Powder Metal Parts

Powder metal parts are robust components created through powder metallurgy, a process that forms solid metal objects from powdered metals. These durable parts are widely used across multiple sectors, including automotive, hardware, electronics, computers, and lawn and garden equipment. Their versatility and strength make them essential in numerous industrial applications.

Quick Links to Powder Metal Parts Information

The History of Powdered Metal

The sintering process can be traced back to around 3,000 B.C., according to archaeological findings. Many historians attribute the use of powdered gold in jewelry to ancient Incan craftsmen centuries ago. Early production methods were very basic compared to modern standards. Ancient artisans could not precisely control metal melting points or produce steel and stainless steel consistently at high temperatures.

It wasn't until after the Industrial Revolution that powder metallurgy was adopted for mass production with regulated processes. The use of powdered metal in manufacturing gained momentum in the early 20th century, particularly with the rise of electric light bulbs and the development of welding. Eventually, powdered metal coatings became vital to the automotive and aviation sectors. Today, the many benefits of powder metallurgy have fueled ongoing growth and innovation in the industry.

Currently, an umbrella metal powder industry federation represents more than seven distinct industry groups. These organizations include manufacturers dedicated to advancing powder metallurgy standards and products. Members range from companies focused on powder metal part production to those making metal powders and powder metallurgy machinery, performing isostatic pressing, metal injection molding, synthesizing metal additives, and researching refractory metals. The formation of this federation highlights the increasing significance of powder metallurgy and the expanding variety of powdered metal component applications in recent years.

Powder metallurgy offers several key benefits. It enables the production of uniform, consistent components with precise properties. This cost-effective process minimizes raw material waste. Powder metallurgy allows for the creation of intricate shapes with tight tolerances, and automated production further adds to its efficiency and appeal across many industries.

Powder metallurgy has evolved greatly in recent years, offering manufacturers access to a broad selection of materials. Commonly used metals for powdered parts include steel, iron, copper, and aluminum. Powders can be produced in various particle sizes, and the base metal will dictate the method for powder production; not all techniques are suitable for every metal.

The European Powder Metallurgy Association states that the main methods for producing metal powders include chemical reduction, electrodeposition, and atomization. Other processes are also used to generate metal powders. As advancements in nanotechnology continue, new powder manufacturing methods are likely to emerge, further expanding material options for manufacturers.

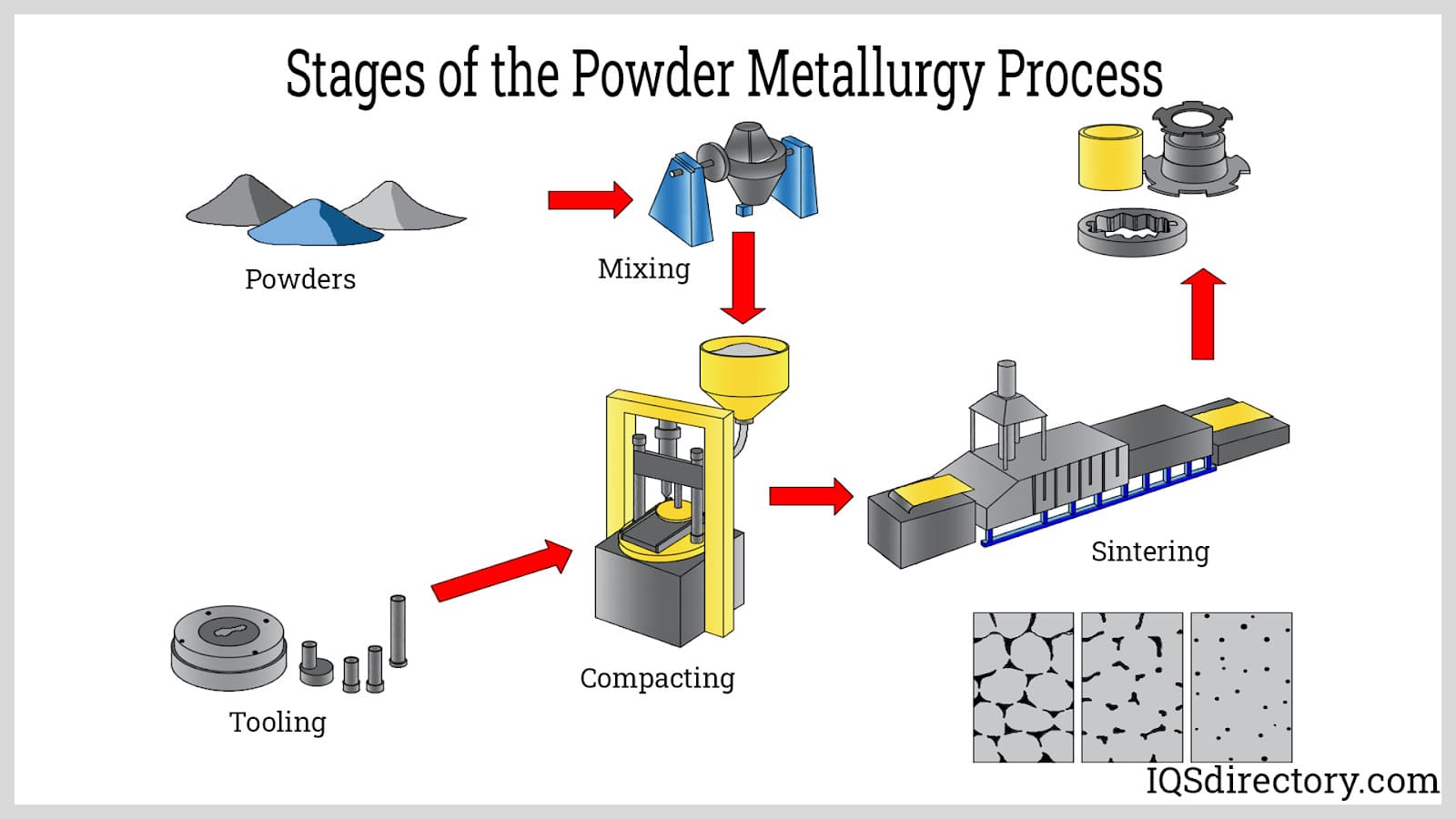

The production of powdered metal parts involves three main steps: preparing the powdered metal mix, compressing the powder into the desired shapes, and sintering to solidify the components:

Phase One: Formulation

Producers can tailor the powder blend for each manufacturing run to achieve specific characteristics. By adjusting the proportions of different metal powders, manufacturers can enhance properties such as strength, ductility, or color. This customization helps ensure the finished part meets required mechanical standards.

Mixing typically involves adding an organic lubricant, such as zinc stearate, stearin, or stearic acid. This lubricant coats the metal particles, aiding compaction and holding particles together before pressing. The lubricant evaporates during heating, allowing the particles to bond during sintering.

Phase Two: Compression

Component shaping is achieved using dies, often made of carbide or steel. The lubricated metal powder is pressed firmly into the die under high pressure, compacting the mix into the desired form. After compaction, the part—called a green part—is ejected and prepared for sintering.

Phase Three: Sintering

The final stage, sintering, is a high-temperature process where green parts are heated below their melting point in a furnace. This bonds the metal particles without changing the shape, boosting strength and controlling porosity. Parts may undergo additional steps such as sizing, deburring, or machining. Although parts appear solid, they have small interconnected pores, making them about 25% porous. Porosity can be sealed with steam treatment, infiltration with a lower melting-point metal, or impregnation with oil or plastic resin for optimal sealing.

Sintered metal parts provide significant advantages over those made by other methods. The process is highly efficient, using about 97% of materials and generating minimal waste. Powder metallurgy enables manufacturers to create complex parts near net shape and within close tolerances, often eliminating the need for secondary operations. This makes it ideal for intricate components with bends, projections, or recesses. Sintered parts can be made from a wide range of alloys and composites, and their controlled porosity is valuable for self-lubrication and for use in filtration applications.

During sintering, metal particles are fused together into a solid form. Automated facilities often use continuous belt furnaces for consistent heat application. Occasionally, vacuum furnaces are used, providing heat without oxidation and achieving higher temperatures for sintered steel production.

Re-Sintering Process

After initial sintering, parts are often re-pressed and then re-sintered. This additional heat treatment further increases hardness. The product may then be finished with plating—such as nickel or copper—for enhanced surface qualities, or undergo resin impregnation to seal micro-pores in liquid-containing parts. Specialized parts may receive vacuum impregnation to improve durability and prevent leakage in metal containers or tubing.

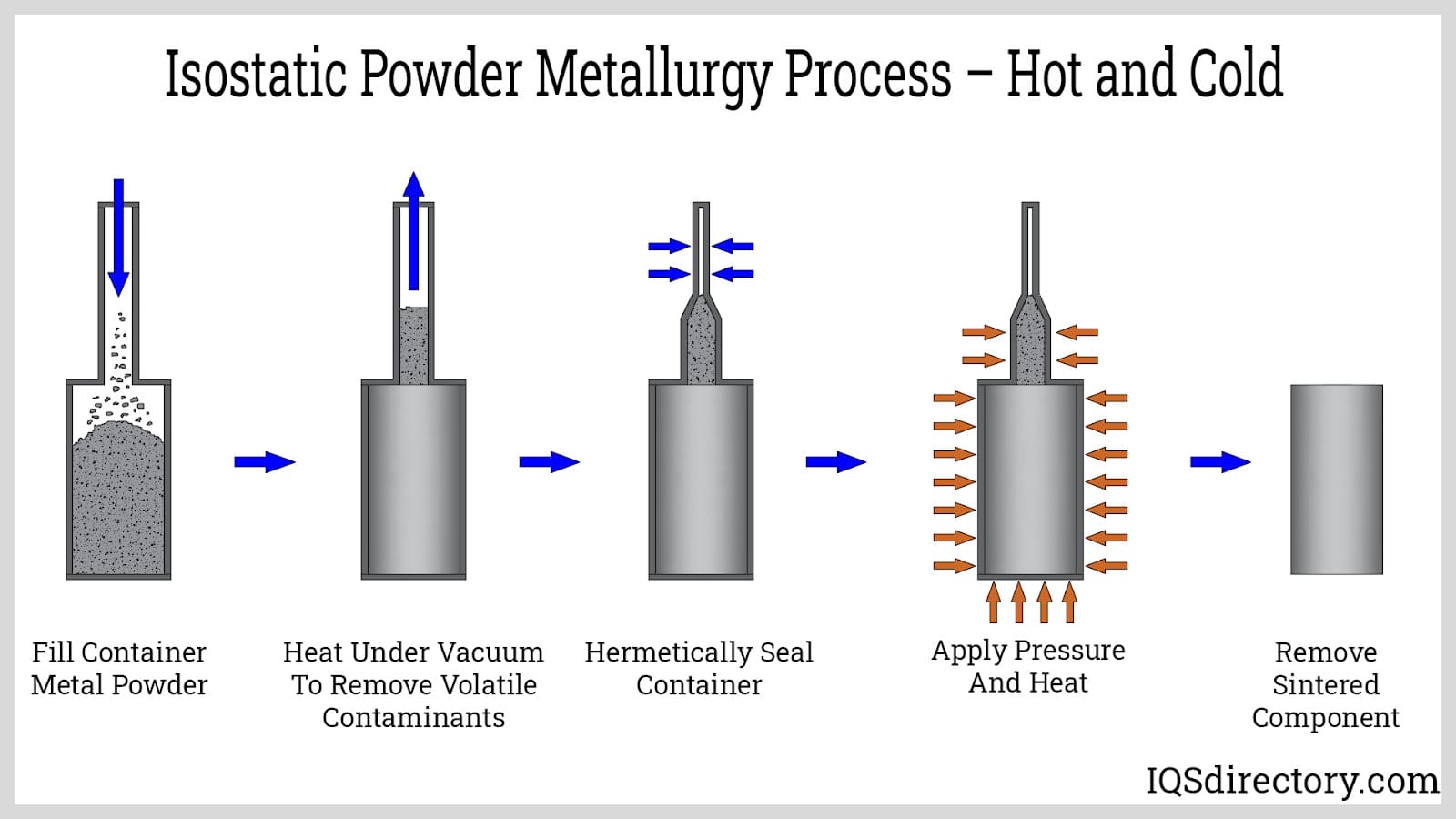

For parts needing extremely tight tolerances, hot isostatic pressing is used to re-press sintered components at high temperatures and pressures instead of re-sintering. Computer modeling helps control part dimensions during this process, increasing component strength. In many automated production systems, hot isostatic pressing is a cost-effective tool for achieving precise results.

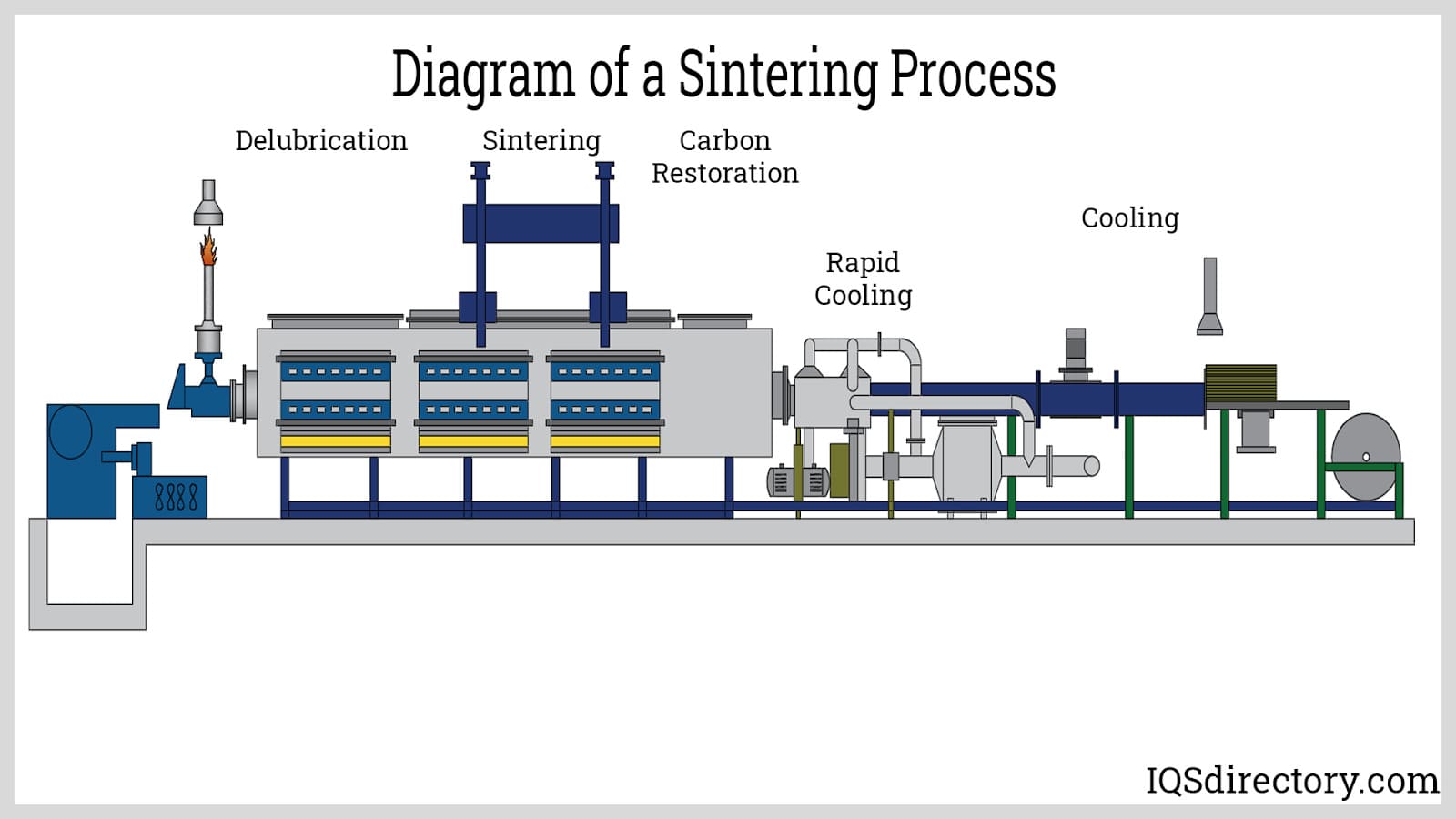

Sintering Process

Powdered metal parts can be manufactured using two main processes: sintering and metal injection molding. Sintered parts, such as sintered bronze and steel, are formed by heating metal powder below its melting point and pressing it into shape. In metal injection molding, polymers or wax are combined with powdered metal, heated until pliable, and then molded. Both methods are commonly used to manufacture aluminum, copper, and iron powder parts.

Powder metallurgy transforms metal powder into finished components using methods like pulverization, chemical reduction, electrolytic techniques, mechanical alloying, or most commonly, atomization. The powder is blended with a lubricant to reduce friction during pressing. The raw material is then compacted or molded into shape before further processing.

Metal Injection Molding

Metal injection molding (MIM) is used to produce smaller, highly complex, dense, and high-performance parts. This process merges plastic injection molding with powder metallurgy and is common in the automotive, medical, dental, firearms, hardware, computer, and electronics industries. MIM allows for intricate designs, reduces assembly costs and waste, and results in denser, stronger, and more corrosion-resistant components. However, it is best suited for small, thin parts and typically has higher tooling costs than conventional powder metallurgy. In MIM, metal powder is mixed with thermoplastics and lubricants, shaped through injection molding, and then the thermoplastics are removed by debinding. The parts are then sintered and may undergo additional finishing operations.

Powder metallurgy is a process that creates precise parts by compressing powdered metals and alloys in a die under high pressure.

Powder metallurgy is a process that creates precise parts by compressing powdered metals and alloys in a die under high pressure.

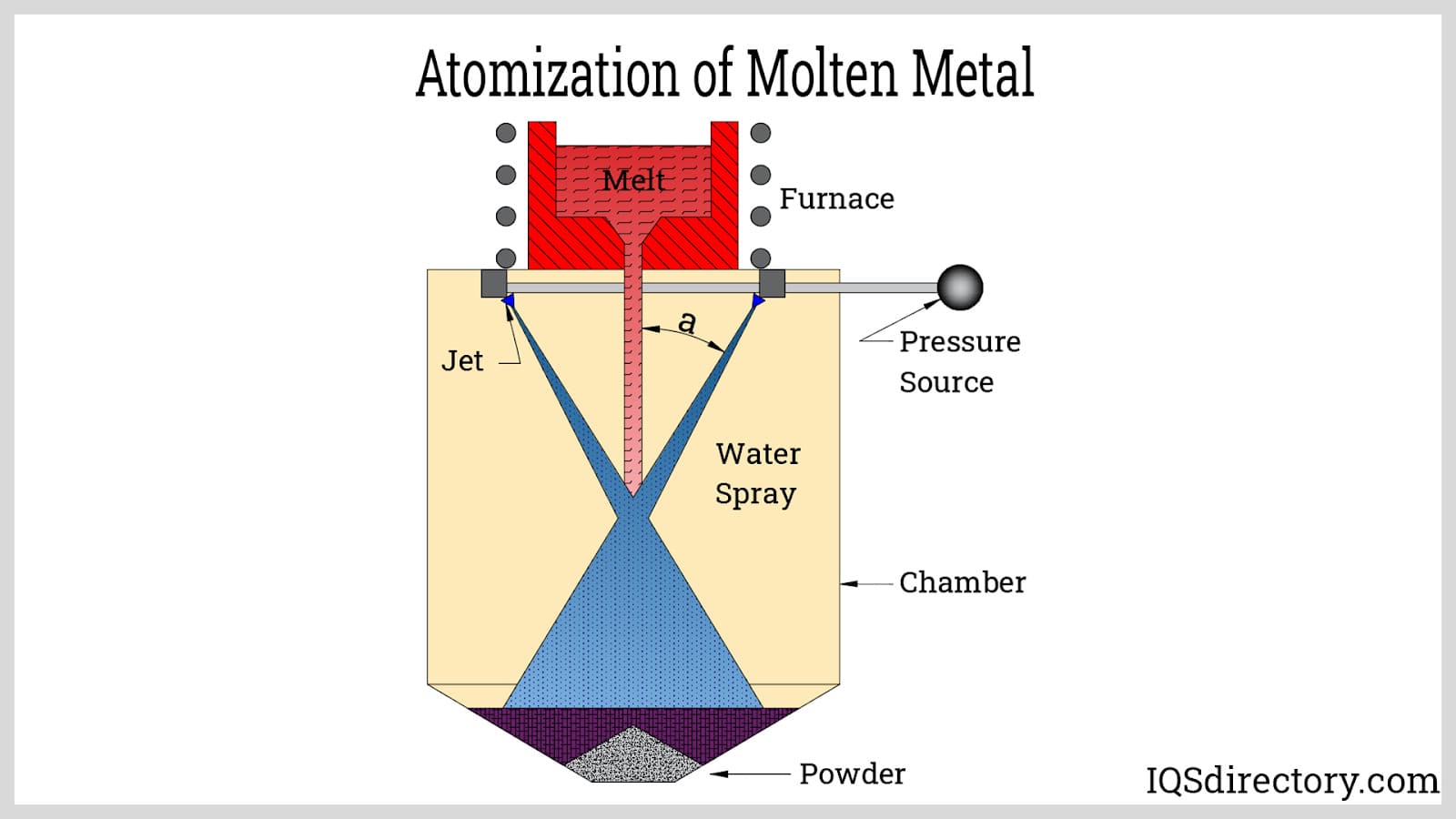

Atomization involves using a powerful water flow to break molten metal into fine particles.

Atomization involves using a powerful water flow to break molten metal into fine particles.

Isostatic pressing applies uniform pressure to all surfaces of the workpiece for consistent compaction.

Isostatic pressing applies uniform pressure to all surfaces of the workpiece for consistent compaction.

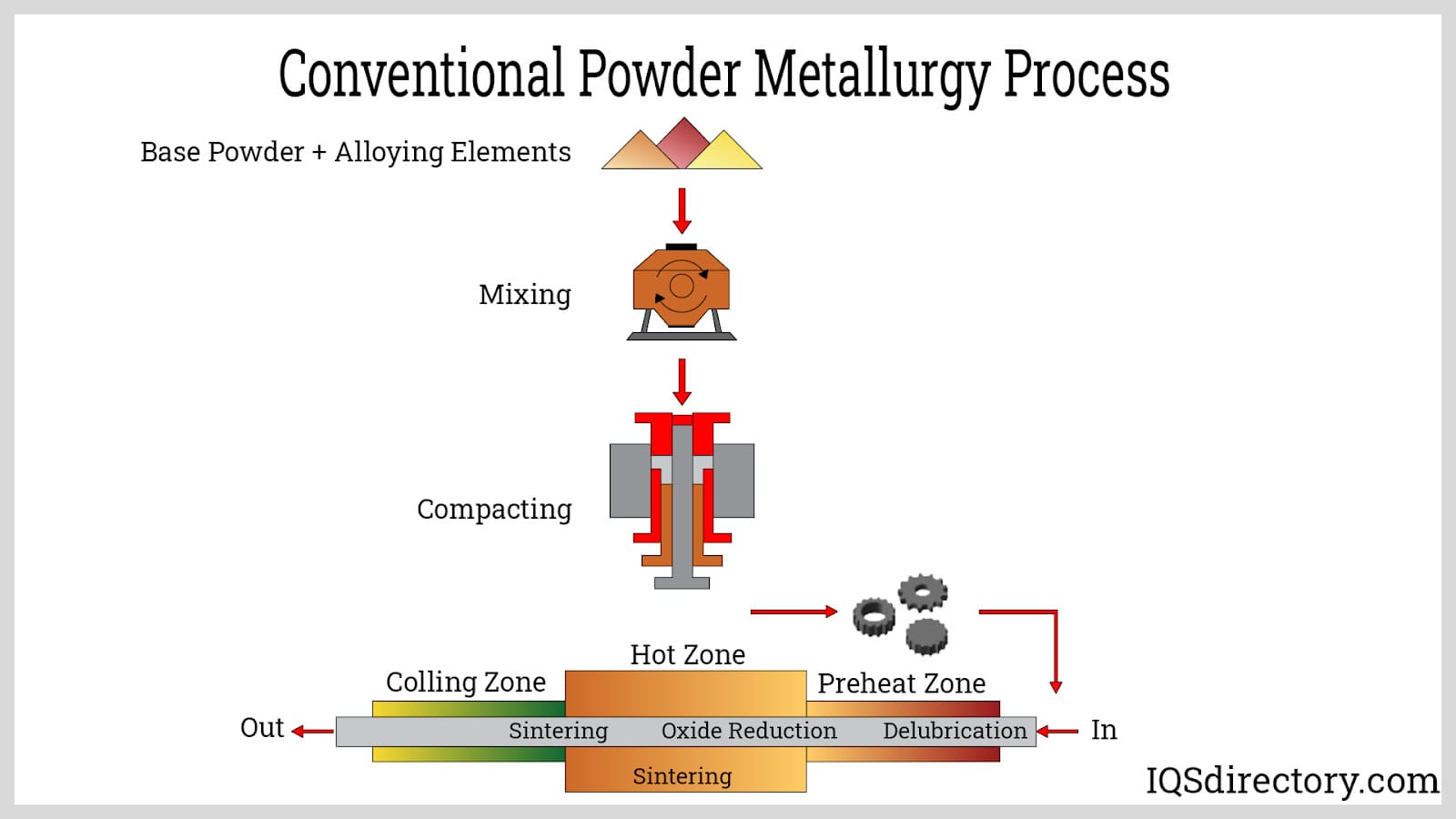

Conventional powder metallurgy includes mixing powders and alloys, compacting, and then sintering to create finished parts.

Conventional powder metallurgy includes mixing powders and alloys, compacting, and then sintering to create finished parts.

The sintering process forms a solid component by bonding powder particles together without melting the entire mass.

The sintering process forms a solid component by bonding powder particles together without melting the entire mass.

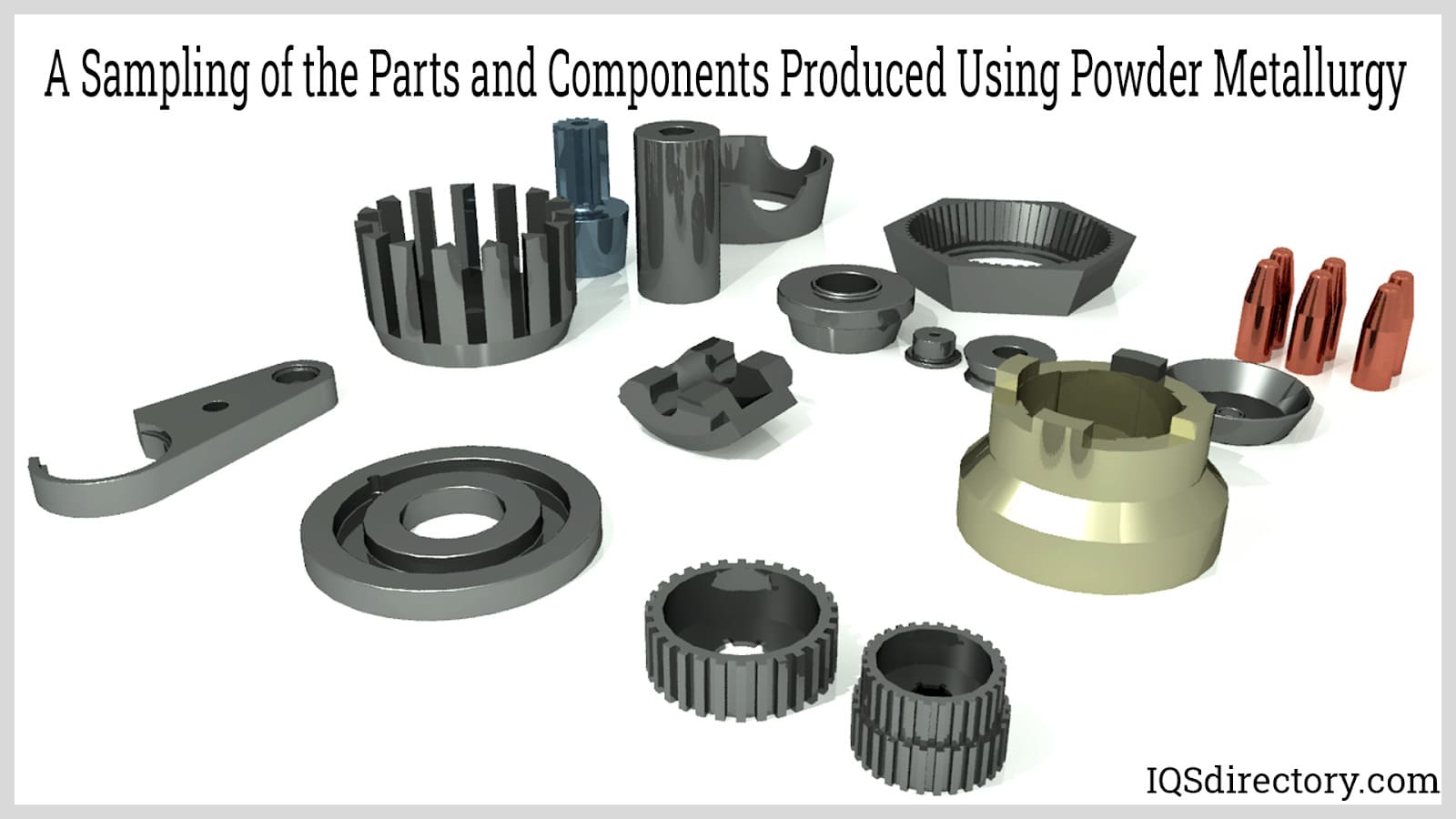

Examples of various parts and components manufactured using powder metallurgy techniques.

Examples of various parts and components manufactured using powder metallurgy techniques.

Numerous metals, such as aluminum, copper, brass, iron, steel, and bronze, can be processed into powder form and used in powder metallurgy to create diverse parts and products.

- Aluminum Powder

- A metal powder derived from aluminum, commonly produced using flaked aluminum for its ductility and lightweight properties. Aluminum is preferred for its conductivity, light weight, and high flammability. It is frequently used in pyrotechnics and high-strength structural applications.

- Bronze Powder

- Utilized to manufacture self-lubricating bearings, bronze powder parts offer higher density and mechanical strength compared to brass.

- Copper Powder Parts

- Made by compacting, consolidating, and heating fine copper flakes. These parts have excellent electrical and thermal conductivity, making them ideal for heat sinks and electrical contactors.

- Iron Powder Parts

- Valued for strength, ductility, and ferromagnetic properties, iron powder is used in structural parts, filters, and bearings. It often includes a graphite additive for enhanced performance.

- Metal Injection Molding

- Also known as "MIM," this process is a cost-effective, high-volume manufacturing technique that combines plastic injection molding with powder metallurgy to create custom metal parts close to final shape.

- Metal Powder

- Produced through powder metallurgy, metal powder can be compacted and formed into solid components using tool and die processes.

- Metal Powder Parts

- Created by compacting, consolidating, and heating various flaked metals—including aluminum, copper, bronze, nickel, brass, steel, stainless steel, and titanium—into solid products.

- Powder Metallurgy

- A method that uses metal powders to manufacture shaped components, resulting in finished or semi-finished products.

- Powdered Metal

- Enables the formation of solid parts from metal powder. Various techniques, including atomization, chemical precipitation, centrifugal disintegration, and hydrogen reduction, are used to create powdered metals.

- Powdered Metal Bearings

- Often self-lubricating, these bearings offer low noise, space efficiency, and minimal maintenance. Oil impregnation enhances performance in supporting rotating parts.

- Powdered Metal Bushings

- Designed to support rotating axles and shafts in engines and machines, powdered metal bushings can be impregnated for improved lubrication and efficiency.

- Powdered Metal Gears

- Mechanical components formed through powder metallurgy to transmit power, change motion or speed, and alter direction between axes.

- Powdered Metal Structural Parts

- Commonly used in automotive exhaust, fuel, and brake systems, as well as in engine and transmission components. Sintered parts are also present in computers and electronic devices.

- Resin Impregnation

- A secondary process where plastic resins are applied to compacted powder metal parts to seal and reduce porosity.

- Steel Powders

- High-strength steel powders, including stainless and tool steels, are used in automotive and weight reduction applications.

- Sintered Bronze Parts

- Produced by heating bronze powder just below its melting point to bond particles and create solid metal objects.

- Sintered Filters

- Provide consistent porosity for enhanced function, strength, easy cleaning, and heat resistance.

- Sintered Metal

- A solid item formed by pressing metal powder into shape through a cold forming process.

- Sintered Metal Parts

- Solid components made by compressing metal powder and heating it just below the melting point. Sintered parts can be produced from various metals, including aluminum, copper, bronze, nickel, brass, steel, stainless steel, and titanium.

- Sintered Steel Parts

- Strong metal components created by carefully heating pressed steel powders to fuse particles together without melting the entire part.

Powder metal technology enables manufacturers to form and shape intricate, complex designs with consistency. This process can be a cost-effective alternative for mass production, especially for components that would otherwise require extensive machining. Powder metallurgy is also increasingly used in CNC machining.

When properly sintered, powder metal parts demonstrate high precision and consistent porosity control. Metallurgists can fine-tune porosity for specific applications, such as manufacturing gears that demand precise net shape. Powder metallurgy generates less waste than many alternative fabrication methods and is ideal for producing high-tolerance parts efficiently.

Powdered metal coatings are often used in finishing to achieve certain functional or aesthetic properties, such as improved corrosion resistance or specific textures. The flexibility of powder coatings has fueled market expansion, with Europe alone reporting annual sales exceeding six billion Euros in the powder metal sector.

Powder metal parts are commonly found in automotive components, structural assemblies, filtration devices, and magnetic systems. Powdered metal gears are especially suited for sintering because their porosity naturally reduces noise. Bushings and bearings are easily produced, although achieving tight tolerances may require secondary sizing. Magnetic parts benefit from powder metallurgy, as the process allows for shapes that are difficult to achieve with traditional forming, while proper sintering enhances magnetic properties.

Powder metallurgy is also used to manufacture diamond and tungsten carbide grinding blades for gemstone faceting. These hard materials, embedded in metal blades, are essential for cutting tough stones like corundum. Many industrial saws now rely on powder metal blades for cutting and grinding.

Another widespread application is in finishing iron or stainless steel parts with coatings that boost corrosion resistance. Powder metal coatings extend the lifespan of parts exposed to friction or harsh environments, such as drills or arctic equipment. Many proprietary coatings are designed to meet specific industry needs.

A major benefit of powder metal manufacturing is the ability to automate production, reducing the need for costly machining during finishing. Most modern CNC metal injection and molding machines use computerized controls for greater efficiency. The specific machinery used depends on the manufacturer’s chosen production process.

Specialized metal injection machinery has been developed for various applications. Powder metallurgy now supports the manufacture of items ranging from fine jewelry and automotive gears to surgical instruments. Many industries rely on dedicated machines for high-volume powder metal part production.

The ideal powder metal manufacturer meets your project requirements. Sometimes a specialized company is preferable to a larger provider. Evaluate your needs carefully and use our directory to find reliable powder metal manufacturers and suppliers that best fit your goals.

Various methods are used to produce powder metal products, with specifications often influencing the chosen process. In addition to the standard three-step powder metal manufacturing, important variations include metal injection molding, powder forging, and spray deposition.

Metal Injection Molding, similar to plastic injection molding, enables the production of highly complex shapes in large quantities. Temporary binders are used to hold the powdered metal together before sintering, and are removed by heating or solvents after ejection from the die.

Powder forging uses intense pressure to compact powder into a die, followed by heating. Powder spraying involves spraying atomized molten metal onto a preformed shape, a technique useful for creating cladded surfaces and other specialized products.

- Acicular Powder

- Powder made up of needle-like particles.

- Activated Sintering

- A sintering process that is significantly accelerated by factors other than temperature or time, such as adding a constituent, thermal cycling, or adjusting the atmosphere.

- Air Classification

- A technique using controlled air streams to sort powder into different particle size ranges.

- Atomization

- The process of creating metal powder by breaking up molten metal into particles using mechanical means or fast-moving streams of liquids or gases.

- Binder

- A medium added to powder to increase "green" strength for compaction, expelled during sintering. It can also refer to a low-melting material that helps powders bond when they wouldn't otherwise sinter strongly.

- Blank

- An unfinished compact that has been pressed, pre-sintered, or fully sintered, but still needs further processing like cutting or machining.

- Cold Pressing

- Forming a metal compact by compressing metal powder at room temperature.

- Comminution

- The process of reducing metal to particles via grinding, flaking, or similar methods.

- Compact

- A solid formed by pressing metal powder into a die.

- Composite Powder

- A compact made from more than one distinct material.

- Die

- A tool with a shaped cavity used to press metal powder into the desired part form.

- Exudation

- Also called "sweating," refers to a component rising to the surface of a compact during sintering when it has a lower melting point than the main material.

- Green

- Describes an object that has not yet been sintered.

- Growth

- An increase in compact size during sintering.

- Impregnation

- A post-sintering process where nonmetallic substances, like oil, fill the pores of a compact.

- Infiltration

- A process, before or after sintering, where the compact's pores are filled with a metal of lower melting point than the compact itself.

- Isostatic Pressing

- Compacting metal powder by applying uniform pressure from all directions.

- Lubricant

- A fluid added to punches, dies, or the powder itself to aid compaction and facilitate removal from the die.

- Molding

- Another term for pressing metal powder into a compacted shape.

- Multiple Pressing

- Making more than one compact at a time by pressing metal powder in separate dies.

- Porosity

- The percentage of open spaces, or pores, in a powdered metal part relative to its overall volume.

- Punch

- The die component that presses metal powder to form a compact, making direct contact during compaction.

- Shrinkage

- A reduction in the size of a compact during sintering.

- Warpage

- Deformations in a compact that occur as a result of sintering.