Sheet Metal Fabrication

Sheet metal fabrication is a versatile manufacturing process that transforms thin, flat sheets of metal into finished parts and products by forming, cutting, and finishing. Common fabrication methods include stretching, drawing, bending, flanging, punching, shearing, and spinning to achieve the desired final component.

Quick links to Sheet Metal Fabrication Information

The History of Sheet Metal Fabrication

- Early History of Sheet Metal Fabrication

- Metal fabrication dates back to ancient times, beginning after the discovery of copper. The oldest known metal artifact is a pendant from northern Iraq, created around 8700 BC. Prehistoric peoples in the Great Lakes Region were also early metalworkers, using hammers and heat to shape copper between 5000 BC and 4000 BC.

- As different metals like gold and iron were discovered, metalworking methods became more advanced. Ancient Egyptians, for example, were renowned for their skills, producing everything from jewelry to weapons using various metalworking techniques.

- During antiquity, techniques such as engraving, cutting, stamping, and bending were developed. Today, these processes are still used, but with advanced technology for greater efficiency and precision.

- Sheet Metal Fabrication Beyond the 1400s

- In 1485, Leonardo da Vinci designed the first rolling mill. The first two rolling mills were built in 1501: one reused metal sheets as strips, while the other fabricated gold sheets for coin production. The rolling mill envisioned by da Vinci was not built until 1590, using cylinders to flatten metal.

- By the 1600s, major developments included the first lead and tin plate factory in 1615 and the first English cold roll mill in 1682.

- The Industrial Revolution, starting around 1760, introduced mass sheet metal fabrication. Innovations like press brakes and the assembly line expanded capabilities. In 1770, Joseph Bramah invented the hydraulic press, which remains important in precision sheet metal fabrication.

- By the 19th century, aluminum had been discovered and Henry Bessemer patented a process to convert iron into steel. Steel and stainless steel became critical materials, and advancements in sheet metal alloys continue to this day.

- Modern Sheet Metal Fabrication

- Modern sheet metal fabrication uses advanced technology such as CNC (computer numerical control) machines and CAD (computer-aided design) software. Equipment like sharper saw blades, faster drills, and stronger press brakes enhance precision and repeatability. Improved machinery allows for consistent bending and shaping, preserving metal thickness and durability in the final product.

Sheet metal fabrication, whether performed manually or with automated equipment, offers numerous advantages. It provides high precision, reduces material and labor costs, and enables the creation of durable, high-quality products. Additionally, sheet metal fabrication is highly versatile, making it suitable for a wide range of products and budgets.

The most frequently used sheet metal materials are aluminum sheet metal and stainless steel sheet metal. Other commonly fabricated metals include copper, titanium, mild steel, structural steel, brass, and bronze.

Aluminum is widely chosen for sheet metal fabrication due to its light weight, as well as its excellent tensile and compressive strength.

Stainless steel sheet metal is highly valued in manufacturing thanks to its corrosion resistance, strength, and durability. Its easy-to-clean surface makes it ideal for use in harsh environments or food processing applications.

- Sheet Metal Fabricating

- The fabrication process begins with sheet metal fabricating. Suppliers melt the raw metal into long, malleable slabs, which are then fed into powerful rollers to compress them into wide, flat sheets.

- Sheet Metal Shipping

- Suppliers cut the sheet metal to specified sizes and ship or deliver it to the next facility, where it will be further designed and fabricated into the desired product.

- Sheet Metal Design

- Fabricators develop a detailed product design plan, considering every aspect of the part. This design is then used as the basis for manufacturing the finished component.

- Part Forming

- During forming, manufacturers draw, cut, punch, stretch, weld, perforate, spin, roll, stamp, bend, iron, shear, saw, drill, blank, deburr, sand, and work sheet metal to achieve the final shape.

- Heat Treating

- Many metalworking steps require heating to alter the metal’s hardness. Processes such as heat treating, including annealing, quenching, and tempering, are used to harden or soften sheet metal as needed.

- Optional Assembly

- If a product consists of multiple components, manufacturers assemble the final product before shipping to customers or distributors.

During the design stage, sheet metal fabricators address more than just dimensions, material, and shape. They consider factors such as part size, required strength, quantity, and any additional materials. Their goal is to ensure the final product is safe, effective, and meets all industry standards, while identifying potential weaknesses or stress points. To reduce costs or support sustainability, manufacturers may also use recycled or previously fabricated sheet metal. Contact your supplier for further details.

Machinery Used in Fabrication

Sheet metal fabrication relies on a wide array of equipment, including punch and die systems, press brakes, drills, automated production lines, CNC machining technology, and more.

Punch and die systems operate by securing flat sheets of metal and then deforming them with a descending punch. These systems often work alongside press brakes or other specialized presses, allowing for various shapes and bends. Press brakes are primarily used to bend sheet metal and can be paired with a range of punch and die tools.

Modern drills used in fabrication are typically laser-powered, enabling both drilling and precise cutting. Laser cutting technology allows manufacturers to achieve clean edges and accurate cuts at specific depths and angles.

Robotic automated lines are common in large-scale facilities. Robots handle and position sheet metal workpieces as they are formed, cut, and finished throughout the fabrication process.

CNC machinery, utilizing advanced software, enables manufacturers to produce highly accurate and consistent parts through automated control.

Sheet metal fabrication shapes and forms metal sheets by cutting, bending, punching, and welding them into different configurations.

Sheet metal fabrication shapes and forms metal sheets by cutting, bending, punching, and welding them into different configurations.

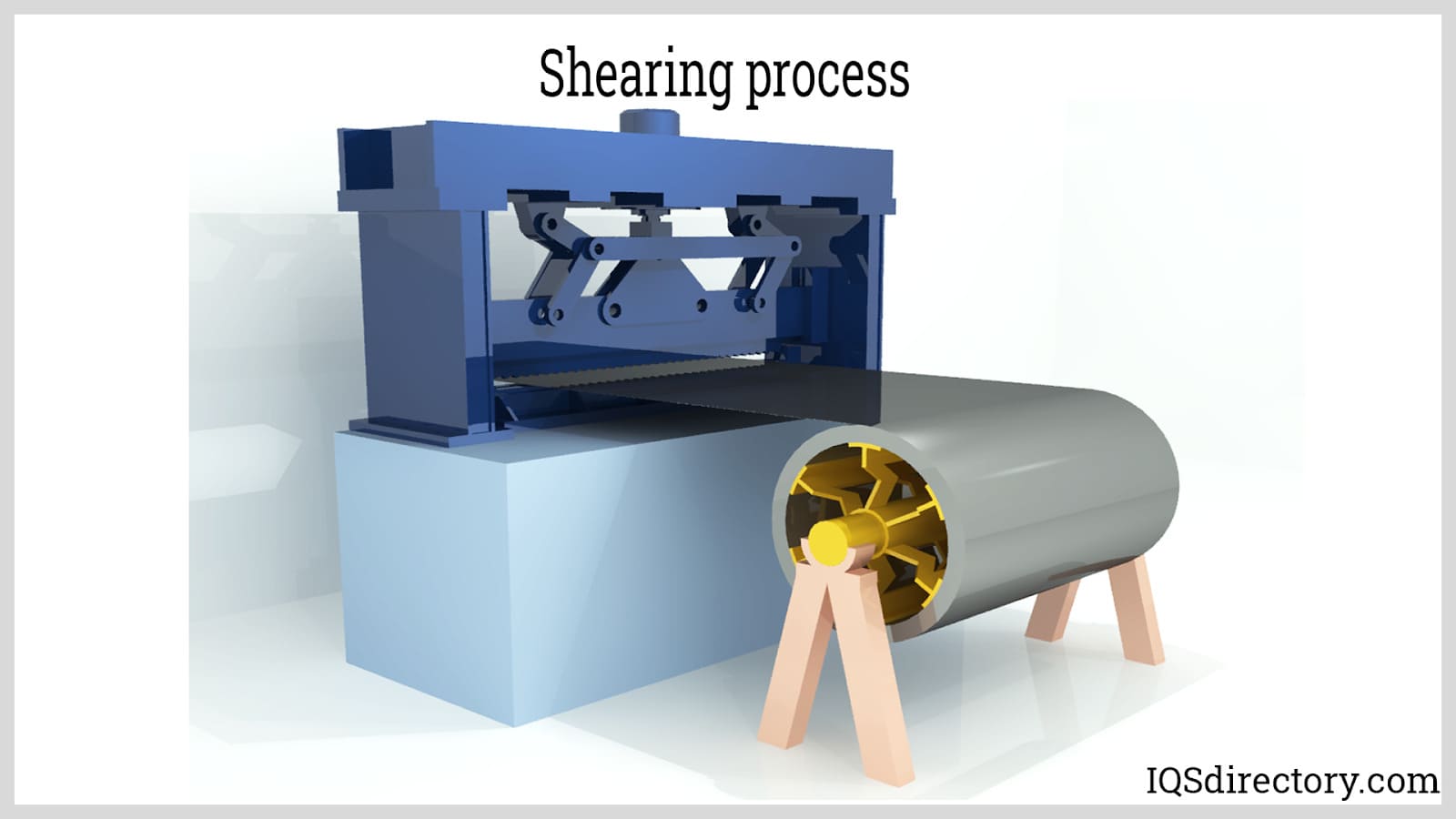

Shear cutting uses upper and lower blades to cut in straight lines.

Shear cutting uses upper and lower blades to cut in straight lines.

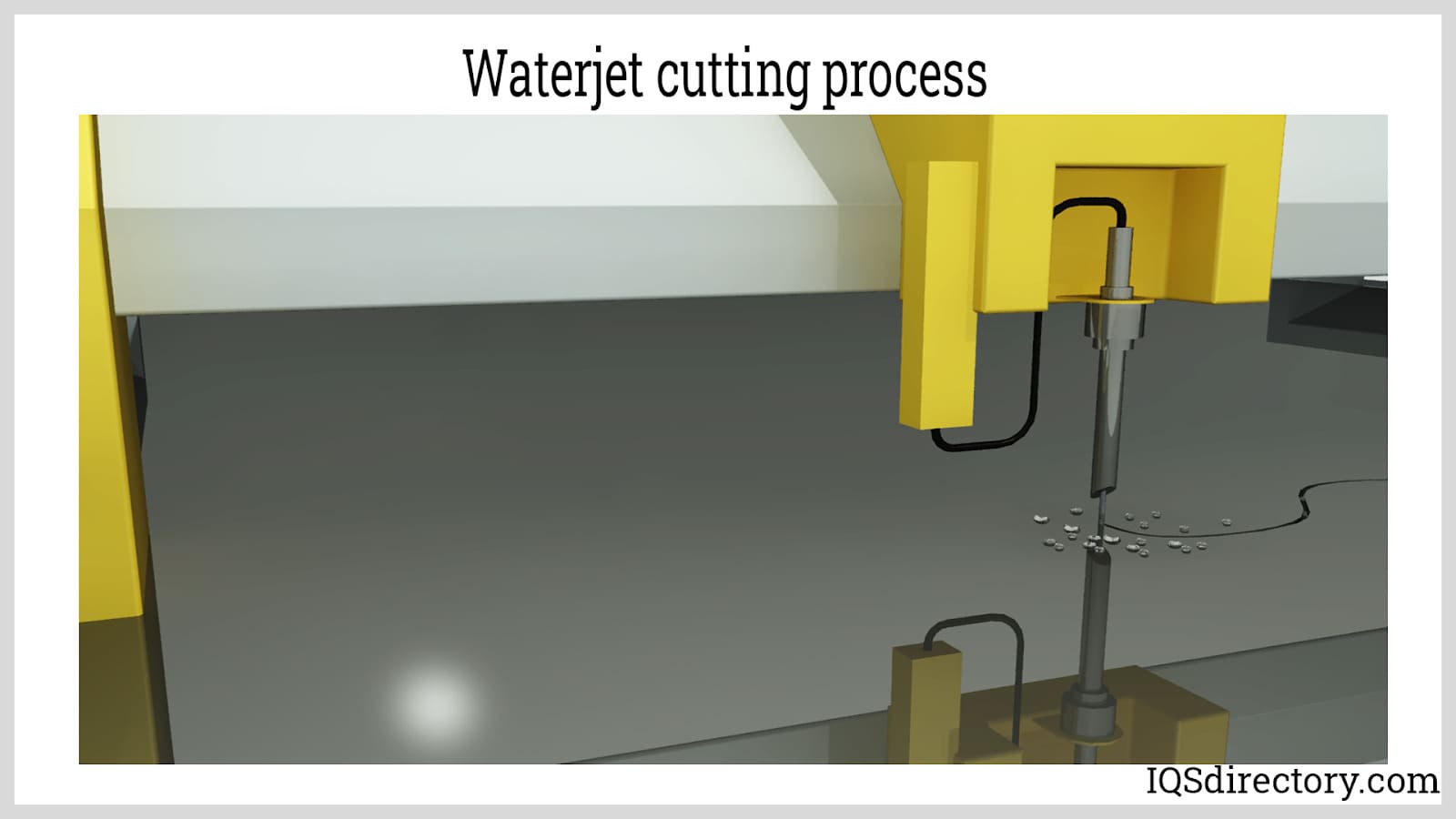

A high-pressure water jet, combined with abrasive material, cuts sheet metal by eroding it at high speed.

A high-pressure water jet, combined with abrasive material, cuts sheet metal by eroding it at high speed.

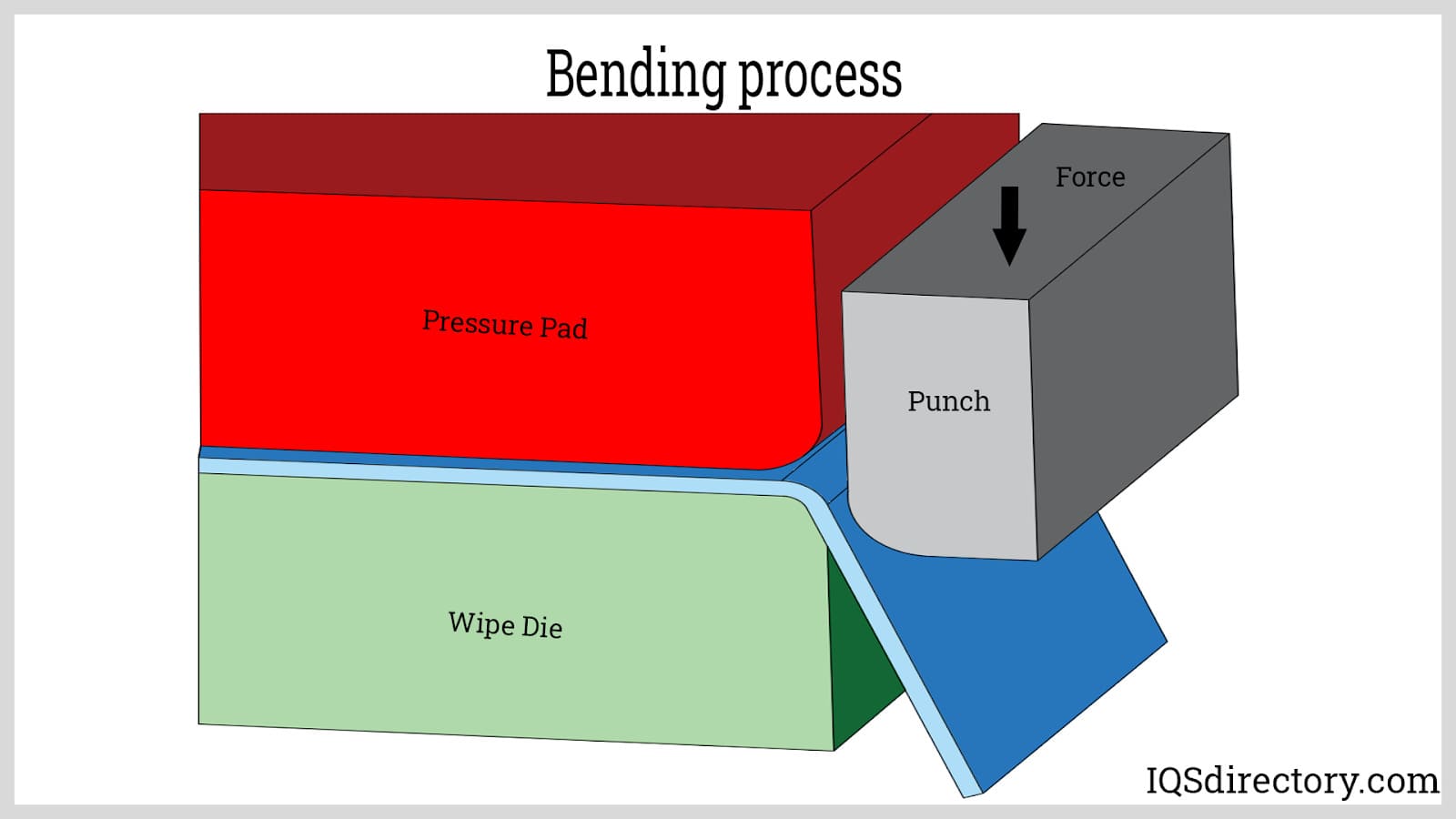

Machines like press brakes are used to bend sheet metal into angles ranging from 0 to 120 degrees.

Machines like press brakes are used to bend sheet metal into angles ranging from 0 to 120 degrees.

Welding fuses two metal pieces by melting them together to create a secure joint.

Welding fuses two metal pieces by melting them together to create a secure joint.

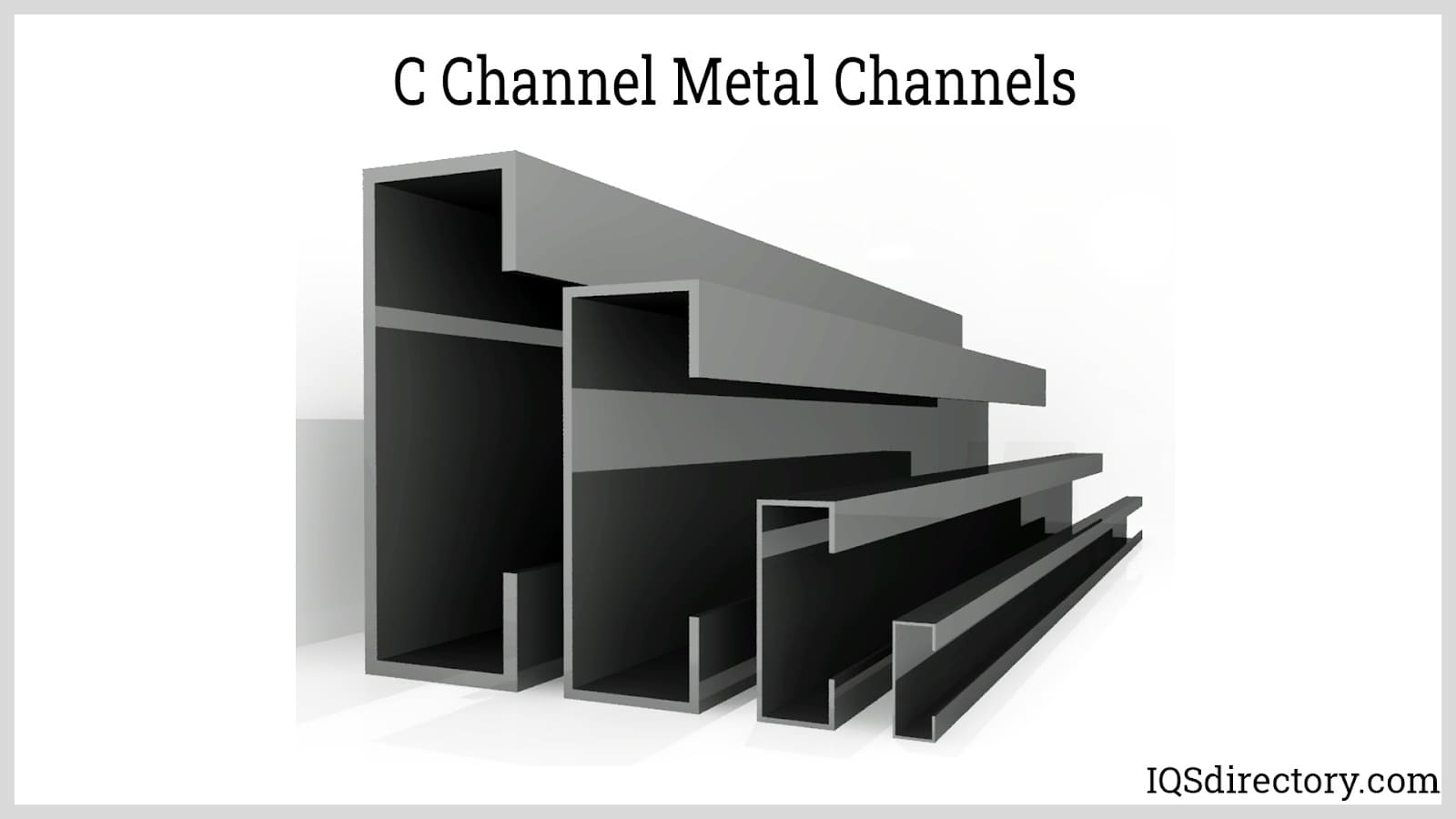

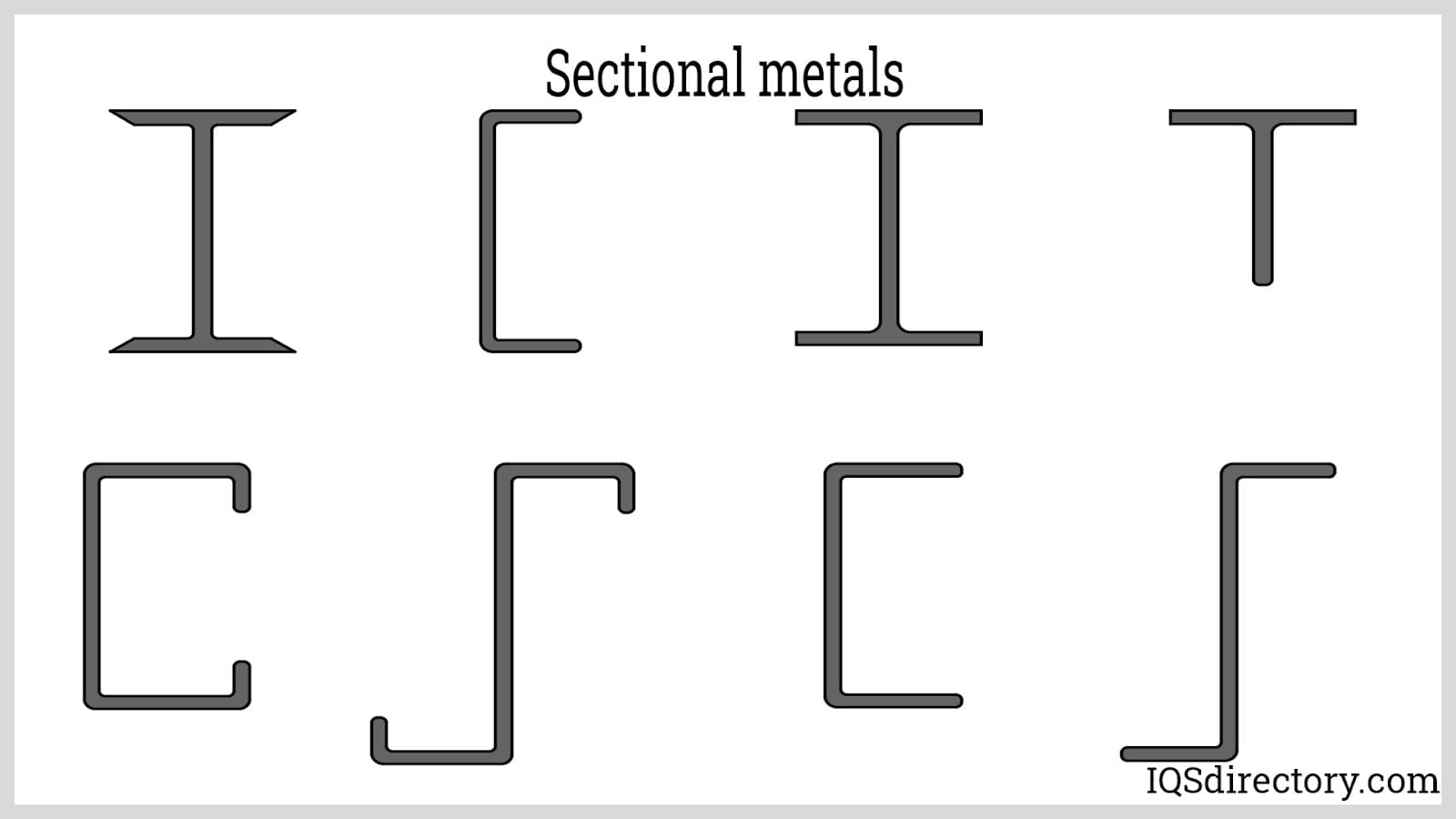

Various shapes are produced during the fabrication process to meet specific requirements.

Various shapes are produced during the fabrication process to meet specific requirements.

Rolling machines shape steel into rolls, resulting in a more finished and uniform product.

Rolling machines shape steel into rolls, resulting in a more finished and uniform product.

Nearly every sector, from residential and commercial to industrial, relies on precision sheet metal fabrication. Key industries that use sheet metal fabrication include military, food processing and storage, communications, automotive, computers, medical, electronics, aerospace, pharmaceutical, and construction.

Manufacturers use precision sheet metal fabrication to produce a wide variety of products. Common examples are HVAC components like grating and ductwork, stairwell railings, structural supports such as airplane frames and bridge skeletons, lighting hoods, cutlery, scissors, fencing, cages, shelving, and fabricated metal furniture such as metal cabinets for storage.

If you need custom sheet metal parts or products, it’s important to work with a manufacturer that understands your specifications and can deliver quality results. Review the companies listed above, browse their profiles, or visit their websites directly to learn more about their services and capabilities. The best choice will be a company that listens to your needs, meets your requirements, and delivers custom products within your budget.

Variations and Similar Services for Fabrication

- Annealing

- A heating and cooling process used to soften metal. Annealing processes change the physical and mechanical characteristics of metal in order to create a specific microstructure.

- Cutting

- Can be performed using drills, lasers, blades or saws. Manufacturers employ cutting when they wish to remove imperfections or excess material from a product.

- Cold Forming Process

- Involve all those that occur at room temperature, such as bending, cold rolling and drawing. Cold forming processes are generally done to increase the strength and hardness of the metal.

- Sheet Metal Bending

- A manufacturing process that involves bending metal material along a linear axis on a neutral plane. Typically, they bend metal from strip metal or flat sheets. After manufacturers remove the stress, because metal flow occurs only within the range of plasticity, the bent portion remains permanently set. Bending typically produces a V-shape, C-shape or channel shape in the metal, but standard die sets are capable of bending the sheet metal into a wide variety of forms.

- Cold Rolling

- The process of shaping sheet metal through rollers by compression and squeezing. The degree of strain establishes the hardness, along with the other characteristics of the completed material.

- Drawing Process

- Process of forming sheet metal into a cup-like shape by forcing the material into a die with a punch, which stretches the metal into shape. The shape of the drawn part can be rectangular, circular, etc. depending on the cross section.

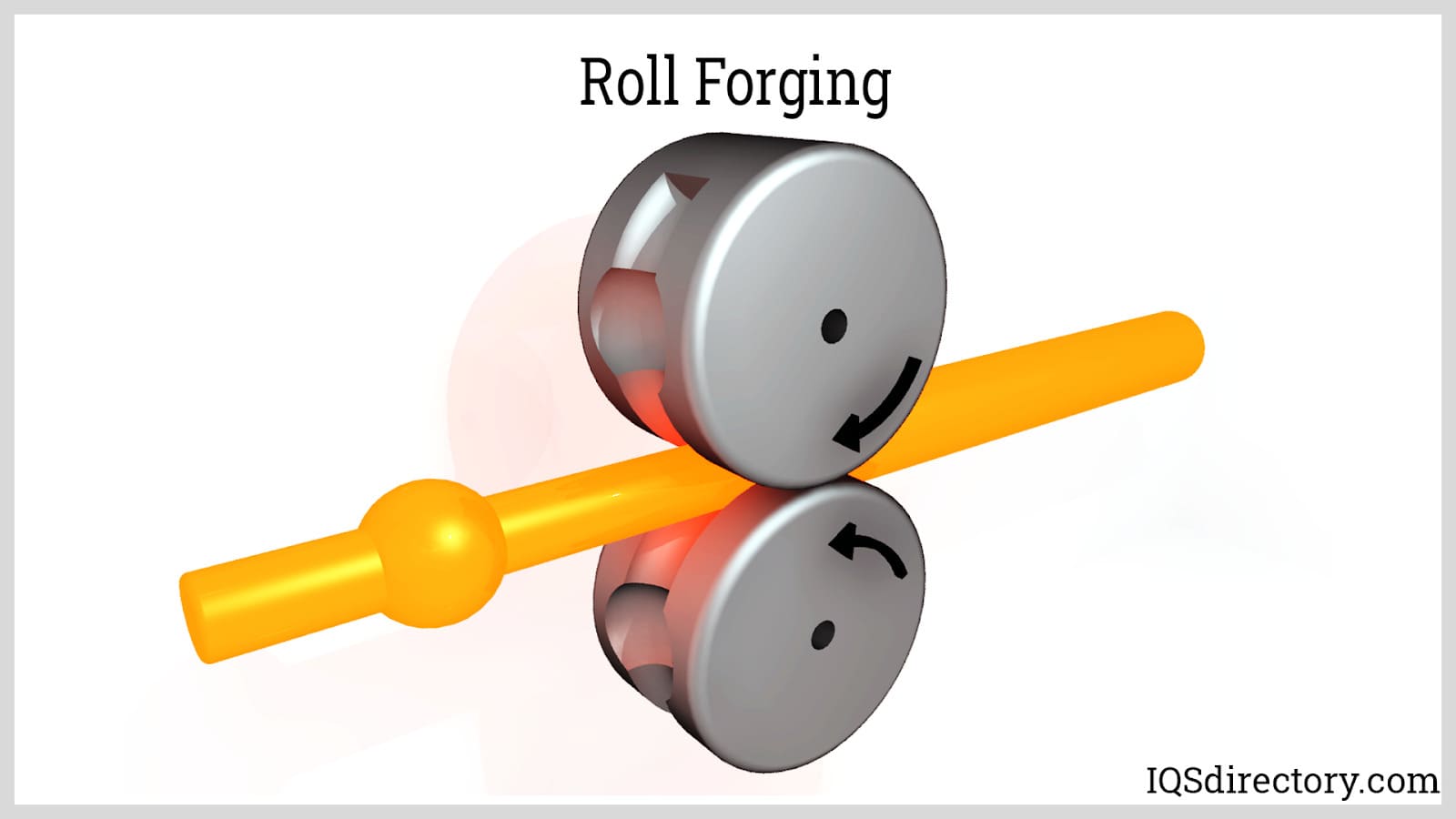

- Forging

- Process of forming a hot or cold metal into a different shape by hammering or pressing.

- Hot Forming Process

- Involve all those that use a high temperature to lower a metal’s resistance to shape change, such as hot rolling and hot stretching.

- Mechanical Working

- Any process that puts pressure on metal with hammers, rolls or presses for altering the shape or physical characteristics of the metal material.

- Piercing

- The process of punching or shearing holes and slots in sheet material. Piercing is similar to blanking, except that the resulting piece from piercing is scrap and the resulting piece from blanking is useful.

- Press Forming

- Any sheet metal forming process that uses a mechanical hydraulic press.

- Punching

- Involves die shearing in sheet metal so that the resulting material is scrap.

- Roll Forming

- A metal forming method for creating long parts with a variety of cross sections. This process forms sheet metal by passing it through a series of powered contoured rolls.

- Shearing

- Involves the separation of material from a blade that forces the material past another opposing blade.

- Slitting

- The cold forming process of cutting a sheet of metal into smaller pieces to meet specifications.

- Stamping

- The procedure of impressing three dimensional designs, lettering or surface definitions through pressurized tools like presses or dies.

- Sheet Metal Work

- Includes the various processes involved in heating and shaping metal sheets. In general, sheet metal is created by compressing the metal materials between rollers.

- Stretching

- The process by which sheet metal is clamped around the edges and stretched to make various products.

- Welding

- A procedure for permanently bonding two or more metal components by melting both materials. Common methods for sheet metal include: spot welding, TIG welding, oxy fuel welding, solid-state welding, seam welding, resistance welding and arc welding.

- Adhesive

- A substance that bonds the inner and outer panels of metal.

- Age Hardening

- Heating a metal to a uniform heat and then rapidly cooling it with air or oil to harden it.

- Alloying Element

- A metallic element that is added to another metal to produce an alloy in order to increase properties, such as hardness, strength and corrosion resistance.

- Bend Test

- A test that is used to determine the ductility and malleability of various metals.

- Blank

- A piece of sheet metal that has been cut for further press operation.

- Bloom

- A semi-finished piece of metal that needs further processing.

- Brazing

- The process of joining solid metals together by using a fusible filler metal with a melting point below that of the base metal.

- Burr

- A leftover ridge on the edge of metal caused by cutting operations, such as trimming, slitting and shearing.

- Cavitation

- The rapid formation and depletion of air bubbles within a metal during the solid/liquid interface. Cavitation can cause permanent damage to the material.

- Cladding

- The application of a thin coat of stainless steel to another metal in order to increase corrosion resistance.

- Corrosion

- The gradual deterioration of metals caused by harsh chemical and environmental conditions.

- Corrosion Rate

- The speed at which corrosion occurs on a particular substance.

- Creep

- The slow strain on metals, caused by stress, that occurs over time.

- Cup

- A sheet metal part that is cylindrical or shell-shaped with one end closed.

- Deburring

- The process of smoothing the rough-cut edges of metal.

- Descaling

- A process that involves removing the oxide layer, which forms on metal after hot forming processes.

- Ductility

- The amount of deformation a metal can withstand before failure.

- Embrittlement

- The loss of malleability in a metal after a physical change or due to chemical treatment.

- Fatigue

- The state of a metal after repeated stress, leading to an eventual fracture.

- Finish Form

- Forming a panel metal shape into a completed product.

- Flange

- A projection from the edge or rim of a metal part, typically narrow and of uniform width for fastening.

- Grinding

- Removing parts of the metal by using abrasives.

- Oxidation

- Corrosion of a metal due to oxygen.

- Pitting

- Localized corrosion on a metal surface.

- Plastic Deformation

- The application of stresses, which strain a metal material past its elastic boundary, resulting in a permanent distortion.

- Plasticity

- The capability of metal to undergo permanent deformation without breakage.

- Strip

- A very thin, flat-rolled metal product.

- Yield Strength

- Stress point beyond which a metal undergoes important permanent flow.