Industrial Shredders

In today’s world, data security and pollution are two pressing challenges, and surprisingly, one industry tackles both. Shredding not only ensures the secure disposal of sensitive information but also promotes environmental sustainability by enabling material recycling. This efficient process reduces energy consumption and minimizes waste, making it a responsible choice for both security and sustainability.

Shredding provides an effective solution for waste disposal across various industries. With specialized units designed for nearly every type of waste, industrial-strength shredders can process everything from metals to biological materials in an eco-friendly manner.

Industrial shredders feature a feed area equipped with blades or gears that break down materials, directing them through a chute into a receptacle or onto a conveyor for further processing. These powerful machines operate in large commercial shredding plants, office settings, homes, or as part of mobile shredding units for on-site destruction.

The History of Shredding Services

The concept of document destruction dates back almost as far as the written word itself. Long before the invention of mechanical shredders, people disposed of unwanted documents by simply tearing them by hand. The earliest recorded instance of this practice can be traced back to around 4000 BC, when the Egyptians developed papyrus—the first known form of paper. When errors were made, the solution was simple: rip it up.

Fast forward to 1908, and the world saw the first specialized paper shredding device. Abbot Augustus Low, a prolific inventor second only to Thomas Edison in U.S. patents, designed and patented the Waste Paper Receptacle in 1909. While groundbreaking, his machine was never mass-produced, leaving his contribution largely forgotten.

In 1935, German engineer Adolf Ehinger created the first machine-operated shredder, inspired by the mechanics of a hand-crank pasta maker. Originally developed to destroy anti-government propaganda in 1930s Germany, his design evolved into an electrically powered unit marketed to government agencies. By 1959, his company, EBA Maschinenfabrik, introduced the world’s first cross-cut paper shredder, a major leap in document security.

The Cold War era—from the 1950s through the 1980s—saw shredding technology become essential to government agencies handling classified information. The increasing need for confidentiality drove demand for more advanced and efficient shredding methods.

With the rise of the digital age, safeguarding sensitive information expanded beyond paper destruction. Hard drive shredding became critical for preventing data breaches, ensuring that medical records, financial information, and personal identifiers could not be exploited. Simultaneously, industries dealing with industrial, biological, and medical waste required powerful solutions for safe and eco-friendly disposal.

From these growing demands, industrial shredders emerged. Advances in technology and a push for environmental responsibility led to high-capacity shredders capable of processing a wide range of materials, from paper to plastics and biomass.

Benefits of Industrial Shredders

Industrial shredders are indispensable across various industries, offering a secure, efficient, and environmentally responsible way to eliminate waste. These high-powered machines can handle everything from confidential documents to hazardous materials, ensuring proper disposal while facilitating recycling efforts.

Businesses benefit significantly from shredding solutions, whether in healthcare, manufacturing, or finance. By removing the burden of waste disposal, shredders allow employees to focus on their core responsibilities while maintaining compliance with data protection and environmental regulations.

Modern industrial shredders are designed to process diverse materials, including wood, textiles, plastics, and biomass. Whatever the waste stream, there is a specialized unit capable of reducing, packaging, and preparing it for responsible disposal or recycling.

In today’s world, shredding technology is no longer just about destroying paper—it’s about safeguarding information, managing waste efficiently, and contributing to a more sustainable future.

How Industrial Shredders Work

Industrial shredders function similarly to smaller household models but on a much larger scale. Material is fed into a designated intake area, where powerful cutting mechanisms break it down into smaller, manageable pieces. Once shredded, the material is collected, packaged, and prepared for transport or disposal. These machines come in a variety of designs, each specialized for different types of waste, from tires and metal to wood, plastic, and general refuse.

Shredders Images, Diagrams and Visual Concepts

Equipment designed for shredding dense and light materials for recycling or destruction of unusable products.

Equipment designed for shredding dense and light materials for recycling or destruction of unusable products.

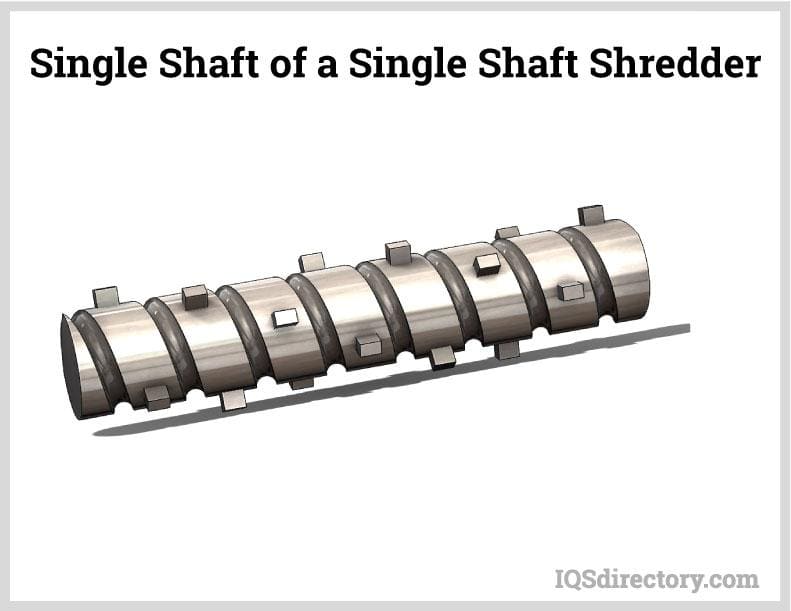

A single shaft rotates at a low RPM rate and shreds materials to one or two inches.

A single shaft rotates at a low RPM rate and shreds materials to one or two inches.

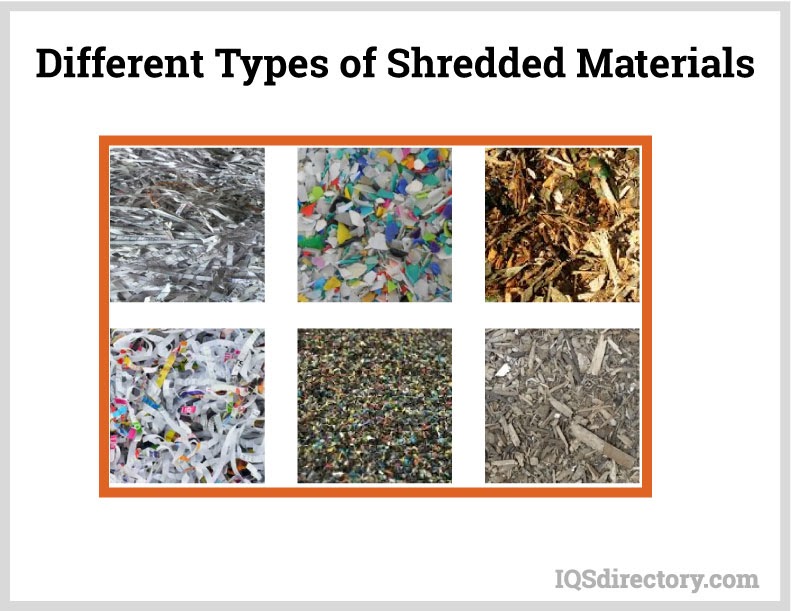

The different type of materials that can be shredded.

The different type of materials that can be shredded.

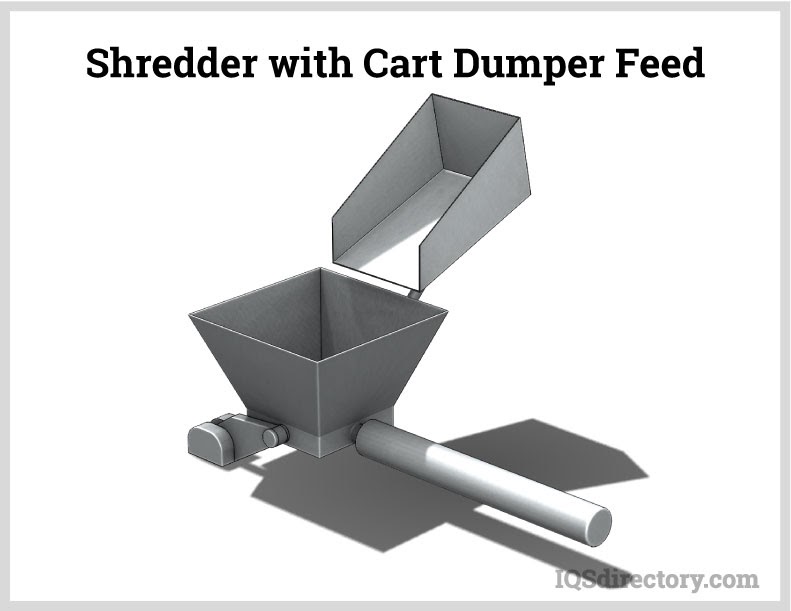

Fed into the shredder to allow processing.

Fed into the shredder to allow processing.

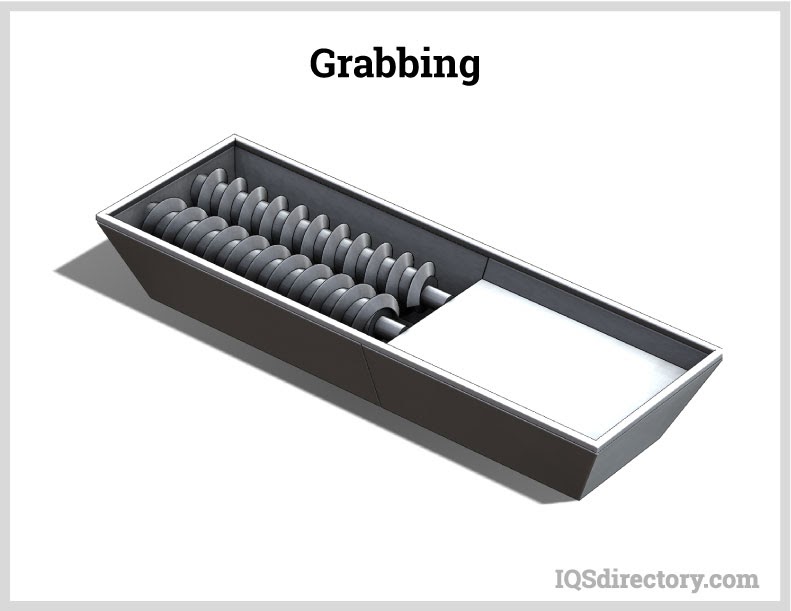

The material is grabbed by the cutting mechanism and is pushed through the rotating blades into smaller pieces.

The material is grabbed by the cutting mechanism and is pushed through the rotating blades into smaller pieces.

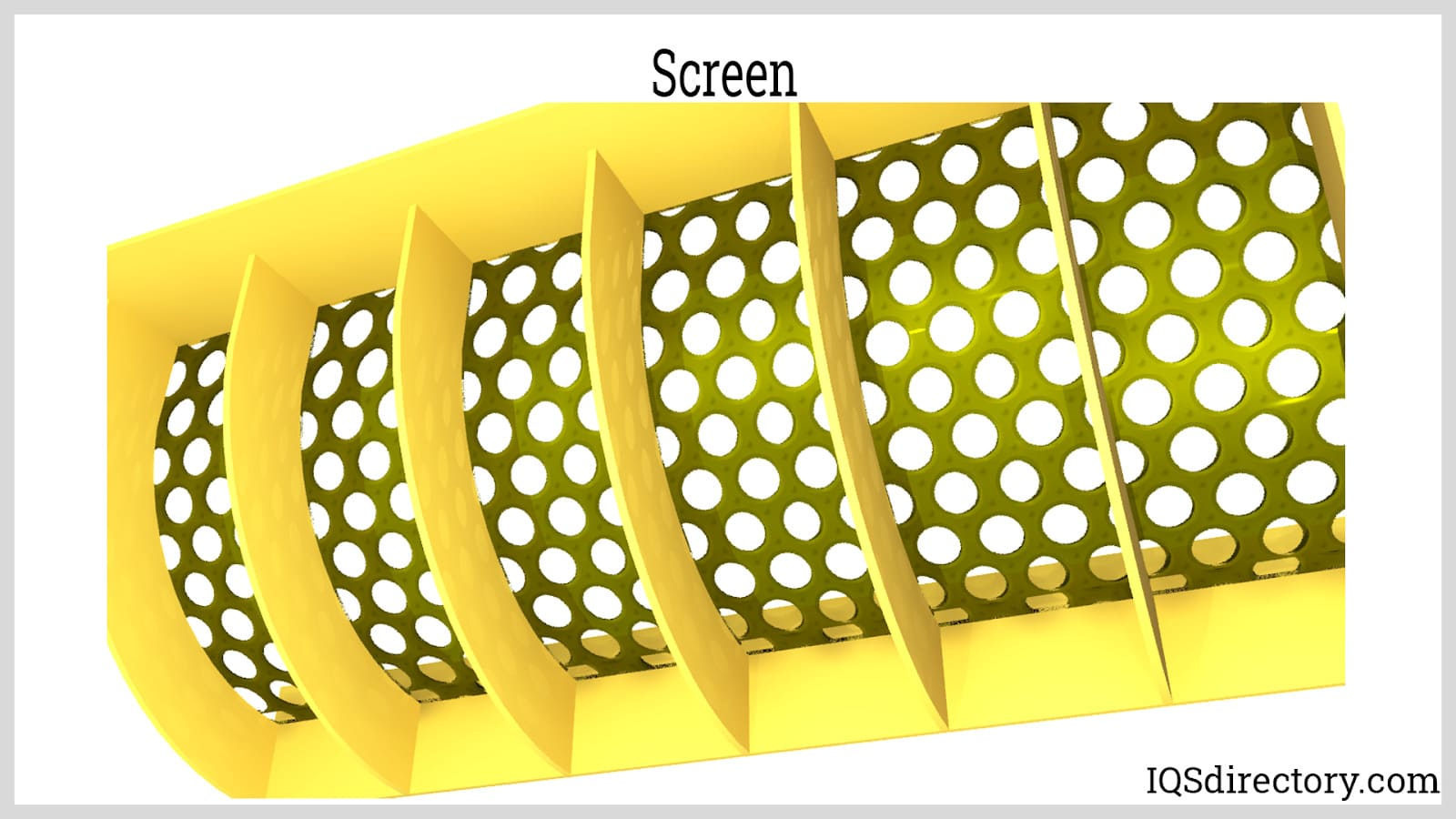

Screens are designed to fit the type of material allowing contaminants to be processed out.

Screens are designed to fit the type of material allowing contaminants to be processed out.

Types of Shredders

Shredders come in a variety of types, each designed to handle specific materials and waste disposal needs. While standard units are sufficient for paper, large manufacturing facilities often require high-capacity machines to manage significant volumes of waste. Investing in an industrial shredder enables manufacturers to efficiently dispose of and recycle materials. Many units are versatile enough to accommodate various waste streams, while some applications require specialized shredding equipment.

Even municipal solid waste can be processed with specialized shredders. These machines condense waste and convert it into a more manageable form for transport. Although different shredders are designed for specific applications, they all operate on similar principles, with modifications to optimize their performance.

- Automobile Shredders

- A specific category of hammermill shredders, automobile shredders are large enough to shred entire vehicles and compact them into small squares for recycling.

- Cardboard Shredders

- Cardboard shredders play a key role in packaging waste disposal and recycling. Given that cardboard is widely used in packaging, these machines ensure efficient minimization and removal of used materials.

- Chipper Shredders

- Chippers are designed to cut wood or other materials into small chips. They are commonly used for processing branches, cardboard boxes, crates, and particle board for recycling or conversion into other products. The resulting wood chips are often repurposed for landscaping, playground surfaces, or garden pathways.

- Document Shredders

- Used to carefully destroy sensitive documents, document shredders ensure the secure disposal of confidential materials.

- Granulation Machines

- Granulators shred small materials, such as plastic bottles, preparing them for further processing.

- Hammermill Shredders

- Hammermill shredders come in horizontal and vertical designs, utilizing high-speed rotors equipped with large hammers to crush materials into smaller sizes. These machines can deliver up to 6,000 horsepower of force, making them suitable for reducing dense materials.

- Hard Drive Shredders

- Specialized hard drive shredders physically destroy the platters of hard discs, ensuring that confidential data cannot be recovered. Unlike deleting, overwriting, or drilling holes in a disc, these machines provide complete data destruction. Hard drive shredders are often offered by companies that also handle paper or microfilm shredding, utilizing saw-tooth hook cutters.

- Hydraulic Drive Shredders

- Equipped with a hydraulic pump powered by an electric motor or diesel engine, these shredders can reverse away from loads and resume forward rotation in less than three seconds, enhancing efficiency.

- Industrial Grinders

- Using attrition and compression, industrial grinders crush materials into smaller pieces. They often break down larger components into more recyclable forms.

- Industrial Shredders

- Industrial shredders are designed for large-scale material destruction ahead of disposal or reprocessing. These machines handle high volumes of diverse materials in various industries.

- Medium-Speed Shredders

- These shredders feature round, drum-like designs with multiple cutter inserts that work against a fixed bed knife. They are commonly used for reducing plastics, electronic scrap, wood waste, and nonferrous metals.

- Metal Shredders

- Designed to process heavy-duty metal waste, metal shredders handle materials such as steel drums, cables, tubing, and sheet metal. They separate metal from non-metal components before compressing them into dense blocks. Given that half of all stainless steel is produced from recycled scrap, these shredders play a crucial role in the recycling process.

- Mobile Shredders

- These shredders are designed for portability, allowing them to be moved from one location to another for flexible material processing.

- Paper Shredders

- One of the most common shredding machines, paper shredders vary in size and capacity. They are standard in offices and paper mills for secure document disposal.

- Plastic Shredders

- These machines cut discarded plastic into manageable pieces before reprocessing. They are essential in plastic recycling operations.

- Shear Type Shredders

- Shear-type shredders operate with high torque at low speeds, using two or more counter-rotating shafts equipped with hooked knives. These machines are effective at processing tires, paper, and baled metals like aluminum.

- Tire Shredders

- Common in junkyards and rubber recycling centers, tire shredders use slow-speed, high-torque mechanisms to process dense rubber from tires and tubing.

- Tube Grinders

- Primarily used for wood and organic material, tube grinders use a hammermill mechanism to tear large materials into smaller pieces. The shredded material is then pulled below the tub floor and forced through openings in grates beneath the mill.

Shredding Location

- Off Site Shredding

- The shredding industry serves customers in multiple ways, with off-site shredding being one of the most common. Recycling plants frequently rely on this method to process materials like tires, wood, organic waste, old automobiles, scrap metals, plastics, and cardboard. In this approach, materials are collected and transported to a dedicated shredding facility.

Remote document shredding operates similarly, where a driver picks up sensitive materials and ensures they are securely destroyed at the facility on the same day. Some companies also offer mobile shredding, where industrial shredders are built into modified box trucks that can process up to 8,000 pounds of material per hour. This on-site service is ideal for businesses that require immediate destruction of sensitive documents, such as medical practices and government agencies bound by privacy regulations like HIPAA. By eliminating an extra step in the chain of custody, mobile shredding minimizes the risk of information being lost or stolen. However, for large-scale industrial waste disposal, this option is not always practical.

- On Site Shredding

- For businesses dealing with significant volumes of cumbersome waste, an on-site industrial shredding unit may be the better choice. Large facilities, in particular, require efficient solutions for waste disposal and recycling. These systems can be manually operated or equipped with heavy-duty loading mechanisms for bulk materials.

A reputable shredding provider will assess your specific needs and recommend the most convenient and cost-effective solution. Many shredding systems not only break down waste but also compress and package it for easy disposal. Additionally, companies often supply debris bags for pre-shredded paper and other materials, ensuring smooth collection and transport.

Environmental Benefits

Industrial shredders play a crucial role in recycling efforts, extending the life cycle of numerous materials while reducing waste into manageable forms for repurposing. Shredded materials are sent to specialized facilities, where they are transformed into new products, contributing to sustainability and significant cost savings for businesses.

What is from recycled refuse?

- Paper Products

- Paper waste is processed at paper mills, where shredders cut it into strips, cross-sections, or fine particles before being reduced to raw pulp. This pulp is then used to manufacture new paper with recycled fibers. Old cardboard boxes and cartons undergo similar shredding processes, producing packing materials or precisely cut sheets for reuse.

On a smaller scale, shredded paper can serve as animal bedding, garden mulch, or protective packaging. On an industrial scale, recycled paper can be refined into high-quality materials used in construction, such as durable, affordable wallboard for homes and commercial buildings.

- Glass Bottles

- Glass stands out as a highly sustainable material, as it can be recycled indefinitely without degrading in quality. Beyond making new glass products, recycled glass finds applications in tiles, concrete, and asphalt, demonstrating its versatility and resilience.

- Plastic Products

- Plastics—including drums, pipes, car bumpers, and bottles—are processed through high-speed granulators that break them into fine particles. These are then heat-treated and reshaped into new plastic products, reducing reliance on virgin materials and lowering environmental impact.

- Rubber From Tires

- Discarded tires provide a valuable resource for numerous industries. After being cleaned and separated from their steel rims, tires are shredded into crumb rubber, which can be used in manufacturing new tires, road asphalt, and even sports surfaces. Additionally, repurposed rubber contributes to artificial reefs and various construction applications.

- Municipal Waste as a Fuel

- One of the most promising advancements in waste management is converting municipal solid waste into refuse-derived fuel. This emerging alternative to fossil fuels holds the potential to revolutionize global energy consumption. As research in this area progresses, the impact could reshape industries and environmental policies worldwide.

Standards and Safety for Shredders

The improper use of shredders can result in severe injuries or even fatalities, making strict adherence to safety protocols essential. Anyone present during operation must follow rigorous safety guidelines to prevent accidents. While each unit comes with specific safety instructions, some universal precautions always apply.

When selecting the right shredder, take a comprehensive approach. Research different models, gather customer insights, and, if possible, observe multiple units in action to determine which best meets your needs.

Shredders have evolved significantly from the days of manually tearing paper. Today, businesses require efficient solutions for destroying documents and handling bulk waste. Beyond paper, industries worldwide seek cost-effective and environmentally responsible ways to manage various waste materials. High-quality manufacturers provide professional waste disposal solutions, including on-site industrial units that enable large companies to manage refuse sustainably. The responsibility to dispose of waste efficiently and ethically ultimately falls on the user.

Safety guidelines apply to all types of shredders, though they are not exhaustive. Always refer to the owner’s manual or manufacturer’s safety guide for unit-specific recommendations.

- Qualified Individuals

- Shredders, whether small office models or large industrial units, should only be operated by trained individuals. While manufacturers integrate safety features into their designs, no safeguard is completely foolproof.

- Know the Safety Features

- Familiarity with a shredder’s safety mechanisms is crucial, including knowing where the emergency shutoff is located and how to use it effectively. Overloading a shredder can lead to jams, making the machine unpredictable and hazardous. Regular maintenance is essential, but only licensed professionals should diagnose or repair a unit.

- Consider Unit Size

- With numerous options available for waste disposal, selecting the right shredder depends on your specific needs. Smaller mobile units may suffice for minimal shredding, while large-scale industrial models are necessary for high-volume waste management.

No two shredders are exactly alike, and manufacturers vary in their commitment to quality. Some prioritize durability and performance, while others cut corners for profit. The best choice is one tailored to your unique requirements—not simply the most popular model on the market. A shredder that works well for another business may not suit your operational demands, so careful consideration is key.

Shredder Terms

- Automotive Shredder Residue (ASR)

- The leftover material from a shredded automobile after all ferrous metals have been removed. Often called "fluff."

- Balers

- Machines that compress shredded materials into compact, rectangular bales for easier handling and transport.

- Bales

- Densely packed bundles of shredded material, typically secured with wire or banding.

- Banding

- Straps, usually made of wire or nylon, wrapped around bales to keep them intact.

- Burden Depth

- The thickness of material spread across a conveyor belt during processing.

- Cross-Cut

- A shredding technique that slices material in two directions, producing smaller, more uniform particles.

- Destruction Chamber

- The interior of an industrial shredder where materials are torn, crushed, or reduced in size.

- Downstream Separation

- The process of sorting shredded material after it leaves the shredder, typically using conveyor belts, magnets, eddy current separators, and trommels.

- Eddy Current Separator

- A device that separates nonferrous metals from nonmetallic materials by generating an alternating magnetic field, which repels metallic particles.

- Feed Width

- The opening size through which material is inserted into an industrial shredder.

- Ferrous

- Metals that contain iron, such as steel.

- Grapplers

- Versatile tools designed for handling waste, scrap metal, and other loose materials in industrial applications.

- Granulator

- A type of shredder specifically designed for reducing small materials, like plastics, into granules.

- Hydraulic

- A system or process powered by pressurized fluid.

- Material Burden

- The volume of material on a conveyor belt that requires sorting.

- Metal Shears

- A cutting method that slices metal sheets in a straight line using an upper and lower blade.

- Non-Ferrous

- Metals that do not contain iron, such as aluminum and copper.

- Pallet Shredders

- Heavy-duty shredders capable of breaking down dense materials like plastic containers, rubber tires, and large volumes of paper and cardboard.

- Shredder Drive

- The motor that powers an industrial shredder, available in electric and hydraulic configurations.

- Slurry

- A liquid-based mixture containing suspended solids.

- Speed

- Measured in feet per minute, this indicates how quickly a shredder processes materials.

- Strip-Cut

- A shredding method that produces long, thin strips, often the same length as the original material.

- Throat

- The feed opening of a shredder, which must be wide enough to accommodate the material being processed.

- Unshreddables

- Objects that are too large or dense for a shredder to process.

- Used Shredders

- A cost-effective and sustainable alternative to new shredders, offering competitive pricing without compromising performance.

- Waste Capacity

- The maximum volume, measured in gallons, that a shredder’s waste bin or bag can hold.

- Waste Shredders

- Machines used in industrial settings, municipal services, and waste disposal facilities to process large volumes of waste efficiently.