Rubber Extrusions

Rubber extrusion is the process of strengthening and shaping natural and synthetic rubber materials into functional products. In this process, rubber is forced through a die of the desired shape, cut, or cross-section using a high-pressure extrusion machine, forming precisely shaped extrusions tailored for various applications.

Frequently Asked Questions About Rubber Extrusions

What is rubber extrusion?

Rubber extrusion is a manufacturing process where natural or synthetic rubber is forced through a die using high pressure to form continuous shapes with consistent cross-sections. The resulting extrusions are later cured to enhance strength and durability for industrial applications.

What are the main benefits of rubber extrusion?

Rubber extrusion allows for complex custom profiles, exceptional flexibility, and uniform strength. It produces durable seals, trims, and gaskets suitable for demanding industrial environments, offering superior performance compared to plastic extrusions.

How does the rubber extrusion process work?

During extrusion, unvulcanized rubber is fed into a screw extruder, where heat and pressure push it through a shaped die. The extruded rubber then undergoes curing or vulcanization, which gives it strength, elasticity, and heat resistance.

What materials are commonly used in rubber extrusion?

Common extrusion materials include natural rubber, EPDM, neoprene, silicone, SBR, nitrile, and polyisoprene. Each offers specific properties such as heat, oil, or UV resistance, allowing customization for automotive, industrial, and commercial uses.

What is the difference between hot feed and cold feed extrusion?

Hot feed extrusion uses preheated rubber, making it easier to shape complex designs. Cold feed extrusion processes solid rubber without preheating, offering better dimensional accuracy for profiles, cables, and sheaths.

What industries use extruded rubber products?

Extruded rubber products are used in automotive, aerospace, marine, construction, and appliance manufacturing. They serve as seals, weatherstripping, trims, bushings, and vibration absorbers across both consumer and industrial markets.

How can manufacturers ensure quality in rubber extrusions?

Quality rubber extrusions depend on expert die design, precise temperature and pressure control, and proper curing methods. Partnering with reputable suppliers or directories that vet manufacturers ensures reliable, high-performance results.

The History of Rubber Extrusions

Rubber is an elastic hydrocarbon polymer (or elastomer) naturally found in the Pará Rubber Tree. The human cultivation of rubber trees dates back to ancient times, with the Mayans believed to have extracted latex from rubber trees and boiled it to produce crude rubber around 1600 B.C.E. However, it was not until the 19th century that advanced processing methods were widely adopted, particularly by tire manufacturers who began incorporating textured rubber profile designs into their products.

In 1909, a research team at Bayer lab in Elberfeld, Germany, successfully polymerized Isoprene, creating the first synthetic rubber. The following year, Sergei Vasiljevich Lebedev, a Russian scientist, developed the first synthetic rubber made from butadiene, which became an essential material for Russia during World War I, when natural rubber was scarce.

In 1931, scientists at DuPont successfully synthesized neoprene, a highly resistant polymer that enabled the production of both standard and custom fuel hoses for automobiles. This breakthrough ignited global competition among scientists, particularly in the United States, Russia/the Soviet Union, and Germany, as they raced to develop cheaper and more efficient synthetic rubber formulations. However, once World War II began, the United States ramped up its synthetic rubber production, as the majority of the world’s natural rubber supply was controlled by the Axis Powers.

By the 1960s, the use of synthetic rubber surpassed that of natural rubber, marking a significant shift in industrial production. Today, both natural and synthetic rubber are used across countless industrial, commercial, and consumer applications. Although various rubber processing methods exist, extruded rubber remains a preferred choice for manufacturers due to its strength, uniformity, and ability to be customized.

Benefits of Rubber Extrusion

There are numerous benefits to choosing rubber extrusion as your preferred rubber manufacturing method.

First, rubber extruders can produce shapes of virtually any size or design, making them ideal for custom rubber applications. Additionally, rubber itself is highly versatile, with a wide range of properties that allow it to be transformed into nearly any product. Whether creating profiles, seals, or specialized components, rubber material provides endless possibilities.

Another key advantage of rubber is its unique combination of strength, flexibility, and softness, which makes it an exceptionally effective sealing material. Although rubber and plastic extrusions frequently compete in the market, rubber extrusions consistently prove superior, offering greater durability, adaptability, and performance.

Designing Rubber Extrusions

When designing a rubber extrusion, manufacturers take several application-specific factors into account. First, they evaluate the material properties, as the ability to form certain shapes depends on the rubber compound’s nature and hardness. They also consider the die shape. For standard applications, they may use pre-existing dies, but for custom rubber extrusions, they often need to design entirely new dies. In high-volume applications, manufacturers typically create a profile die, ensuring that each extrusion maintains a consistent cross-section profile from one production run to the next.

Rubber is an excellent choice for custom extrusion applications because it can be easily cut and shaped with minimal labor and effort. Furthermore, the wide variety of rubber materials available allows manufacturers to customize products to meet diverse requirements, from rubber sponges to shock-resistant seals, ensuring optimal performance and durability.

Process of Rubber Extrusion

Rubber extrusion begins with raw rubber material (or stock) processed through a rubber extruder or a screw extruding machine.

Step 1: The process starts with selecting a suitable rubber material. An external supplier provides the rubber in a form compatible with the extrusion system.

Step 2: The unvulcanized rubber is fed into the extruder machine. The stock is deposited in a hopper, a container suspended above the conveyor.

Step 3: Gravity moves the stock through the bottom of the hopper onto the conveyor. Pre-heating of the stock is optional, depending on the precision of the die and the desired strength qualities. Hot extrusion uses pre-heated stock, while cold extrusion uses solid rubber.

Step 4: From the conveyor, the rubber is pushed through the die using a flute/base connected to a rotating screw. At this stage, the temperature and pressure are increased, allowing the material to fully contact the die.

Step 5: The combination of pressure, heating, and shearing softens the rubber, enabling it to pass through the die opening. Inside the die, the rubber swells and takes its final shape.

Step 6: The rubber emerges from the extruder in a profile that precisely matches the die shape.

The post-processing stage, called curing (or vulcanization), gives the rubber its physical properties, making it capable of withstanding extreme environments. This process begins immediately as the shaped rubber exits the die. After curing, additional post-processing steps may include splicing, taping, end joining, coiling, drilling, and cutting.

Curing Methods

Using a Mold

Manufacturers use a metal mold tool to shape the final product. A raw rubber feed is injected into the mold, where a press applies heat and pressure for a set duration. After cooling, the cured rubber product is removed. This method provides high accuracy and is commonly used to cure tires.

Using an Autoclave

Extruded rubber products are placed on a metal rack inside an autoclave, a pressurized chamber. The products are subjected to elevated pressure (up to 300 PSI) and high temperatures, which eliminate porousness and improve structural strength. Though this method is slow and sometimes less precise, it is cost-effective and can cure multiple rubber products at once.

Continuous Curing

A high-speed process integrated with extrusion, continuous curing uses microwaves, hot air vulcanization, salt baths, oil, or glass beads. This method produces extruded rubber products with high stress tolerance and reduces labor, energy, and space costs. However, it has higher setup and raw material costs, and certain sizes and shapes cannot be cured using this method.

Rubber Extrusion Images, Diagrams and Visual Concepts

Rubber Extrusion, a group of products made by softening and pressurizing an elastomeric compound resulting in a continuous piece of material that has the same cross-section throughout its length.

Rubber Extrusion, a group of products made by softening and pressurizing an elastomeric compound resulting in a continuous piece of material that has the same cross-section throughout its length.

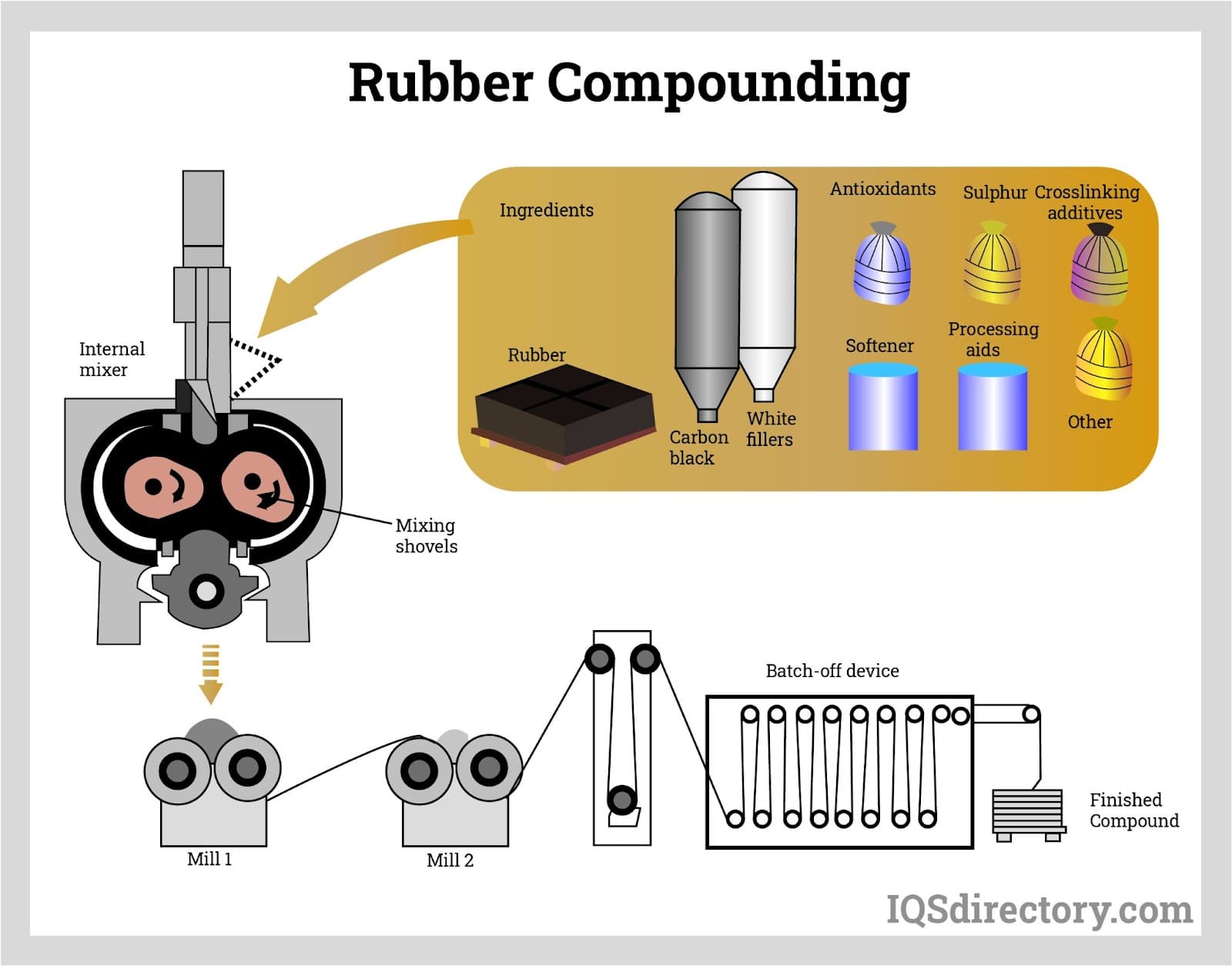

The compounding process is the formulation of the rubber material where the additive ingredients obtain the desired properties.

The compounding process is the formulation of the rubber material where the additive ingredients obtain the desired properties.

Extruded rubber bushings are shock absorbers which can isolate moving parts to prevent vibration and noise from transfering throughout the equipment.

Extruded rubber bushings are shock absorbers which can isolate moving parts to prevent vibration and noise from transfering throughout the equipment.

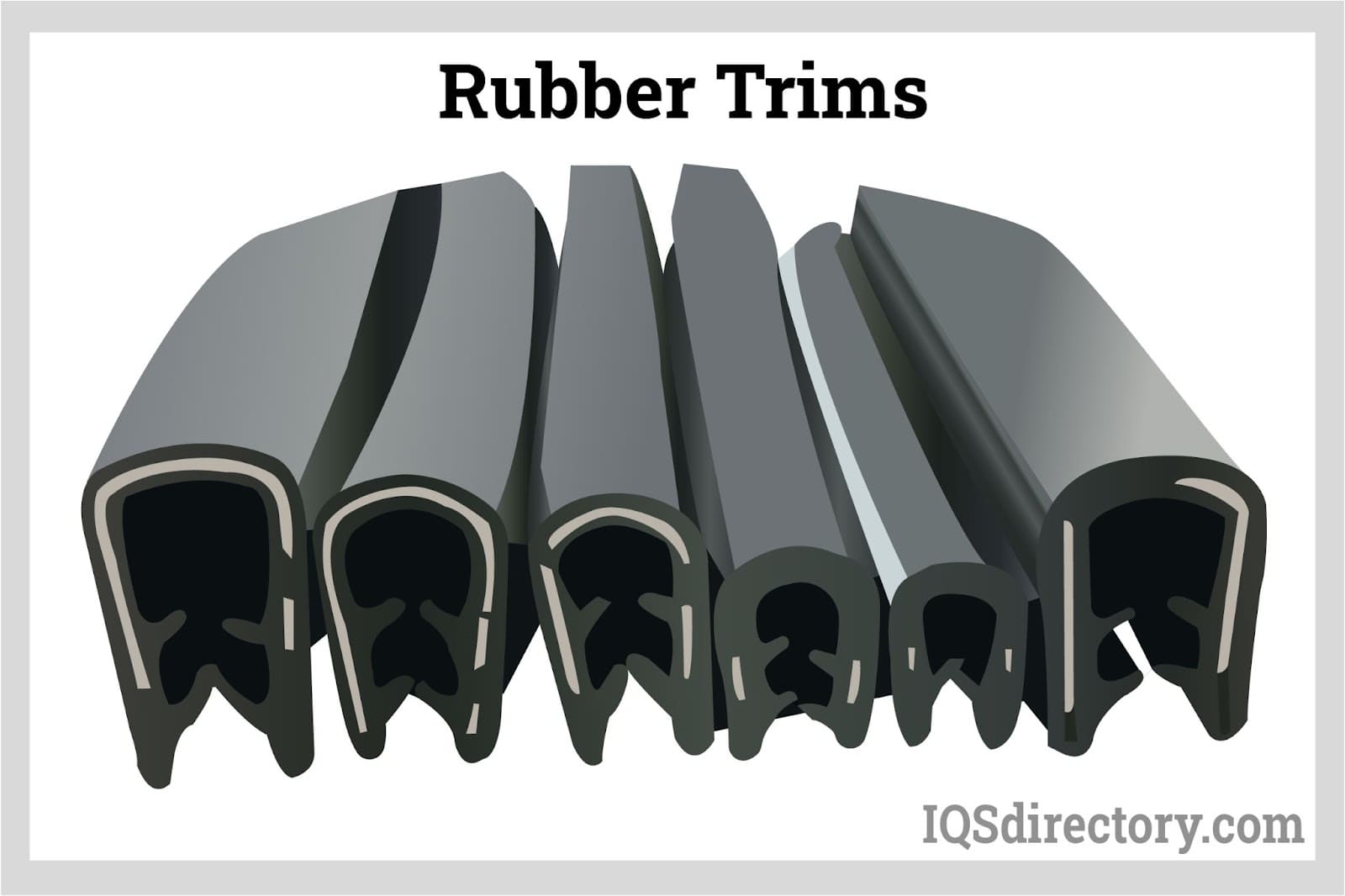

Rubber trims are extruded products used to protect edges or surfaces of rigid objects from sudden impacts.

Rubber trims are extruded products used to protect edges or surfaces of rigid objects from sudden impacts.

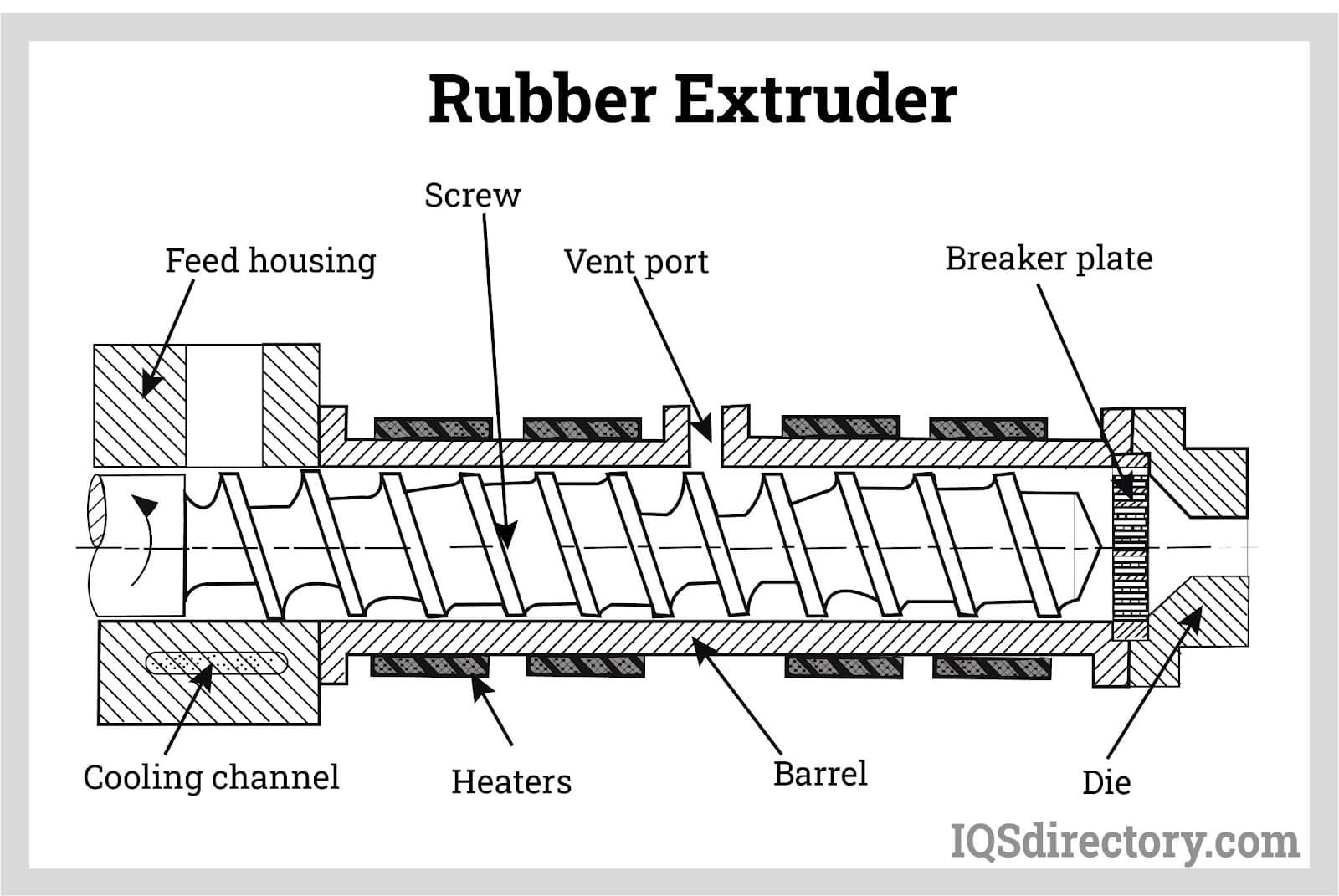

Rubber extruder machine turns rubber material to the specific shape for a product.

Rubber extruder machine turns rubber material to the specific shape for a product.

Rubber Extrusion Types

-

Co-Extrusion

A variation of the basic extrusion process where two separate extruders connect to a single die. Two or more separate batches of rubber material are mixed by separate screws and then fed into the die simultaneously. This allows for the convergence of rubber materials with different properties, such as color and consistency.

Cold Feed Extrusion

Involves performing the extrusion process without preheating. This method is best suited for producing profiles, hoses, cables, and sheaths.

Extruded Rubber Seals

Products used to seal or fill gaps, insulate surfaces or spaces from water or atmospheric conditions, and protect surfaces from corrosion.

Extruded Rubber

Rubber that has been melted and forced into a die to take on a specific shape.

Hot Feed Extrusion

Involves pre-heating the rubber material before performing the extrusion process.

Pin Barrel Extruders

Feature a unique design with multiple pins protruding from the cylinder wall toward the screw’s center. These pins enhance the mixing and dispersing of the rubber as it is kneaded between the screws and the cylinder. This method applies to a wide range of rubber compound formulations for diverse applications.

Rubber Bumper

Serves as a shock absorber in consumer and commercial applications. It also reduces vibration and noise caused by moving parts in industrial machinery.

Rubber Bushings

Placed between moving parts to absorb vibration. They are commonly used in vehicle suspension systems, manufacturing machinery, and other mechanical applications.

Rubber Connectors

Extruded rubber products designed to join the ends of tubes or pipes together.

Rubber Extruders

Machines that mold raw rubber material into usable products using heat, pressure, and a die.

Rubber Grommet

Rubber rings inserted into an opening in sheet metal to protect cords or electrical wires from abrasion.

Rubber Profiles

Extruded rubber products available in various shapes and forms to meet different application needs.

Rubber Sheets

Used for a variety of purposes, including matting, lining, floor covering, and stair treads.

Rubber Trim

A long, thin piece of extruded rubber that serves multiple applications.

Silicone Extrusions

Extruded rubber products processed from raw silica stock, offering excellent heat and chemical resistance.

Vented Extruders

Feature uniquely designed screws that simplify maintenance and require minimal floor space.

Weatherstripping

Used to insulate buildings, improving heating and cooling efficiency by sealing gaps and preventing air leaks.

Materials Used in the Extrusion Process

The qualities of the finished product depend on both the extrusion process and the properties of the raw rubber stock. Rubber comes in many forms, each with unique characteristics that allow for custom creations. Properties such as tensile strength, hardness, aging resistance, flexibility, permeability, and speed of recovery from deflection vary between different materials.

Natural Rubber

Also called gum rubber, this material has excellent abrasion and acid resistance.

Silicone Rubber

Silicone extrusion products have recently gained popularity after receiving FDA certification for being non-reactive to a wide variety of substances. Silicone rubber can withstand both high and low temperatures without undergoing any change. It is also resistant to biological fluids, making it a favorite in the beauty industry. Additionally, because of silicone’s heat resistance and chemical inertness, silicone extrusions are highly valued in the healthcare and food service industries.

EPDM

Ethylene propylene diene terpolymer (EPDM) is a synthetic rubber material known for its heat resistance, UV resistance, aging resistance, ozone resistance, and oxidation resistance. EPDM products, such as EPDM sponge rubber and EPDM foam rubber, are ideal for use in commercial and industrial settings. This material is commonly used for door gaskets, weather stripping, window gaskets, roofing membranes, and tarp straps.

SBR

Styrene-butadiene rubber (SBR) offers exceptionally high abrasion resistance, making it perfect for automobile products like belt covers and motor mounts.

Polyisoprene

Also known as synthetic natural rubber, polyisoprene is a flexible polymer with mild abrasion resistance, making it suitable for various industrial applications.

Nitrile Rubber

Also called nitrile butadiene rubber (NBR), Buna-N, Perbunan, or acrylonitrile butadiene rubber, this synthetic rubber copolymer is highly resistant to oils. Because of this, NBR is widely used for hydraulic seals, hoses, and O-rings, as well as any rubber products exposed to oil.

Neoprene

Neoprene is highly resistant to heat, water exposure, oil, and ultraviolet rays. Additionally, it has high tensile strength and fire resistance, making it a preferred material for many industrial and commercial applications.

Machinery Used in the Extrusion Process

The machinery used to extrude rubber, known as the rubber extruder, consists of two primary components: a heated shearing screw conveyor and an extrusion die. These parts work together to shape raw rubber material into a continuous profile with the desired cross-section.

Shearing Screw Conveyor

This component consists of a conveyor and a rotating screw positioned parallel to the conveyor. As the screw turns, it pushes the rubber material forward while simultaneously heating it inside the conveyor channel. This shearing action ensures the rubber is evenly distributed and softened before it reaches the die.

Extrusion Die

Extrusion dies are custom-designed tools that determine the final shape of the extruded rubber. Engineers design and cut these dies to precisely match the intended rubber profile. Before extrusion begins, the die is installed in the extruder, ensuring that the rubber takes on the desired shape as it is forced through. Most extrusion dies are made from hard metals like steel, which provide sharp edges and durability. During the extrusion process, high pressure and temperature are applied to push the softened rubber through the die, creating a continuous profile that meets the required specifications.

Rubber Extrusion Applications

The rubber extrusion process serves a wide range of purposes across numerous industries. Extruded rubber profiles are widely used to waterproof appliances, making them essential in applications requiring climate and moisture control. Additionally, extruded rubber components play a crucial role in connecting applications, such as securing aerospace hoses and sealing industrial equipment. They also enhance workplace and equipment safety, particularly in flooring applications where slip resistance is necessary.

Rubber extrusions are versatile, used for connecting tubing, insulating electronics, and even erasing mistakes on paper. These products are designed to perform in extreme environments, whether in outer space, deep underwater, or on the road.

Industries that depend on rubber extrusion products include automotive, aerospace, appliance manufacturing, electronics, sports and recreation, flooring, industrial cleaning, marine, and more.

Rubber Products Produced

The most common extruded rubber products include extruded rubber seals, rubber sheeting, rubber bushings, gaskets, rubber profiles, rubber channels, rubber trim, rubber weatherstripping, and rubber tubing.

Weatherstripping, rubber trim, and extruded rubber are essential for climate and moisture control, ensuring that homes, vehicles, and industrial equipment remain protected from environmental factors. Rubber sheeting is widely used in floor matting, commonly found at the entrance of homes and businesses for traction and safety. Rubber bumpers, bushings, grommets, and connectors contribute to safe and efficient workplaces, vehicles, and homes. In cases where a custom rubber part is required, rubber extruders can create unique rubber profiles tailored to meet specific needs.

In residential settings, rubber trim protects baseboards, paint, and wallpaper from damage. Rubber U-channels serve as door seals or trim seals, while rubber mats placed under rugs help protect floors and prevent slips. Rubber grommets reinforce openings in sheet metal power strips, preventing cord wear and reducing the risk of electric shock. Rubber sealants keep bathroom fixtures watertight and contribute to water efficiency in kitchens. Weatherstripping has become increasingly important for commercial and residential buildings, helping maintain energy efficiency.

In industrial applications, rubber rods, rollers, and sheets absorb vibration and noise from heavy machinery. Rubber bushings are integral to vehicle suspension systems, ensuring smooth and stable performance. Rubber bumpers protect freight trucks and loading docks, reducing the impact of collisions. Ultimately, rubber profile production is only limited by the creativity and innovation of its designers.

Finding Rubber Extrusion Manufacturers

The quality of the rubber product you receive is directly related to the expertise of the supplier or manufacturer you choose to work with. The challenge is finding the best extruded rubber supplier for your needs.

Use a Business Directory

Searching for a supplier via search engines can be unreliable, as you cannot always determine a company's reputation. To avoid partnering with an unverified or low-quality supplier, consider using a trusted business directory. High-traffic online directories, like IQS Directory, provide curated lists of reputable, experienced manufacturers and suppliers specializing in high-quality extruded rubber products. Using a directory helps ensure that you find a dependable and vetted supplier.

- Ask the Right Questions

Once you identify three or four potential suppliers, contact them directly to inquire about their products, prices, and services. Discuss your specific requirements—including size, shape, stiffness, flexibility, color, and quantity—and confirm their delivery timeline. Also, evaluate their customer service. A manufacturer may offer great pricing, but if they lack responsiveness or reliability, it could lead to delays, errors, or unexpected costs. Compare service quality, pricing, and reliability across multiple suppliers before making your final decision.

Variations and Similar Processes

-

Plastic Extrusion

The rubber extrusion process is similar to plastic extrusion, where raw material, in the form of nuggets or kernels, is fed into a screwing column. This column transforms the raw material into a semi-fluid state through the combined action of pressure and temperature. The material is then passed through a die, which gives it a predefined shape. The key difference between plastic and rubber extrusion lies in the post-processing steps. Plastic extrusion has its own set of post-processing procedures, while rubber extrusion relies on curing to determine the final physical properties of the product.

Injection Molding

A common alternative to rubber extrusion is rubber injection molding. This method is often used when working with thermosetting polymers, elastomers, or highly complex designs. The process involves heating the rubber material until it becomes warm or molten, then injecting it into a mold cavity, where it takes shape, cools, and hardens.

Feed Extruder

A variation of rubber extruding is feed extruding. A feed extruder is an extrusion machine specifically designed for the commercial production of animal feed. The machine processes the feed through three main steps: pre-conditioning, extrusion cooking, and texturing/shaping, ensuring the final product meets nutritional and consistency requirements.

Rubber Extrusion Terms

-

Accelerator

A substance that quickens the pace of vulcanization and lowers the operating temperature required during the process.

Adhesion

Term for the bond between a rubber surface and a non-rubber surface.

Air Curing

Vulcanizing a rubber product in the air instead of in a press or steam vulcanizer.

Atmospheric Cracking

Crevices that form on rubber surfaces due to exposure to environmental conditions, such as temperature extremes and precipitation.

Atmospheric Pressure

The amount of force the atmosphere exerts upon the earth’s surface, measuring 14.7 psi at sea level.

Chalking

The development of a powdery residue on a rubber surface as a result of surface breakdown.

Checking

Small cracks on the surface of rubber, usually from environmental damage.

Compression Set

A measurement of a rubber material’s return to its initial shape after deformation.

Creep

Deformation on a rubber surface due to the application of stress.

Die Swell

The incidence of swelling that occurs after the extruded profile comes out of the die. The rubber product’s properties determine the amount of swelling that will occur.

Drift

A change in a rubber material’s hardness over time.

Durometer

An apparatus used for measuring the hardness of rubber.

Dusting

Applying powder to rubber to prevent adhesion to something else.

Elasticity

A characteristic of rubber, describing its tendency to return to its initial shape after warping.

Elastomer

A material capable of returning to its initial length after being stretched at room temperature to twice its original length.

Elongation

An increase in length after the application of stress. This occurs during stretching.

Flex Test

A laboratory test that measures a rubber material’s resistance to bending deformation.

Friction

The resistance to motion when different surfaces are in contact.

Hysteresis

Energy loss in the form of heat that results from the deformation of elastomeric material, caused by the application of stress.

Mastication

The softening of raw rubber by mechanical and atmospheric forces.

Memory

The extent of a rubber material’s ability to resume its original shape after deformation.

Modulus

The amount of stress required to create a certain amount of elongation.

Optimum Cure

The point during vulcanization at which rubber material attains the intended properties.

Plasticity

The degree to which rubber will retain deformation.

Psi

Pounds per square inch. This measurement indicates pressure level.

Resilience

The comparison of the amount of energy needed to create an elastic deformation and the amount of energy needed to recover from such a deformation.

Tensile Strength

The maximum amount of stress that may be applied to rubber before breaking occurs.

Vulcanization

The process of increasing the strength and elasticity of rubber materials through the application of heat and pressure