Power Cords

Power cords, also known as electric cords, serve as the critical link in transferring either direct current (DC) or alternating current (AC) electricity. While power cords can facilitate both types of electrical flow, most are designed as AC power cords, which carry energy in a pattern where the direction of current flow periodically reverses. A power supply cord, or cable assembly, consists of a conductive wire, often made from copper due to its high conductivity, encased in an insulating material and further protected by an outer jacket. This jacket, along with a molded plug cover, ensures safety when connected to an electrical outlet. In North America, power cords follow the standards set by the National Electrical Manufacturers Association (NEMA), which define electrical plug designs, voltage ratings, and receptacle configurations. Outside of North America, international power cords and plug adapters enable electrical appliances to function in regions different from where they were originally manufactured. Electrical cord sets are fundamental to any environment requiring electrical energy for operation, from office spaces and industrial plants to medical facilities and commercial appliances. When equipment must function in areas without direct access to a power source, such as construction sites, entertainment venues, emergency response situations, or workshops, extension cords provide the necessary reach, carrying electrical current over distances of hundreds of feet.

Across industries, from retail and healthcare to large-scale manufacturing and industrial operations, power cords are indispensable in delivering energy from power sources to machinery. Voltage ratings, measured in volts or kilovolts (kV) for higher capacities, determine the power a cord can safely handle. Selecting the correct power cord for any given application requires consideration of multiple factors, including the operational environment, the length and duration of use, and the electrical load demands. Power cord manufacturers adhere to rigorous standards governing voltage capacity, current ratings, wire gauge, cord length, and insulation materials. Additional specifications such as the type of molded plug, female receptacle, and maximum allowable temperature ensure compatibility with various applications. The American Wire Gauge (AWG) system classifies wire sizes based on voltage capacity, ensuring proper energy transmission without overheating or inefficiency. Depending on the intended use, cord wires may be flat or round to accommodate installation requirements. The outer jacket material plays a crucial role in durability, with variations designed for indoor or outdoor use. A cord designated for rugged outdoor environments features waterproof and reinforced insulation, while one intended for indoor applications, such as powering a laptop, prioritizes flexibility and compact design. In medical or high-precision environments, shielding against electromagnetic interference may be necessary to protect sensitive electronic devices from disruptions.

Ensuring safety in electrical supply components is paramount, and regulatory organizations such as NEMA establish stringent guidelines in North America to maintain consistent power quality and reduce the risk of failure. Other countries implement their own standards for voltage regulation and component configurations, tailoring safety measures to their specific electrical systems. Industry-wide manufacturing regulations, including those enforced by NEMA, contribute to standardized production processes and help prevent malfunctions due to material or design inconsistencies. Because power cords handle live electrical currents, their misuse or deterioration can lead to severe consequences, including personal injury, electrocution, or property damage. Safety measures such as polarization and grounding are critical, particularly for high-voltage equipment or appliances where electrical shock risks are greater. Grounded or polarized cord sets should always be used for sensitive electronics to ensure protection against power surges and electrical faults. Additional safety features, including waterproofing, plug covers, integrated fuses, and circuit breakers, further enhance protection, preventing overloads and minimizing hazards associated with electrical supply components.

Power Cords FAQ

What is the difference between AC and DC power cords?

AC power cords carry alternating current used in most homes, offices, and industrial facilities, while DC power cords deliver direct current, commonly used in portable electronics like laptops and flashlights.

What standards govern power cords in North America?

In North America, power cords follow National Electrical Manufacturers Association (NEMA) standards, which regulate plug types, receptacle configurations, voltage ratings, and safety requirements.

How do I choose the right generator power cord?

Selecting a generator power cord requires matching the plug type, amperage, and gauge to your generator. A 10-gauge cord is commonly used, ensuring safe power transfer during outages without overheating or voltage drop.

Why is grounding important in power cords?

Grounding protects users and devices by directing fault currents safely into the ground. Three-prong cords with grounding pins reduce risks of shocks, surges, or electrical faults in household and industrial equipment.

What materials are used for power cord insulation?

PVC is the most common insulation material due to its durability and heat resistance. Alternatives like XLPE or EPR are used in industrial and high-voltage applications for added strength and performance.

When should I use a heavy-duty extension cord?

Heavy-duty cords are required for high-power appliances, outdoor equipment, and construction tools. These cords have lower gauge numbers, reinforced insulation, and locking connectors to prevent overload or disconnection.

History of the Power Cord

The origins of the power cord trace back to 1882, when Thomas Edison pioneered the first power distribution system. He designed a three-layer cord that featured a central copper rod, which was encased in a bundle of vegetable fiber known as jute. This core assembly was then further shielded by an outer bituminous layer, which provided additional protection against environmental elements and electrical hazards.

Copper was chosen as the primary conductor due to its superior ability to transmit electricity with minimal resistance. The surrounding layers served multiple functions: they kept the copper rod securely in place, provided insulation to prevent electrical leakage, and protected individuals from direct exposure to the dangerous effects of electrical current.

As electrical technology advanced, bituminous insulation was replaced with vulcanized rubber, a more effective insulator that could withstand higher temperatures without degrading. Unlike bitumen, which could break down under heat, vulcanized rubber maintained its protective integrity while ensuring electrical safety.

Over time, technological innovations led to the development of materials specifically engineered for electrical applications. Today, polyvinyl chloride (PVC) is widely used in power cords due to its durability, flexibility, and resistance to high temperatures. PVC’s insulating properties make it an ideal material for modern power cables, ensuring efficiency, reliability, and enhanced safety across various industries.

How Power Cords Are Made

The manufacturing process of power cords consists of three key stages:

- Wire-Drawing

- Insulation

- Phase Wiring

While both copper and aluminum can be used as conductors, copper remains the preferred choice due to its superior conductivity and durability. Aluminum is sometimes used for specialized applications but does not match copper’s efficiency in transmitting electrical current.

Wire-Drawing

The process begins with the delivery of massive 5-ton coils of copper wire rods, each measuring 8 mm in diameter. The first step is to refine these rods by reducing their diameter to 2 mm, a modification that enhances both ductility and conductivity.

Further refinements are made based on the specifications required for the intended application. To restore any ductility and conductivity lost during this reduction process, the wires undergo a specialized heat treatment known as annealing. This process softens the wire, making it more flexible and suitable for electrical use.

Once annealed, the wires are stranded, meaning multiple thin wires are bundled together to form conductors. This configuration improves flexibility and enhances the cord’s ability to handle electrical loads effectively.

Insulation

After the wire strands have been assembled into conductors, they are coated with an insulating material using extrusion techniques. This protective layer prevents electrical current from leaking and ensures safe operation.

PVC is one of the most commonly used insulating materials, but other specialized options include:

- Cross-linked Polyethylene (XLPE) Cable – Designed for high-voltage applications, XLPE insulation offers exceptional resistance to heat and mechanical stress.

- Ethylene Propylene Rubber (EPR) Cable – Known for its outstanding durability and heat resistance, EPR insulation is widely used in industrial wiring due to its flexibility and long lifespan.

Once the insulation layer has been applied, the entire cable undergoes high-voltage testing to verify that there are no electrical leaks or defects.

Phase Wiring

In the final stage of manufacturing, multiple conductors are grouped together to form multi-core cables. Each phase is assigned a distinct color or number, following industry-standard coding systems that facilitate proper identification and wiring.

Following the completion of phase wiring, the power cord is subjected to another round of rigorous testing to confirm that its insulation meets all safety and performance standards. This final evaluation ensures that the finished cable can reliably transmit electrical energy while maintaining structural integrity and user safety.

Power Cord Features

Power cords, typically flexible but sometimes semi-rigid for specific applications, serve as the essential connection between electrical power sources and electronic devices. They consist of a cord with electrical plugs at both ends: a male plug that connects to an electrical receptacle or outlet and a female plug that attaches to the equipment or appliance being powered.

Various features can be integrated into power cords or added to custom orders to enhance functionality and safety. One such feature is twist-locking mechanisms, which reduce the likelihood of accidental disconnection. This is particularly useful in industrial or high-vibration environments where a secure power connection is essential. For applications where electromagnetic interference (EMI) could pose a problem, such as audio/video equipment or sensitive electronics, shielded power conductors help prevent signal disruption.

Additional safety and performance-enhancing features include leakage current detectors, which monitor and prevent unintended electrical discharge, pilot lamps that indicate the presence of voltage, and fuses that provide overcurrent protection by interrupting power flow in the event of a surge.

Retaining clamps, also known as safety lock devices, are another critical feature, particularly in environments where accidental disconnection poses a safety risk. These clamps secure appliance couplers to prevent them from being unintentionally pulled free, making them essential in medical applications, computing systems, and stage and lighting setups. They are also widely used with extension cords, ensuring a reliable connection even when cords are stretched over long distances or moved frequently.

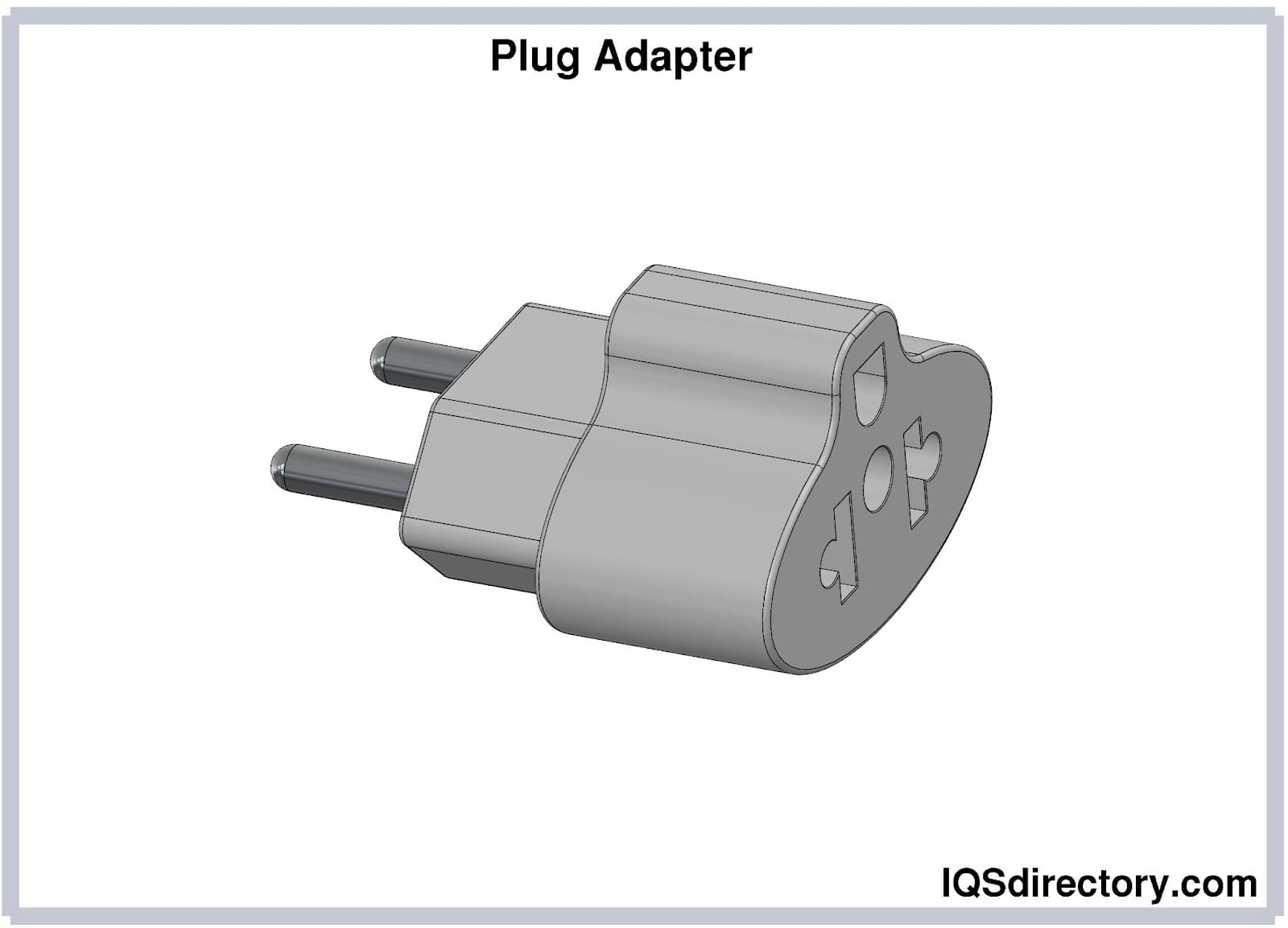

Plug adapters are indispensable for international travel or use in regions with different electrical standards. These adapters allow appliances to function safely in countries with varying plug configurations and voltage requirements. When combined with voltage converters, they protect electronic devices from damage due to electrical incompatibilities. Since different manufacturers may offer varying features and accessories, it is essential to carefully select power cords that meet the operational and safety needs of a given application.

How Power Cords Work

Understanding how power cords function requires tracing the journey of electrical power from its source to its final destination in homes, businesses, and industrial settings.

Power suppliers distribute electricity in multiple ways, depending on infrastructure and location. Overhead power lines are the most common method, carrying electricity across cities and suburban areas through aerial transmission. One approach to overhead power distribution is the use of aerial bundle cables (ABCs), which consolidate multiple wires to improve efficiency. While ABCs have historically presented safety concerns, advancements in low-voltage technology have helped address these issues.

In contrast, subterranean power systems transmit electricity through underground cables, protecting power lines from weather-related disruptions such as wind and rain. Since underground power lines are less susceptible to environmental damage, they tend to last longer and reduce the likelihood of outages. However, due to the high costs associated with installation and maintenance, only about 18% of the United States’ power transmission infrastructure is underground.

Once electricity reaches its destination, power cords serve as the conduit, delivering energy from power outlets to various electronic devices. A wall-mounted outlet is the most common power source, but power cords can extend their reach through extension cords and distribute power to multiple devices via power strips.

Different power cords are designed to accommodate various applications based on location, electrical standards, and device requirements.

AC Power Cords

Alternating current (AC) power cords are widely used in both residential and commercial applications. Devices that require a direct connection to the electrical grid but do not have built-in power conversion mechanisms rely on these cords to function. Since most stationary electronics operate on AC power, these cords are essential for household appliances, office equipment, and industrial machinery.

DC Power Cords

Direct current (DC) power is more suited for portable electronics, such as mobile phones, flashlights, and battery-operated devices. Since most electrical grids supply AC power, devices requiring DC power must convert the electricity using a rectifier, which transforms the alternating current into a compatible form for the DC cord to deliver.

Both AC and DC power cords come in multiple variations, each suited for specific applications:

Standard 2-Conductor Power Cord

Commonly used in class 2 consumer electronics, these cords are compatible with the standard receptacles found in modern U.S. construction. They are low-cost, available in various colors, and designed to handle 10, 13, and 15 amp devices with a maximum voltage of 120V.

Standard 3-Conductor Power Cord

Designed for devices that require additional safety features, these cords are commonly used in light fixtures, heaters, air conditioners, and exercise equipment. They feature a ground pin, which provides an extra layer of electrical protection against faults.

Locking Power Cords

In environments where an interruption in power supply could cause significant issues, locking power cords provide a secure connection that prevents accidental disconnection. These are widely used in IT infrastructure, ensuring that systems remain powered without risk of sudden shutdowns.

Healthcare Approved Power Cords

Medical applications demand hospital-grade power cords, which undergo rigorous testing to ensure reliability in life-critical scenarios. These cords are engineered for durability and conductivity, with strict quality control measures in place before they are approved for use in hospitals, laboratories, and other healthcare environments.

Power cords do not operate in isolation; several accessories enhance their functionality, efficiency, and safety.

Plug Adapters

Essential for international travel, plug adapters enable electronic devices to function in different countries with varying electrical standards. They ensure compatibility and prevent damage from voltage mismatches.

Control Cables

As an integral component of complex electronic systems, control cables transmit signals between a control unit and the various parts of a device. These cables function similarly to the nervous system in the human body, sending and receiving information to ensure smooth operation.

Power cords are indispensable in modern electrical infrastructure, serving as the connection between energy sources and the devices we rely on daily. Whether providing power to household appliances, industrial machinery, or critical medical equipment, the right power cord—paired with the necessary accessories—ensures reliable, efficient, and safe energy transmission.

Points to Consider When Buying a Generator Power Cord

Uninterrupted power supply is an ideal scenario that rarely becomes reality. Power disruptions can stem from faults in the electrical grid, but more often, they occur due to severe weather conditions. While these outages may last only a short time, there are occasions when an entire home or neighborhood experiences prolonged power loss. To counteract these situations, many Americans rely on backup power solutions such as centralized generators or solar-powered standby systems.

For a generator to function efficiently and without disruption, selecting the right generator power cord is essential. A generator cord is a specialized cord set designed for use with portable generators, ensuring seamless energy transmission. However, purchasing the correct power cord and using it properly can be challenging, especially for homeowners unfamiliar with the nuances of electrical connections. Even those who have prior experience with generators may find themselves uncertain when connecting the machine to the main power supply.

Common Types of Generator Cords

Several variations of generator power cords exist, with TT, 5, L5, 14, L14, and CS being among the most commonly used. Additional types are also available, which can be found online or at local electrical supply stores.

What Do These Labels Mean?

Generator cord labels indicate the plug and receptacle type, helping users determine compatibility with their specific generator model. If a cord set features only numerical labeling, it signifies that the cord is designed with a slotted, easily detachable plug or receptacle. However, when the labeling includes a character (such as "L"), it denotes a twist-lock mechanism, which allows the cord to be inserted, securely locked, and used without the risk of accidental disconnection.

Many manufacturers now simplify product labeling, prominently displaying only key specifications such as amperage, plug type, and receptacle end type in bold lettering on modern packaging. While additional technical details can still be found in product manuals or online, these simplified labels help buyers quickly identify the right generator cord for their needs.

The Gauge of the Cord

One of the most critical factors to consider when purchasing a generator power cord is the gauge, which determines the cord’s electrical capacity and strength. This measurement refers to the thickness of the electrical conductors within the cord. The lower the gauge number, the thicker and stronger the wire, enabling it to handle higher electrical loads.

For example, a 10-gauge power cord is one of the lowest gauge numbers commonly available and is widely used with portable generators due to its ability to transmit power efficiently over extended distances. Choosing the correct gauge ensures that the cord can handle the generator's output without overheating or experiencing voltage drop.

Strong Connectors

Investing in a high-performance generator power cord with durable connectors is crucial for maintaining a steady power supply. Well-known brands offer cords that undergo rigorous product testing and come with warranties, ensuring longevity and reliability. Heavy-duty cords are specifically engineered with reinforced connectors, preventing wear and tear and enabling uninterrupted power flow to homes and businesses during outages.

Modern generator cords now incorporate advanced safety features such as LED-powered indicators, which provide a visual cue when the cord is actively conducting electricity. Some models also feature smart plugs and connectors designed to enhance user safety while optimizing energy efficiency.

Generator Cord Safety

Using an improper or non-compatible power cord with a generator poses significant risks, both to the user and the connected appliances. Power cords not specifically designed for generator use may fail to handle the electrical load, leading to overheating, power surges, or potential fire hazards. Additionally, a mismatched cord may not connect securely to the generator, resulting in intermittent power loss or equipment damage.

For maximum safety, it is essential to invest in high-quality generator cords produced by reputable manufacturers. Choosing a reliable, first-rate power cord ensures proper electrical transmission and reduces the risk of accidents, such as electric shock, short circuits, or damage to sensitive appliances.

Furthermore, caution should always be exercised when working with generator power output. Handling electrical connections improperly can result in personal injury or extensive damage to household electronics. Proper grounding, secure connections, and adherence to manufacturer guidelines are critical in ensuring safe and efficient generator operation during power outages.

How to Choose the Right Power Cord

Selecting the appropriate power cord requires a clear understanding of your power needs and the device requirements before making a purchase. Identifying the correct specifications ensures both efficiency and safety, preventing potential damage to electrical components or hazardous situations in homes and workplaces.

Once the necessary power specifications are determined, the next step is choosing among the numerous power cord manufacturers available in the market. While customer reviews and testimonials can provide insight, they should be considered carefully, as individual power needs often vary. A product that meets one person’s requirements may not be suitable for another’s application.

Original Equipment Manufacturer (OEM) power cords are produced by one company and sold under the branding of another. While OEM custom power cords can be a reliable choice, it is essential to research both the original manufacturer and the company marketing the product to ensure transparency regarding quality and compatibility. In many cases, the brand name on the packaging does not match the actual manufacturer, making research a key step in the selection process.

Equally important is understanding the specific power needs of the device that will be connected. A power cord for a laptop will not be suitable for medical equipment, just as a household extension cord cannot safely power an industrial-grade machine. The wrong cord can degrade electrical components, reduce efficiency, or even pose serious fire and safety hazards over time. Reputable power cord manufacturers include UL certification (or other industry-recognized safety approvals) to indicate that the product has undergone rigorous testing for efficiency and safe operation.

Extension cord sets add convenience in residential, commercial, and industrial settings. With numerous design variations and electrical capacities available, choosing the right power or extension cord can be overwhelming. Understanding key features and applications helps in selecting the best power solution for any given need.

Here are some tips to help you choose the right cord set:

- For table lamps in bedrooms or study areas, an 18-gauge, two-prongcord set is an ideal choice for light-duty applications. Cords with built-in folding mechanisms offer additional convenience for storage and organization.

- A three-prong, 14-gauge power cord is the standard for laptops. However, this type of cord is also versatile enough to be used for other general applications, such as table lamps and small music systems.

- Toasters typically operate at 750 watts (1 HP), similar to coffee makers and boilers. Given their high power consumption, these appliances should not be used with extension cords unless absolutely necessary. If an extension board is required, it must have a minimum current capacity of 12 amperes. Additionally, all kitchen appliances should be positioned away from sinks and water sources to prevent electrical hazards.

- Hairdryers demand 15 amps of current and should be directly plugged into a power board. Due to their high power draw, they should never be connected to an extension cord, as doing so could lead to overheating or fire risks.

- Home treadmills require a stable and robust power supply. Most manufacturers advise against using extension cords, as fluctuations in power can damage the treadmill’s motor. If an extension must be used due to space constraints, it should be a high-quality extension board specifically designed for treadmills.

- Vacuum cleaners typically come with extended power cords, but for greater reach, an outdoor vacuum cleaner should be paired with a three-prong, 12-gauge power cord. It is essential to ensure that the extension cord includes a plug locking mechanism, as vacuum cleaner plugs often get pulled out during use. For indoor vacuum cleaners, a 16-gauge cord set is generally sufficient.

- Room heaters consume a significant amount of power, making them unsuitable for use with extension cords. To avoid electrical overload or fire hazards, they should always be directly plugged into a wall outlet.

- For holiday lighting displays, the appropriate cord gauge depends on the length of the extension cord required. A 16-gauge cord is suitable for distances over 20 feet, while a 14-gauge cord is appropriate for shorter distances.

- For televisions, home theater systems, and other medium-capacity appliances, a three-prong, 14-gauge cord is a safe choice. This medium-duty power cord supports various household electronics, ensuring consistent performance and electrical safety.

Do’s and Don’ts to Follow with Power Cord Sets

Power cord sets are essential electrical components that require careful handling to ensure safety, longevity, and reliable performance. Misuse can lead to accidents, equipment failure, and even hazardous electrical fires. Following proper guidelines will help prevent damage and extend the life of your power cords.

Do's:

- Regularly inspect for damage. Before each use, check the power cord for any visible signs of wear and tear. Exposed wiring, frayed insulation, or broken connectors pose serious safety hazards. If you notice any damage, cover minor openings with electrical tape or replace the cord if repairs are not feasible

- Verify safety certification marks. All electrical appliances, including power cords, undergo rigorous testing before being approved for use. Look for a UL, ETL, or other certified verification sticker on the packaging or directly on the cord itself to ensure it meets safety standards.

- Ensure secure plug connections. A loose or improperly inserted plug increases the risk of short circuits, electrical sparks, or overheating. Always fully insert plugs into sockets to maintain a stable and secure electrical connection.

- Keep power cords and extension boards away from moisture. Exposure to water or damp environments can lead to electric shock, short circuits, or permanent damage to the cord. Even if the power cord is unplugged, never leave it in a wet or humid location.

- Unplug cords when not in use. Even when powered off, electrical currents can remain in the sockets of extension boards. Disconnecting cords when they are not actively powering devices prevents potential overheating, energy waste, and electrical hazards.

- Repair minor damage immediately, or replace the cord if necessary. If the cord is repairable, address frayed insulation, loose connectors, or damaged plugs as soon as possible. If a repair is not possible, replace the cord entirely to avoid potential fire or shock risks.

Don'ts:

- Never overload a power cord. Every cord has a maximum wattage and amperage rating. Exceeding these limits can result in overheating, reduced efficiency, or even electrical fires. Always ensure that the power demand of your appliance does not surpass the cord’s capacity.

- Do not use indoor cords for outdoor applications. Indoor cords are designed for light-duty use, whereas outdoor-rated cords are built to withstand harsher environments, higher power loads, and weather exposure. Using an indoor cord outdoors can lead to electrical failure, insulation breakdown, and increased safety hazards.

- Avoid forcing plugs into sockets. Forcing a plug into an outlet that does not match its design can damage both the plug and the socket. If a plug does not fit properly, verify that you are using the correct cord type rather than applying excessive force.

- Do not step on or place heavy objects over cords. Walking on a power cord can weaken the internal wiring, leading to breakage, electrical failure, or an increased risk of sparks and short circuits. Keep cords routed safely along walls or under protective covers to prevent accidental damage.

- Never pull, twist, or swing a power cord. Rough handling, bending, contorting, or swinging a cord can weaken its internal structure and cause it to deteriorate faster. Over time, this can result in short circuits, internal wire breakage, or insulation damage. Always handle power cords gently to maximize their lifespan.

Power Cord Images, Diagrams and Visual Concepts

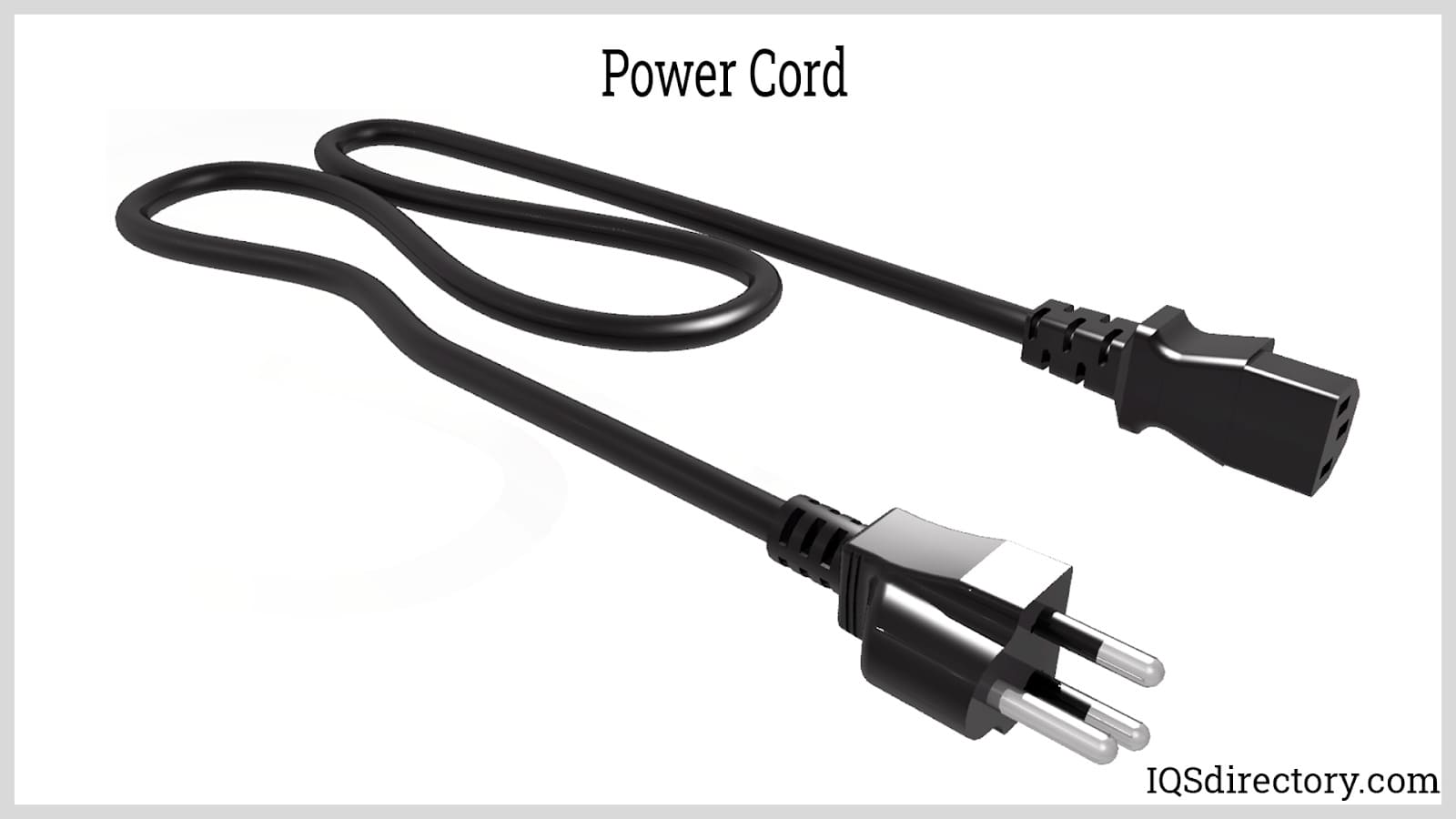

A power cord is a component used for connecting appliances to a power supply.

The pins consists of a live pin which connectos to the power supply, the earth pin which acts as grounding for the current, and the neutral pin provides a return path for the electrical current.

A cord set consists of a plug, a power cable, and a connector which are used for connecting an electrical appliance to an electrical utility.

NEMA power cords are electrical cords which follow the specifications set by the National Electrical Manufacturers Association which are mainly used North America and some parts of South America

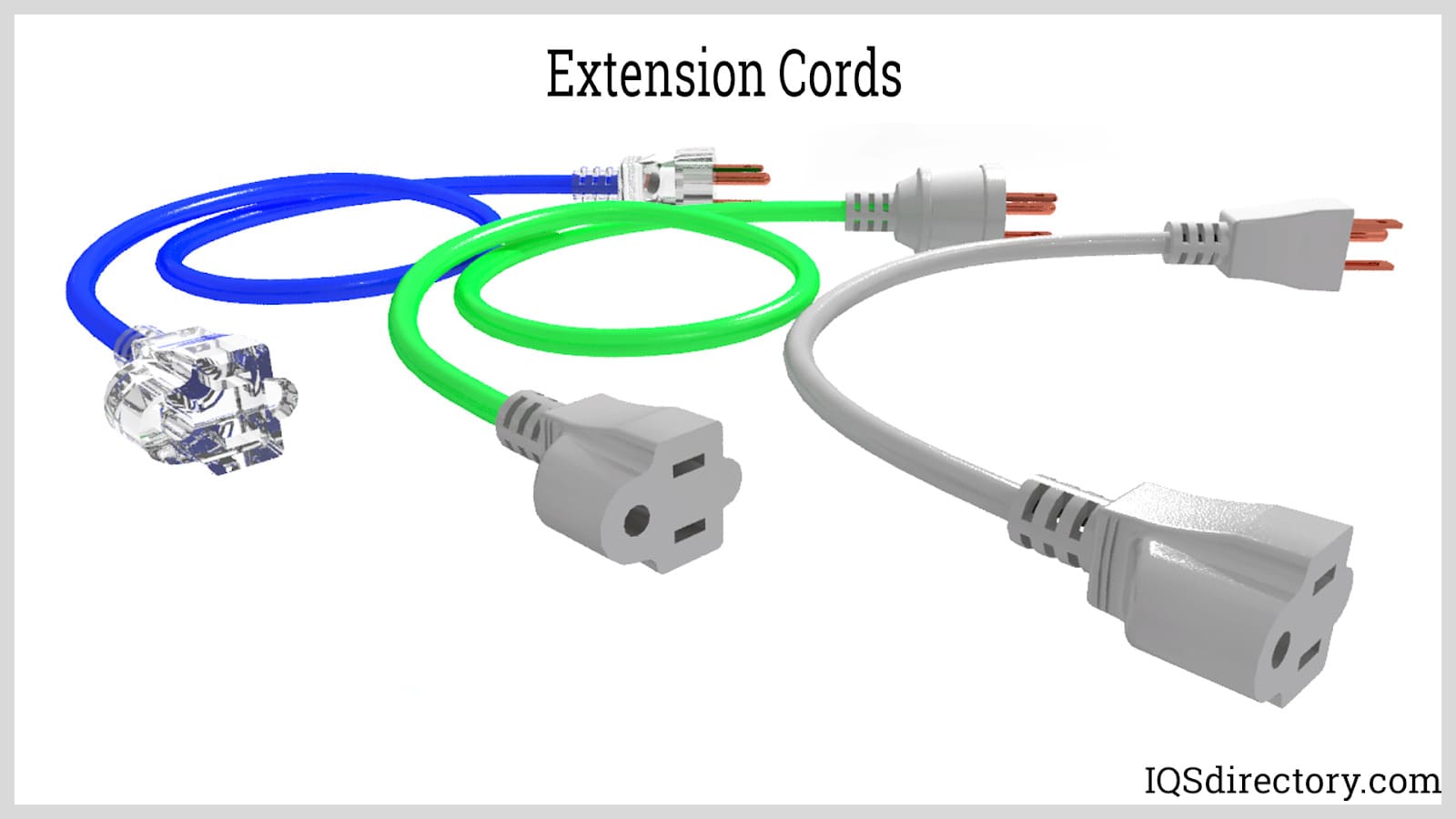

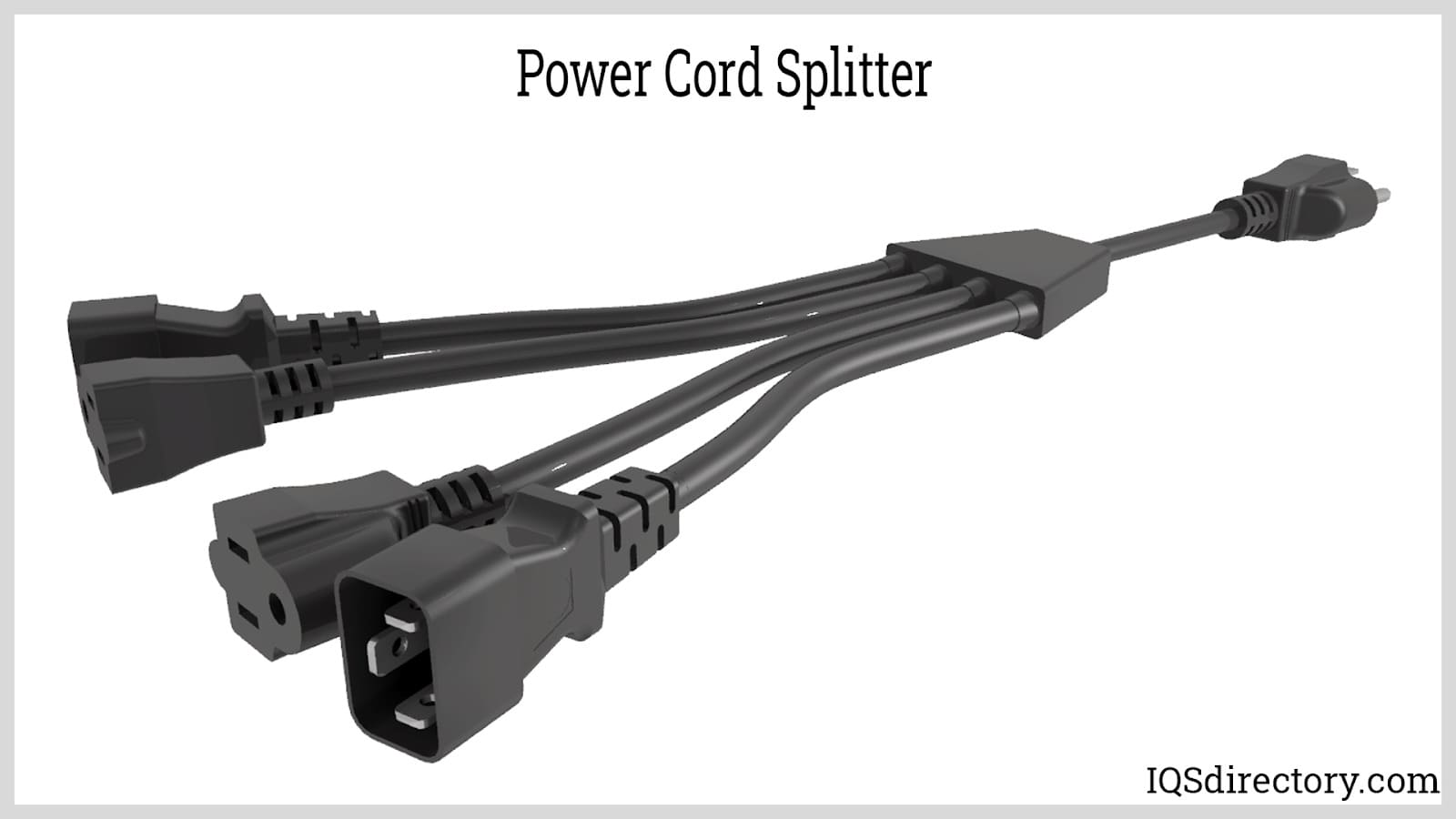

Extension cords are a cables that have a power plug and sockets to connect appliances to an electrical source.

This allows for multiple appliances to be plugged in a single outlet.

Plug adapters allow electrical devices to connect with sockets and plugs that are incompatible by converting voltage to what is required for the sockets or plugs.

Power Cord Types

AC Power Cords

AC power cords conduct alternating current (AC) from one point to another. These cords consist of a copper conductor, which serves as the medium for electricity transmission, surrounded by an insulating layer and a protective outer jacket to ensure safety and durability.

Business Machine Cords

Designed specifically for computers and related electronic equipment, business machine cords provide reliable power connections for devices such as printers, monitors, and desktop systems.

Cable Assemblies

Cable assemblies contain multiple wires or cables combined into a single unit, typically with connectors on one or both ends. These pre-configured assemblies streamline electrical connections in various applications, reducing clutter and improving efficiency.

Cord Covers

Cord covers serve as protective shields, safeguarding loose cords and wires from damage, tripping hazards, and exposure to hazardous conditions.

Cord Sets

A cord set consists of a male electrical plug on one end and a female plug on the other, allowing for easy and secure connections between power sources and electrical devices.

Electric Cords

Electric cords are conductive cables that transfer AC power from a plug to an electrical device. They are fundamental components of electrical systems across various applications.

<a data-cke-saved-href="Electrical Plugs

Electrical plugs are male electrical connectors with metal blade contact prongs designed to fit into female receptacles to establish an electrical connection.

Electrical Receptacles

Commonly known as outlets or sockets, electrical receptacles provide the point of connection for power cords, delivering electricity to device

Extension Cords

Extension cords extend the reach of a power supply and are marked with key specifications, including usage rating, wire size (gauge), and wattage capacity. Available in various lengths, these cords follow the American Wire Gauge (AWG) system for classification.

Heavy Duty Cords

Designed for industrial and commercial applications, heavy-duty cords withstand rugged environments and intensive usage. They feature non-slip grips, large flat surfaces, and molded strain relief shrouds, which protect the cord-to-plug connection from stress and wear.

Hospital Plugs

Hospital plugs meet the strict safety and durability requirements of medical applications. They feature heavy-duty solid brass blades and pins, which are soldered or welded to the conductors for maximum reliability in critical environments.

International Power Cords

International power cords allow electrical appliances and equipment to be used across different countries, providing a detachable connection between foreign power sources and otherwise incompatible devices.

NEMA Power Cords

NEMA power cords adhere to North American electrical standards, specifying plug types, voltage capacities, and receptacle configurations for safe and consistent power distribution.

Polarized Plugs

Polarized plugs feature one blade wider than the other, ensuring the plug can only be inserted one way to reduce the risk of electrical shock. Three-prong plugs are inherently polarized due to their grounding pin, which dictates a single orientation.

Power Supply Cords

Power supply cords are flexible lengths of cable with molded attachment plugs on one end. These cords transmit electricity from a power source to an electrical device and may include terminations or molded strain relief on the opposite end. Unlike cord sets, which are detachable, power supply cords are permanently installed in the device being powered.

Plug Adapters

Plug adapters serve as connectors between otherwise incompatible electrical sockets and plugs, enabling the use of appliances across varied plug configurations and voltage systems.

Plug Covers

Plug covers provide protective barriers to reduce hazards such as electrical shock or accidental exposure to open outlets.

Right Angle Power Cord

Right-angle power cord sets allow users to connect electrical equipment in tight spaces without bending or damaging the cord. These are available in two-conductor (polarized or non-polarized) or three-conductor configurations, with the grounding pin positioned at either the top or bottom.

Three-Conductor Plugs

Three-conductor plugs feature two vertical blades and a grounding pin, ensuring a safe and stable connection. These plugs are inherently polarized, as they can only be inserted in one orientation.

Two-Conductor Plugs

Two-conductor plugs consist of two vertical blades—one serving as the neutral line and the other as the hot line. Since they lack a grounding pin, they are available in both polarized and non-polarized variations, depending on the application.

Power Cord Terms

Abrasion Resistance

The ability of a power cable or insulating material to withstand surface wear, friction, and mechanical damage over time.

Alternating Current (AC)

An electrical current that changes direction periodically in a cyclical pattern.

American Wire Gauge (AWG)

A standardized wire and cable-sizing system used in North America to identify the diameter of copper conductors. A higher gauge number indicates a thinner wire, while a lower gauge number represents a thicker wire.

Ampacity

The maximum amount of electrical current, measured in amperes (amps), that a wire or power cord can safely conduct without overheating. Also known as current-carrying capacity.

Arc Resistance

The amount of time it takes for an electrical arc to form a conductive path in a given material.

Attenuation

The loss of electrical power in a system, typically measured in decibels (dB) per unit length.

Boot

A protective covering placed over a conductor, cable, or connection point to provide insulation and mechanical protection.

Braid

A woven covering made from fibrous or metallic filaments, used to enhance durability, shielding, and flexibility of cables.

Breakdown Voltage

The maximum voltage that an insulating material can withstand before it fails, causing electrical arcing or dielectric breakdown.

Bunch Stranding

The process of twisting multiple wires together within a conductor to create a specific gauge and flexibility.

Cold Flow

Permanent deformation of insulation or jacket material due to prolonged mechanical pressure or compression.

Conductivity

A material’s ability to carry electrical current, typically expressed as a percentage of copper's conductivity, which is 100% conductive.

Conductor

A metallic material, usually copper or aluminum, that allows electrons to flow freely, enabling electrical current transmission. Conductors can be solid wire or stranded multi-wire cables.

Conduit

A tube or protective channel through which wires and cables are routed for mechanical and environmental protection.

Continuity Check

A diagnostic test used to determine whether an electrical current can flow continuously through a wire or cable, ensuring no breaks or faults exist.

Cord

A small, flexible, insulated cable designed to withstand mechanical wear in various applications.

Dielectric

An insulating material used within cables to prevent electrical contact between conductors and ensure efficient operation.

Direct Current (DC)

Electric current that flows in only one direction, commonly used in battery-operated and low-voltage electronic devices.

Electrical Circuit

A complete path that allows electrical current to flow. A closed circuit enables the current to travel uninterrupted, while an open circuit disrupts the flow.

Europlug

A standardized international plug used in many European countries, commonly referred to as CEE 7/16 with a 2.5 amp, Class II rating.

Farad

A unit of measurement for electrical capacitance, denoted by the symbol F.

Fatigue Resistance

The ability of metal conductors to resist crystallization and breakage caused by continuous flexing or mechanical stress.

Flanged Inlets/Outlets

A nylon-mounted housing that allows electrical inlets or outlets to be securely mounted to a panel or equipment, fastened in place with screws or bolts.

Frequency

The number of cycles per second that an alternating current (AC) completes, measured in Hertz (Hz). The standard frequency is 60 Hz in North America and 50 Hz in most other regions.

Gauge

A numerical indication of wire thickness. A lower gauge number signifies a thicker wire, while a higher gauge number indicates a thinner wire.

Ground

A conductive connection between an electrical circuit and the earth or another large conducting body, ensuring safety and stability in power systems.

Hi-Pot

A high-voltage test conducted on a cable to detect damage, insulation weaknesses, or defects after manufacturing or transport.

High Voltage

Typically defined as any voltage exceeding 600 volts, used in industrial, power transmission, and high-energy applications.

IEC 60320

An international standard for electrical plugs, connectors, and inlets, formerly known as IEC 320, commonly used in computers, medical equipment, and electronic devices.

Insulated Wire

An electrical conductor covered in a non-conductive material to prevent short circuits and ensure safety.

Insulation

A material with high resistance to electrical current, used to shield and protect conductors within a power cord.

Jacket

An outer protective covering made from plastic, rubber, or elastomer, designed to enhance insulation and mechanical durability.

Line Cord

A power cord with a plug at one end, designed to connect electrical equipment to a power outlet.

Loss

The dissipation of electrical energy in a circuit, often as heat, without performing useful work.

Molded Plug

A plug that is permanently attached to a cord using a molded plastic or rubber encasement, enhancing durability and insulation.

Multiconductor

A power cord or cable containing multiple conductors, allowing for multiple circuits or power transmission paths.

National Electrical Code (NEC)

A set of electrical safety standards established by the National Fire Protection Association (NFPA), governing wiring practices and regulations in the U.S.

Neoprene

A synthetic rubber compound known for its chemical, oil, and flame resistance. Also called polychloroprene.

Nylon

A durable, abrasion-resistant thermoplastic commonly used in wire jacketing, plugs, and connectors.

Ohm

A unit of electrical resistance, represented by the symbol Ω.

Outlet

A female electrical receptacle that provides access to a power source for electrical devices.

Pin and Sleeve

A plug or receptacle system with round pins or sleeve-type contacts, typically used for industrial and heavy-duty applications.

Plug

A male electrical connector with metal prongs designed to fit into an outlet or socket. Also known as an attachment plug.

Power Cord Splitter

A device that allows multiple machines or devices to connect to a single power outlet, expanding power access.

Sheath

The outermost protective layer of a wire or cable, often made of extruded plastic or elastomer. Also known as a jacket.

Shield

A metallic protective layer around conductors that reduces electromagnetic interference (EMI) and electrostatic interference (ESI).

Signal

An electrical transmission that conveys digital, analog, audio, or video information.

Single Phase

An electrical circuit containing one live (hot) wire, one neutral wire, and a ground.

Socket

A receptacle that connects with a plug, securing an electrical connection through spring-loaded or tension-based metal contacts.

Surge

A temporary spike in voltage within an electrical system, often caused by power fluctuations or external interference.

Three-Phase

An electrical circuit consisting of three live wires and a ground or three live wires, a neutral, and a ground, used in high-power industrial applications.

Voltage Rating

The maximum voltage a wire or cable can safely handle according to industry standards.

VW-1

A UL flame-retardant rating indicating that a wire or cable has passed vertical flame tests for fire resistance.

Watt

A unit of electrical power, measuring the rate at which energy is consumed or transferred.

Wire Gauge

A numerical designation system for wire sizes, most commonly referring to AWG (American Wire Gauge).

More Power Cords Information

Power Cord Manufacturers