Plastic Tanks

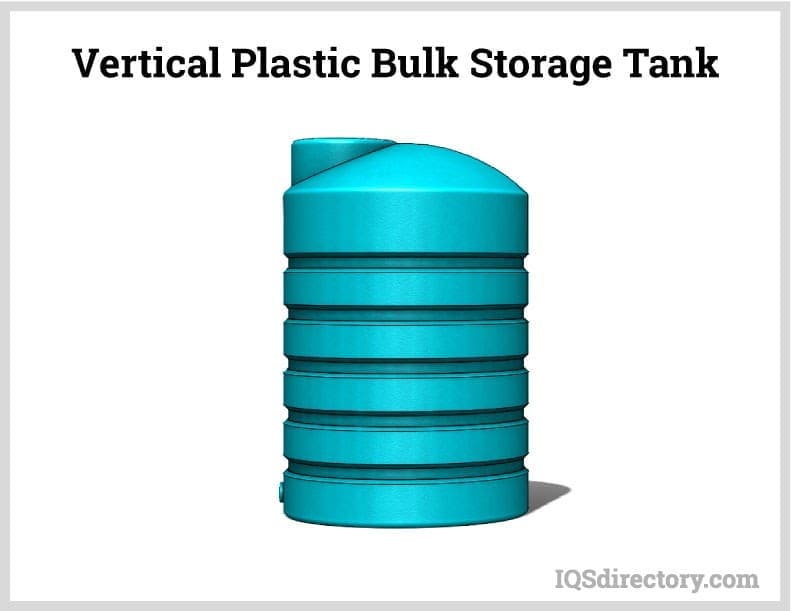

Plastic tanks, also known as poly tanks, are versatile storage containers designed for bulk storage of a wide range of industrial liquids and substances. These tanks come in various sizes and configurations, including vertical or horizontal orientations and rectangular, circular, or square shapes. They are capable of storing volumes ranging from as little as 15 gallons to as large as 20,000 gallons, making them suitable for both small-scale and large-scale industrial applications.

Plastic tanks are widely preferred due to their high chemical resistance, ensuring they do not react with the stored liquids. Many bulk storage tanks are equipped with slots for secure tie-downs, while others feature centered and offset self-vented, slosh-proof lids, enhancing safety and ease of use in demanding industrial environments.

Plastic Tanks FAQ

What sizes do plastic tanks come in?

Plastic tanks range from small 15-gallon containers to large 20,000-gallon storage units. They are available in vertical, horizontal, rectangular, circular, and square designs for both residential and industrial use.

What are common applications for plastic tanks?

Plastic tanks are widely used in chemical storage, water treatment, sewage systems, fertilizer and feed storage, car washes, oil collection, and petroleum or gas storage in industrial and agricultural facilities.

Why is HDPE popular for plastic tanks?

High-density polyethylene (HDPE) is durable, UV-treated, FDA-approved, and resistant to most chemicals. It offers long service life—up to 25 years—making it the preferred material for water, chemical, and agricultural tank applications.

How are plastic tanks manufactured?

Most plastic tanks are made using rotational molding. Plastic powder is heated in a rotating mold, coating the interior to form a seamless, durable tank. The thickness and strength depend on the amount of material used.

What accessories are used with plastic tanks?

Plastic tanks may include fittings like valves, hoses, vents, float valves, rainwater adapters, pumps, tie-down kits, and gauges. These accessories improve handling, installation, and monitoring of stored materials.

What are the installation requirements for plastic tanks?

Plastic tanks should be placed on flat, stable surfaces such as concrete or compacted bases. Proper support, secure fittings, and correct pipe sizing are essential for safe installation and long-term performance.

How long do plastic tanks last?

With proper installation and care, plastic tanks can last decades. UV-treated HDPE tanks typically provide up to 25 years of service, depending on environmental exposure and the type of stored material.

Applications of Plastic Tanks

Plastic Tank Applications

Plastic tanks serve a wide range of industries, offering reliable storage solutions for various substances. Some, like chemical tanks, are specifically designed to process or store highly reactive materials, including acids used in large-scale industrial chemical applications. However, their use extends far beyond the chemical industry, benefiting sectors where stainless steel or other material tanks may not be suitable.

Other Applications Include:

Plastic tanks are commonly used in water treatment and storage, sewage treatment and disposal, liquid fertilizer storage, and liquid feed for agricultural applications. They are also essential in reverse osmosis systems, car wash operations, waste and vegetable oil storage, and even in the petroleum and gas industries for gas tanks.

History of Plastic Tanks

Water Tank Applications

Water tanks used in manufacturing industries often feature translucent tank walls for easy level viewing and sidewall gallon indicators. These tanks are commonly used in electroplating, parts washing, and recycling plants, where durability and chemical resistance are essential.

Evolution of Plastic Tanks

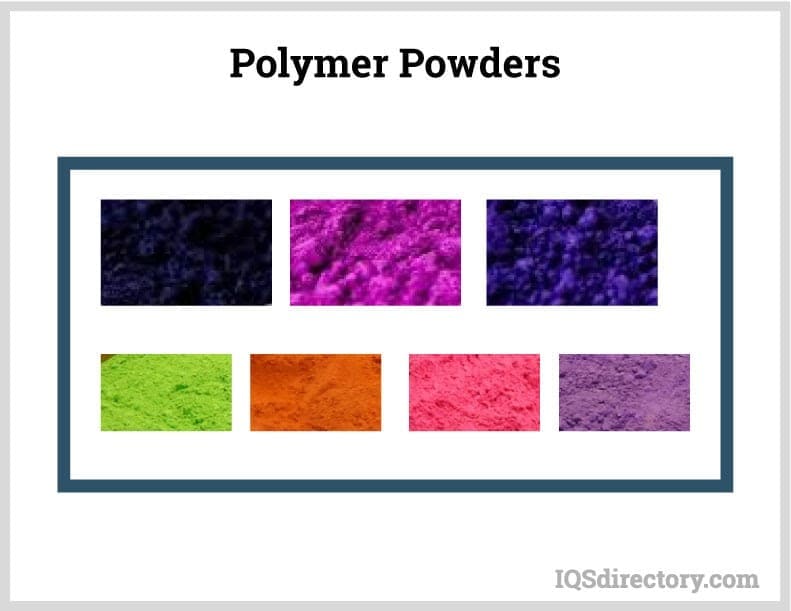

The plastic tank industry has undergone significant advancements over time. Modern rotational plastic molding techniques emerged in the 1960s, allowing manufacturers to produce large, hollow containers using low-density polyethylene (LDPE). As technology improved, better equipment and refined plastic powders were developed, making production faster and more efficient. These advancements fueled the rapid growth of rotational molding and plastic fabrication, leading to the highly durable plastic tanks available today.

Plastic Tank Production and Customization

Plastic tanks are primarily made from UV-treated high-density polyethylene (HDPEspan style="font-size: 11pt; font-family: Arial, sans-serif; color: rgb(0, 0, 0); background-color: transparent; font-variant-numeric: normal; font-variant-east-asian: normal; font-variant-alternates: normal; font-variant-position: normal; font-variant-emoji: normal; vertical-align: baseline; white-space-collapse: preserve;">), an impact-modified, FDA-approved material that ensures safety for home applications like water storage tanks. Other plastic tank materials include polypropylene (PP), polyvinyl chloride (PVC), and polyvinylidene fluoride (PVDF), each offering unique chemical and environmental resistance properties.

HDPE is the most popular plastic tank material due to its durability and resistance to sunlight, lasting up to 25 years. Additionally, poly plastic does not readily react with most substances or chemicals, making it the ideal choice for a wide range of applications.

The rotational molding process begins with a stainless steel mold resembling a large canister, which is filled with plastic powder or granules and sealed. The mold is then rotated over a heating source, melting the plastic evenly. Once cooled, the mold is opened, revealing a fully formed tank. The thickness and durability of the tank depend on the amount of plastic powder or granules used in the mold.

Manufacturers produce plastic tanks in various designs, styles, shapes, and colors, often using computer-generated precision to ensure uniformity and structural strength. The corrugated design is particularly popular for its enhanced durability and reinforcement.

For specialized needs, some manufacturers offer custom plastic tanks, designed to meet specific material and application requirements. These custom tanks can be engineered to blend seamlessly into their surroundings while maintaining the functionality and durability expected from high-quality plastic storage solutions.

Features of Plastic Tanks

Material Compliance and Durability

Polyethylene material meets the standards of various countries and is an FDA-approved food-grade material, making it safe for water storage applications. Additionally, it is UV-treated for enhanced durability, ensuring long-lasting performance in outdoor and above-ground storage. Some HDPE tanks are self-supporting, eliminating the need for additional support structures. Their corrugated and smooth designs make them versatile for a variety of home and industrial storage applications.

Environmental and Industrial Benefits

Plastic tanks are environmentally friendly, non-reactive, and highly recyclable, making them a sustainable choice for water storage, treatment, and liquid gas transport. In manufacturing and industrial chemical applications, plastic tanks can be equipped with specialized fittings to contain acids, highly corrosive substances, or volatile materials. Double-wall tanks provide an added layer of protection in certain industries, preventing leakages during aggressive chemical processes. Additionally, hazardous waste storage is another critical function of these durable plastic storage tanks.

Advantages of Plastic Tanks

Perhaps the most notable advantage of plastic tanks is their lightweight nature, which reduces costs and allows for easy transportation and installation in various spaces. Their handling and setup are quick and efficient, making them a practical choice for numerous applications. Additionally, plastic materials are less likely to react with the substances they store. Many are FDA-approved, making them safe for drinking water and food storage.

Cost-Effectiveness and Durability

Plastic tanks are more affordable than metallic and other alternative tank materials while offering exceptional durability. In many cases, their lifespan rivals or exceeds that of other tank options. They require virtually no maintenance, making them a cost-efficient investment. Available in a variety of sizes, colors, and shapes, plastic tanks can also be designed with double walls for added reinforcement, ensuring increased strength and durability for demanding applications.

Accessories Used with Plastic Tanks

Plastic tanks may not require many accessories, but depending on their industrial use, several fittings and components can enhance their functionality and ensure proper installation. In water storage tanks, valves are essential for controlling flow, while hoses are commonly used for draining or filling the tanks with various materials.

Additional Accessories

Other important accessories include vents, manways or lids, restraints, pumps, siphon tubes, tie-down kits for securing tanks, float valves, rainwater collection adapters, and precision gauges. Each accessory is designed for specific tank applications, ensuring optimal performance. Strainer baskets are also widely used to filter out unwanted substances, maintaining the purity of stored liquids.

How to Install Plastic Tanks

Installation Considerations

The installation of plastic tanks depends on site conditions, platform stability, and whether the tank will be placed above or below ground. Regardless of the setup, it is essential to ensure that the tank is positioned safely and securely, with easy access based on its intended use.

Preparing the Tank Base

Before installation, the tank base or platform must be properly prepared. Many installations require a concrete or compacted material base, particularly for stationary tanks like water storage tanks and industrial gas tanks. When handling the tank, always use appropriate tools and safety precautions to prevent distortion or damage.

Installation Process

Tanks come with manufacturer instructions detailing installation, mounting procedures, and necessary fittings. If the process seems complex, professional installation services are available to ensure proper setup. It is also crucial to consult the manufacturer regarding installation details, especially when installing above-ground tanks designed for burial or vice versa.

Final Steps

Once the tank is positioned, all screws and fittings should be securely tightened. The platform should be continually supported, and bulkhead drains checked for security. If necessary, tanks should be connected with properly sized pipes, following the manufacturer's specifications. Additionally, access caps should be fitted with breather valves when required to maintain proper airflow and pressure regulation.

Proper Care of Plastic Tanks

Handling and Support

When transporting, loading, or unloading plastic tanks, always handle them with care and ensure the bottom of the tank is continually supported to prevent damage.

Proper Placement

Tanks should always be placed or installed on flat, stable surfaces capable of withstanding the pressure exerted by the stored liquid or substance.

Environmental Considerations

Install tanks in areas free from falling objects that could damage their walls, especially during stormy weather or high winds.

Temperature Limitations

Avoid storing excessively hot liquids unless the tank is specifically designed for high-temperature resistance. Most plastic tanks can withstand temperatures up to 40 degrees Celsius, unless otherwise stated. Tanks that are laminated or reinforced with additional materials may have a higher temperature threshold, but always check the manufacturer’s specifications before use. Similarly, plastic tanks should be kept away from open flames and heat sources, as they pose a significant fire hazard, especially when storing flammable substances.

Regular Maintenance

Plastic tanks should be cleaned regularly after use to maintain hygiene and performance, particularly inreverse osmosis water filtration systems.

Plastic Tank Standards and Compliance

Standards Compliance

Standards compliance ensures that products are safe, high-quality, and reliable. While some standards are voluntary unless mandated by the government, it is essential to verify that the manufacturer adheres to the required industry regulations. The easiest way to confirm this is by checking whether the manufacturer is certified.

Regulatory Requirements

Most plastic tank standards cover proper usage, installation, and maintenance while also specifying design and material requirements for manufacturing. Additionally, these standards should detail performance expectations and necessary fittings, ensuring that tanks meet industry safety and durability guidelines.

Choosing the Right Plastic Tank Manufacturer

A manufacturer’s specification stating that a tank has double walls for strength, is made from durable plastic, and is infused with fiberglass is not sufficient to guarantee a high-quality product. It is essential to ensure that the manufacturer is certified, has a strong reputation, and provides reliable product support.

Manufacturer Reliability

Look for a manufacturer that offers after-sales services, such as installation, regular inspections, and a solid warranty, as these can enhance the longevity and performance of the tank. Additionally, if you require a custom tank for a specific application, choosing a manufacturer that offers customization options will ensure you get the best fit for your needs.

Plastic Tanks Images, Diagrams and Visual Concepts

Plastic tank, a large capacity liquid or granular storage unit which can be vertical, horizontal, below or above ground, and permanent in place or movable.

Plastic tank, a large capacity liquid or granular storage unit which can be vertical, horizontal, below or above ground, and permanent in place or movable.

Polymer material in powder form into the mold to form the plastic tank.

Polymer material in powder form into the mold to form the plastic tank.

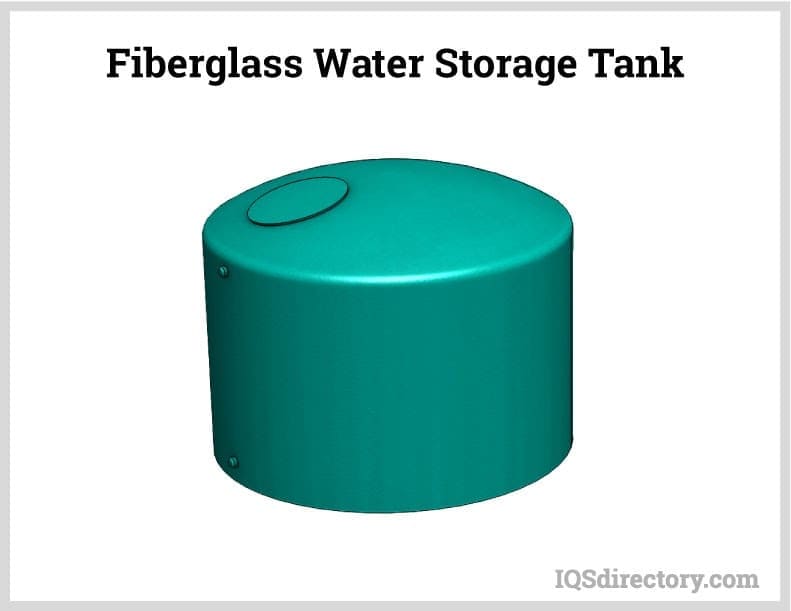

Fiberglass storage tanks are used for underground and above ground storage since they are durable, corrosion resistant, and do not deteriorate.

Fiberglass storage tanks are used for underground and above ground storage since they are durable, corrosion resistant, and do not deteriorate.

An example of a the type of water tanks that is constructed with an inner tank and outer tank to prevent pollution.

An example of a the type of water tanks that is constructed with an inner tank and outer tank to prevent pollution.

Since plastic tanks are flexible, durable, strong,and long lasting which can be used to store or transport a variety of liquids.

Since plastic tanks are flexible, durable, strong,and long lasting which can be used to store or transport a variety of liquids.

Types of Plastic Tanks

-

Chemical Tanks

Made of plastic, these tanks offer superior resistance to harsh chemicals that no other material can match. They are used for chemical processing and storage of highly reactive substances like sulfuric acid. Their fittings and interiors are designed to resist corrosion and chemical reactions, unlike stainless steel tanks.

Clarifiers

Tanks designed for sediment and other precipitate to settle during water treatment processes.

Cone Bottom Tanks

Feature a bottom angled to a point, ensuring complete drainage of liquids or materials inside.

Double Wall Tanks

Provide superior protection against hazardous chemical spills. They feature strong linings for high-pressure applications and offer the best defense against leakage or contamination.

Dual Laminate Tanks

Constructed with a thermoplastic lining bonded to a fiberglass structure for enhanced reinforcement and chemical resistance. Common liner materials include polypropylene, polyvinyl chloride (PVC), and polyvinylidene fluoride (PVDF).

FRP Tanks

Manufactured from resin and glass, these rust-proof, long-lasting tanks are commonly used in industrial and potable water applications when made from FDA-accepted raw materials.

Plastic Fuel Tanks

Designed for the safe storage and transportation of flammable substances. They can also gauge fuel levels, provide venting, and support engine feeding. In specialized applications, they store liquid hydrogen and other gases.

Plastic Oil Tanks

Made from industrial-grade plastics, such as fiberglass-reinforced plastic (FRP) and molded polyethylene, these tanks are ideal for storing, transporting, and holding oil safely.

Plastic Water Tanks

Used for primary or secondary water storage, including drinking water reserves and fire safety systems. As drinking water availability decreases, the demand for these tanks is rising.

Poly Tanks

Known for their durability, corrosion resistance, and low maintenance, poly tanks are more cost-effective than comparable steel or fiberglass tanks. They are widely used in the water treatment and chemical processing industries, storing hazardous fluids such as sodium hypochlorite, sulfuric acid, caustic soda, and hydrochloric acid.

Polyethylene Tanks

A type of poly tank designed for atmospheric, non-pressure storage of various industrial substances.

Polypropylene (PP) Tank

These tanks offer excellent chemical and corrosion resistance, high rigidity, and good structural strength. They can withstand a wide range of temperatures and are easily fabricated using hot air, extrusion, and fusion welding techniques. They are ideal for electroplating applications and steel processing environments.

Septic Tanks

Large plastic tanks used for sewage treatment and waste storage. Commonly found in on-site sewage systems, these tanks are essential in wastewater treatment and disposal industries.

Storage Tanks

Plastic containers designed for industrial storage of various liquids, chemicals, and substances.

Water Tanks

Constructed from food-grade plastic, these tanks store water for home use, industrial applications, and fire suppression systems.

Plastic Tank Terms

-

Additive

A substance added to a polymer to increase effectiveness without enhancing strength. Examples include flame retardants, anti-static compounds, pigments, and lubricants.

Bag Molding

A process in which atmospheric force is applied to a laminate using an elastic or woven material.

Blister

A flaw that forms between laminate layers or between the laminate and the gel coat film of a fiberglass tank.

Blow Molding

The formation of a hollow object, such as a plastic tank, by using air to expand a hollow tube (parison) against the internal walls of a mold.

Casting

A process in which a mold is filled with a mixture of resin, fillers, and/or fibers to create a finished product like a plastic tank.

Contact Molding

A process in which layers of polymer and reinforcement materials are applied to a single or open mold, producing one finished cosmetic side.

Copolymer

A polymer composed of two monomers in which each repeating unit in the chain consists of units of both monomers.

Crazing

Very thin cracks in a polymeric material caused by chemicals or other agents, such as ultraviolet radiation.

Degree of Polymerization

The length of the molecular or monomeric units in a polymer chain, determining the properties of the polymer.

Depolymerization

The breakdown of a polymer into its original monomers or into a polymer of lower molecular weight, often occurring when exposed to chemicals or high temperatures.

Die

A metal piece of equipment through which plastic is forced to provide shape, such as in the creation of plastic tanks.

Extrusion

A plastic shaping process in which plastic is softened by heat and pushed through a die.

Filler

Typically inert organic or inorganic material added to resins, plastics, or gel coats to change properties, increase volume, or reduce production costs.

FRP (Fiber Reinforced Plastic)

Also called GFRP (glass fiber reinforced plastic), GRP (glass reinforced plastic), or RP (reinforced plastic), FRP is a durable, rust-proof material made of glass and resin.

Gel-Coat

A surface coat of colored or clear polyester resin that enhances fiberglass laminate cosmetically and provides weather resistance.

Hand Lay-Up

A process in which fiberglass and resin layers are manually built up using hand rollers, spray equipment, and brushes.

Hot Air or Gas Welding

A process that joins two pieces of plastic by blowing heated air or gas to melt and fuse them together.

Injection Molding

A process where molten plastic is forced under pressure into a mold, then cooled to produce the final product, such as a plastic tank.

Laminant

A composite formed by lamination, a process in which thermoset polymers and fiber reinforcement are layered.

Mold

A hollow, heat-resistant container where liquid substances solidify into specific shapes.

Monomer

The most basic polymeric unit, usually a liquid or gas, consisting of molecules from the same organic substance.

Permeability

The ability of liquids and gases to flow through a substance. Low permeability is advantageous for plastic tank resins.

Plastic

A material whose primary component is an organic substance of large molecular weight, which becomes solid in its final form. Plastics can be shaped by flow at some stage of the manufacturing process.

Plasticizer

A substance added to plastic to increase flexibility and workability.

Polymer

A chain of two or more monomers bonded through a chemical reaction, with repeating units forming the polymer structure.

Potable Water

Water suitable for human consumption, often stored in plastic water tanks.

Regulated Substance

Petroleum or any hazardous substance stored in an industrial tank, as defined by the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA).

Reinforcement

A substance added to a polymer to increase its strength. Examples include clay, mica, and glass fibers.

Resin

A class of polymers, chemically distinct from naturally occurring resins obtained from trees and plants. Examples include polyethylene, polyurethane, and acrylics.

Rotational Molding

Also called rotomolding, this process forms hollow objects like tanks by simultaneously rotating and heating a mold filled with thermoplastic resin powder. The resin evenly coats the mold walls, creating a seamless, cost-effective final product.

Stress Cracking

Cracks that form due to mechanical stress, often initiated by exposure to chemicals or ultraviolet radiation, leading to larger fractures when stress is applied.

Thermoplastic

A category of plastics that softens when heated and hardens upon cooling, without altering its chemical structure.

Thermoset

A category of plastics that cannot be reshaped when reheated, remaining permanently hard.

Underground Storage Tank System

A plastic tank system designed to store regulated substances such as petroleum, with at least 10% of the tank, piping, and associated equipment located underground.