Power Supplies

Power supplies, or power supply units (PSUs), are essential devices that generate and regulate electrical currents to power electronics, machinery, and industrial and commercial systems. These units ensure reliable energy distribution, supporting the vast array of technology that drives modern life.

Power Supplies FAQ

What is the main function of a power supply?

A power supply converts and regulates electrical energy, ensuring devices and systems receive the proper voltage and current for safe and reliable operation in electronics, industrial machinery, and commercial equipment.

How do power supplies convert AC to DC?

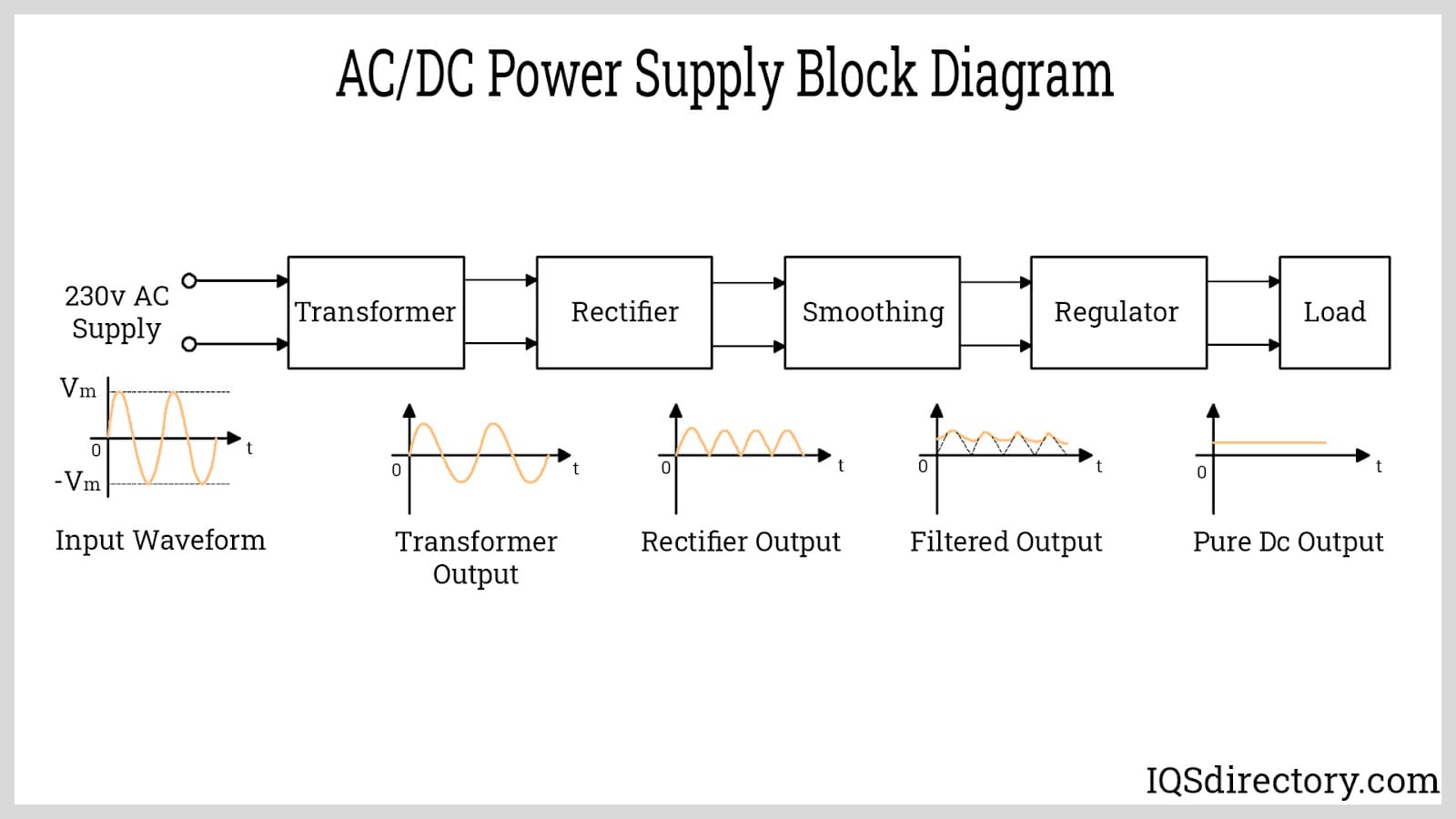

AC power supplies use a transformer to step down voltage, then rectifiers convert AC to pulsating DC. Filters remove ripples, producing a stable DC output for electronics such as computers and medical devices.

What is the difference between AC and DC power supplies?

AC power supplies deliver alternating current, commonly used in homes and businesses. DC power supplies provide direct current, required by devices like phones, laptops, and process control equipment.

What are the main types of uninterruptible power supplies (UPS)?

UPS systems include offline units for standby use, line interactive UPS with voltage regulation for business needs, and online UPS that provide double-conversion for critical applications like hospitals and data centers.

Why are variable power supplies used in testing?

Variable power supplies allow users to adjust voltage output, making them ideal for testing and product development where different operating conditions need to be simulated safely and precisely.

What safety standards apply to power supplies?

Power supplies must comply with standards from organizations like IEC, ISO, CSA, and UL. These cover efficiency, insulation, and safety requirements for use in medical, laboratory, and industrial environments worldwide.

The History of Power Supplies

The power supply industry emerged in the 1920s, initially providing energy for commercial and household radios. By 1929, engineers had integrated power supply units directly into radio designs, paving the way for more efficient and self-contained systems. Throughout the 1930s and 1940s, vacuum tube linear regulators became the standard for power control. These early regulators, while effective, posed significant risks due to the extreme heat they generated—glass tubes would glow red and even melt under prolonged use.

The 1950s introduced a transformative breakthrough with the development of transistors. First perfected in 1947 at Bell Labs, transistors quickly replaced vacuum tubes, offering a more compact, efficient, and safer alternative. However, early transistors were limited to low and medium voltage applications, prompting engineers in the 1960s to develop magnetic amplifiers (mag-amps), which strengthened small electrical signals and remained in use through the 1980s and 1990s.

During the 1960s, Dr. Kenneth Kupferberg patented the first remotely controlled power supply systems, ushering in a new era of power management. As the transition from analog to digital progressed, engineers introduced innovative power supply methods, including linear series pass systems, high-power operational amplifiers, and voltage feedback control mechanisms.

The 1970s saw significant advancements in efficiency. Researchers combined high-speed silicon transistors with low-loss ferrite transformer cores, enabling power supplies to operate at inaudible frequencies exceeding 20 kHz. In 1972, Hewlett-Packard pioneered the use of a switching power supply in a pocket calculator. By the late 1970s, engineers had also developed computer-controlled linear power supplies, leading to the introduction of digital control technologies such as Binary Coded Decimal (BCD) digital control and digital-to-analog power conversion (DAC). Hewlett-Packard’s creation of the instrumentation bus standard, later known as RS232, enabled faster and more efficient communication between power supplies and their controllers.

The rapid expansion of digital technology in the 1980s fueled the demand for more powerful and sophisticated power supplies. This demand led to the rise of numerous power supply manufacturers worldwide, driving continuous improvements in efficiency and control.

By the 1990s, power supply units had become increasingly compact and energy-dense. Advances in materials and circuit design allowed manufacturers to develop smaller, more efficient systems capable of delivering higher power outputs. Today, power supplies are indispensable, ensuring the seamless operation of everything from consumer electronics to industrial automation. As technology continues to evolve, power supply innovations will remain central to powering the digital world.

Power Supply Design

Power supply manufacturers offer a wide range of designs and configurations tailored to specific applications, current types, frequencies, wattages, and voltage levels. When developing a custom power supply unit or assisting in the selection of a standard model, they consider critical specifications such as the number of outputs, DC and AC output voltages, DC output power, AC output frequency, operating temperature, and apparent power.

Power supplies come in both external and internal designs. External units function as standalone components and are available in styles such as board, cabinet, desktop, module, open-frame, enclosed, rack-mount, and wall-mount configurations. Internal power supplies, when operating at low temperatures, can be integrated directly into electronic devices. Manufacturers also provide various display options to monitor voltage and current, including digital numerical displays, analog indicators, and graphical or video displays.

For details on available customizations, visit a supplier’s website or reach out to them directly.

How Power Supplies Work

Power supply units (PSUs) operate by:

- Receiving input power from a source such as a battery or wall socket.

- Converting, inverting, or adapting the power as needed.

- Delivering the converted power to an electronic device as output power.

Power supplies regulate two primary types of electrical current: alternating current (AC) and direct current (DC). While both power different electronic devices, most input power sources, such as wall outlets, provide AC.

Alternating Current

Alternating current periodically reverses direction, moving back and forth in cycles. This makes it the standard for commercial and residential power distribution. The rate at which the current changes direction is measured in Hertz (Hz); for example, a frequency of 60 Hz means the current switches direction 60 times per second.

Direct Current

Direct current flows in a single, continuous direction through conductors such as wires, semiconductors, insulators, or even a vacuum. Devices such as cell phones, laptops, medical equipment, video technology, and process control systems rely on DC power. DC power supplies are typically external to the device and housed in protective casings to ensure safety and efficiency.

Power Supplies Images, Diagrams and Visual Concepts

Power supplies are electrical circuits and devices designed to convert mains power or electricity from any electric source to specific values of voltage and current for the target device.

An example of an alternating current (AC) power supply.

An example of an direct current (DC) power supply.

High voltage power supplies are designed to produce a high electrical load.

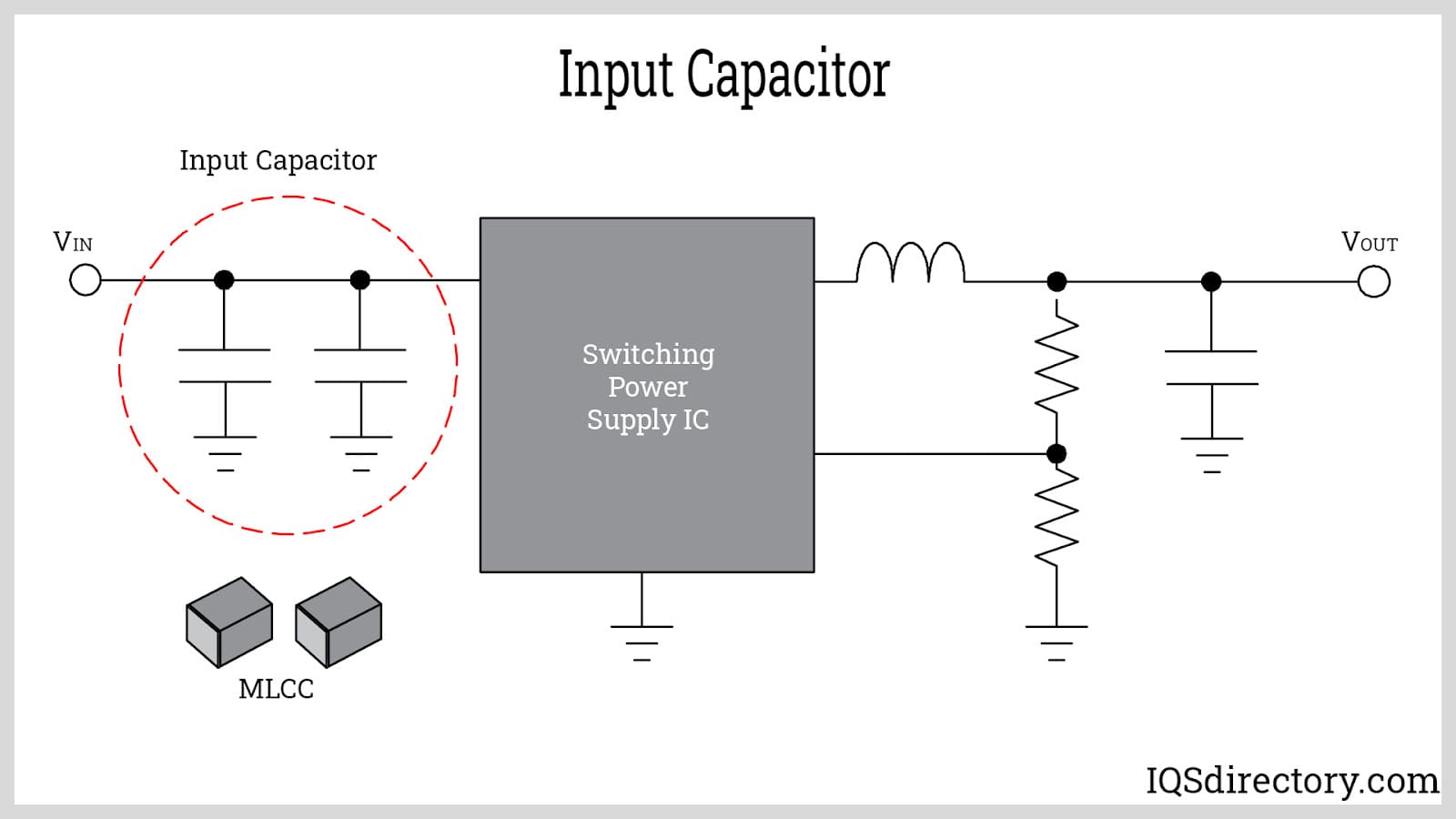

The input capacitor acts as the power supply ripple elimination capacitor for the IC for step down DC DC power supplies.

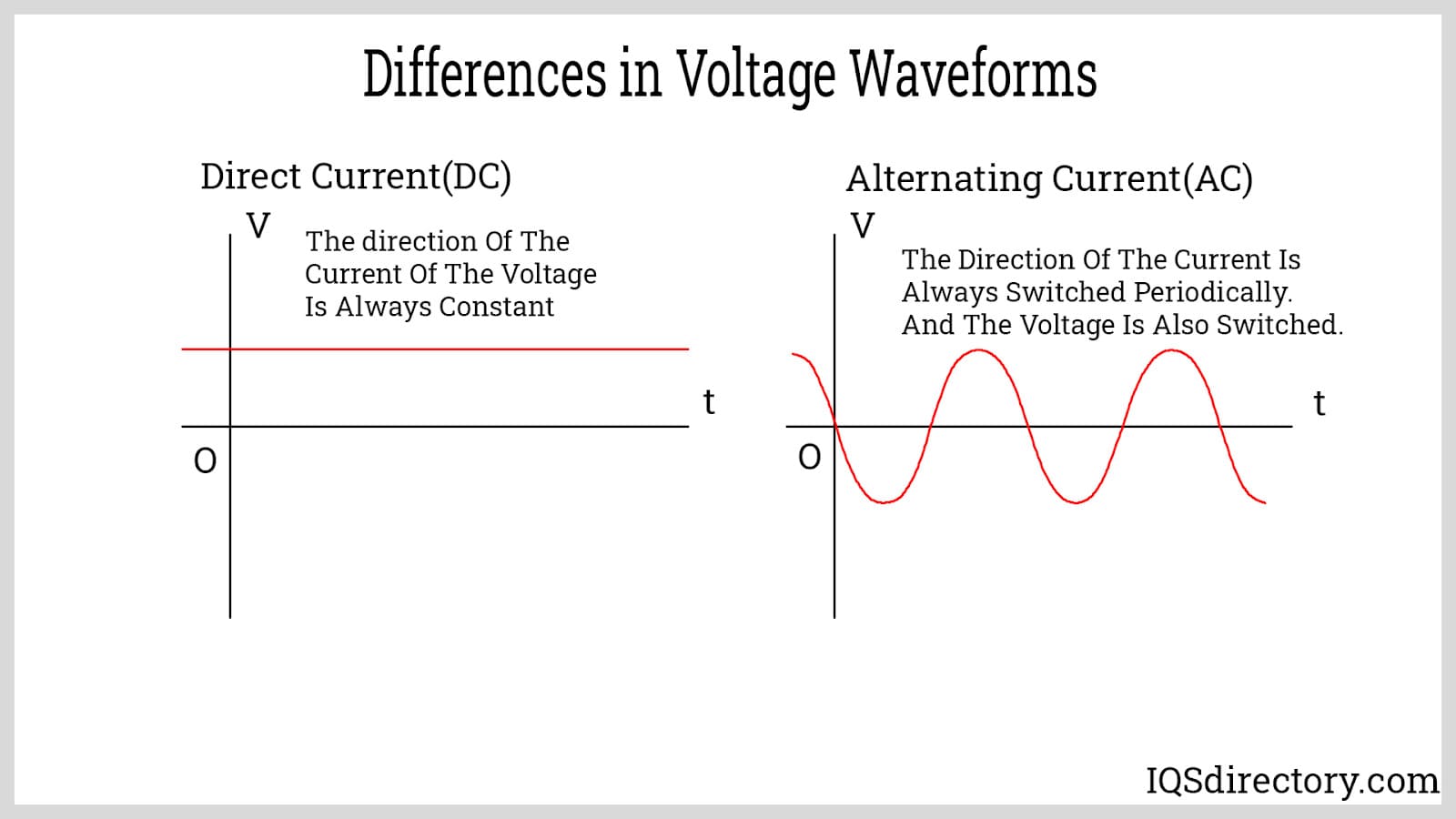

THe difference of the waveforms of both DC and AC current.

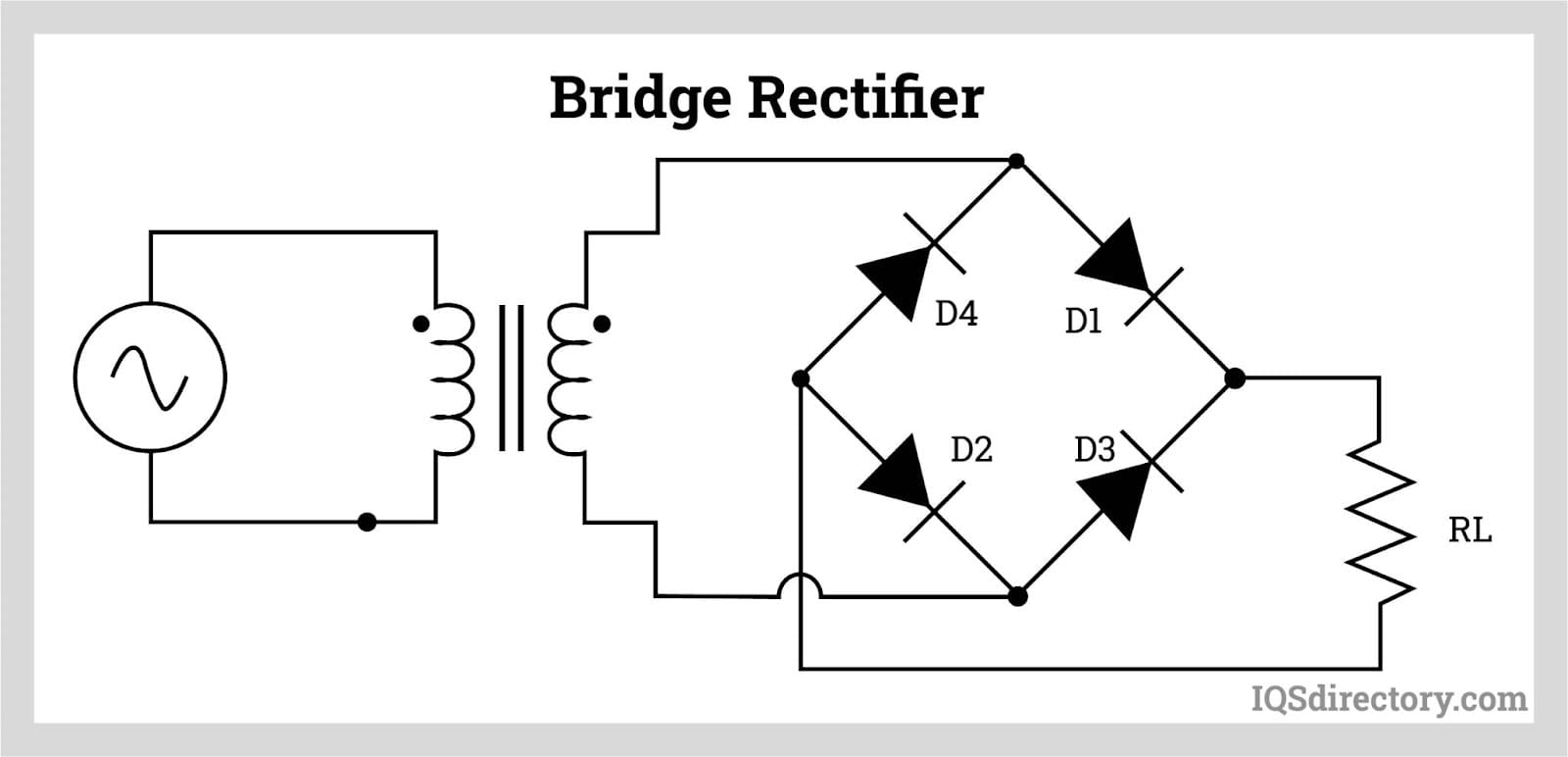

A rectifier, a device that changes the AC power into a pulsating DC.

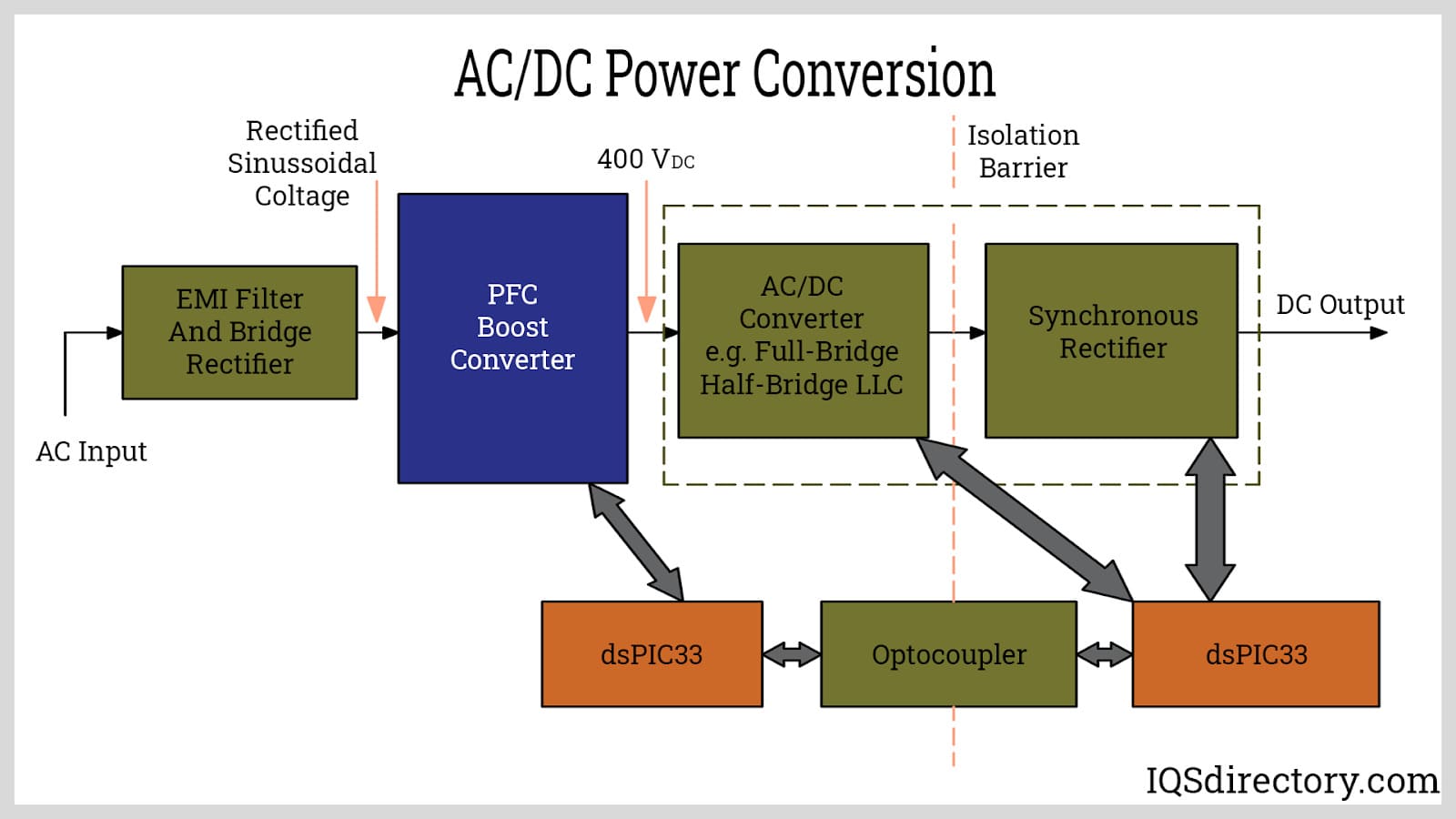

The process in converting AC current input into a DC current output.

The use of a transformer is employed for the reduction of AC voltage into a smaller, the reduced voltage is then rectified into a DC voltage that is filtered to eliminate the ripples.

Types of Power Supplies

Power supplies can be categorized in various ways based on their functionality and application. The primary classifications include variable power supplies and uninterruptible power supplies (UPS).

Variable Power Supplies

Variable power supplies allow users to adjust the output voltage to meet specific requirements, making them ideal for product testing and design applications. However, they are less commonly used today as most electronic devices require regulated power supply.

Uninterruptible Power Supplies (UPS)

Uninterruptible power supplies serve as backup units, ensuring continuous power during outages, brownouts, or surges. They provide a stable, consistent voltage output, often utilizing a DC/AC inverter or DC/DC converter. These units can be standalone or integrated within equipment. Standalone units are known as external UPS, while embedded units are referred to as battery backup UPS.

There are three main types of UPS systems:

- Offline UPS: These standby systems activate when the main power supply drops below a set threshold. They are cost-effective and commonly used for home offices.

- Line Interactive UPS: These systems function like offline UPS but include a voltage regulator to stabilize fluctuating power, making them ideal for business applications.

- Online UPS: Offering the highest level of protection, online UPS units continuously convert AC to DC and then back to AC, ensuring seamless power delivery even during overloads or failures. Often called double-conversion UPS, they are essential for critical systems such as medical equipment.

AC to DC Converters

These power supplies convert AC power from a standard wall outlet into a regulated DC current suitable for electronic devices.

Constant Current Power Supplies

These units maintain a steady output current, compensating for variations in load, line voltage, temperature, and time.

Constant Voltage Power Supplies

Designed to regulate voltage output, these power supplies counteract fluctuations in load, line conditions, and environmental factors.

DC/DC Converters

DC/DC converters modify DC voltage levels by stepping them up or down, as DC power cannot be transformed using conventional transformers like AC power.

DC Power Supplies

These units, including linear power supplies, switching power supplies, and high-voltage power supplies, process input power to deliver a controlled DC output.

Ferroresonant Power Supplies

Used in stable-frequency applications, ferroresonant power supplies offer reliable performance but are sensitive to input frequency variations.

Frequency Converters

These specialized transducers convert periodic electrical signals into digital or analog equivalents. Common types include frequency-to-digital and frequency-to-DC converters.

Half Bridge Converters

These power-switching circuits, composed of two transistors and two capacitors, operate similarly to full bridge converters.

High Voltage Power Supplies

Capable of generating hundreds or thousands of volts, these power supplies are commonly used in telecommunications, video systems, and medical equipment. Some models offer adjustable outputs controlled locally or via computer interfaces.

Power Inverters

Power inverters convert DC power into AC power and can be mechanical (motor-driven), ferroresonant, or solid-state.

Linear Power Supplies

Equipped with a large laminated transformer, linear power supplies isolate and step down AC input voltage before rectifying and regulating it into a stable DC output.

Modular Power Supplies

These power supplies consist of independent sections, such as power modules, input filters, and regulation units, allowing for customizable configurations.

Off-Line Power Supplies

Operating directly from an AC power source, off-line power supplies bypass the need for an initial power transformer before rectification and filtering.

Operational Power Supplies

These units feature a high open-loop gain regulator, which can be programmed using passive components, enabling them to function similarly to operational amplifiers.

Rectifiers

Rectifiers convert AC power into DC power using diode assemblies, ensuring a consistent and regulated electrical output.

Switch Mode Power Supplies

These power supplies use a series of diodes, capacitors, and transformers to convert high-voltage AC into regulated, low-voltage DC power. By utilizing high-frequency switching technology, they achieve efficiency and compactness while providing a stable power output.

Power Supply Applications

Power supplies serve as the backbone of nearly every electrical device, whether integrated directly into a system or operating as an external, portable module. Their design depends on factors such as operating temperature and the potential for overheating. From everyday electronics to industrial machinery, power supply units (PSUs) play a crucial role in ensuring uninterrupted functionality. They power desktop and laptop computers, mobile devices, lasers, medical equipment, telecommunications systems, lighting, household appliances, and heavy-duty industrial machinery.

PSUs deliver either alternating current (AC) or direct current (DC), depending on the application. Most modern home and office electronics operate on a 12V power supply, while industrial systems often require high-voltage solutions for enhanced performance and reliability.

Equipment Components of Power Supplies

The components of a power supply unit vary based on its configuration and intended use. At the core of these systems are power inverters, converters, and adapters, which regulate and transform electrical energy to meet specific device requirements.

Advanced power supplies may feature adjustable voltage controls, frequency modulation, computer interfaces, cooling mechanisms, and built-in safeguards such as overcurrent protection and heatsinks. A prime example is the PSU in desktop computers, typically housed in a compact metal box with a power cord receptacle and a cooling fan visible at the rear of the system.

Many power supply systems are also equipped with backup batteries to ensure continued operation in the event of a power outage. Additional features may include overvoltage protection, power factor correction, pure sine wave output, remote on/off capabilities, short circuit protection, and water-cooling systems for high-performance applications.

Standards and Specifications for Power Supplies

Power supplies must meet rigorous safety and compliance standards, which vary by industry, application, and location. Organizations such as the International Electrotechnical Commission (IEC), International Organization for Standardization (ISO), Canadian Standards Association (CSA), and Underwriters Laboratories (UL) establish guidelines governing energy efficiency, insulation, voltage classifications, and safety measures for medical, laboratory, and industrial use. To ensure compliance, businesses should consult industry experts to identify the necessary certifications for their specific power supply applications.

Finding a Power Supply Manufacturer

Selecting a reliable power supply provider is key to obtaining efficient, high-quality solutions tailored to your needs. The manufacturers featured on this page have a proven track record of delivering exceptional products and service. To find the best match, start by outlining your specifications, including budget, lead times, delivery and installation requirements, and post-installation support. Partnering with an experienced supplier ensures you receive the right power supply solution for your unique application.

Power Supply Terms

Autoranging Input

An internal sensing circuit that automatically adjusts to the appropriate input voltage range within the power supply.

Breakdown Voltage

The maximum AC or DC voltage that can be applied to the power supply’s input, output, or chassis without causing failure.

Burn-in

The process of operating a newly manufactured power supply at its rated load for a set period to identify early failures or latent defects before delivery to the customer.

Common-Mode Noise

Electrical noise measured between the DC output and return lines relative to the input ground.

Compliance Voltage

The output voltage of a constant current power supply.

Cooling

The process of dissipating heat from a power supply through convection, forced air, radiation, or liquid cooling, mitigating heat generated during regulation, transformation, filtering, and rectification.

Cross Regulation

The percentage of voltage variation in one output of a multi-output power supply caused by a load change in another output.

Current Limiting Circuit

A protective circuit that restricts the maximum output current to prevent damage to the power supply or connected load.

Design Life

The expected operational lifespan of a power supply, during which it maintains its specified performance.

Differential Mode Noise

Also called "ripple," this is the noise measured between the DC output and its return line.

Drift

The gradual change in output voltage over time, measured under stable conditions after an initial warm-up period.

Efficiency

The ratio of output power to input power, typically measured at full load under nominal conditions.

Electromagnetic Interference (EMI)

Also known as radio-frequency interference (RFI), unwanted high-frequency energy conducted through input/output lines or radiated into space. EMI is primarily caused by switching transistors, output rectifiers, and zener diodes.

Foldback Current Limiting Circuit

A protection circuit that progressively reduces output current under overload or short-circuit conditions to prevent excessive power dissipation.

Ground

An electrical connection to earth or a conductor with zero voltage potential.

Inhibit

A function that allows remote shutdown of a power supply’s output.

Input Line Filter

A low-pass or band-reject filter designed to reduce noise at the power supply input, sometimes installed externally.

Isolation Voltage

The maximum continuous AC or DC voltage that can be safely applied between input and output or between chassis and power supply components.

Margining

The intentional adjustment of output voltage above or below its nominal value to test system performance within supply voltage tolerances, often controlled electronically.

Minimum Load

The lowest current or power required to maintain the power supply’s specified performance.

Non-Shutdown Overvoltage Protection

A feature that allows a power supply to continue operating at a predefined upper voltage limit without shutting down, automatically resuming normal function once the overvoltage event ends.

Overvoltage Protection

A safety circuit that either shuts down the power supply or diverts excess voltage to ground if an overvoltage condition occurs.

Parallel Operation

The connection of multiple power supplies with identical output voltages to share a load, increasing overall output current.

Peak Power

The maximum output power a supply can momentarily deliver without damage, typically exceeding its continuous rated capacity and used only intermittently.

Power Fail

A warning signal indicating that the input voltage is insufficient to sustain regulated output power.

Reverse Voltage Protection

A safeguard preventing damage if reverse voltage is applied to the power supply’s input or output terminals.

Safety Ground

A dedicated path to earth designed to prevent electric shock by diverting potentially hazardous currents caused by faults or malfunctions.

Turn-on Time

Also known as "warm-up time," the period required for a power supply to reach stable operation after receiving proper input power.

More Power Supplies Information