Solenoid Valves

Solenoid valves are electromechanical devices designed to regulate the flow of fluids or gases with precision. Often referred to as control valves, they operate by responding to electrical signals, enabling automated flow control in various applications.

Pressure ratings for solenoid valves are typically measured in pounds per square inch (psi) or bars, with psi being the standard unit of measurement among manufacturers and users in the United States.

Solenoid Valves FAQs

What is a solenoid valve and how does it work?

A solenoid valve is an electromechanical device that regulates the flow of fluids or gases using an electric current. When energized, the magnetic field moves a plunger to open or close the valve, allowing precise, automated flow control in industrial systems.

What are the main advantages of using solenoid valves?

Solenoid valves offer rapid switching, compact design, and low maintenance due to fewer moving parts. They enable remote operation, integrate easily into pneumatic and hydraulic systems, and provide reliable performance for automated industrial applications.

What materials are solenoid valves made from?

Solenoid valves are commonly made from metals such as stainless steel, brass, and aluminum or plastics like PTFE and PVC. The choice depends on chemical compatibility and environmental conditions, with Viton seals often used for resistance to heat and chemicals.

What is the difference between direct-acting and pilot-operated solenoid valves?

Direct-acting solenoid valves use a plunger to open or close the flow path directly, ideal for low-pressure systems. Pilot-operated valves rely on differential pressure and a diaphragm for operation, making them suitable for higher-pressure applications.

Where are solenoid valves commonly used?

Solenoid valves are used in HVAC, refrigeration, car washes, irrigation systems, and pneumatic or hydraulic machinery. They ensure precise flow control and efficient operation in manufacturing, automotive, and process industries across North America.

How should solenoid valves be installed for best performance?

Install solenoid valves in a dry, ventilated area and follow the directional arrow on the body to align flow correctly. Professional installation is recommended to prevent overheating or flow obstruction and ensure long-term reliability.

What maintenance do solenoid valves require?

Regular cleaning prevents buildup and performance loss. Avoid incompatible fluids, freezing, or exceeding pressure limits. Maintenance kits can restore function without disassembling the entire valve, extending lifespan and operational safety.

The History of Solenoid Valves

The solenoid control valve made its debut in 1910 when ASCO Numatics introduced the first manufactured and commercially available model. As industries expanded, so did the technology behind these valves.

By the 1950s, manufacturers began incorporating plastic-molded bodies into solenoid valve designs, significantly improving their resistance to chemicals and corrosion. This innovation enhanced their durability, efficiency, and overall reliability in various applications.

The 1970s saw another leap forward with the widespread adoption of automatic shut-off valves. Unlike manual shut-off valves, these offered safer and more precise control, revolutionizing industries that required quick and reliable fluid regulation.

Standardization efforts in the 1990s further transformed the solenoid valve market. With unified design and performance criteria, manufacturers could facilitate international trade, streamline maintenance, and enable seamless collaboration across industries.

Most recently, sustainability has become a driving force in solenoid valve development. Regulatory standards, such as RoHS, have led to restrictions on hazardous materials, encouraging engineers to explore environmentally friendly alternatives. These advancements not only reduce ecological impact but also improve safety for human health.

Advantages of Solenoid Valves

Solenoid valves hold a distinct edge over other valve types due to their efficient design and versatile functionality. Because they rely on natural pressure and electromagnetic force, they contain fewer moving parts than traditional mechanical valves, minimizing wear and reducing maintenance requirements.

Their ability to be operated remotely through solenoid coil activation makes them particularly valuable in hazardous environments where manual operation is impractical or unsafe. Additionally, solenoid valves seamlessly integrate with both hydraulic and pneumatic systems. However, pneumatic power is often preferred for its cleanliness and lower maintenance demands, as it eliminates the need for fluid management and disposal.

With rapid and precise switching, a compact yet robust design, and long-lasting performance, solenoid valves continue to be a cornerstone of fluid control technology, offering efficiency and reliability across countless industrial applications.

Design of Solenoid Valves

Manufacturing Process

Solenoid valve production involves precise fabrication methods, including coil winding, CNC machining, injection molding, and laser welding. Once individual components are crafted, manufacturers meticulously assemble them to ensure seamless functionality.

At the core of every solenoid valve are two primary components: the solenoid coil and the valve itself. Additional elements, such as a spring, inlet and outlet ports, an orifice that connects them, and an actuator (often a plunger or ferromagnetic core), complete the assembly.

To meet varying environmental demands, solenoid valves come with different coil housing types. Standards set by the American National Standards Institute (ANSI) and the National Electrical Manufacturers Association (NEMA) determine a valve’s suitability for specific conditions. In general, the higher the ANSI/NEMA rating, the greater the valve’s resistance to external elements. For instance, NEMA Type 1 is ideal for indoor use, while NEMA Type 4 is designed for outdoor applications. In more hazardous environments, such as areas with explosive vapors or dust, valves must meet the stringent requirements of NEMA Type 7 or Type 9.

Material Selection

The choice of materials for solenoid valves varies based on their intended use and the substances they will handle. Manufacturers work with a range of plastics and metals to ensure durability and compatibility.

Plastic solenoid valves may be constructed from PTFE, PVC, CPVC, natural polypropylene, or PVD, offering excellent chemical resistance. Metal solenoid valves, on the other hand, are commonly made from stainless steel, bronze, aluminum, or brass. To enhance performance, some valves incorporate rubber seals, with viton seals being the most prevalent due to their resilience against chemicals and extreme temperatures.

Design Considerations

Each solenoid valve is designed with specific applications in mind, influencing factors such as material, size, configuration, and port count.

- Brass solenoid valves are well-suited for handling water, light oil, and inert gases but are not recommended for highly corrosive substances.

- PTFE solenoid valves offer superior chemical resistance, making them ideal for aggressive fluids and harsh gases.

- Stainless steel solenoid valves excel in chemical processing due to their exceptional corrosion and abrasion resistance, ensuring precise control over acids, gases, and analytical reagents.

- Miniature solenoid valves are perfect for medical applications, including gas analyzers, biotechnology instruments, and portable medical devices.

- High-pressure solenoid valves enable precise fluid and gas flow control in demanding environments, such as heavy machinery or inaccessible lines where other valves may fail.

Customization Options

Manufacturers offer a range of customization options to tailor solenoid valves to specific needs. While the standard 2-way solenoid valve features two connection points and a single orifice, 3-way configurations are also available for more complex flow requirements.

Additionally, power source adaptability allows solenoid valves to operate beyond the standard 12-volt DC, with options for 3V, 6V, or 24V power sources. Other customizable features include size, spring return mechanisms, pressure tolerances, and material variations, such as specialized brass alloys or different stainless-steel grades.

For specialized applications, manufacturers can modify solenoid valves to optimize performance. If you have unique requirements, don’t hesitate to explore customization options to ensure the perfect fit for your system.

Solenoid Valve Images, Diagrams and Visual Concepts

Solenoid valve used to regulate flow of liquid or gas.

The parts of a solenoid valve are separated into two major components the solenoid and the valve body.

A special type of solenoid valve that provides a continuous variation in flow or pressure in response to electrical input.

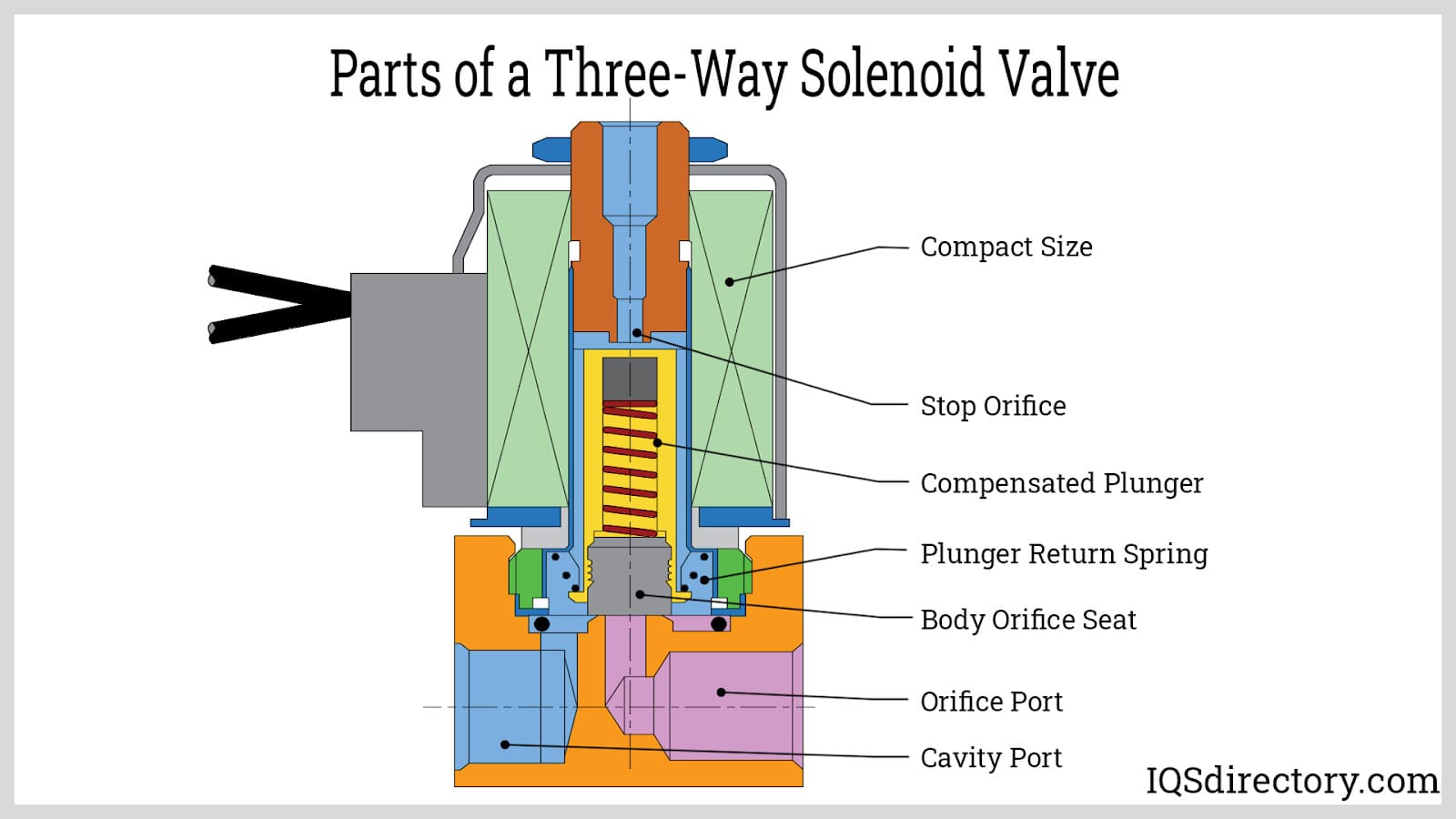

A three-way solenoid valve which allows for three connections the body orifice, a cavity, and a stop port.

FM Approvals are an international leader in third-party testing and certified to test property loss prevention products and services for quality, technical integrity and performance.

Solenoid Valve Types

3-Way Solenoid Valves

Designed for hydraulic and pneumatic applications, 3-way solenoid valves feature three ports: one for pressure, one for the tank, and one for service.

12 Volt Solenoid Valves

Standard in direct current (DC) systems, these valves operate efficiently within typical voltage ranges.

Air Valves

Regulate the controlled release of air in various applications.

Gas Solenoid Valves

Commonly used for flow control, these valves precisely manage the movement of gaseous media.

Hydraulic Solenoid Valves

Utilize fluid pressure and route excess flow through the return line to a reservoir.

Miniature Solenoid Valves

Compact and precise, these valves fit into small spaces and accurately measure or dispense fluids, making them essential in medical applications.

Direct Operated

Featuring a plunger-sealed orifice, these valves manage small flow rates and function from 0 bar pressure up to maximum permissible levels. Available in 2-way or 4-way configurations, they can be Normally Closed or Normally Open.

Indirect Operated

These normally closed valves rely on differential pressure for operation, requiring at least 0.5 bar (7.25 psi). Ideal for one-way flow applications such as showers, irrigation systems, and car washes.

Semi-Direct Operated Solenoid Valve

Combining direct and indirect actuation, these valves operate from 0 bar and support high-flow applications, making them ideal for high-pressure systems.

Purge Valve

Integral to vehicle EVAP systems, purge valves prevent fuel vapors from escaping into the atmosphere. Made from durable materials like stainless steel, they ensure controlled vapor flow for optimal engine performance.

Actuated Ball Valve

Primarily used to start or stop flow rather than regulate it, these Normally Closed valves employ a rotating ball mechanism. They are ideal for high-flow applications requiring manual override capabilities.

Poppet Valve

Also known as mushroom valves, these precision-engineered components control the timing and quantity of air and gas flow in engines. Their disk-shaped plug seals an opening to regulate fluid movement effectively.

Plastic Solenoid Valves

Resistant to corrosion and chemicals, these valves are ideal for handling aggressive substances in demanding environments.

Pneumatic Solenoid Valves

Similar to hydraulic valves, but with an exhaust port venting to the atmosphere. Used in HVAC systems, industrial automation, and power tools, they regulate air and gas flow efficiently.

High Pressure Solenoid Valves

Engineered for demanding environments, these valves control the flow of fluids or gases in high-pressure applications.

Proportional Solenoid Valves

Deliver precise flow control with linear response to electrical signals. Designed for applications requiring accuracy, repeatability, and minimal hysteresis.

Rotary Solenoids Valves

Convert linear motion into rotary motion using three bearing balls on an inclined plane. Their magnetic design allows direct rotational movement.

Solenoid Air Valve Controls

Electrically actuated valves that regulate airflow with precision.

Solenoid Water Valves

Typically pilot-operated and Normally Closed, these valves control water flow in various applications. Constructed from materials like brass, carbon steel, or stainless steel, they ensure durability and reliability.

Stainless Steel Solenoid Valves

Resistant to corrosion and abrasion, these electromechanical valves excel in chemical processing applications, effectively handling acids, analytical reagents, and bases.

Solenoid Valve Applications

Solenoid valves play a crucial role in controlling the flow of fluids and gases across a diverse range of industries. They perform essential functions such as shutting off, dosing, releasing, mixing, and distributing liquids or gases with precision and reliability.

Widely utilized in HVAC systems, refrigeration, automotive engineering, hydraulics, pneumatics, and household appliances, solenoid valves enhance efficiency and ensure smooth operation. Here’s how they contribute to various applications:

Refrigeration

In air conditioning and refrigeration systems, solenoid valves regulate the flow of refrigerant to heat exchangers. A properly functioning valve ensures energy efficiency, while a faulty one can significantly impact system performance.

Pneumatic and Hydraulic Systems

Pneumatic conveyor systems rely on air-operated solenoid valves to manage airflow, while hydraulic systems use specialized valves to regulate fluid movement in motors, buffers, and cylinders. These valves ensure precise control and optimize system functionality.

Car Wash

In automated car washes, solenoid valves control detergent flow and high-pressure water release. Typically made from stainless steel, these Normally Closed (NC) valves handle high-pressure applications, while Normally Open (NO) valves are used for lower-pressure systems like foam brushes.

Compressed Air Systems

Solenoid valves in compressed air systems manage air supply and actuators, often serving as unloader valves. Designed to minimize pressure drop, these valves maintain efficiency by accommodating pressure differentials, with direct, semi-direct, or indirect configurations depending on the system’s requirements.

Central Heating

In residential heating systems, solenoid valves work in tandem with thermostats and pressure switches to regulate the flow of hot water to radiators, ensuring consistent and efficient heating.

Clothes and Dish Washing

Modern washing machines and dishwashers depend on solenoid valves to control water intake, ensuring the correct volume and timing for optimal cleaning performance.

Agricultural Irrigation

For large-scale irrigation, solenoid valves enable efficient water distribution, managing high flow rates to ensure crops receive the necessary hydration while conserving resources.

Across all these industries, solenoid valves provide precise, automated flow control, improving performance, energy efficiency, and operational reliability.

Features of Solenoid Valves

Solenoid valves operate through the interaction of electricity and magnetism. When an electric current flows through the coil, it generates a magnetic field that pulls the plunger toward the center of the coil. This movement opens the orifice, allowing fluid or gas to pass through. Once the current stops, a spring pushes the plunger back into place, closing the valve and halting the flow.

The way a solenoid valve functions depends on whether it is normally closed (NC) or normally open (NO).

Normally Closed (NC)

In a normally closed solenoid valve, the plunger remains in a closed position, blocking the flow of gas or fluid. When the coil is energized, it creates a magnetic field strong enough to lift the plunger, opening the passage and allowing flow.

Normally Open (NO)

A normally open solenoid valve works in reverse. The valve stays open by default, permitting flow. When the solenoid is activated, the plunger moves down to seal the orifice, stopping the flow and maintaining pressure.

Another key distinction in solenoid valve operation comes down to whether they are direct-acting or pilot-operated.

Direct-Acting Solenoid Valves

Direct-acting solenoid valves rely on a plunger that directly opens and closes the orifice within the valve body. When the solenoid is energized, the plunger moves to allow fluid or gas to pass through. When de-energized, the plunger returns to its original position, sealing the orifice.

Pilot-Operated Solenoid Valves

Pilot-operated solenoid valves combine a smaller solenoid valve with a pneumatic or hydraulic valve. Instead of using a plunger, they operate with a diaphragm, utilizing differential pressure to regulate the flow of gas or fluid. Regardless of type, solenoid valves stand out for their precise control over fluid and gas movement.

Installing Solenoid Valves

Proper installation ensures optimal performance and longevity. Solenoid valves should be placed in a dry, well-ventilated environment since they can heat up during operation. Pay close attention to the flow direction, which is usually indicated by an arrow on the valve body. Aligning the valve correctly prevents operational issues. If you’re unsure about the installation process, it’s always best to seek professional assistance—whether from the supplier or an experienced technician—to ensure everything is set up correctly.

Standards and Specifications for Solenoid Valves

Selecting the right solenoid valve requires compliance with various industry standards, ensuring both operational safety and regulatory approval. Manufacturers and buyers alike must adhere to these standards to guarantee performance and legal compliance.

For instance, U.S. state plumbing and drinking water codes mandate that reverse osmosis (RO) equipment meets NSF 61-G requirements, a regulation ensuring leachate- and lead-free materials. Buyers and manufacturers should verify that Original Equipment Manufacturers (OEMs) comply with these regulations, especially when specifying composite valves for RO systems. In states such as Vermont and California, NSF certification is required for all RO systems.

To further minimize lead in drinking water, all pipes, plumbing fittings, fixtures, and flow control components—including electric solenoid valves—must be lead-free. Certified valves should meet NSF International, ANSI, and Standards Council of Canada accreditation for international use.

Things to Consider When Purchasing Solenoid Valves

Beyond selecting the right size, pressure level, and wattage, several critical factors influence solenoid valve quality and suitability:

Availability

Timely access to components is essential, especially in lean manufacturing environments. Delays in valve supply can disrupt production schedules, leading to extended lead times and assembly slowdowns. When assessing suppliers, verify their inventory levels, standard lead times, and quick-shipment programs.

Certification

Ensure the manufacturer meets required industry standards and can provide certification upon request. A reputable supplier will readily comply, confirming their commitment to quality and regulatory adherence.

Installation

Integrating solenoid valves into a system can be complex, particularly when pressure switches come in closed versions that may necessitate additional diverter valves. Opt for a vendor that offers both open and normally closed versions to streamline installation and prevent compatibility issues.

Support System

Beyond hardware, strong technical support is crucial. Reliable suppliers offer expert guidance, troubleshooting assistance, and even on-site training. Vendors with local service capabilities are preferable, as geographic constraints can hinder response times. North American customers often find Asian and European products less suitable due to logistical and support challenges.

Look for a supplier who can address your needs regarding 2-way, 4-way, or 12-volt solenoid valves, pressure specifications, and other technical concerns while respecting your timeline and budget. Start by exploring top-rated companies listed at the top of this page.

Proper Maintenance for Solenoid Valves

Routine maintenance extends the lifespan of solenoid valves and prevents performance issues. If you notice excessive noise, sluggish operation, or leakage, a thorough cleaning may be necessary. Fortunately, with the right tools—such as those found in a maintenance kit—you can often clean your valve without fully dismantling the assembly.

For optimal performance:

Avoid using incompatible fluids that could accelerate wear.

Prevent internal freezing to maintain proper functionality.

Keep valves operating within recommended pressure and temperature ranges.

Solenoid Valve Accessories

Enhancing solenoid valve performance often requires additional components. Connectors facilitate more advanced system configurations, while other accessories—such as lights, gaskets, screws, and manifolds—improve functionality and integration. Consult with your manufacturer to determine which accessories best suit your application.

Solenoid Valve Terms

Analog Position Sensor

A position sensor that produces varying voltage outputs depending on its state.

Bubble-Tight Sealing

A condition where no air leaks between a valve’s internal sealed ports, whether the valve is energized or not, within a five-second test period. Leakage is typically detected using soap bubbles.

Closed State

Occurs when the valve pinches the tubing, stopping flow.

Coil Voltage

The maximum voltage required to fully energize the coil and enable the valve to operate at peak capacity.

Continuous Duty

The ability of a solenoid valve to remain energized at a steady power level for its entire operational duration.

Current Drain

The amount of current, measured in amperes, that flows through a solenoid valve coil when it is energized.

Cycle

A complete sequence of a valve opening and closing.

Cycle Rate

The number of times a valve can open and close within a given time frame.

Duty Cycle

The proportion of time a solenoid valve remains powered relative to its total operating time.

Flow Control

A feature that enables manual regulation or restriction of flow through the valve.

Flux Plate

A magnetic steel plate that transmits magnetic flux from the solenoid’s enclosure to its sleeve. Essential for valves with non-metallic bodies.

Frequency Response

The change in output under steady-state conditions due to a sinusoidal input.

Gain

The relationship between input and output, reflecting the device’s sensitivity.

Hysteresis

The difference in response when a system approaches the same input value from opposite directions.

Normally Closed

A valve configuration where the valve remains closed when not energized.

Normally Open

A valve configuration where the valve remains open when not energized.

Open Loop

A system that operates without direct feedback to adjust or measure response.

Position Sensing

The use of electronic sensors to monitor valve position and provide feedback.

Pulse and Hold

A method to improve solenoid valve efficiency by reducing power consumption and heat generation. The valve is initially pulsed open and then maintained at a lower power level.

Pulse Width Modulation (PWM)

A control technique that uses a modulated wave signal to regulate analog devices.

Repeatability

The capability of a device to consistently reproduce the same results across multiple operations.

Stroke

The total distance the plunger moves during a state change.

More Solenoid Valves