Your Operators are Properly Dressed

- Operators can inadvertently transfer contaminants like oils and hair, which can hinder the washing process. It's essential to have operators wear hairnets, lint-free gloves, work coats, and bodysuits. This not only ensures cleanliness but also protects them from potential exposure to corrosive wash materials or chemicals.

Parts Washer Standards

Given that your parts washer will be operating around workers, it’s important to ensure that your wash system complies with OSHA standards. Additionally, it’s a good idea to request ISO and/or ASME certification, as these provide general quality assurance. The specific requirements will depend largely on your application. For instance, if the parts washer is used for military products, it will need to meet Mil-Specs.

Things to Consider When Purchasing a Parts Washer

Selecting the right parts washer for your machine parts can be challenging, even though parts cleaning systems themselves are easy to understand.

To help you choose your wash system, use the list of considerations below.

- What materials are your parts made from?

- How large and what shape are your machine parts?

- Do you need a wash rinse system or just a wash system?

- What type of contaminants do you need to wash from your parts? (carbon, oil, grease, mold release agents, corrosion, dust, metal chips, cutting fluids, etc.)

- How skilled are your engineers in cleaning machine parts?

- What are your environmental safety concerns?

With these considerations in hand, the next step is to choose the right manufacturer. Start by browsing the listing above and visiting their websites. Reach out with any questions you may have. Look for a manufacturer who is not only knowledgeable but also attentive to your needs. The ideal manufacturer will apply their expertise to design a high-quality system that meets your specifications while respecting your budget and timeline.

Parts Washer Images, Diagrams and Visual Concepts

Immersion parts washers uses a system of agitation or oscillation to clean parts in a cleaning solvent.

Immersion parts washers uses a system of agitation or oscillation to clean parts in a cleaning solvent.

The diagram shows the different parts involved in the cabinet.

The diagram shows the different parts involved in the cabinet.

The pump supplies pressure to the system.

The pump supplies pressure to the system.

Detergent that can remove grease, grime, oil, chemicals, and soil from high volume parts production.

Detergent that can remove grease, grime, oil, chemicals, and soil from high volume parts production.

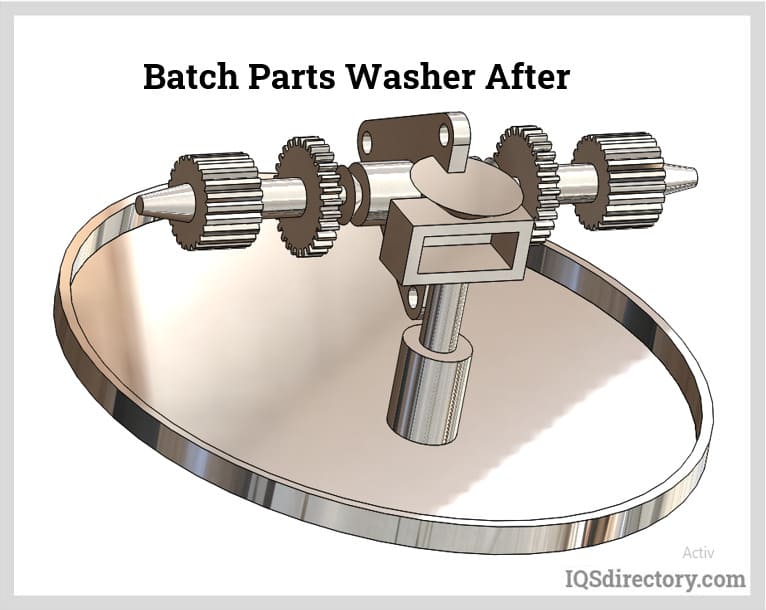

An example of what parts would resemble after being washed.

An example of what parts would resemble after being washed.

Parts Washer Types

Broadly, washers are either solvent or aqueous-based:

- Solvent Parts Washer

- These washers clean metal parts by dissolving dirt, grease, and scum. The first parts cleaning equipment was solvent-based, requiring gallons of petroleum-based solvents. Over time, different varieties of solvent-based cleaners emerged. However, due to environmental concerns, solvent-based parts washers have become less popular. Solvents are not eco-friendly, and it is harder to find solvents that meet modern environmental safety standards.

- Aqueous Parts Washer

- Aqueous washers use pH-neutral or water-based solutions to break down and clean contaminants from metal surfaces. In some cases, semi-aqueous cleaning solutions, which combine a small amount of solvent with water, are used. The process typically employs detergent, water, and mechanical or heat energy to clean, often through jet spray or power wash methods.

In addition to these categorizations, parts washer systems can be broken down by their level of automation, from manual to semi-automatic, and, most commonly, fully automatic.

- Manual Cleaning Washer

- These are typically drum or vat-style systems suitable for low-volume cleaning. Ideal for part cleaning processes that take 30 to 40 minutes daily and especially effective when dealing with many small parts.

- Semi-Automatic Washer

- These washers feature some automated stages but still require manual loading and unloading, or they may work alongside a conveyor system for additional efficiency.

- Automated Cleaning Washer

- Automated washers are best for operations where parts are cleaned for extended periods each day, typically over 45 minutes. Switching to automation can result in significant time and cost savings.

Some modern washers are classified by their functionality:

- Cabinet-Style Parts Washer

- These washers are shaped like cabinets and use a combination of heated aqueous spray and mechanical energy to clean grease and carbon from metal parts. Cabinet-style washers often have a fixed or retracting turntable to grip and rotate the parts during cleaning.

- High-Pressure Spray Washer

- Commonly a type of cabinet-style washer, high-pressure spray washers use powerful water jets to clean parts. These jets, often accompanied by aqueous-based chemicals like detergent and hot water, ensure thorough cleaning by spraying the parts from different angles.

- Ultrasonic Cleaner

- Ultrasonic cleaners use a cleaning bath where ultrasonic energy causes the solvent to vibrate and create bubbles that implode, cleaning surfaces with tiny underwater air blasts. This method is particularly effective for cleaning hard-to-reach areas like pipes and small machine parts.

Finally, some other parts washer varieties include green washers, spray washers, rotary drum washers, drum washers, conveyor parts washers, immersion/agitating washers, small parts washers, and automotive part washers.

- Green Washer

- These modern washers use biomatics, combining biology and technology to benefit the environment. Parts are placed in a heater washer with a pH-neutral solution and a microbe colony. The microbes break down grease and other contaminants, converting hydrocarbons into carbon dioxide and water, which are filtered and reused.

- Spray Washer

- Spray washers are equipped with an enclosed conveyor belt that moves parts through a spraying system. They typically use multiple nozzles to apply water for cleaning, although they are generally less intense than high-pressure spray washers.

- Rotary Drum Washer

- In these washers, smaller parts are tumbled through a rotating drum, which washes, rinses, and dries the parts. The drum has a spiral conveyor that moves parts in a circular motion, ensuring all sides are cleaned.

- Drum Washer

- Drum washers are used to clean larger containers, such as barrels or pails, that hold chemicals, paints, or adhesives. These washers clean both the interior and exterior of the containers, using spray washers or rotary washers to clean the drum interiors and drying them with air or heat.

- Conveyor Parts Washer

- Unlike cabinet-style washers with turntables, conveyor parts washers use a conveyor to move parts through the cleaning process. These can use a simple belt conveyor or an overhead conveyor system.

- Immersion Washer/Immersion Agitation Washer

- These washers submerge parts in a bath of cleaning solution. Using a combination of agitation, spray, and ultrasound, they remove contaminants. Impellers or paddles create mechanical energy to mix the solution, which helps clean large and small parts effectively.

- Small Parts Washer

- Designed for small parts like fasteners and screws, these washers typically use rotary or immersion cleaning methods to clean a large quantity of small components.

- Automotive Parts Washer

- These washers clean automotive parts such as engines, transmissions, pneumatic parts, and hydraulic components, using hot water solutions and ultrasonic cleaning for thorough cleaning.

- Agitating parts washers

- Cleaning tools that use agitators to improve the efficiency of the cleaning process.

- Aqueous Cleaning Systems and Aqueous Parts Washing

- These systems use water-based chemicals, detergents, saponifiers, and other additives to cleanse parts. The cleaning process can include agitation, rotation, or jet spraying, and these systems are either basic, acidic, or neutral.

- Automatic parts washers

- These systems are fully controlled by computers, automating the cleaning process for large-scale operations.

- Critical Cleaning

- This cleaning process meets extremely stringent standards, ensuring that parts are free from contaminants that could interfere with later processes. The equipment is designed to meet high cleanliness requirements.

- Gross Cleaning

- The most common form of cleaning used in industrial applications, gross cleaning involves the bulk cleaning of products to remove major contaminants.

- Industrial Washers

- Machines specifically designed for cleaning industrial parts, commonly used in manufacturing and production environments.

- Parts Cleaners

- Machines designed to clean components after they come off the production line to ensure they are contaminant-free before moving to the next stage.

- Parts Washers

- Large-scale machines that are used to clean heavy industrial components, especially in high-volume operations.

- Parts Cleaning Equipment

- All machinery and tools used in a parts washing system, including washers, filters, and dryers.

- Parts Cleaning Systems

- Machines and systems used to wash parts on an industrial scale, ideal for large factories and plants.

- Parts Washing Machinery

- The collective term for all machines used in the cleaning of industrial parts.

- Precision Cleaning

- This cleaning process ensures that parts meet strict cleanliness standards, with no contaminants remaining at a specified level for the next production stage.

- Ultrasonic Cleaning

- A cleaning method that uses ultrasonic waves to create bubbles in a solvent. The bubbles collapse in high-pressure areas, transferring energy that dislodges contaminants from the surface of the part.

Parts Washer Terms

- Abrasive Media

- A substance used for aggressive cleaning, commonly consisting of materials such as sand, garnet, steel, or aluminum oxide.

- Acid

- An aqueous solution with a pH less than seven on a 1 to 14 scale. Acids with a pH below three are considered strongly acidic.

- Acid Cleaning

- The use of acids combined with surfactants to remove rust, metal, or scale. Acids with a pH lower than six are not effective as degreasers.

- Acid Pickling

- The use of mineral acids to remove scale and rust from metal surfaces.

- Knife

- A device that generates a pressurized “curtain” of air to cleanse, cool, or dry surfaces.

- Alkaline Cleaning

- An aqueous cleaning process utilizing a pH level greater than 7, using phosphates, silicates, or other alkaline salts combined with surfactants in water.

- Biodegradable

- Materials that can be naturally broken down by microorganisms into simpler chemical compounds.

- Bioremediation

- A natural cleaning process using microorganisms such as bacteria, enzymes, and fungi to break down organic compounds in waste or pollutants.

- Blow-Off

- The use of pressurized air to clean or remove excess water from a surface.

- Buffers

- Solutions of salts in aqueous cleaning systems that maintain a stable pH level. Buffers are important because the precipitation and solubility of metals affect the pH level of the solution.

- Builders

- Additives that enhance the effectiveness of detergents by sequestering metals like magnesium and calcium. However, many builders contribute to environmental damage, especially those containing phosphates.

- Cascade Rinse

- A rinsing process where the product moves through a sequence of tanks, with the rinse water from the last tank flowing into the previous tanks. This countercurrent flow results in the product being cleaned with progressively purer water.

- Centrifugal Drying

- A drying process where a spinning basket separates excess oils, water, or other substances from parts. A turbine fan beneath the basket helps improve the drying process.

- Closed-Loop System

- A cleaning system where water is purified and re-circulated through the system after treatment. This system is cost-effective as it reduces the need for fresh water by using filtration methods like reverse osmosis or ion exchange.

- Conductivity

- The measure of an aqueous mixture’s ability to conduct electricity, indicating the purity of the water. Lower conductivity corresponds to higher resistance and greater purity.

- Contract Cleaning

- Outsourcing cleaning tasks to companies specializing in cleaning industrial parts and components. These companies provide services such as aqueous cleaning, solvent cleaning, and analytical testing.

- Convection Oven Drying

- A drying method where water is evaporated from components using heated air within a chamber.

- Corrosion Inhibitor

- A substance used to slow or prevent the chemical reaction that causes rust.

- Cosolvent System

- A cleaning process that uses a combination of two solvents to clean and rinse parts. The solvents work together based on their characteristics to address specific contaminants.

- Degreaser

- A solvent or material used to remove grease, oils, or fats from substrates.

- Deionized (DI) Water

- Water that has been purified by removing ionic species, resulting in enhanced purity.

- Detergent

- A solution composed of surfactants that make grease and oil water-soluble, aiding in the cleaning process by emulsifying soil with water.

- Diphase Solvents

- Solvent cleaners that have an insoluble aqueous layer. Typically used with paint strippers, they combine with denser chlorinated solvents to form two layers, with water being the upper layer.

- Dispersing Agent

- A substance that enhances the stability of particles suspended in a liquid-solid or liquid-liquid suspension, also known as an emulsifying agent.

- Emulsification

- The process of dispersing liquid or solid globules into a bulk liquid, creating micelles that help clean surfaces.

- Eductor

- A device that circulates large amounts of solution within tanks.

- Filtration

- The process of cleaning the cleaning solution and removing contaminants so it can be reused, ensuring the parts do not retain soil or particulates.

- Hydrophilic

- Describes a surfactant molecule that is water-soluble and tends to interact with water.

- Hydrophobic

- Refers to substances that are resistant to water.

- Immersion

- A cleaning method in which parts are submerged in an aqueous solution, allowing the solvent to work by soaking.

- Inhibitors

- Additives that prevent harmful chemical reactions between an aqueous cleaner and the substrate, often used to retard corrosion in non-ferrous substrates.

- Liquid Agitation

- The use of mechanical energy to circulate the cleaning solution through a system, aiding in the removal of contaminants from parts with simple configurations.

- Micelle

- A structure formed when solutions with both hydrophilic and hydrophobic properties trap non-water-soluble oils, aiding in the cleaning process.

- Nozzle Drying

- A drying method where air is directed at specific areas of a component using nozzles to remove water.

- Pressure Drying

- A drying process where forced air enters the passages of a cleaned component to dry it, using clamping to secure the part.

- Rinse Stage

- The process of flooding washed components with clean water or a rinse solution.

- Sequestrant

- A substance that binds to chemicals, preventing unwanted reactions.

- Solubility

- The ability of a substance to dissolve into another substance, usually a solid dissolving in water. The solubility of a substance is typically quantified in grams per liter.

- Solvent

- A liquid that cleans a part by dissolving the contaminants on its surface.

- Sludge

- Heavy contaminants that settle at the bottom of an aqueous cleaning solution.

- Soaking

- The process of immersing components in a cleaning solution, allowing the chemicals to "lift" contaminants from the surfaces.

- Substrate

- Any item or surface being cleaned in an industrial parts washing process.

- Surfactant

- An additive that reduces surface tension between an aqueous cleaning solution and hydrophobic soils, helping loosen and remove contaminants. Detergents are primarily composed of surfactants.

- Terpenes

- Organic compounds found in essential oils, commonly used in semi-aqueous cleaners, derived from natural sources like citrus fruit or pine trees.

- Vacuum Drying

- A drying method that uses a vacuum to evaporate water at relatively low temperatures, making it ideal for heat-sensitive materials.

- Vertical Part Agitation

- An up-and-down motion used to clean components with cavities, allowing the cleaning solution to remove contaminants effectively.

- Wastewater

- Soiled water produced from the cleaning process, typically requiring treatment before disposal.