Pressure Switches

A pressure switch is a device that detects variations in fluid pressure and reacts by either establishing or interrupting an electrical connection to activate an alarm or control the operation of equipment. These switches are precisely calibrated to engage at a specific pressure level, known as the setpoint, and are engineered to open or close the circuit based on whether the pressure is increasing or decreasing. While there are multiple techniques employed to measure pressure, pressure switches generally fall into two main categories: electromechanical or electronic.

Pressure Switches FAQs

What does a pressure switch do?

A pressure switch detects changes in fluid pressure and either opens or closes an electrical circuit to control equipment, trigger alarms, or maintain system safety based on the set pressure level.

What is the difference between mechanical and electronic pressure switches?

Mechanical pressure switches operate through direct contact and do not require power, while electronic pressure switches use sensors and provide precise, programmable digital outputs for advanced control systems.

Where are pressure switches commonly used?

Pressure switches are used in industrial systems, water wells, HVAC units, compressors, and hydraulic or pneumatic equipment to regulate pressure, ensure safety, and prevent over-pressurization or system failure.

What materials are pressure switches made from?

Pressure switches are typically constructed from stainless steel, brass, or acetal, with specialized materials like Hastelloy or Monel used for corrosive or harsh chemical environments to ensure durability and performance.

What industries rely on pressure switches?

Industries such as manufacturing, utilities, automotive, aerospace, and wastewater treatment use pressure switches to control fluid flow, protect equipment, and maintain safe operating conditions in pressurized systems.

What standards apply to pressure switches in the U.S.?

In the United States, pressure switches often follow NEMA standards for safety and performance. Additional certifications like UL or CE may apply to ensure compliance with national and international regulations.

What factors should be considered when selecting a pressure switch?

Key factors include cost, accuracy, repeatability, operating temperature, vibration resistance, and material compatibility. Partnering with a reputable manufacturer ensures performance reliability and long-term durability.

Advantages of Pressure Switches

Pressure switches play a critical role in a wide range of applications, offering reliability and safety in processes that involve pressurized fluids. Their ability to provide dependable operation ensures that systems function smoothly while preventing potential hazards. These devices are designed for user-friendly operation, with electronic pressure switches being particularly simple to configure and control. Their adaptability makes them valuable across industries, accommodating diverse pressure levels, system sizes, environmental conditions, and operational requirements.

The History of Pressure Switches

The study of pressure measurement dates back to the late 16th century, beginning with Galileo’s pioneering work. In 1594, he secured a patent for a water pump that utilized pressure to facilitate irrigation. This early exploration of pressure principles laid the groundwork for future developments. In 1644, the Italian physicist Evangelista Torricelli constructed a sealed vacuum tube containing mercury. By submerging one end of the tube in a basin of mercury, he observed that the liquid consistently fell to a height of precisely 760 mm, leaving an empty space at the top. While he could not fully explain the phenomenon, he named this void a vacuum, bringing the world closer to understanding pressure mechanics. Just four years later, Blaise Pascal identified the force responsible—the weight of the air above—and coined the term "pressure" to define it. The 17th century saw further experimentation with air pressure, as scientists and engineers explored its ability to move objects and influence physical elements. In 1661, the Anglo-Irish chemist Robert Boyle conducted experiments using "J"-shaped tubes to examine the relationship between pressure and trapped gas. His work led to Boyle’s Law, which established that pressure and volume have an inverse relationship when temperature and the quantity of gas remain constant.

Developments in the 1800s

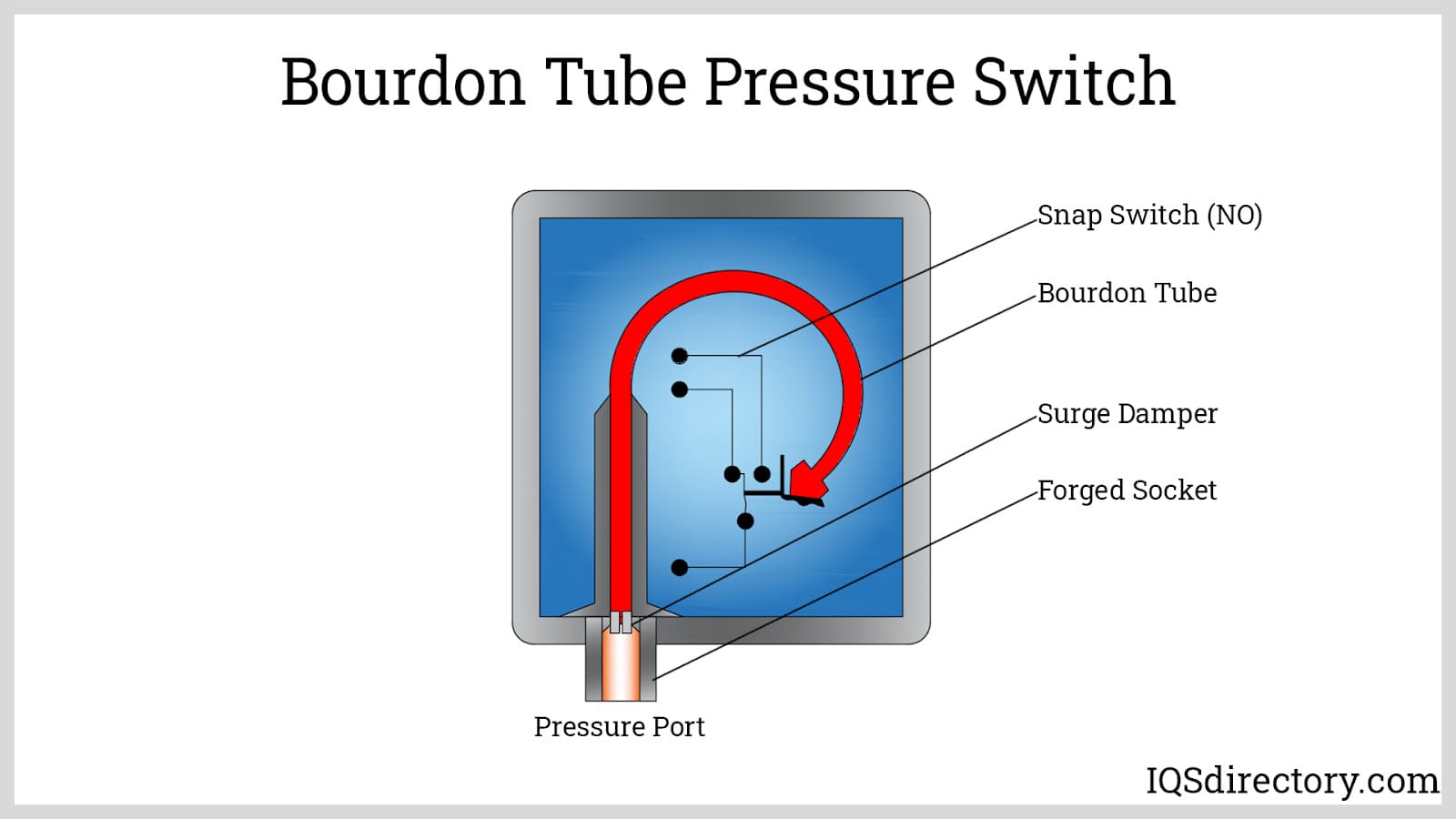

Building upon these scientific principles, inventors in the 19th century began creating practical applications for pressure measurement, leading to the development of pressure switches. In 1843, French scientist Lucien Vidie introduced the aneroid barometer, which utilized a spring balance to measure atmospheric pressure. This instrument mechanically amplified changes in pressure through an indicator system. Six years later, Eugene Bourdon patented the Bourdon tube pressure gauge, which became the first widely recognized mechanical pressure measurement device—a design still in use today. The integration of the Bourdon tube with a mercury switch facilitated the creation of one of the earliest pressure switches, laying the foundation for electromechanical pressure switches. These early devices relied on sensing elements like the Bourdon tube to activate a switch in response to pressure changes.

While the Bourdon tube pressure switch was a groundbreaking invention, it had its limitations. As a tracing-type sensing element, the Bourdon tube had a shorter operational lifespan and struggled with environmental factors such as pump ripple, surge pressure, vibration, and ambient temperature fluctuations. Efforts to improve performance by using higher-quality materials proved costly, prompting engineers to seek alternative pressure switch designs.

Advancements in the 1900s

By 1930, engineers began incorporating transduction mechanisms into pressure sensing devices, transforming mechanical movements into electrical signals. This innovation led to the development of the first pressure transducers. In 1938, researchers at the Massachusetts Institute of Technology and the California Institute of Technology independently worked on bonded strain gauges. E.E. Simmons of Caltech won the race to secure a patent, marking a significant advancement in solid-state pressure switches. Decades later, in 1980, Barksdale Inc. introduced the first widely available solid-state pressure switches, featuring bonded strain gauge sensors combined with triac switches.

Meanwhile, in 1956, Roy Dunlap recognized a need for a reliable pressure switch to prevent oil tank overflows. Seeking assistance, he collaborated with Ben Brown, a physics professor at the University of Kansas. Together, they designed the Static “O” Ring® pressure switch, which featured a force-balanced, piston-actuated assembly sealed by a flexible diaphragm and a static o-ring. This design minimized wear and tear, ensuring long-term durability. Dunlap soon established a company to manufacture and distribute these switches, which later evolved into SOR Inc.

Modern-Day Pressure Switches

Today, solid-state pressure sensors dominate the industry, offering advanced features such as digital displays, digital and analog outputs, full programmability, and multiple switch points. These enhancements provide precise pressure monitoring and control across various industrial applications.

Despite the advantages of electronic pressure switches, mechanical pressure switches remain essential. Unlike electronic models, which require a power source to function, electromechanical pressure switches operate purely through mechanical contact. This makes them invaluable as backup safety devices in situations where power failure could lead to system failure, financial losses, or safety hazards. Many industries continue to rely on pressure switches as redundant safeguards, ensuring that equipment continues to function even if a primary pressure transmitter loses power. Additionally, their lower acquisition costs and minimal operational expenses make mechanical pressure switches a cost-effective solution, reinforcing their relevance in modern industrial systems.

Pressure Switch Design

-

Production Process

Manufacturers construct pressure switches using either a mechanical sensing element paired with a snap-action switch or an electronic system featuring an output signal and a programming interface. In mechanical pressure switches, the device is calibrated to a specific setpoint, either predetermined by the manufacturer or specified by the customer. These switches may feature either a fixed or adjustable setpoint, depending on the design. In electronic pressure switches, the system is either factory-programmed with predefined switch points or equipped with a programming interface that enables users to set and adjust switch points manually. Some models incorporate logic systems that dynamically modify switch points and output signals based on operating conditions. To enhance usability, programming interfaces include integrated buttons and an LED or LCD digital display.

Switch Materials

The key wetted components in a pressure switch are the sensing element and the process connection, both of which must be constructed from materials suited to the specific application. Pressure switch materials vary widely, depending on the intended environment and media, and may include acetal, brass, stainless steel. For particularly harsh applications involving corrosive chemicals, more specialized materials such as Alloy 20, Hastelloy, and Monel provide superior resistance and durability.

Switch Considerations and Customization

Manufacturers must take multiple factors into account when designing pressure switches, including accuracy requirements, cycle rates, adjustability, and the specific pressure points at which the switch must actuate. Each switch is calibrated to at least one actuation point, ensuring automatic response to pressure fluctuations. While some models are factory-set and non-adjustable, others allow users to modify actuation points as needed. Certain pressure switches are designed to operate at multiple pressure points, enabling them to serve as sophisticated regulators in complex pressure systems.

The goal in manufacturing pressure switches is to create a product that is durable, long-lasting, precise, and easy to operate. To achieve this, manufacturers can tailor various aspects of the switch, including pressure sensitivity, cycle speed, operational lifespan, actuation point flexibility, and the optimal pressure range for performance. Depending on the application, pressure switches can also be configured to automatically open or close in response to pressure changes, either interrupting or initiating the flow of fluid or electrical current within a system.

Pressure Switch Images, Diagrams and Visual Concepts

Pressure switch, a mechanical or electronic device activated by the pressure of fluids, air, or gas when reaches a threshold.

Pressure switch, a mechanical or electronic device activated by the pressure of fluids, air, or gas when reaches a threshold.

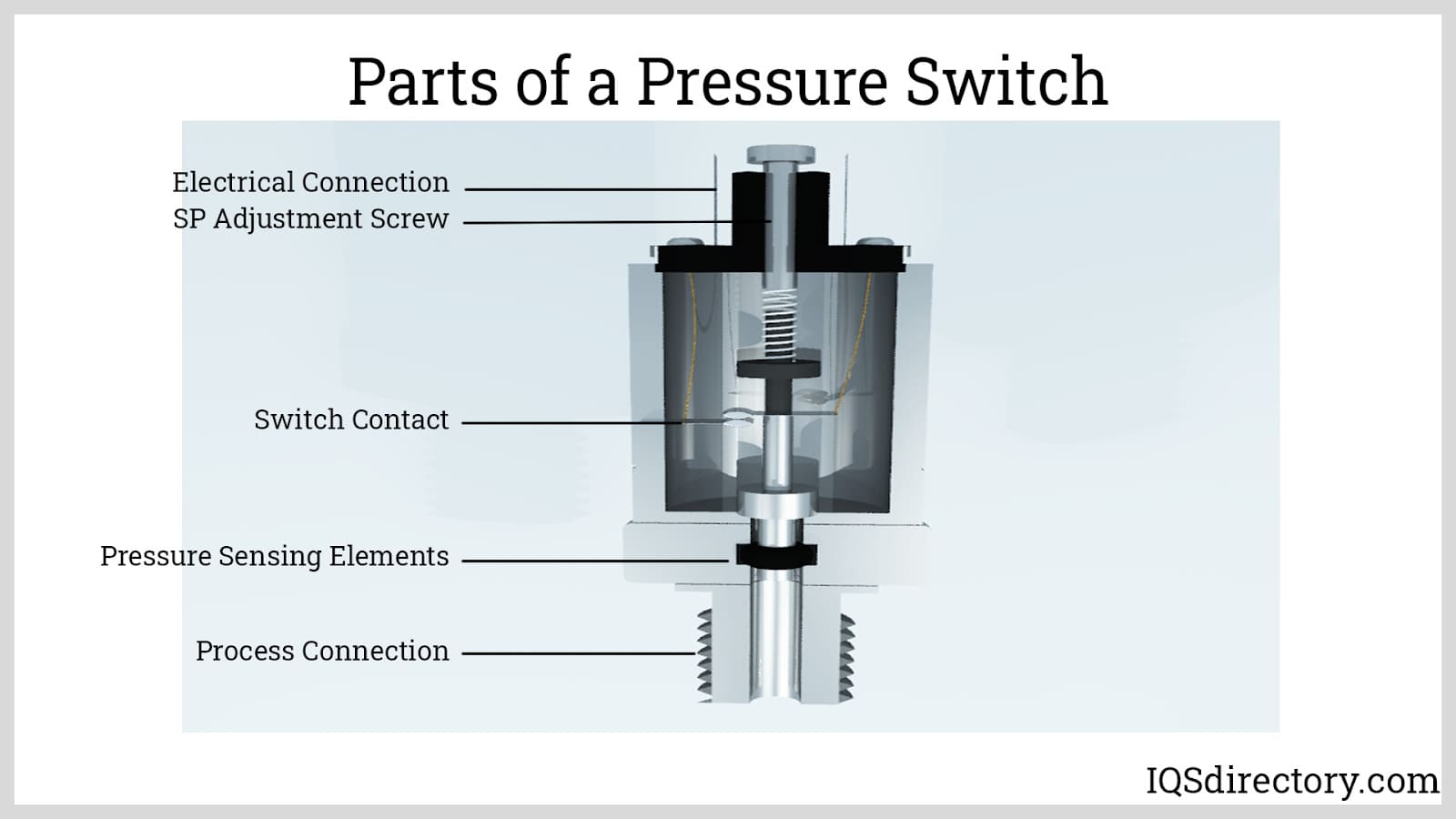

The different parts of pressure switches shows one side is subject ot fluid pressure and the other is subject to atmospheric pressure.

The different parts of pressure switches shows one side is subject ot fluid pressure and the other is subject to atmospheric pressure.

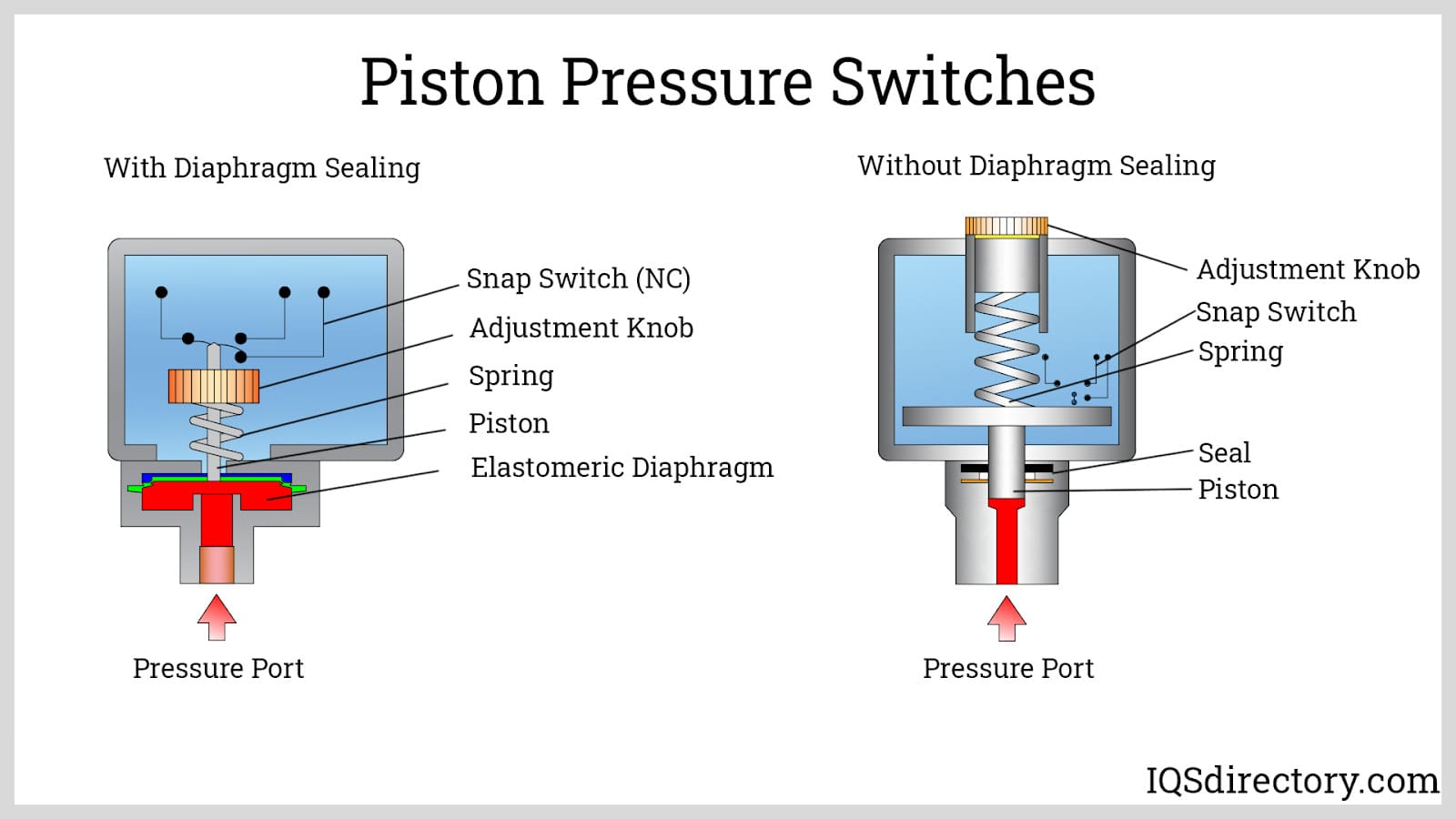

As the fluid pressure changes, causes the piston to move axially, which activates the switch.

As the fluid pressure changes, causes the piston to move axially, which activates the switch.

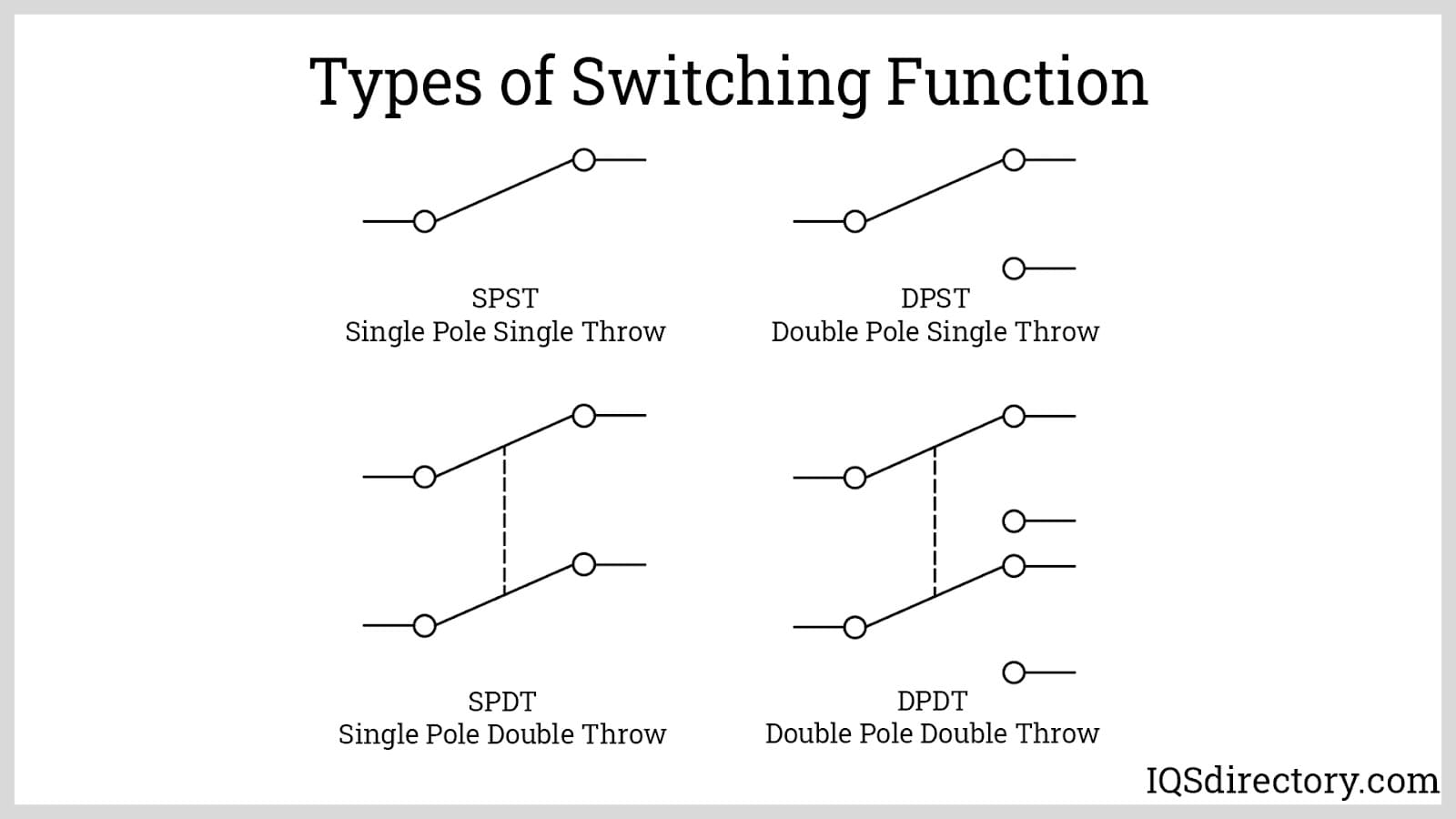

Switches can be characterized according to the number of poles which refers to the number of circuits a switch can control and throws, the number of connections the switch can make.

Switches can be characterized according to the number of poles which refers to the number of circuits a switch can control and throws, the number of connections the switch can make.

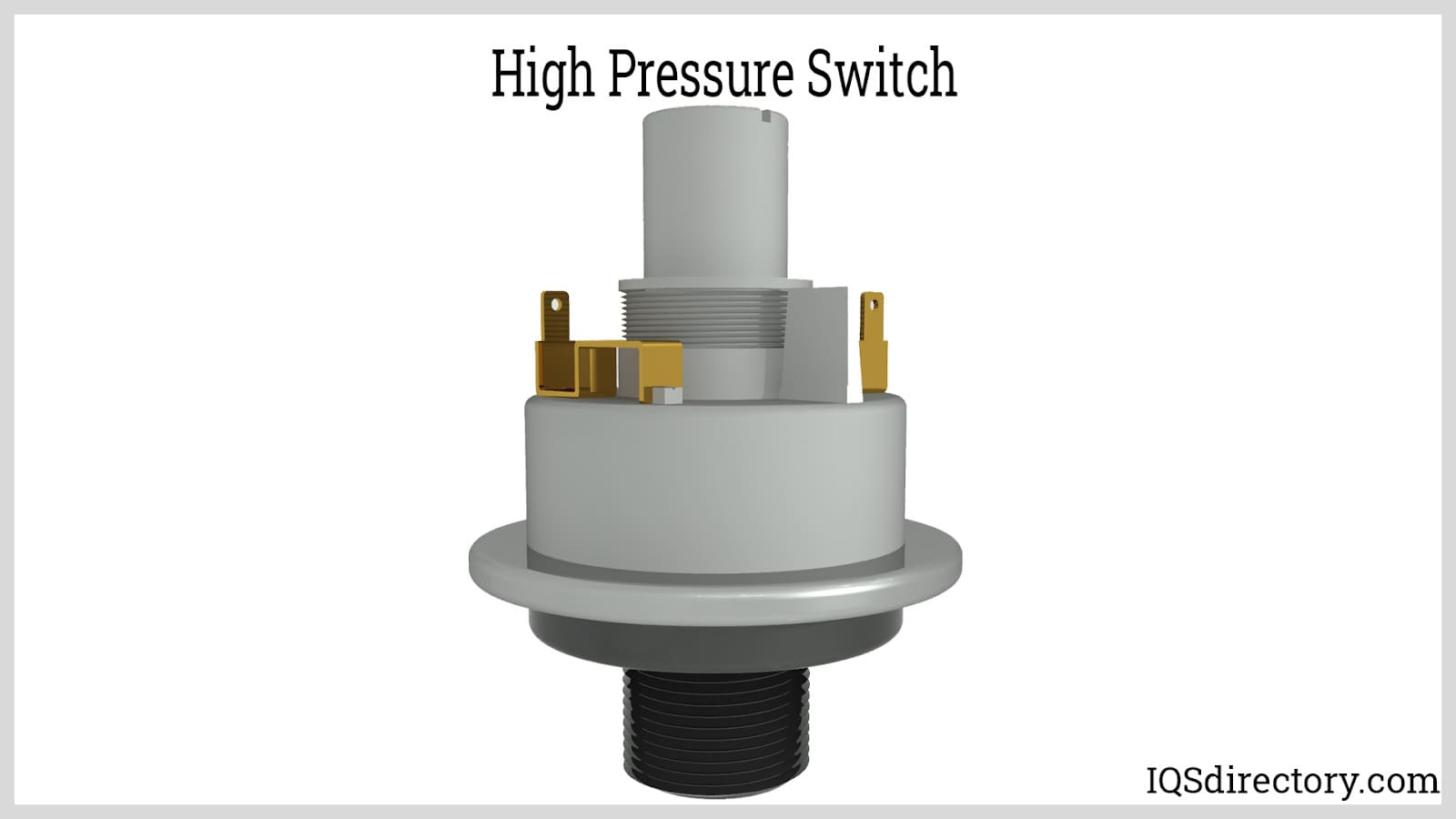

High pressure switches have high pressure-proof pressure limits with high durability and tensile strength.

High pressure switches have high pressure-proof pressure limits with high durability and tensile strength.

Low pressure switches are designed to respond to reduced or small fluctuations in pressure.

Low pressure switches are designed to respond to reduced or small fluctuations in pressure.

Bourdon tube pressure switch includes a flexible metallic or elastomeric tube as the pressures increases in the tube it straightens which actuate the switch.

Bourdon tube pressure switch includes a flexible metallic or elastomeric tube as the pressures increases in the tube it straightens which actuate the switch.

Diaphragm pressure switches consists of a metal membrane joined or welded directly to the wetted part of the pressure switch.

Diaphragm pressure switches consists of a metal membrane joined or welded directly to the wetted part of the pressure switch.

Pressure Switch Types

-

Adjustable Pressure Switches

Designed for field adjustments, these switches allow users to modify setpoints directly at the site of operation, providing flexibility in various applications.

Air Compressor Switches

Specifically designed to regulate pressure in air compressors, these switches ensure the system maintains optimal pressure levels by signaling when to increase or decrease pressure.

Air Pressure Switches

These switches monitor and control air pressure within pneumatic systems, responding to changes in air flow and maintaining stable operation.

Displacer Level Switches

Capable of controlling liquid levels in sumps or tanks, these switches offer quick and easy field adjustments to accommodate changing operational needs.

High Pressure Switches

Engineered to withstand extreme pressures, these switches function reliably in systems that reach high pounds per square inch (psig) without compromising performance.

Low Pressure Switches

Sensitive to minimal pressure variations, these switches activate in response to small or reduced pressure levels, making them ideal for delicate pressure regulation.

Oil Pressure Switches

Used to monitor and regulate oil pressure, these switches measure flow rates based on volume, velocity, or mass, ensuring optimal lubrication and system performance.

Solid State Pressure Switches

Equipped with electronic pressure sensors, these switches transmit signals to remote controllers, providing precise pressure regulation with advanced monitoring capabilities.

Ultrasonic Pressure Switches

Commonly utilized in lubrication storage vessels for rotating equipment, these switches detect pressure leaks and alert operators to prevent potential equipment damage.

Water Pressure Switches

Designed to monitor and regulate water pressure in conjunction with pumps, these switches activate based on predefined pressure setpoints.

Well Pump Pressure Switches

Essential for water well systems, these switches automatically control the pump, switching it on or off in response to fluctuations in water pressure.

Pneumatic Pressure Switches

Also referred to as air or gas pressure switches, these devices detect and respond to variations in gas pressure, ensuring system stability. A widely used variety is the air compressor switch, which signals the compressor to adjust pressure levels and indicates insufficient air supply for the suction stage.

Hydraulic Pressure Switches

Activated by liquid pressure, these switches are commonly found in water, oil, and hydraulic systems. Examples include well pump pressure switches, water pressure switches, oil pressure switches, ultrasonic level switches, and displacer level switches.

- Well pump and water pressure switches regulate water flow by initiating it when pressure falls below a certain level and stopping it once optimal pressure is achieved.

- Oil pressure switches are widely used in automotive engines to monitor oil pressure and signal critical low-pressure conditions.

- Ultrasonic level switches excel in liquid storage tanks, as they remain unaffected by pressure and temperature fluctuations while operating without moving parts, eliminating issues related to sediment accumulation.

- Displacer level switches effectively maintain liquid levels in sumps by responding to a predefined setpoint, offering an affordable, reliable, and easily adjustable solution.

-

Furnace Pressure Switches

Designed to monitor fuel supply or fresh air intake, these switches help maintain safe and efficient furnace operation.

Differential Pressure Switch

Used to regulate pressure differences between a cavity and an open atmosphere, these switches play a crucial role in systems like airplane cabins, where pressure must be balanced relative to external conditions. Differential pressure is measured in psi using a differential pressure gauge.

Vacuum Switches

Responsible for maintaining pressure between two closed cavities, these switches activate based on negative pressure changes within a system.

Diaphragm Pressure Switches

Mechanical pressure switches that use an elastomeric diaphragm to detect pressure fluctuations, triggering either a mechanical switch or a valve, such as a solenoid valve, when activated.

Pressure Sensitive Mats

Mats designed to generate an electrical signal when force is applied. Depending on the design, they may provide a single output or multiple signals. Common applications include interlock systems in hazardous machinery areas, automatic door activation, and security or attendance tracking through movement detection.

Pressure Switch Applications

Pressure switches play a crucial role in the alarm, shutdown, activation, and pressure regulation of pneumatic and hydraulic systems, making them indispensable in any process that requires flow control or over-pressurization protection. Industries such as utilities, chemical manufacturing, process manufacturing, automotive, and home appliances rely heavily on pressure switches to maintain safe and efficient fluid pressure regulation. Public buildings also integrate pressure switches into their systems to ensure safety in high-pressure applications.

These switches contribute to the safe and reliable operation of an extensive range of equipment, including https://www.iqsdirectory.com/air-compressors/, pressurized vessels, furnaces, industrial heating systems, blowers, generators, cars, off-road equipment, compressors, turbines, space stations, wastewater treatment facilities, process equipment, pumps, control panels, and pipelines. In battery systems, pressure switches prevent overcharging by shutting off the charger when the internal cell pressure reaches a critical level. Industrial facilities particularly benefit from pressure switches for over-pressurization protection, as they serve as a safer and more cost-effective alternative to safety relief valves. Unlike relief valves, which can leak during operation and waste energy—sometimes creating additional hazards—pressure switches enable precise pressure regulation at the source. By accurately detecting pressure anomalies, they can automatically shut down a process before dangerous conditions escalate.

Features of Pressure Switches

Pressure switches are designed to detect and respond to fluctuations in gas or liquid pressure. They achieve this through various sensing mechanisms, which allow them to actuate mechanical switches or control valves as needed. Some models incorporate pressure sensors that directly react to changes in pressure levels, triggering a mechanical switch or valve actuation. Others operate in conjunction with pressure transducers, also known as pressure transmitters, which convert pressure levels into electrical signals and relay them to a display meter for monitoring.

Mechanical or electromechanical pressure switches operate by bringing the actuated switch into direct contact with the pressurized fluid. These switches function with either a pre-set or user-adjustable switch point, enabling tailored pressure control. Electronic or solid-state pressure switches, on the other hand, utilize piezoresistive pressure sensors that measure pressure levels and translate them into electrical signals, providing highly accurate and automated pressure regulation.

Standards and Specifications for Pressure Switches

In the United States, one of the primary organizations responsible for establishing pressure switch standards is the National Electrical Manufacturers Association (NEMA). NEMA publishes standard ratings that provide critical information on safety, performance, construction, composition, and tolerances, ensuring that pressure switches meet stringent industry requirements. Selecting a manufacturer that adheres to verified NEMA ratings is a reliable way to ensure quality and compliance.

In Europe, pressure switches are commonly evaluated using IP (Ingress Protection) ratings and CE (Conformité Européene) certification, both of which indicate a product’s durability and adherence to regional safety standards. Additionally, it is often beneficial to look for a pressure switch with a UL (Underwriters Laboratories) safety rating that aligns with the intended application. Regardless of location, it is essential to verify that a pressure switch has been tested and certified for safety and performance. These certifications serve as clear indicators of reliability and regulatory compliance.

Many industries also impose specific certification requirements for pressure switches, making it crucial to confirm that a manufacturer or supplier can meet those standards before proceeding with a purchase. Ensuring compliance with both industry regulations and international safety ratings helps guarantee that the chosen pressure switch will function effectively within its designated environment.

Things to Consider When Purchasing Pressure Switches

Some things to consider and evaluate when looking for a pressure switch are cost, accuracy, repeatability, and the material to be handled. Also important are operating temperature and capacity to operate with vibration and shock. In addition to these technical considerations, you must also make sure to partner with the right manufacturer. Who is the right manufacturer? The right manufacturer is the one who will listen carefully to your requirements and requests, and make sure to do everything to deliver you the best product and experience possible. Find a contract manufacturer or supplier like that by browsing towards the top of this page, where we have our top picks listed.

Several factors should be carefully evaluated when selecting a pressure switch, including cost, accuracy, repeatability, and compatibility with the material being handled. Additional considerations such as operating temperature, resistance to vibration and shock, and overall durability are critical to ensuring reliable performance.

Beyond technical specifications, choosing the right manufacturer is equally important. A reputable manufacturer will take the time to understand specific application requirements and prioritize customer needs to deliver the best possible product and service experience. Partnering with a supplier that values quality and customer satisfaction ensures that the pressure switch will not only meet performance expectations but also provide long-term reliability.

Pressure Switch Accessories

Several accessories can enhance the functionality and longevity of pressure switches, including audible alarms, delay relays, and solid-state relays, which improve monitoring, control, and response capabilities.

One of the most widely used accessories is the diaphragm seal, which is installed between the pressure switch and the vessel containing the measured fluid. Acting as a protective barrier, the diaphragm seal isolates the pressure switch’s sensing element from the process fluid, preventing contamination or damage. This accessory also allows the pressure switch to be removed for maintenance or replacement without requiring a complete system shutdown, ensuring uninterrupted operation.

Another essential accessory is the snubber, designed to protect the pressure switch from pressure surges. Sudden pressure spikes can lead to inaccurate readings, shorten the switch’s lifespan, or even damage the sensing element. By suppressing pulsations and absorbing shock, snubbers help maintain accurate performance and extend the durability of the pressure switch in high-pressure environments.

Pressure Switch Terms

-

Accuracy

The allowable deviation from the switch setpoint, measured in pounds per square inch (psi) or as a percentage, ensuring reliable and precise operation.

Actuation Point/Setpoint

The specific pressure level at which the snap-action switch activates, either opening or closing the circuit in response to the pressure change.

Actuation Value/Deadband

The difference between the actuation point and the re-actuation point in a pressure-actuated switch, defining the range between switching cycles.

Adjustable Range/Working Pressure

The span of pressure levels a switch is designed to handle under normal operating conditions without failure or performance degradation.

Ambient Pressure

The surrounding pressure that exists around the pressure switch, which may impact its operation and calibration.

Differential

The mechanical motion lost as a switch element reverses itself during operation, influencing the precision of actuation.

Differential Pressure

The variance between a reference point and the actual pressure measurement, often critical for monitoring system performance.

Electrical Switching Element

A component that responds to signals from the pressure sensing element by either opening or closing an electrical circuit.

Flow Meter

A device that quantifies the amount of fluid or gas passing through a system, ensuring accurate flow monitoring and control.

Hysteresis

The difference between a switch’s response to rising pressure versus falling pressure, affecting performance consistency.

Pressure Gauge

An instrument that measures the pressure buildup within a closed system, providing real-time monitoring.

Pressure Sensing Element

The component that moves in response to pressure fluctuations, triggering the switch mechanism.

Pressure Transducers

A device that translates pressure readings into an electrical signal for monitoring or control purposes.

Repeatability

The ability of a pressure switch to consistently actuate at the same setpoints, ensuring precision in repeated operations.

Solenoid Valves

A valve that utilizes an electromagnetically operated solenoid to control fluid or gas flow within a system.

Snap-Action Switch

A mechanism that rapidly shifts contacts from one position to another, ensuring swift circuit opening or closure.

Variable Pressure

The fluctuating pressure levels that activate the pressure switch, dictating its operational response.