Ropes

Ropes are a type of woven or twisted cordage that have served as essential tools for hauling, suspension, and mooring watercraft, among many other uses, since ancient times. Rope construction begins with fibers twisted together to form yarn, which is then twisted into strands. These strands are further twisted or braided to make the final rope. Typically, the fibers are twisted in one direction while the strands are twisted in the opposite direction, creating internal friction that significantly enhances the rope’s strength and durability.

Quick links to Ropes Information

History of Ropes

While the precise origin of rope is debated, the Egyptians are recognized as the first to develop specialized tools for rope-making. Fossilized remnants of ropes and knots have been dated to 15,000–17,000 years ago. Early ropes were hand-made from natural fibers. Today, most ropes are machine-produced and utilize advanced synthetic materials for greater strength, lighter weight, and improved resistance to decay. Early rope applications included fishing nets, hunting traps, attaching stones to sticks for tools, constructing bows, building shelters, making baskets, fastening clothing, and more. Although some ropes are still crafted from natural fibers like coir and sisal, synthetic materials such as nylon and polypropylene have been widely adopted since the 1950s.

Applications of Ropes

- Purpose

- Rope is designed for pulling and lifting but lacks compressive strength, making it unsuitable for pushing. Throughout history, rope has supported hunting, carrying loads, lifting, and climbing. Originally handcrafted, modern ropes benefit from synthetic materials and advanced manufacturing, providing increased strength, lighter weight, and better durability.

- Product Use

- Because rope is used in so many different ways and faces various environmental factors, there is no universal recommendation for the ideal rope type. Common uses include hauling, lifting, construction, maritime activities, sports, fastening, theater, and climbing.

- Manufacturers produce ropes for specialized applications. Twine is a thinner, twisted rope usually made from natural fibers like cotton or linen, used in kitchens, butcher shops, as clotheslines, or for packaging. Twine is also found in sporting equipment such as hockey and basketball nets. Elastic cords have a multi-strand rubber core, allowing them to stretch up to 125% of their length, and are covered with braided synthetic or cotton fibers. Marine rope is specifically designed for use on boats and docks, requiring resistance to salt and water exposure. Proper storage and maintenance are essential for maximizing rope lifespan and safety. When the right rope is selected and maintained, it remains a vital tool in many fields.

Rope Design

Rope manufacturing begins by twisting or braiding fibers and filaments into yarn. The two primary rope construction methods are twisting and braiding. Twisting involves winding three or more strands in one direction while twisting the yarn in the opposite direction, creating a balanced rope that resists kinking and stays intact. The rope ends are fused upon completion to prevent fraying. Twisting has long been the dominant construction technique, but braiding has grown increasingly popular.

Braid rope remains stable under load without spinning or untwisting. Braided ropes come in three main varieties: hollow diamond, diamond with cores, and solid braid. Hollow diamond braids lack a core and are made by weaving fibers over and under each other. Diamond braids with cores include a central solid material for added strength. Solid braid rope uses a lock-stitch construction, preventing unraveling when cut. Solid braids and diamond braids with cores cannot be spliced. Splicing is a method for joining two ropes by interweaving their strands. The strongest and most costly rope is the double braid, in which both outer rope and core are braided.

A rope’s diameter is determined by the yarn thickness, the number of yarns per strand, and the number of strands or braids in the rope. For natural fiber ropes, the fibers are first lubricated with natural oil, then cleaned, straightened, separated, and combed by machines. Synthetic fibers follow a similar process but are usually easier to align. When using long synthetic filaments, several are grouped together through doubling or throwing. The finished yarn is wound onto spools called bobbins and may be dyed to create colored strands or ropes.

Rope Images, Diagrams and Visual Concepts

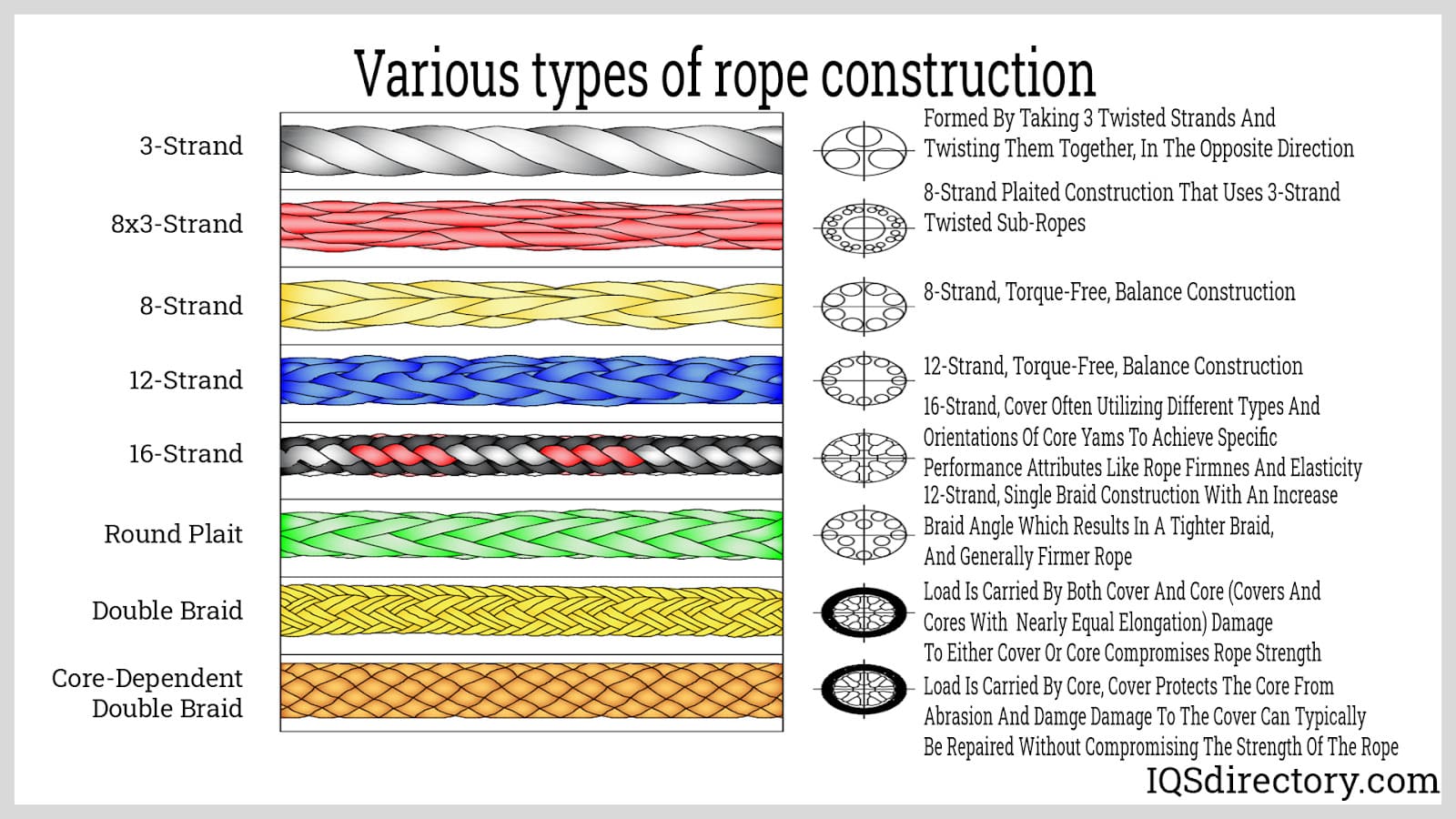

Different rope construction types and the various techniques used to create them.

Different rope construction types and the various techniques used to create them.

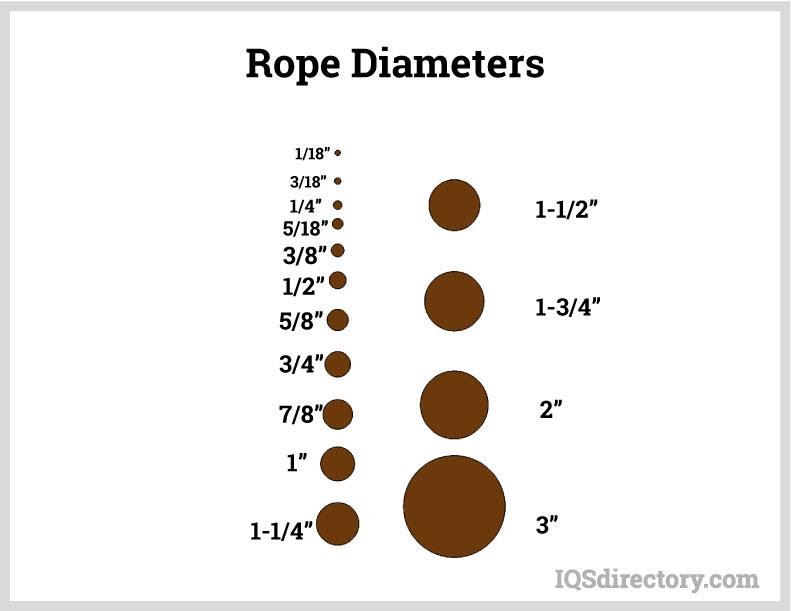

The diameter of a rope affects how easily it can be handled, its comfort, safety, and overall maneuverability.

The diameter of a rope affects how easily it can be handled, its comfort, safety, and overall maneuverability.

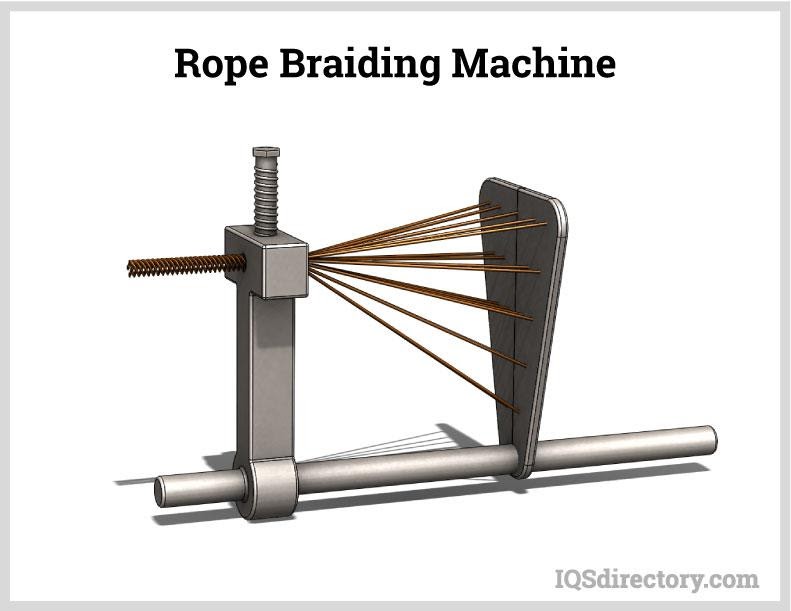

To form rope, strands are fed into a compression tube that twists them before winding them onto the bobbin.

To form rope, strands are fed into a compression tube that twists them before winding them onto the bobbin.

Natural ropes are made from eco-friendly materials like cotton, hemp, or sisal, which are biodegradable and renewable.

Natural ropes are made from eco-friendly materials like cotton, hemp, or sisal, which are biodegradable and renewable.

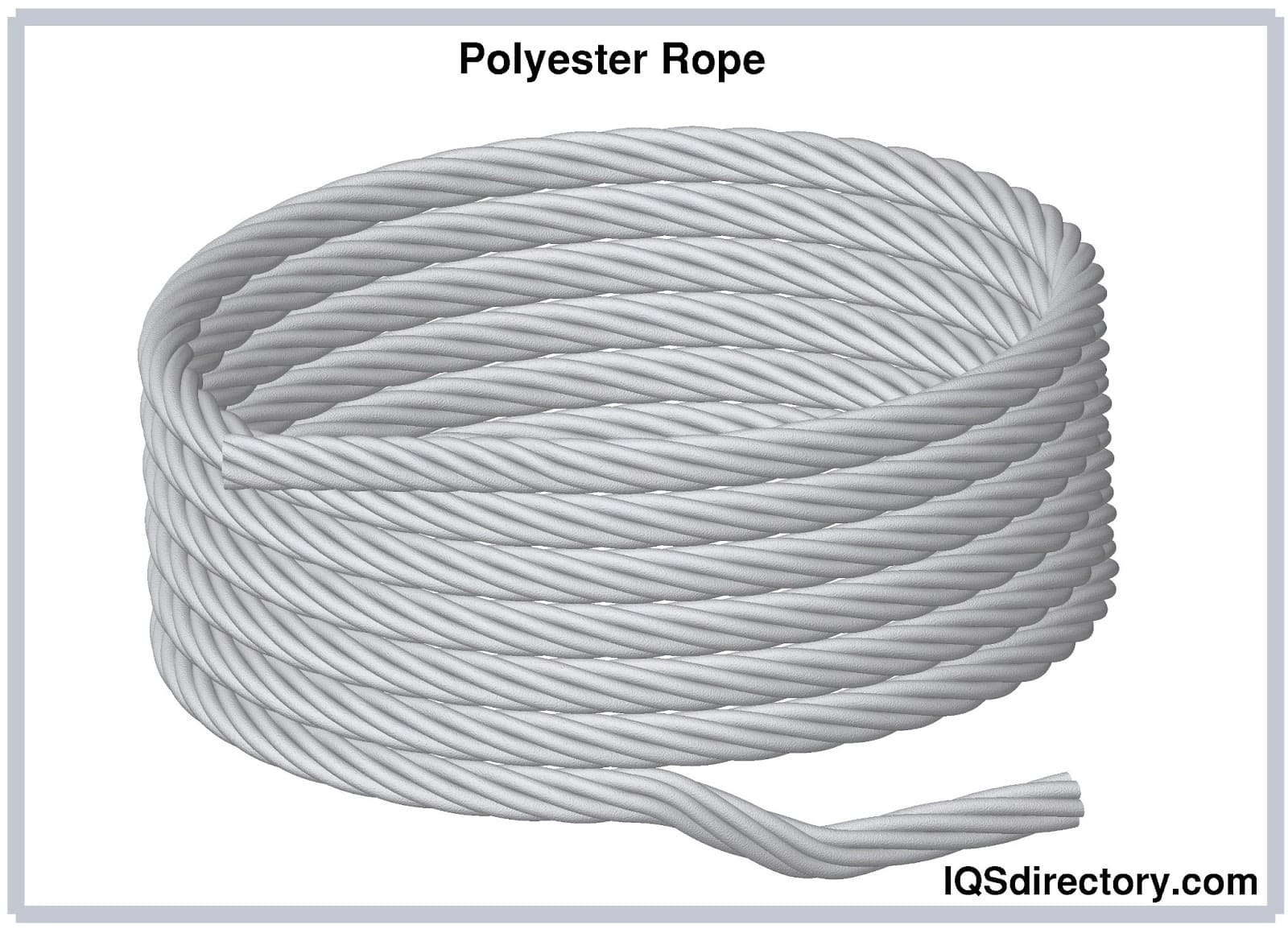

Polyester is a leading synthetic fiber for ropes due to its UV and abrasion resistance.

Polyester is a leading synthetic fiber for ropes due to its UV and abrasion resistance.

Bungee cords consist of two or more elastic strands encased in a woven fabric, typically with hooks on both ends.

Bungee cords consist of two or more elastic strands encased in a woven fabric, typically with hooks on both ends.

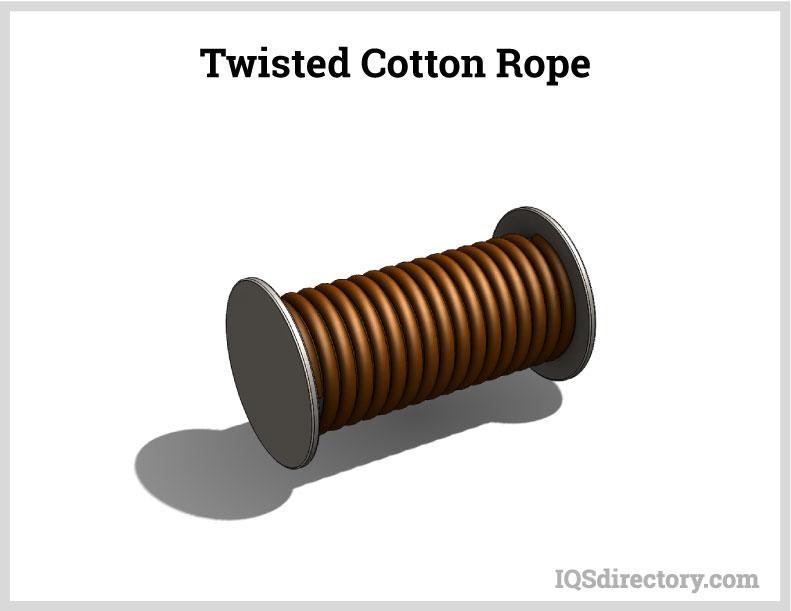

Cotton ropes are flexible and stretchable compared to other natural fibers, but are less durable overall.

Cotton ropes are flexible and stretchable compared to other natural fibers, but are less durable overall.

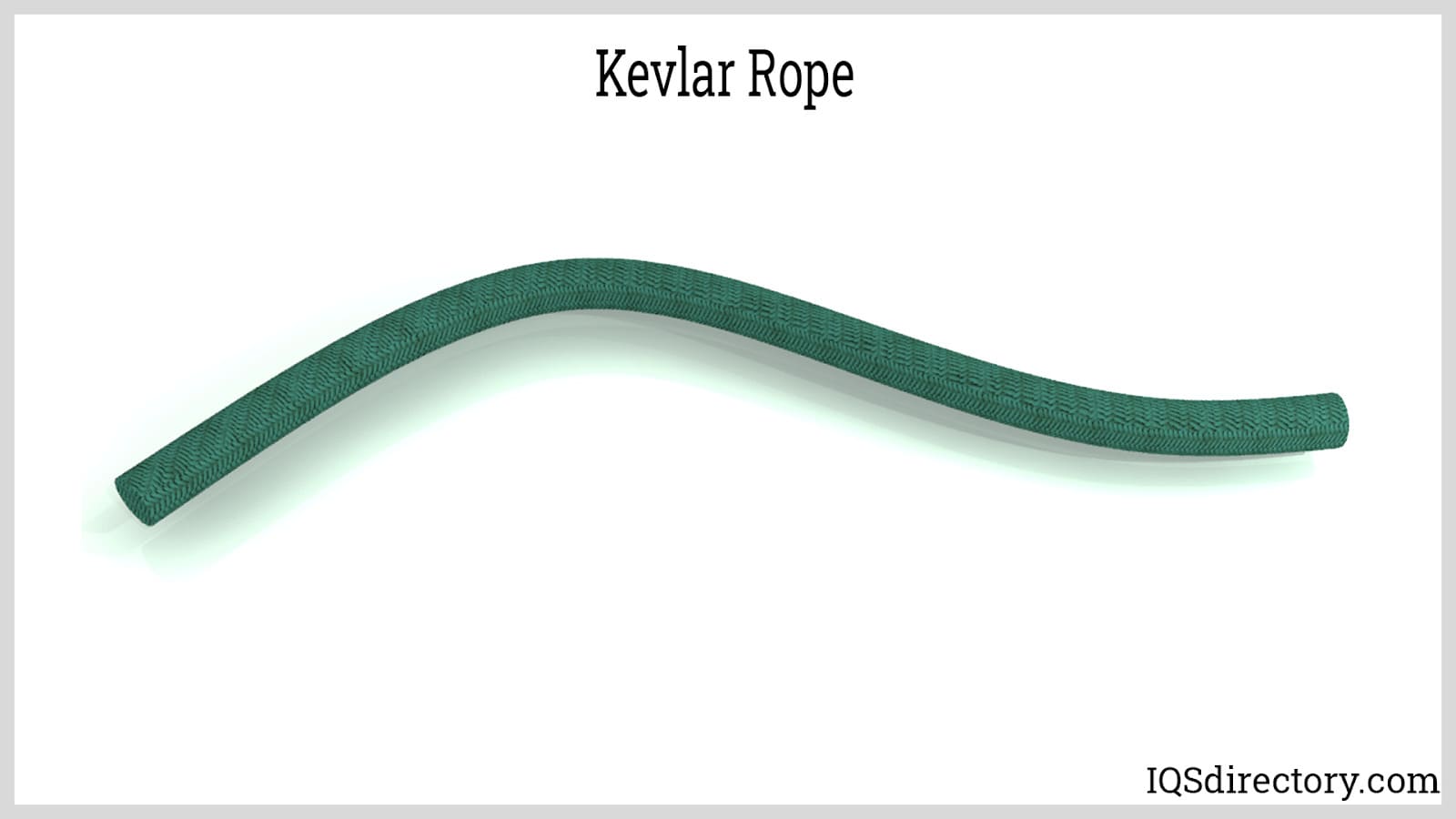

Kevlar rope offers outstanding strength, stiffness, and thermal stability, and performs even better in subzero temperatures.

Kevlar rope offers outstanding strength, stiffness, and thermal stability, and performs even better in subzero temperatures.

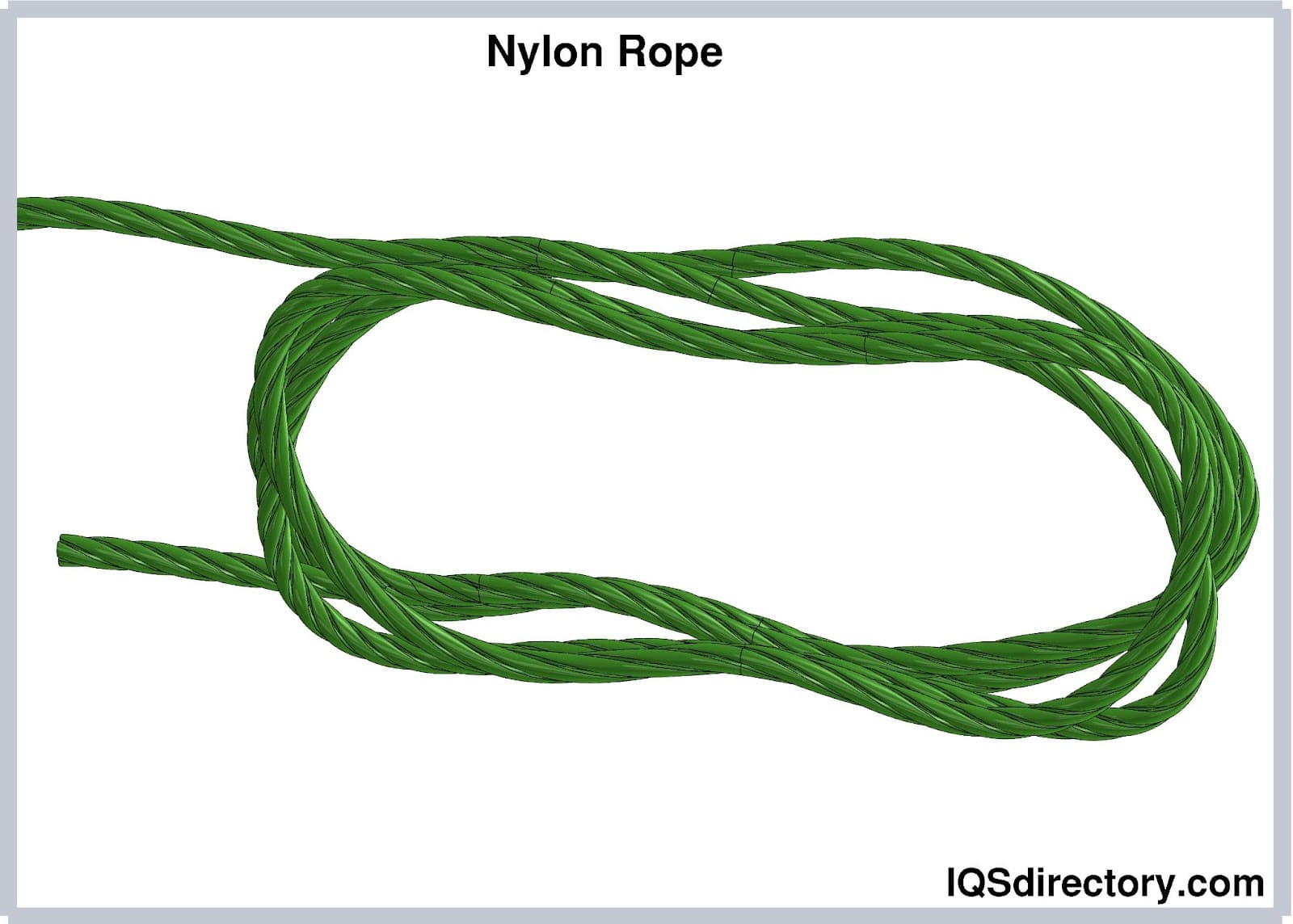

Nylon is one of the strongest synthetic fibers for rope, with impressive elasticity and abrasion resistance.

Nylon is one of the strongest synthetic fibers for rope, with impressive elasticity and abrasion resistance.

Shock cords are made with a premium rubber core and a polyester cover for flexibility and strength.

Shock cords are made with a premium rubber core and a polyester cover for flexibility and strength.

Types of Ropes

Rope is generally defined as an assembly of strands woven together to form a thicker, stronger cord. Some ropes are designed for strength and flexibility, others for decorative use, and many for industrial, mechanical, or electrical applications. Rope suppliers offer a wide range of products for households, commercial, and industrial needs. The following sections describe several types of ropes commonly encountered in daily life.

- Twisted Ropes

- Composed of three main strands twisted together, giving them a spiral appearance. Also known as laid ropes, these are often made from polypropylene, making them cost-effective and water-resistant. Twisted ropes are ideal for wet environments, and highly visible yellow varieties are used in rescue operations.

- Braided Ropes

- Made by interlacing high-quality fibers. Hollow braided ropes can be flattened into a pipe-like shape. Double braided ropes, often made from nylon, are used where strength and abrasion resistance are needed. These ropes also provide a comfortable grip for manual use.

- Guyline Ropes

- Used to adjust the length or tension in various setups. Made with reflective materials, these ropes are ideal for use at night or in low visibility, making them popular for camping and tent applications.

- Bungee Ropes

- Commonly used for tents to secure poles in place. Available in various thicknesses and flexibilities, bungee ropes should be checked for quality before purchase. Also known as elastic cords or "bungee cords," they have a multi-strand rubber core for superior stretch, strength, and durability.

- Twine

- A durable cordage created by twisting two or more threads or yarns into a single, thin cord, suitable for a range of uses.

- Wire Rope

- Constructed from several strands of metal wire twisted into a helix. "Wire rope" generally refers to diameters larger than 3/8 inch, while smaller sizes are called cable or cords. Wire rope strength varies, supporting loads from 5,480 lbf for 1/4" diameter up to 320,000 lbf for 2" diameter ropes.

Additional rope types include parachute cord, baling twine, mooring rope, hoist rope, static rope, and tow ropes.

Materials Used in the Production of Rope

Ropes are used in countless ways at home and across industries. Many kinds of ropes are available, including nylon, polypropylene, bungee, braided, double-braided, and sisal. Rope material selection depends on its intended application and performance requirements. Rope suppliers offer a broad selection to meet a variety of needs.

The following are some of the main materials used to produce various rope types:

- Polypropylene

- A lightweight, cost-effective synthetic material with lower density than water, allowing it to float. Polypropylene is widely used in marine applications for its water and weather resistance, although it is less strong than nylon or polyester rope and degrades with UV exposure. It is commonly used in agriculture as a substitute for baling rope and is found in yachts and boats.

- Nylon

- A popular synthetic rope material, nylon is valued for its high strength, shock absorption, UV and chemical resistance, and durability. It is ideal for tasks demanding high shock absorption and returns to its original shape after stretching, making it suitable for many rigorous applications.

- Cotton

- Soft, flexible, and easy to handle, but less strong and durable compared to other natural or synthetic ropes.

- Manila

- A tough rope favored in construction for its sunlight resistance, minimal stretch, and high heat tolerance. Manila fibers come from the abaca plant and are also saltwater resistant.

- Sisal

- A sturdy natural fiber rope similar to manila rope, but not as strong. Sisal holds knots well and is often used in gardening and bundling applications where high strength isn’t necessary. Its fibers are sourced from the agave plant.

- Polyester

- A synthetic polymer used for ropes of various thicknesses, made from a blend of natural and artificial chemicals. Polyester can be engineered as thermoplastic or thermoset depending on the application. Its thin strands are interwoven into thick ropes that are resistant to water and UV rays, making them ideal for boating. Polyester ropes are nearly as strong as nylon but have less stretch.

- High Molecular Density Polyethylene (HMDPE)

- HMDPE ropes are extremely strong, lightweight, flexible, and stable, making them suitable for heavy-duty industrial, chemical, and mechanical applications. This synthetic material is designed to handle significant loads without excessive wear.

- Vectran

- Vectran ropes are ideal for demanding industrial uses requiring high reliability and strength. Vectran is a Naphthalene-based Thermotropic Liquid Crystal Polymer (NTLCP), stronger than HMDPE and other rope materials. It is resistant to stretching and abrasion, but lacks UV resistance, limiting its use in certain situations.

- Kevlar

- Kevlar rope is made from DuPont’s Kevlar synthetic polymer fiber. It offers greater strength than steel by weight, making it excellent for high-strength applications.

Things To Consider When Purchasing Ropes

When selecting a rope, working load is a key factor. However, due to the variety of rope uses, conditions, and exposure to different elements, it is difficult to set universal working load guidelines. Always inspect ropes for signs of abrasion, which can result from friction with rough surfaces, heat, UV rays, or chemicals. Synthetic ropes like nylon, polyester, polypropylene, polyethylene, Kevlar, and co-polymer blends are generally stronger than natural fiber ropes. When choosing a rope manufacturer, consider their qualifications, certifications, experience, supervision, insurance, and documentation. When choosing a rope, evaluate its strength, fatigue resistance, crush resistance, resistance to metal loss and deformation, and rotational resistance.

Maintenance Tips From Rope Suppliers

Proper and timely maintenance can significantly extend the life and performance of your ropes. Rope suppliers and manufacturers recommend several best practices to care for different types of rope, such as nylon, polypropylene, and fiber ropes.

- Damages

- Inspect ropes for damage before each use. The importance of a rope depends on its application, so always make sure the rope is in safe condition. Feel along the rope for breaks, cuts, or surface damage. Small cuts or damage should be closely monitored and repaired or replaced before they worsen.

- For minor damage near rope ends: Some do-it-yourself repairs can address small cuts or curls.

- If the damage is at either end, cut off the affected section to restore a safe, slightly shorter rope.

- Use a sharp knife or scissors for this simple repair.

- Seal the cut end with a lighter or candle to prevent fraying of the strands.

- Alternatively, molten wax can be used, but it may not be suitable for all rope types or conditions.

- Ropes cut in the middle usually cannot be safely repaired, but may be used for lighter tasks. For synthetic ropes, melting the cut area can help prevent further unraveling, but avoid using these ropes for demanding applications.

- Upkeep

- Guidelines for climbing rope maintenance: Without proper care, climbing ropes deteriorate faster than expected. Follow these tips for rope upkeep:

- Use a rope bag, ideally supplied by your rope manufacturer, to store and transport ropes conveniently.

- To prevent tangling, coil the rope in loops when storing.

- Tie both rope ends together to make it easier to untangle for the next use.

- Avoid storing ropes or rope bags in damp areas. Even water-resistant ropes should be kept dry.

- Protect ropes from direct sunlight, as exposure can weaken their integrity over time.

Rope Terms

- Abrasion Resistance

- A rope’s ability to hold up under internal and external wearing.

- Acceleration Stress

- Extra stress placed on rope due to increasing load velocity.

- Bend

- A knot that joins two ends together from a single or two separate ropes.

- Bight

- A loop in any part of a rope.

- Bitter End

- When splicing or tying knots, the end opposite the end that is in use.

- Blend

- A rope’s composition of various synthetic fibers.

- Bonding

- A liquid coating on rope that prevents absorption of water and provides abrasion resistance.

- Capstan

- A rotating cylinder used to wind rope.

- Cordage

- A term that refers to rope, line or string with a small width.

- Creep

- The gradual increase of a synthetic rope’s length over time while under high temperature or load stress.

- Dock Rope

- Primarily used to secure a marine vehicle, such as a sailboat, to a dock.

- Elastic Recovery

- The degree to which a rope will return to its original shape after being stretched.

- Elongation

- A rope’s deformation in the direction of the load.

- End

- The end of the rope that is in use.

- Fiber

- Natural or synthetic material that can be spun into yarn.

- Flexibility

- A rope’s agility and ease of handle under working conditions.

- Hand

- A rope’s feel, determined by touch.

- Heavy Duty Rope

- Contributes greatly to the endeavors of the modern world, not just in architecture, but also in landscaping, recreation, leisure and even exercise.

- Nylon Cord

- Braided, which increases its strength.

- Rigging

- The ropes and apparatuses used on sailboats that transfer wind to the ship, moving it forward through the water.

- Sliver

- A continuous strand of overlapping parallel natural fibers that is ready for twisting.

- Safety Rope

- Straps on to a harness and is designed to bear the weight of a person in case they slip or lose their footing and fall.

- Splice

- The joining of two ropes by interweaving different strands and braids.

- Strand

- Yarn that is twisted together. A rope is made from strands that are twisted or braided together.

- Strength

- A measure of a rope’s ability to lift a load or do work.

- Tensile Strength

- The load amount at which a rope will break under tension.

- Towing Rope

- Used to pull vehicles and equipment during towing or when something becomes stuck in mud or snow.

- U.V. Resistance

- A rope’s ability to resist damage from the sun’s ultraviolet rays.

- Water Repellency

- A rope’s ability to keep from absorbing water and swelling.

- Winch Rope

- Specialized, heavy rope, often used with gas-powered winches and remote, electric winches.

- Yarn

- Fibers that are twisted together.