Stainless Steel Butterfly Valve

A stainless steel butterfly valve is simply one constructed of stainless steel. Although this valve's interior parts, such as the seats, seals, O-rings, and gaskets, may be made of stainless steel, they can also be made of plastic, rubber, or other materials. Both the substance being transferred and the temperature of this medium influence the material which may be utilized for its internal components. Because metallic materials can endure significant thermal heat, for instance, stainless steel butterfly valves composed entirely of metallic materials are appropriate for use in both low and high temperatures. Makers of stainless steel butterfly valves make different varieties (sizes, internal materials, etc.) to better serve across various demanding and challenging environments. As a result, stainless steel butterfly valves are exceptionally well adapted for withstanding different pressure tolerances and various liquids or slurries. Stainless steel butterfly valves can be automatically or manually operated.

Stainless Steel Butterfly Valve Varieties

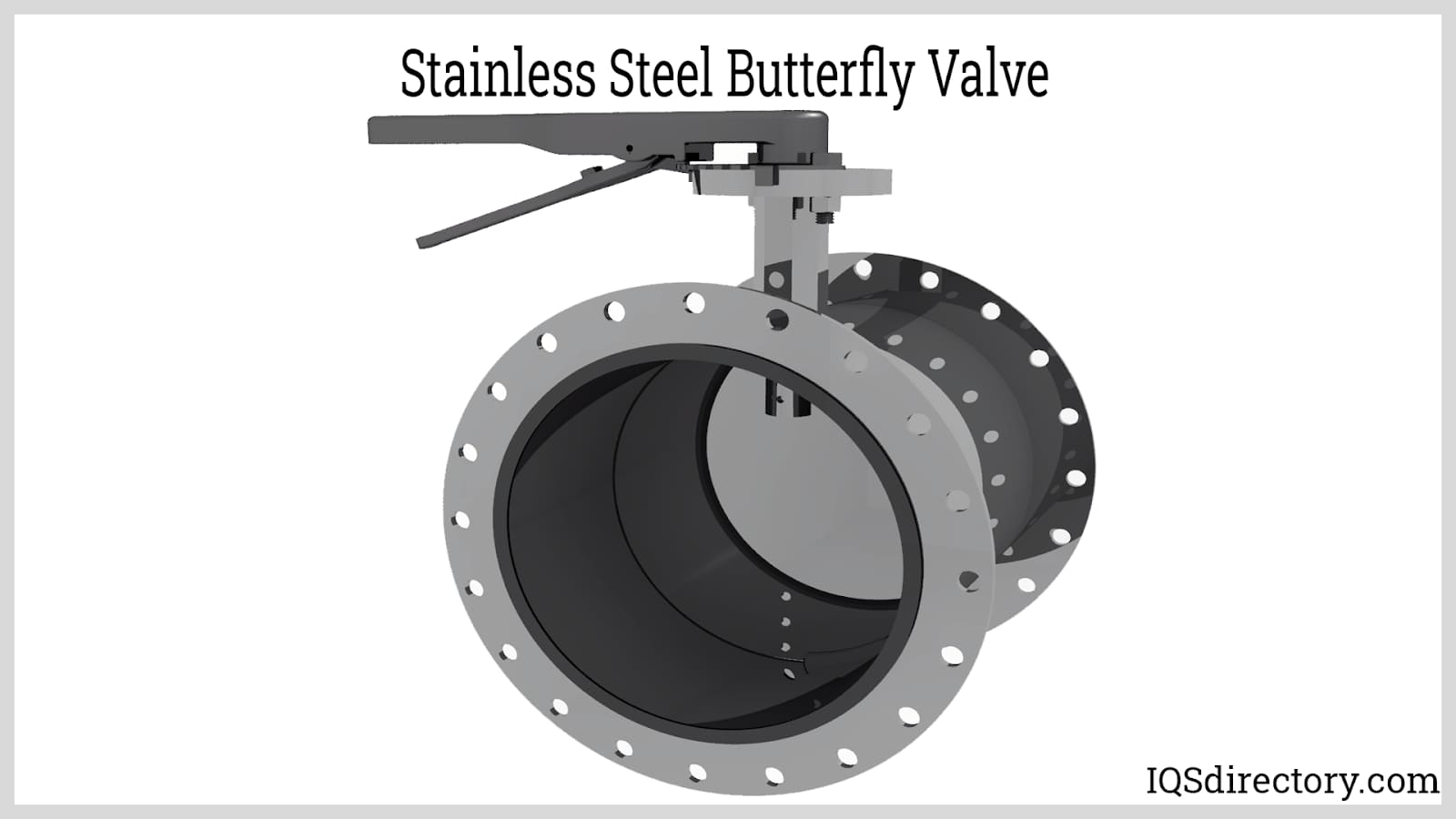

Stainless Steel Wafer Butterfly Valves

A stainless steel wafer butterfly valve attaches to a piping system in between two pipe ends that are joined by protruding long bolts. The flange holes on the valve body are optional when producing stainless steel butterfly valves. To provide a bubble-tight seal, gaskets and O-rings are installed on the flat intake and outlet sides of the valve and the pipe flanges. Compared to other connections utilized with other butterfly valves, this design is the most cost-effective. Stainless steel wafer butterfly valves, however, cannot be utilized as isolation valves or for end-of-line service due to their design to connect pipe ends. Another limitation to their use occurs when there is a need to shut down a pipe system on either side in order to repair a damaged valve.

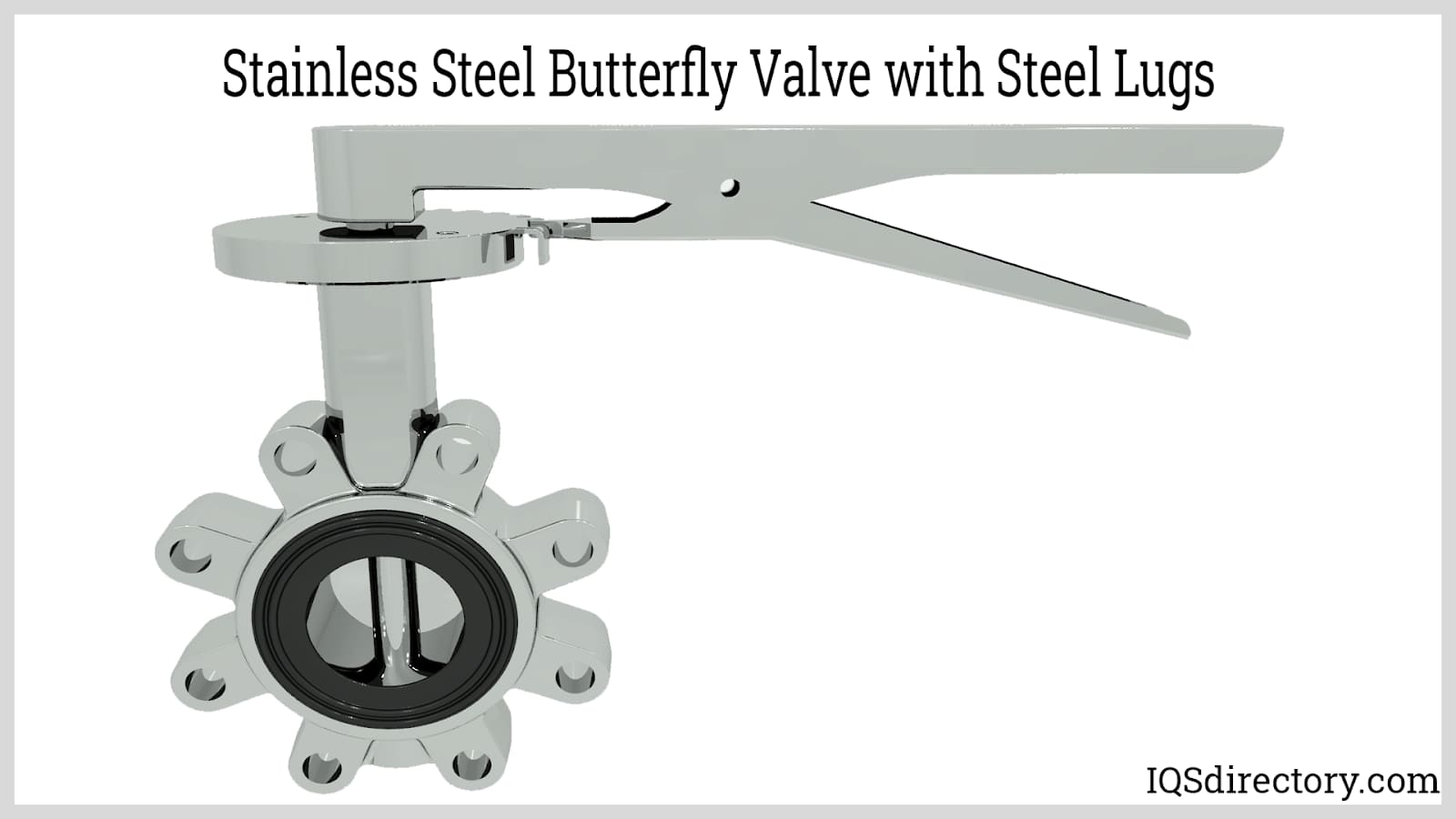

Stainless Steel Butterfly Valves with Steel Lugs

This is a stainless steel butterfly valve with threaded lugs on the valve body's outside. With this design, the valve is placed into the piping system by placing it between two pipe flanges. The connection between the valve and the pipes is tightened using bolts, without using nuts. The valve is supported on each side by two different sets of bolts and, as a result, this valve can be utilized as an isolation valve or in end-of-line service.

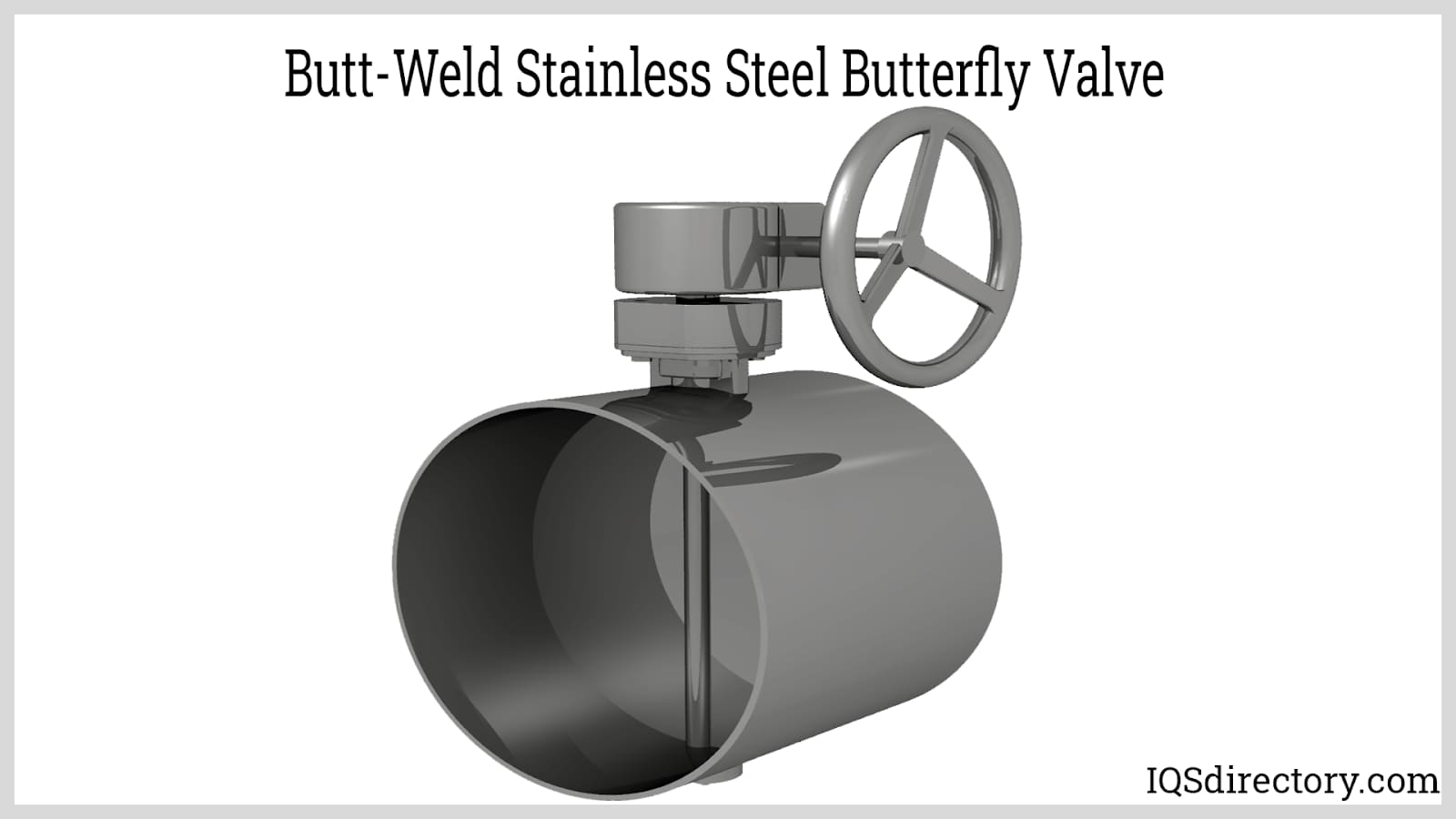

Butt-Weld Stainless Steel Butterfly Valves

A butt-weld stainless steel butterfly valve is one which gets welded to the pipe. In order to save their customers from wasting money, manufacturers of butt-weld stainless steel butterfly valves advise against using these devices in applications where they may require frequent maintenance. This is due to the fact that these valves cannot be opened while they are in the field for maintenance or cleaning. Their weld must also be taken out prior to repairs.

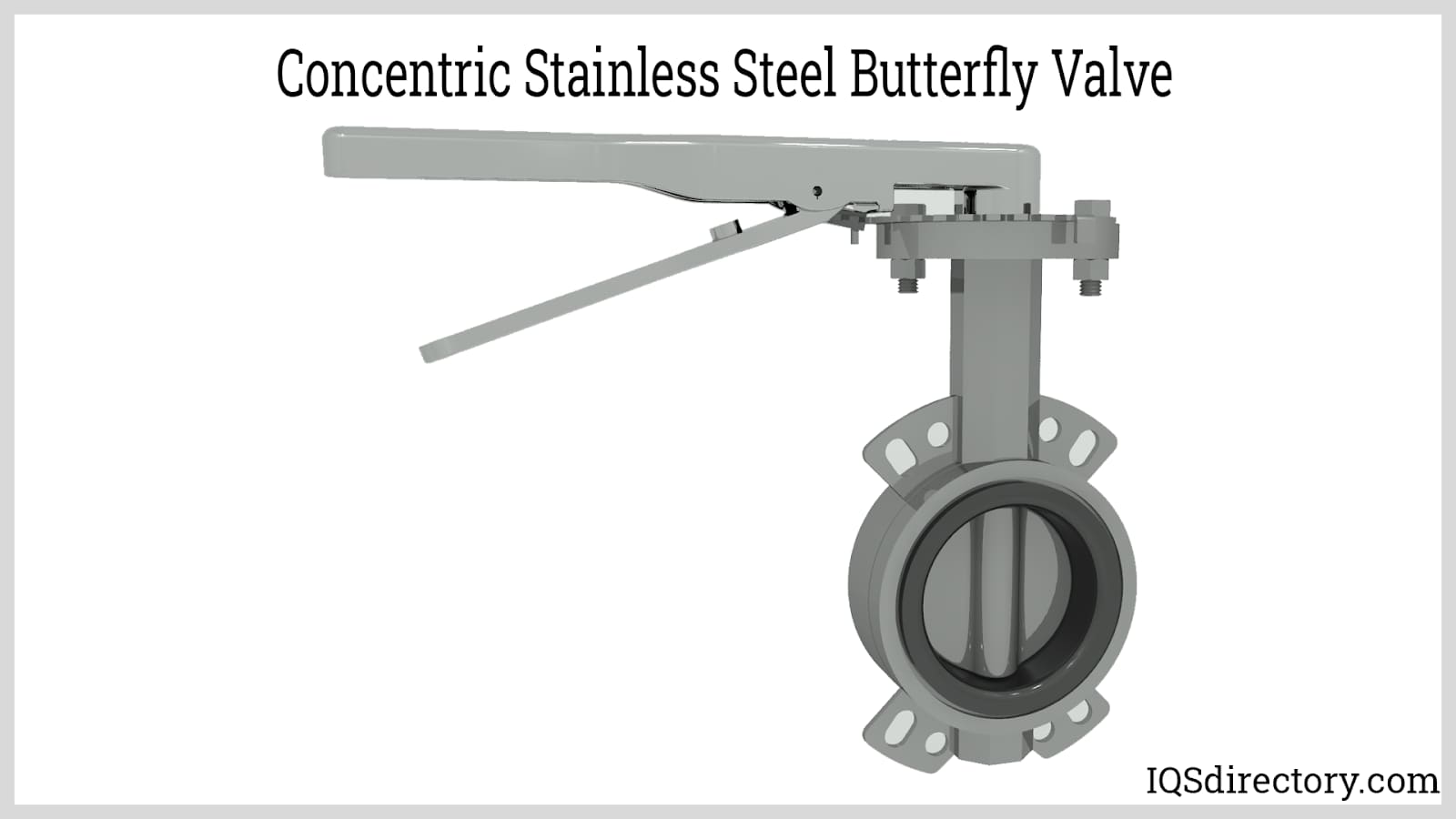

Concentric Butterfly Valves Made of Stainless Steel

Another name for this type of valve is the stainless steel zero offset butterfly valve. As the name implies, the stem crosses the disc's centerline. As a result, the pipe bore and the stem centerline are parallel. The seat is positioned on the outer edge of the diameter of the valve body. These stainless steel butterfly valves often feature rubber seats (the surface the valve rests against when the valve is closed). The concentric stainless steel butterfly valve's most fundamental design is shown below.

Applications for Stainless Steel Butterfly Valves

- Stainless steel butterfly valves are used across heating, ventilation, and air conditioning (HVAC) systems.

- These valves are in wastewater treatment applications.

- They are employed in the mining sector.

- Stainless steel butterfly valves are used to regulate the flow of water and steam in steam power plants.

- They are employed in the production of several compounds.

- Butterfly valves made of stainless steel are employed during food and beverage processing.

- They are employed in the production of sugar and the processing of petroleum products.

- Stainless steel butterfly valves are employed in the transmission of oil and gas.

- These valves are sturdy and long-lasting.

- Comparatively speaking to other valves, they operate quickly.

- Stainless steel butterfly valves enable fluid flow in both directions.

Drawbacks of Stainless Steel Butterfly Valves

- They can be more expensive than similar valves made from other materials (like plastic).

- These valves open while the disc is in the middle of the fluid flow, which lowers efficiency and lowers pressure.

- It is advised to use stainless steel butterfly valves for throttling flow only in situations where any pressure drop will be minimal.

Summary

Although manufacturers of stainless steel butterfly valves sometimes blend stainless steel with other materials in order to construct these valves, stainless steel butterfly valves have stainless steel as their main component. This material ensures the valve is sturdy and able to function flawlessly while carrying contents under high pressure and at high temperatures. Their interior parts (like seats, O-rings, gaskets, and packing) may also be made of stainless steel, but often feature other materials depending on their intended application.

Choosing the Proper Stainless Steel Butterfly Valve Supplier

To make sure you have the most positive outcome when purchasing Stainless Steel Butterfly Valve from a Stainless Steel Butterfly Valve Supplier, it is important to compare at least 4 Companies using our list of Stainless Steel Butterfly Valve manufacturers. Each Stainless Steel Butterfly Valve Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Stainless Steel Butterfly Valve company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Stainless Steel Butterfly Valve companies with the same quote.