Rubber Molding

Molded rubber components play a vital role in countless industries, serving as essential parts in everything from industrial machinery and medical equipment to consumer appliances and household goods. Whether it's gaskets, seals, grommets, or custom-molded parts, rubber molding provides the flexibility and durability required for modern manufacturing. This process involves heating raw rubber and shaping it within a mold, making it the preferred method for producing complex rubber products with precision.

Rubber Molding FAQ

What is rubber molding used for in manufacturing?

Rubber molding is used to create precise components like gaskets, seals, grommets, and custom parts. It provides durability, flexibility, and the ability to produce complex shapes required in industries from medical to automotive manufacturing.

How did vulcanization change rubber molding?

Charles Goodyear’s discovery of vulcanization in 1839 stabilized rubber by adding sulfur, making it durable and heat-resistant. This breakthrough made rubber reliable for molding and spurred its widespread use in industrial and consumer applications.

What is the difference between injection and compression molding?

Injection molding heats and injects rubber into a mold cavity for high-volume, precise parts. Compression molding places pre-measured stock in a mold, applying heat and pressure to form durable components, often used for low-tolerance parts.

Why is EPDM rubber commonly used in construction and automotive parts?

EPDM rubber offers excellent durability and weather resistance, making it ideal for roofing, gaskets, seals, and hoses. Its ability to withstand heat, moisture, and environmental exposure ensures long-lasting performance in construction and vehicle applications.

What advantages does liquid injection molding provide?

Liquid injection molding uses liquid silicone rubber, allowing faster production and reduced energy use compared to solid stock. It creates high-precision parts with minimal finishing, making it efficient for industries requiring tight tolerances and smooth surfaces.

How does transfer molding differ from other rubber molding methods?

Transfer molding places rubber stock in a chamber above the mold and uses a ram to force it into cavities. This method ensures even distribution, making it ideal for bonding rubber to metal and producing intricate, detailed components.

Why choose custom rubber molding for industrial applications?

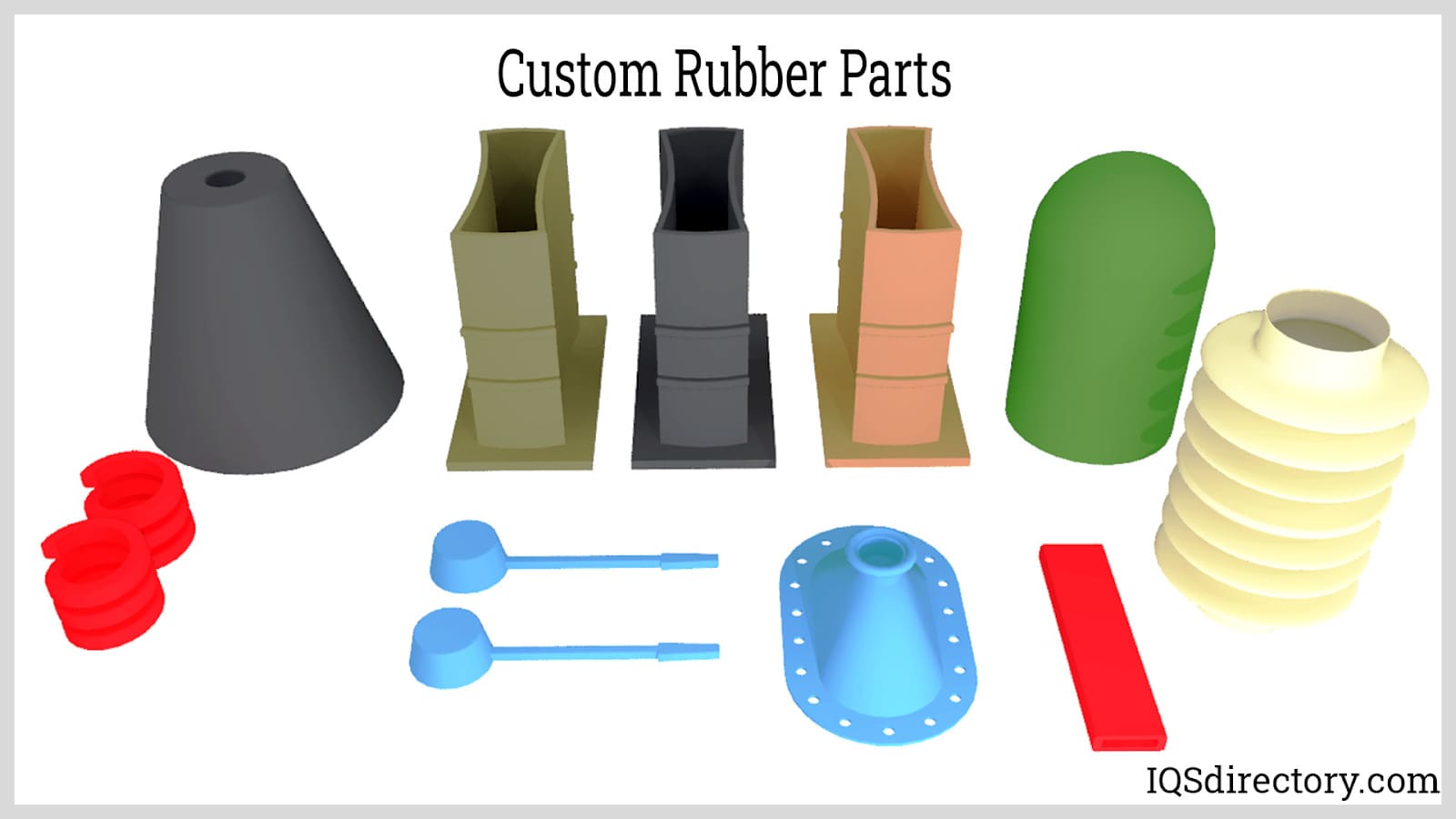

Custom rubber molding allows manufacturers to design specialized parts tailored to unique needs. It ensures precise fit, flexibility in material selection, and efficiency for large-scale production or prototyping in industries such as medical, aerospace, and electronics.

The History of Rubber Molding

For centuries, indigenous South American cultures harnessed the sap of rubber trees to create functional household items. However, rubber remained largely a natural curiosity until the 19th century, when advancements in material science transformed it into a commercial powerhouse.

In 1823, Scottish chemist Charles Macintosh pioneered a method of bonding rubber to fabric using a coal-tar solvent, sparking early interest in rubber-based products. Yet, these initial applications had drawbacks—rubber often became sticky in warm temperatures and degraded over time. It wasn't until 1839 when American inventor Charles Goodyear discovered vulcanization, that rubber became a truly reliable material. By adding sulfur to natural rubber, Goodyear created a more stable and durable product, though it took decades before his breakthrough gained widespread adoption. The introduction of bicycle and automobile tires in the late 1800s fueled a global demand for rubber, leading to large-scale rubber plantations in tropical regions and the rise of an international rubber industry.

While rubber molding technology emerged alongside these developments, it was the innovation of injection molding that revolutionized the industry. In 1872, brothers John and Isaiah Hyatt patented the first injection molding machine, paving the way for mass production of both rubber and plastic parts. Further advancements in chemistry and engineering refined the molding process, and by the 20th century, rubber molding had become a dominant force in manufacturing.

The late 20th century saw even greater leaps in molding technology. James Watson Hendry’s development of a gas-powered injection molding process in the 1970s significantly enhanced precision and efficiency. As automation and computer-assisted production took hold, rubber molding evolved into a high-tech industry capable of delivering customized solutions for an ever-expanding range of applications. Today, manufacturers continue to push the boundaries of rubber molding, producing specialized components that meet the rigorous demands of modern engineering and industrial design.

The Advantages of Rubber Molding

Rubber molding presents distinct advantages over other manufacturing processes, particularly when precision and complexity are key. While it may not match the speed of rubber extrusion, it excels in producing intricate, custom-designed components. This process offers exceptional versatility, accommodating a wide range of rubber formulations to achieve specific performance characteristics such as durability, flexibility, or high heat resistance. Modern molding technology enables efficient mass production while also allowing for rapid prototyping, making it an ideal solution for businesses developing proprietary rubber compounds or scaling up production for market-ready products.

The Rubber Molding Materials Process

Manufacturers use several techniques to mold natural and synthetic rubber, each catering to different production needs and material properties. These processes include:

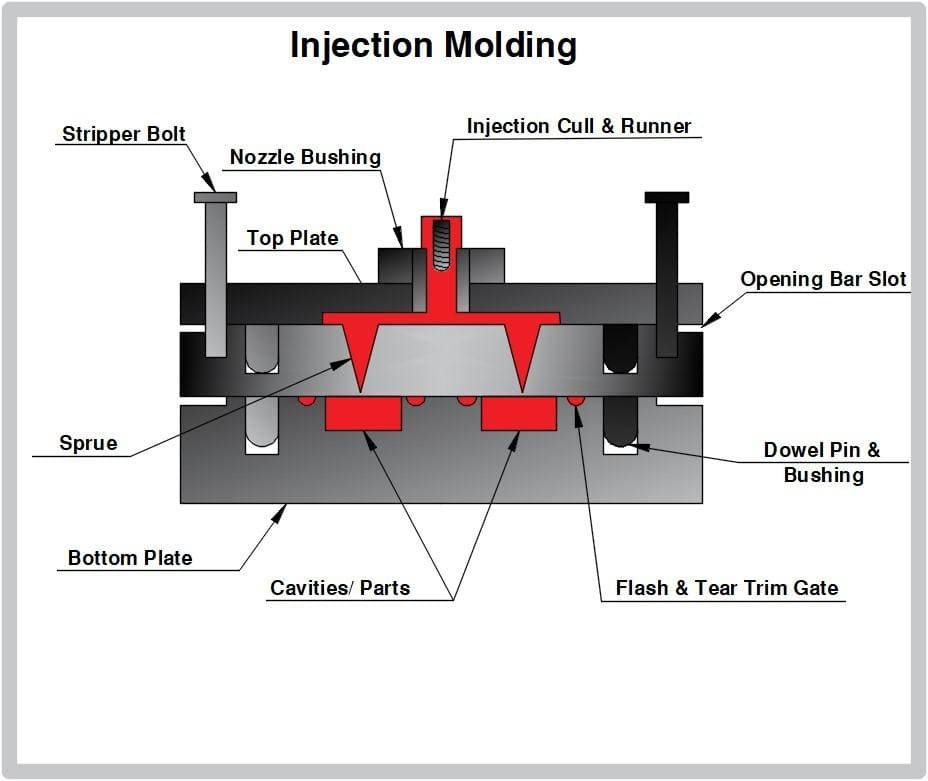

Injection Molding

As the dominant method in commercial production, injection molding is widely used for high-volume manufacturing of rubber and plastic components. This process begins with solid rubber stock, which is heated until molten and injected into a mold cavity. Automated Machinery precisely controls this operation, ensuring uniform filling under high pressure and heat. Once cooled, the molded piece solidifies and is ejected, sometimes requiring minimal finishing before final use.

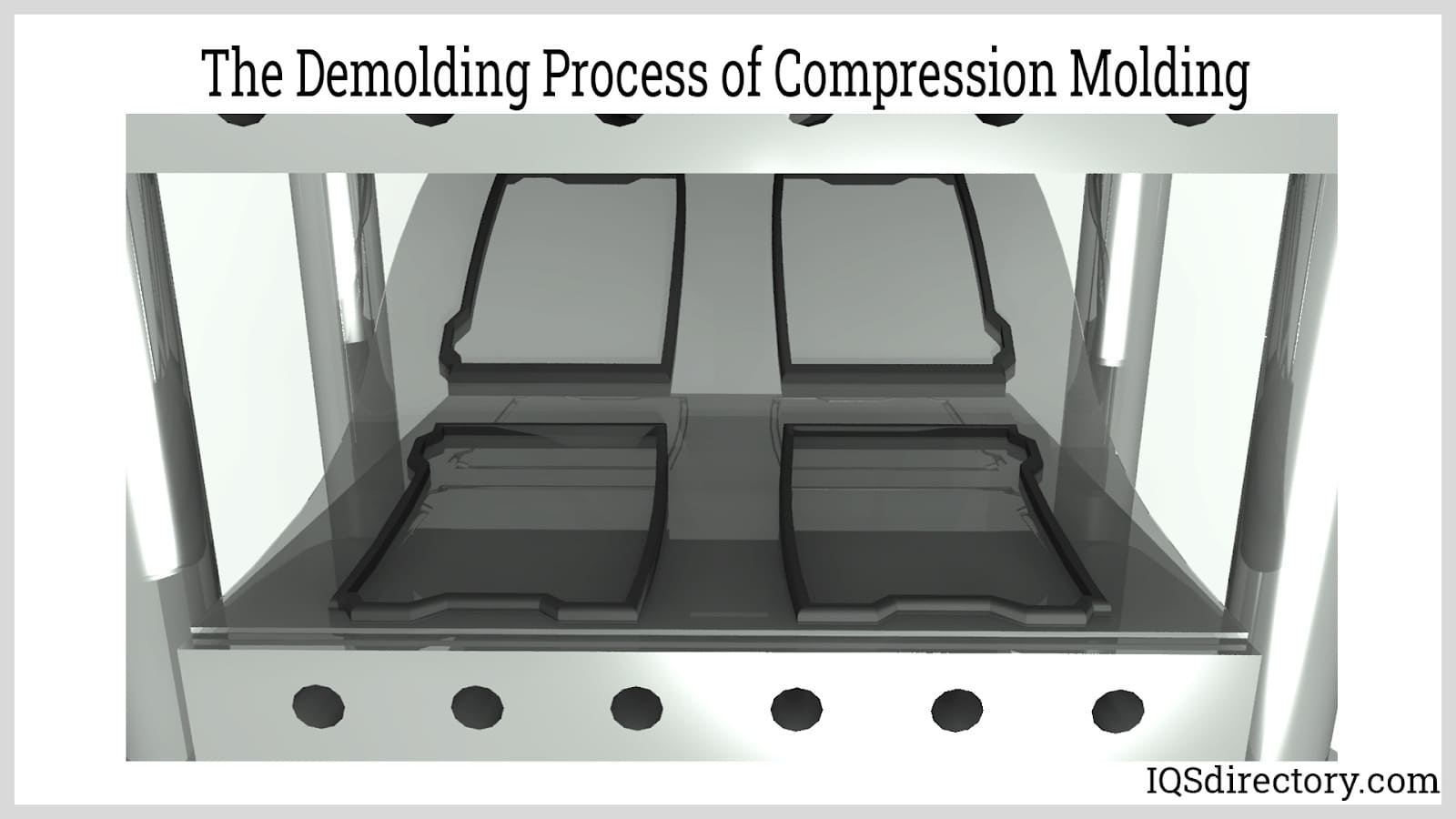

Compression Molding

Compression molding is favored for producing low-tolerance rubber parts. The process starts with a pre-measured rubber stock, shaped and weighed before being placed into a mold cavity. When the mold closes, high pressure forces the material to conform to the cavity’s shape. The application of controlled heat and dwell time ensures optimal curing, resulting in durable, high-quality parts.

Liquid Injection Molding

This technique closely mirrors traditional injection molding but utilizes liquid silicone rubber as the primary material. A metered pump system regulates the silicone’s flow, mixing it with other additives before injection. Once inside the mold, heat and pressure complete the curing process. Because the raw material is already in liquid form, production is faster, requiring less energy to convert solid stock into a moldable state. Additionally, products made through this method typically require minimal post-processing.

Transfer Molding

Transfer molding is particularly useful for creating rubber components bonded to metal or requiring high precision. Unlike compression molding, the rubber stock is placed in a separate chamber, or "pot," above the mold. A ram mechanism forces the material through a runner and gate system into the mold cavity under heat and pressure. This method ensures uniform distribution, allowing for intricate detailing and strong adhesion to metal inserts.

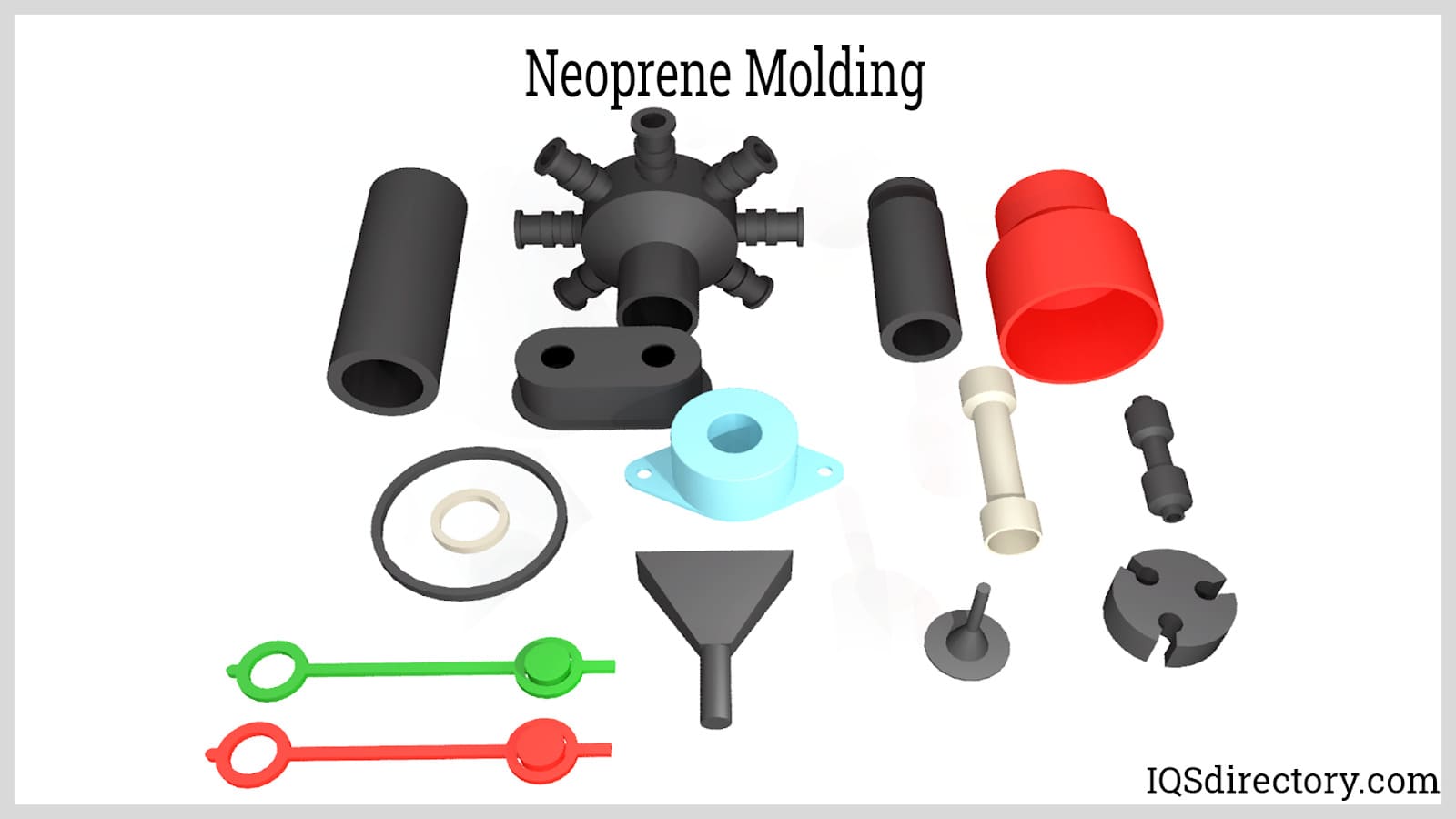

Rubber Molding Images, Diagrams and Visual Concepts

Rubber molding is the process of transforming an elastomer by transferring, compressing, or injecting raw rubber material into a metal mold cavity.

Rubber can be molded in different shapes and sizes which have a multitude of uses.

The injection molding rubber begins with raw liquid rubber that flows into a mold cavity, then is tightly clamped to form the desired shape.

The transfer molding process feeds raw rubber into multiple mold cavities after the closure of the press.

Compression molding uses heat and pressure, once unvulcanized rubber is placed in the mold cavity, the mold is closed and heated whlie pressure is applied with a hydraulic press.

The process of rubber to metal molding to bond rubber with metal to cancel out noise and other vibrations.

Ethylene Propylene Diene Monomer(EPDM) rubber is resistant to temperatures up to 302 °F (150 °C) and is highly durable.

Neoprene rubber is a multipurpose material with temperature and abrasion resistant properties.

Rubber Molding Types

Blow Molding

This method involves placing a hollow tube between two halves of a mold, which then closes and seals the bottom. Air is injected into the top, expanding the material outward to form the desired shape against the mold’s walls.

Foam Rubber

A lightweight, flexible material created by incorporating a foaming agent into the rubber during manufacturing, resulting in an air-filled structure.

Liquid Silicone Rubber

A synthetic, two-component elastomer in liquid form, derived from silicone elastomers, offering excellent flexibility, durability, and heat resistance.

Rubber Baseboard

A molded rubber product designed to cover the seam where walls meet floors, providing a protective and aesthetic finish.

Rubber Diaphragm

Highly flexible seals engineered to withstand varying pressures and a range of media in industrial applications.

Rubber Grommets

Protective rubber rings inserted into metal holes to prevent electrical wires or cords from abrasions and damage.

Rubber Seals

Designed to prevent leaks at joints by providing a secure, flexible barrier.

Rubber Sheets

Flat rubber materials used across industries for gasketing, cushioning, and insulation applications.

Rubber Tubing

Hollow, flexible cylinders used for transporting liquids and gases in medical, industrial, and consumer applications.

Rubber Washers

Used primarily to support threaded fasteners, they also play a role in controlling liquid or gas flow in taps and valves.

Rubber Molders

The process of shaping rubber into functional components for diverse industrial and commercial applications.

Viton Rubber Molding

A high-performance synthetic rubber blended with fluoropolymer elastomers, offering exceptional resistance to harsh chemicals and extreme environments.

Molded Rubber Applications

Molded rubber's versatility allows manufacturers to shape complex components for critical applications. These parts provide sealing, cushioning, vibration absorption, and noise reduction in mechanical assemblies. Advances in synthetic rubbers such as neoprene, silicone, and EPDM have expanded the range of rubber products, allowing for specialized formulations to meet industry-specific demands.

Custom rubber molding further enhances product development, offering the ability to create prototypes, unique components, and branded OEM parts. Whether producing grommets, gaskets, or intricate rubber trims, molded rubber remains a cornerstone of industries such as agriculture, transportation, defense, construction, consumer goods, and biotechnology. Its adaptability and precision ensure a steady demand for innovative rubber-based solutions across various markets.

A Closer Look at Rubber Molding

Rubber molding today incorporates both synthetic and natural rubber, with manufacturers relying on a variety of raw materials to meet the demands of diverse industries. Some common raw materials used in rubber molding include:

Natural Rubber Latex

Despite the rise of synthetic alternatives, some manufacturers continue to produce natural rubber latex products. Harvested from the hevea brasiliensis tree or select species of the Ficus genus, natural latex begins as a milky sap collected through careful incisions in the bark. Once gathered, the latex is combined with formic acid, triggering coagulation into a solid sheet. This uncured rubber then serves as a key raw material for natural rubber latex molding.

Rubber

Rather than using natural latex rubber in its raw state, producers typically vulcanize it before export. This process strengthens the rubber, making it more durable and easier to handle. Once vulcanized, it is transformed into a wide array of rubber products across multiple industries.

Neoprene

Developed by DuPont in the 1930s, neoprene was one of the first synthetic rubbers and remains a versatile material today. Manufacturers mold it into gaskets, liners, and household items, as well as gardening tools. However, certain chemicals—such as iodine, turpentine, and acetic acid—can degrade neoprene, limiting its use in industrial applications.

EPDM (Ethylene-Propylene-Diene Monomer)

EPDM has become a staple in construction and automotive applications. It plays a critical role in roofing materials for commercial buildings and is widely used in electrical gaskets, door and window seals, and engine cooling system hoses. Its durability and weather resistance make it a go-to choice for long-lasting components.

Silicone Rubber

A synthetic rubber made from silicon, oxygen, carbon, and hydrogen, silicone offers exceptional heat resistance, maintaining stability at temperatures up to 446°F. This makes it invaluable in molds used for metal casting. Its ability to be easily sanitized has also led to widespread adoption in medical, biotech, and food processing equipment. Available in both liquid and solid forms, silicone remains one of the most versatile rubber materials in modern manufacturing.

Rubber Molding Machinery

Advancements in rubber molding technology have enabled the production of complex components across numerous industries. As automation has expanded, so has the investment required for high-volume injection molding machines, which play a crucial role in large-scale production.

Custom molding services have further democratized the market, allowing businesses of all sizes to manufacture rubber products. The choice of materials, molding techniques, and equipment varies significantly depending on the specific needs of a given production environment, ensuring that rubber molding continues to evolve alongside industry demands.

Why Choose Custom Rubber Molding?

Custom rubber molding allows businesses to design and manufacture specialized rubber components tailored to their exact specifications. Whether developing new products or optimizing existing ones, this process ensures precision and flexibility for industries requiring unique solutions. While various methods exist for creating custom rubber products, not all are equally effective for every application.

One of the key benefits of rubber molding is its versatility. Injection molding, in particular, is a cost-effective approach for large production runs, making it an ideal choice for companies seeking efficiency without sacrificing quality. With advancements in molding technology, automation has further streamlined production, reducing costs and improving turnaround times. Additionally, materials like liquid silicone rubber enable the creation of high-precision parts with tight tolerances and a range of surface finishes.

Industries That Benefit from Custom Rubber Molding

Custom rubber molding serves a wide range of industries, offering durable and reliable components tailored to specific applications:

- Medical – Custom devices, blood analysis machines, and surgical instrument components.

- Electronics – EMI shielding, electrical connector inserts, and high-performance seals.

- AerospaceVibration isolators, cable boots, and power supply gaskets.

- Industrial – Fluid pumps, oil and gas components, and vibration-absorbing buttons.

From simple seals to complex engineered parts, rubber molding provides an affordable and effective solution for diverse manufacturing needs.

Selecting a Rubber Molding Manufacturer

Selecting the right manufacturer is essential to achieving the best results. IQS Directory offers a comprehensive listing of top-tier rubber molding manufacturers, many of whom specialize in specific molding processes. Using this directory can help businesses connect with the right partner for their unique production requirements.

Variations of Rubber Creation

While molding is a widely used process, some manufacturers opt for alternative methods such as extrusion or calendaring, depending on the intended application:

- Rubber Extrusion – This method forces rubber or plastic through a cross-sectional die to produce continuous shapes like tubing, strips, or profiles used in products such as baseboard molding and curtain rods.

Rubber Calendaring – This process involves rolling and flattening rubber material, often layering it onto textiles to create rubberized coatings, films, or composite fabrics.

Rubber Molding Terms

Abrasion Resistance

The ability of a rubber compound to resist wear and deterioration caused by mechanical friction.

Accelerated Life Test

A test designed to simulate long-term wear and breakdown in a condensed time frame by exposing rubber to extreme conditions.

Accelerator

A substance that speeds up the vulcanization process when combined with vulcanizing agents in small amounts.

Activator

A compound used in minimal quantities to enhance the effectiveness of an accelerator.

Adhesion

The tendency of rubber to bond or stick to surfaces it comes into contact with.

Aftercure

The continuation of vulcanization even after the heat or energy source has been removed.

Air Checks

Surface imperfections, such as depressions or marks, caused by trapped air during molding.

Autoclave

A pressurized steam chamber used for vulcanizing rubber products.

Backrind

A molding defect where the rubber near the parting line sinks below the surface, leaving a rough, torn edge.

Batch

The final product of a rubber mixing process.

Blank

The portion of rubber compound used to fill a mold before shaping.

Bloom

A surface discoloration caused by a liquid or solid migrating to the rubber’s exterior.

Breakout Friction

The force required to initiate movement between a rubber seal and its mating surface.

Chalking

The formation of a powdery residue on rubber due to surface degradation.

Checking

The appearance of small surface cracks, often caused by environmental exposure.

Compression Set

The permanent deformation that remains after a rubber material has been compressed and released.

Conducting Rubber

A rubber compound designed to conduct electricity.

Crosslink

A chemical bond that links polymer chains together, enhancing rubber’s strength and stability.

Cure Date

The date marking the completion of the rubber molding process.

Deflashing

A process used to remove excess material, or "flash," from molded rubber parts.

Dispersion

The uniform distribution of various compounds throughout a rubber mixture.

Durometer

An instrument used to measure the hardness of rubber.

Dusting

The application of powder to prevent rubber from sticking to other surfaces.

Dynamic Seal

A seal designed to prevent leaks in applications where parts are in motion.

Elasticity

Rubber’s ability to stretch and return to its original shape after deformation.

Elongation

The extent to which rubber can be stretched under stress before breaking.

Extruder

A machine that forces rubber through a shaped opening to create a specific profile or form.

Fatigue Breakdown

The gradual deterioration of rubber due to repeated flexing or deformation.

Flexural Strength

The ability of rubber to bend without breaking or permanently deforming.

Flow

The movement of uncured rubber within a mold during the molding process.

High Consistency Rubber (HCR)

A rubber compound with higher viscosity than liquid silicone, processed on a rubber mill.

Hysteresis

The conversion of mechanical energy into heat within rubber when subjected to stress.

Insert

A material embedded into rubber during molding to create a bonded assembly.

Logy

The slow recovery rate of rubber after being stretched or compressed.

Mastication

The mechanical softening of raw rubber through repeated working.

Monomers

Simple chemical compounds that undergo polymerization to form rubber polymers.

Non-Fill

A defect where rubber fails to completely fill the mold, resulting in an incomplete part.

Parting Line

The visible line on a molded rubber part where the two halves of the mold meet.

Peptizer

A substance that accelerates the softening of rubber compounds under heat or mechanical action.

Pigment

An insoluble substance added to rubber to provide color.

Plasticity

The extent to which rubber can be deformed without returning to its original shape.

Polymerization

A chemical reaction where simple molecules combine to form a more complex, durable polymer.

Reinforcing Agent

A material added to rubber to improve its resistance to stress and enhance durability.

Scorch

Premature vulcanization that occurs when rubber cures too quickly.

Spew

Excess rubber that seeps out of the mold during the molding process.

Splice

The joining of two sections of rubber to form a continuous piece.

Vulcanization

A heat and pressure-driven chemical process that strengthens rubber, enhancing its elasticity and durability.

More Rubber Molding Information