Permanent Mold Castings

Discover the world of permanent mold casting in detail on this page, including:

-

Key characteristics that set permanent mold castings apart.

-

An overview of the permanent mold casting process.

-

Examples of products created with permanent mold casting.

-

Common applications and uses for permanent mold casting.

-

And additional valuable information.

Core Traits of Permanent Mold Castings

Also called gravity die castings, permanent mold castings refer to a metal casting process that uses strong, reusable molds, typically made from tough metals like steel or iron. Unlike the disposable molds used in sand casting and lost wax casting, permanent molds enable repeated use, making them a more sustainable option for large-scale casting production.

Key features and advantages of permanent mold casting include:

-

Material of Molds: Molds are generally made of metal materials with excellent heat resistance and long service life, such as steel or cast iron, allowing them to withstand repeated exposure to molten metal with minimal degradation.

-

Process: Molten metals—including aluminum, magnesium, and copper alloys—are poured into the mold cavity. The metal fills the mold by gravity alone, as opposed to the external pressure used in die casting processes.

-

Reusability: Permanent molds can be used multiple times, providing a significant benefit in terms of efficient and economical mass production of metal castings.

-

Quality of Castings: Castings produced from permanent molds usually feature a smoother surface finish and more consistent mechanical properties compared to those made with expendable molds. The rapid cooling provided by metal molds leads to finer grain structures and higher strength in the finished parts.

-

Applications: This casting method is widely used for components that require improved strength, ductility, and surface quality over those made by sand casting. It is commonly utilized in automotive, aerospace, and a range of industrial markets.

The Permanent Mold Casting Process and Advantages

Molds are central to the permanent mold casting process and have a major impact on the dimensional accuracy of the final product. Maintaining precision and following design requirements at each stage is essential for achieving the desired tolerances and quality.

"Permanent mold casting" describes several techniques that all use reusable molds for manufacturing components. Each method involves introducing molten metal into a mold, with variations in how the metal is inserted depending on the casting process and the intended properties.

The main types of permanent mold casting are:

-

Gravity casting

-

Low-pressure casting

-

Vacuum casting

-

Slush casting

Molds are made from durable materials that resist wear, such as iron, steel, bronze, graphite, or copper-based alloys, chosen for their ability to withstand repeated exposure to molten metal. The complexity of the part to be cast may require the mold to be constructed in several sections.

The permanent mold casting process begins with the creation of a pattern for the desired part, which includes gates and sprues to control the flow of molten metal. Most molds are designed in two halves, with the gates and sprues positioned to ensure complete and even filling of the mold cavity.

Each mold serves as an exact negative of the intended casting, reproducing the pattern's design with high accuracy. Using solid materials such as steel or iron reduces the risk of porosity and increases the structural integrity of the casting. The thickness of the mold walls also helps distribute stresses more evenly, enhancing the strength of the finished cast part.

Once built, a permanent mold can be used for thousands of cycles, with its lifespan depending on factors like temperature, the mold material, and the type of molten metal being cast.

Permanent mold castings offer several benefits over traditional casting processes:

-

They have the lowest shrinkage rates among casting methods.

-

They deliver a high-quality surface finish.

-

They help minimize waste and reduce scrap material.

Types of Permanent Mold Castings

The four main types include gravity casting, slush casting, low-pressure casting, and vacuum casting. Each method introduces molten metal into the mold differently. Below are detailed descriptions of each casting method.

All permanent mold casting types share common features: the use of a reusable two-part mold, pouring molten metal into the cavity, and relying on the long-lasting nature of the mold. These fundamentals provide the basis for specialized casting techniques.

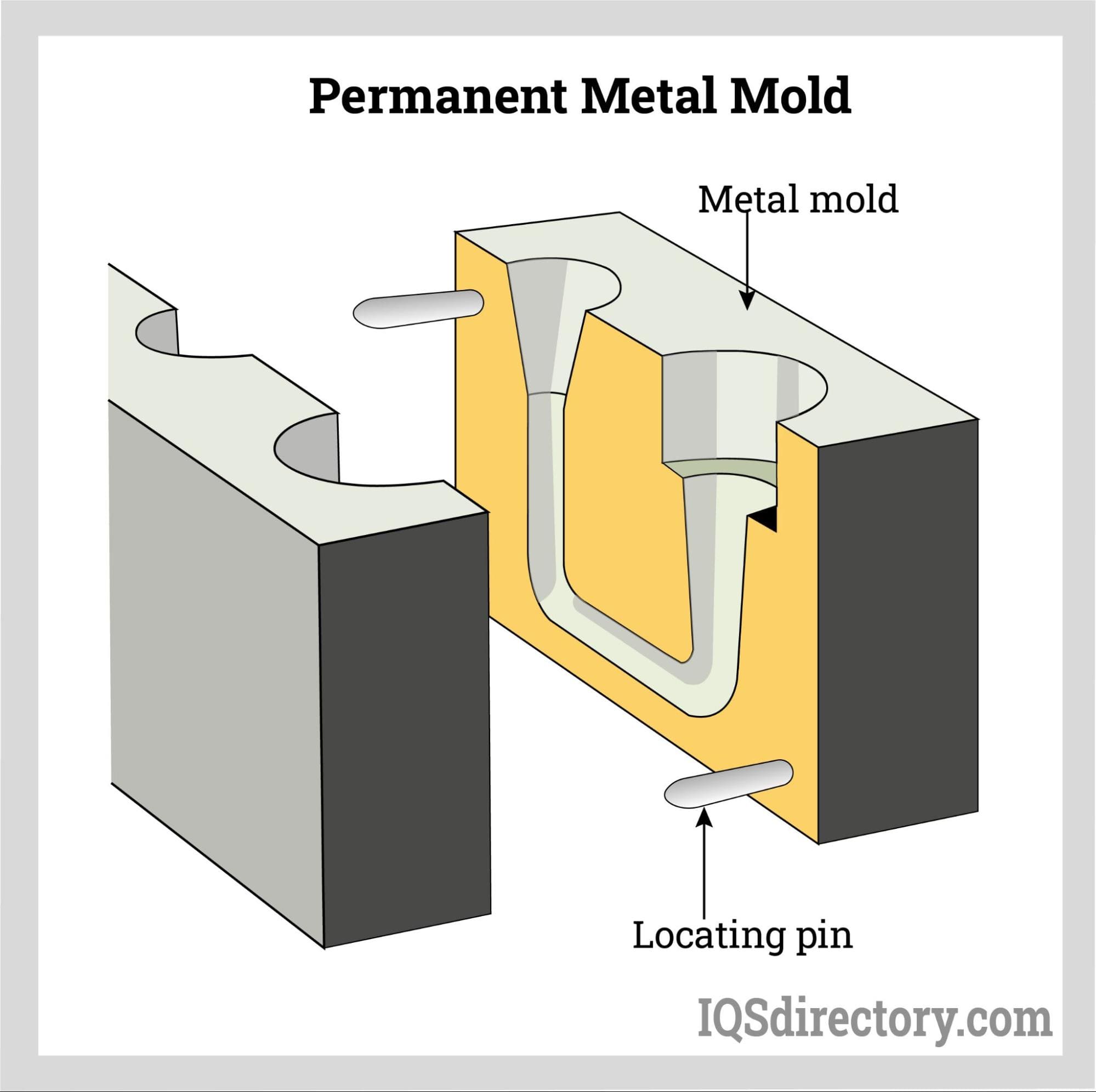

An essential aspect of mold construction is the use of guide, alignment, or locating pins. These pins ensure precise joining of the mold halves, with one side featuring pins that fit into holes on the other. Proper alignment is vital for achieving required tolerances in finished castings, which is the primary purpose of these pins.

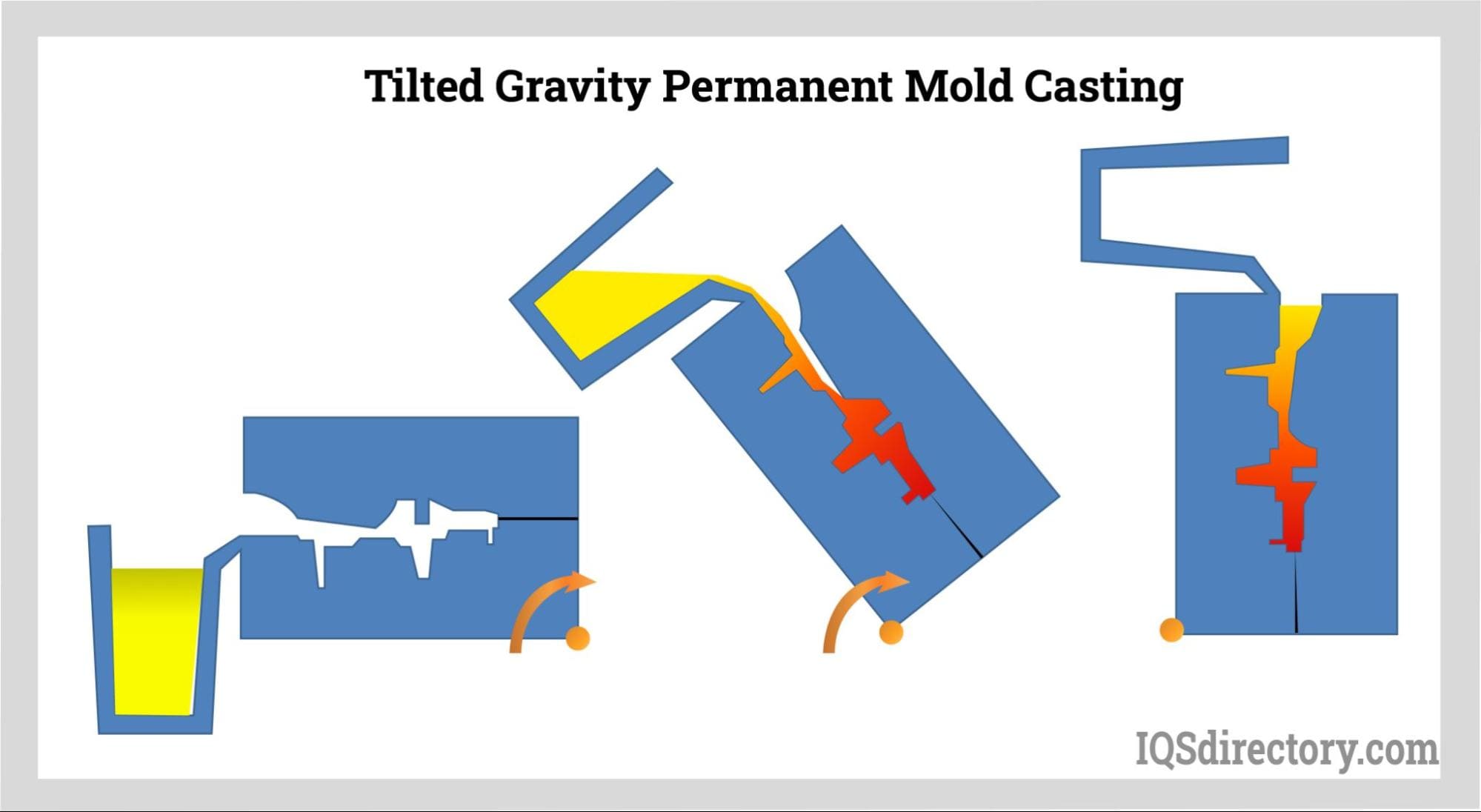

Gravity Casting

Gravity casting with permanent molds is the most widely used form of permanent mold casting. As the name suggests, molten metal enters the mold by gravity alone. The metal is poured straight into the mold or as the mold is gradually tilted.

This technique ensures the mold cavity is filled properly by channeling the molten metal through a system of gates and sprues to the main cavity.

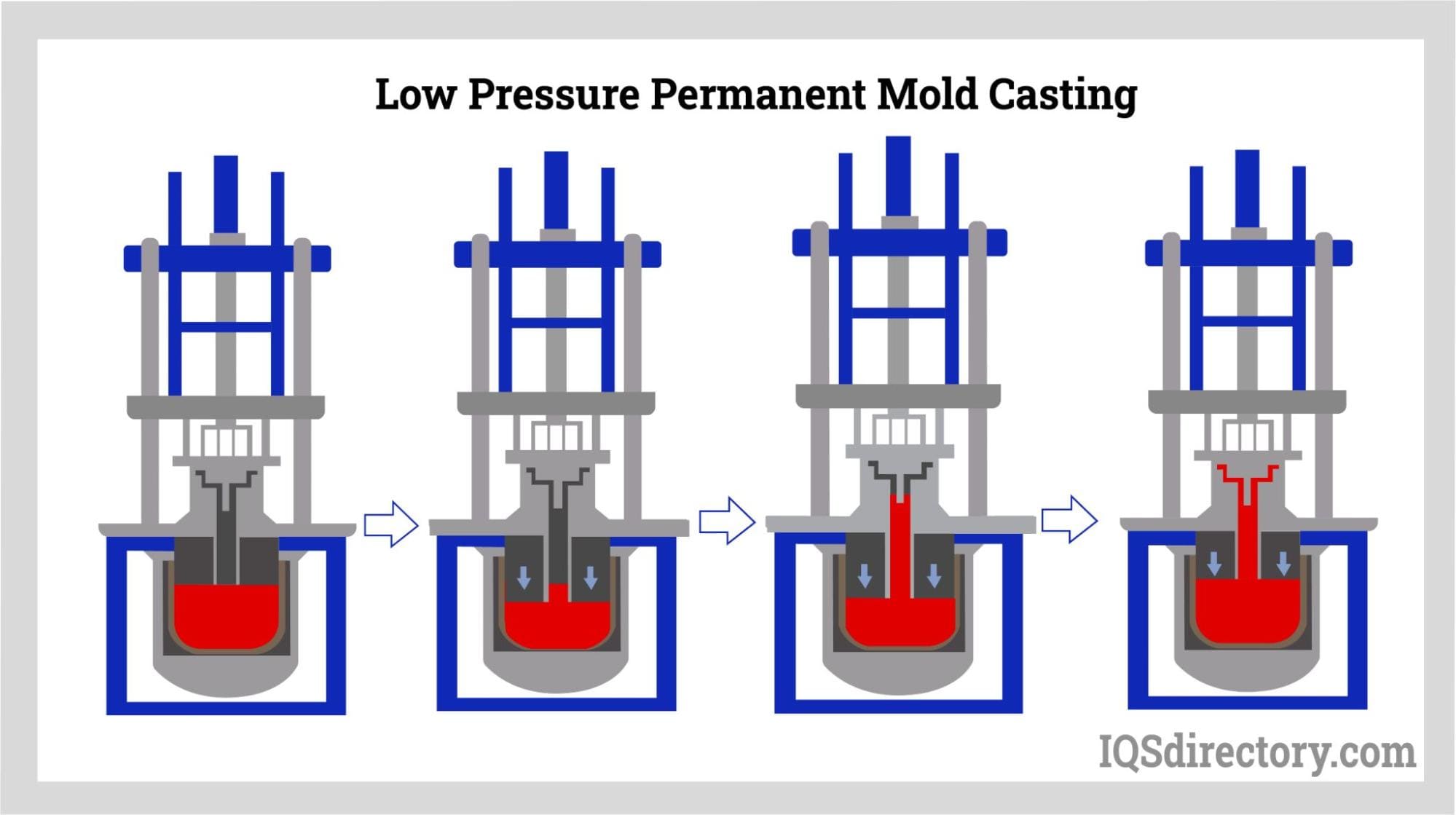

Low-pressure Casting

Low pressure permanent mold casting uses a controlled pressure, typically between 3 and 15 psi, to push molten metal from a reservoir up into the mold. Unlike gravity casting, the metal is forced upward through risers, allowing for more uniform filling of the mold cavity.

The applied pressure is held steady until the metal solidifies, after which it is released so excess molten metal returns to the reservoir. Careful control of pressure helps achieve uniform filling, reduces porosity and oxide defects, and produces dense, strong, and dimensionally stable castings.

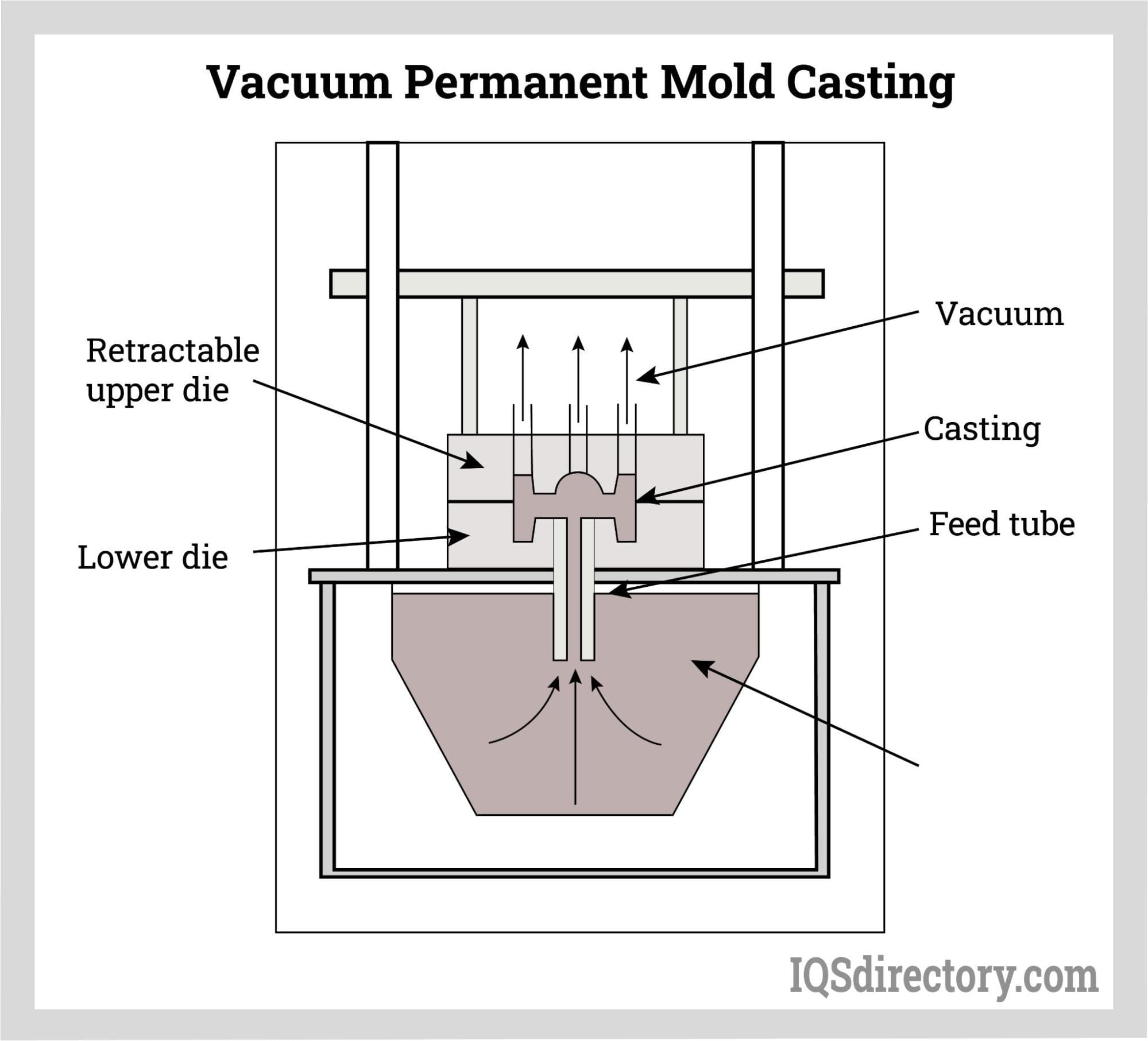

Vacuum Casting

Vacuum casting is similar to low-pressure casting, with the molten metal reservoir below the mold, connected via risers and gates. The mold is often handled by a robotic arm for precise movement. By reducing the pressure inside the mold, the molten metal is drawn upward to fill the cavity.

This method limits gas defects in the finished piece by extracting air during casting.

Once the metal solidifies, the mold separates from the reservoir and the casting is removed. Vacuum permanent mold casting is valued for its accuracy, surface finish, and superior mechanical properties, making it ideal for thin-walled castings.

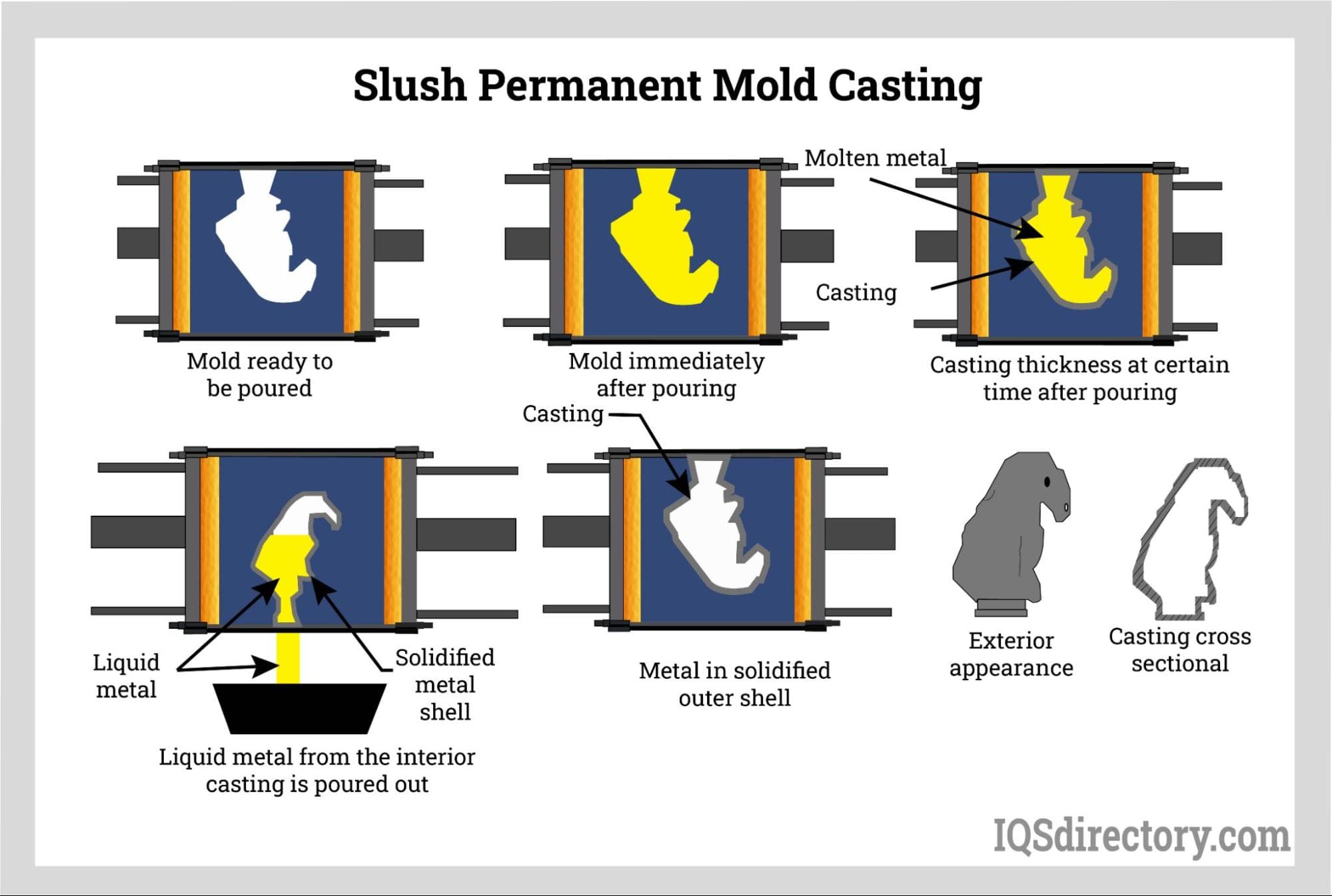

Slush Casting

Slush permanent mold casting is used for producing hollow castings. While following the typical steps of permanent mold casting, such as heating and clamping the mold and pouring in molten metal, it allows for less geometric and structural precision.

In this process, the outer surface solidifies first against the mold walls. Once a shell is formed, the remaining liquid metal is drained out, leaving a hollow product. The duration the metal remains in the mold determines the wall thickness of the finished casting.

Conclusion

Permanent mold casting includes a wide range of processes, each with its own advantages and applications. From basic gravity casting to highly precise vacuum casting, these techniques highlight the adaptability and efficiency of permanent mold casting for modern manufacturing.

Because it produces durable, high-quality castings with excellent surface finishes and tight tolerances, permanent mold casting is favored in industries like automotive, aerospace, and many others.

If you want to learn more about the benefits of permanent mold casting for your application or are seeking reliable permanent mold casting manufacturers, contact our leading suppliers for more information.