Stainless Steel Tanks

Tanks serve as essential containers designed to store and transport liquids, compressed gases, and certain solids. While they are occasionally referred to as drums, the most widely recognized terms for these containers are tanks and vessels. At their core, tanks feature a sturdy outer shell paired with a secure lid. Stainless steel tanks, as their name suggests, are constructed from stainless steel, a robust steel alloy that contains 10% to 12% chromium. This composition grants stainless steel exceptional strength and remarkable resistance to corrosion, making it an ideal material for tanks exposed to demanding environments.

The History of Stainless Steel Tanks

Stainless steel tanks have become an essential part of modern industry, but just over a century ago, they did not exist. This is because stainless steel itself was only discovered in the early 20th century. Before its invention, carbon steel was the only available option for tank fabrication. In 1913, Harry Brearley of Sheffield, England, created what he initially called "rustless steel." While others had experimented with similar alloys before him, Brearley was the first to produce true stainless steel by incorporating 12.8% chromium, the key element that gives the material its exceptional resistance to corrosion.

The first stainless steel tank was fabricated in 1925 using stainless steel plate. Designed to hold nitric acid, it was labeled as a chemical tank and marked a significant breakthrough—it was the first metal tank capable of storing acid without corroding. This advancement represented a major improvement over early steel tanks, which relied on riveted seams that were highly susceptible to corrosion. In 1927, Heil Truck of Milwaukee, an American shipping truck company, introduced the first welded stainless steel tank for road transport, making it possible to safely ship dairy products. By the following year, brewers had adopted stainless steel tanks as fermenting vessels, a transition that led to the widespread use of these tanks throughout the food and beverage industry.

Today, stainless steel tanks are more prevalent and versatile than ever before, with manufacturing spanning the globe. In 2010 alone, China produced over 11 million washing machines featuring stainless steel drums. Modern stainless steel tanks are no longer limited to simple single-shell designs but have evolved into highly sophisticated systems. For instance, LNG ships such as the Methane Shirley Elisabeth now utilize advanced stainless steel gas tanks known as membranes. These membranes consist of alternating layers of stainless steel and thick foam insulation, combined with other specialized materials. Inside, they are lined with stainless steel corrugated in two dimensions to prevent frozen gas from shifting during transport. As technology continues to advance, the stainless steel tank industry is poised for even greater innovation and complexity in the years to come.

Advantages of Stainless Steel Tanks

Stainless steel tanks offer a multitude of advantages, making them a superior choice for various applications. One of their most significant benefits is their exceptional resistance to corrosion. This quality allows them to safely contain corrosive chemicals and acids that would quickly degrade other tank materials. In addition to their durability, stainless steel tanks are easy to clean and sterilize, ensuring high levels of hygiene and making them ideal for industries requiring sanitary conditions, such as food processing and pharmaceuticals.

Another major advantage of stainless steel tanks is their suitability as pressure vessels. Stainless steel’s excellent thermal conductivity and controlled thermal expansion rate are crucial for maintaining the structural integrity of tanks, particularly those designed to withstand high pressure. Additionally, stainless steel has a natural resistance to heat transfer, which helps regulate internal temperatures and enhances overall efficiency. These properties combine to make stainless steel tanks a reliable and long-lasting solution for demanding environments.

Stainless Steel Tank Design

-

Production Process

Stainless steel tanks are thin-walled structures manufactured using either a hot or cold-rolling process or through welding. Rolling is the preferred method because it produces seamless tanks, eliminating weak points where leaks or bursts could occur under excessive pressure. In contrast, welded tanks have seams that can become vulnerable over time.

Operating a stainless steel tank is straightforward. Materials are added through the manway, which is then securely sealed. When access is needed, the manway is reopened, and various accessories, such as pumps, facilitate material extraction. Pressure levels can be monitored using gauges and digital readouts, ensuring safety and efficiency in operation.

Material Process

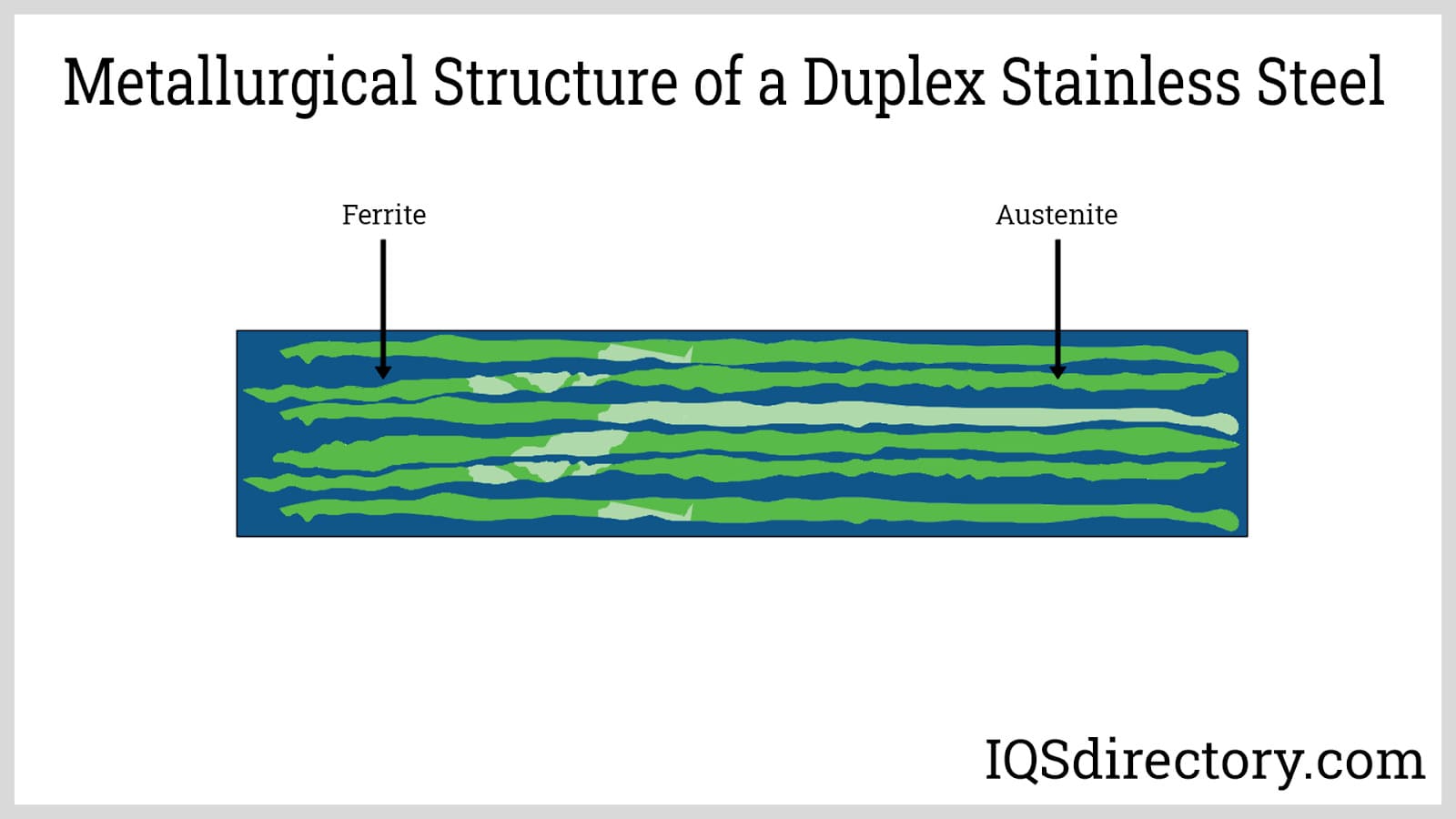

Stainless steel tanks are exclusively constructed from stainless steel, but manufacturers choose from different grades depending on the application. The most commonly used type is duplex steel, a combination of austenitic and ferritic stainless steels. This blend offers superior strength, exceptional crack resistance, and outstanding corrosion protection. Unlike mild steel or carbon steel, which lack the necessary strength and resistance, duplex steel ensures durability and safety. Failure in a tank made from weaker materials could lead to catastrophic consequences, including serious injury or loss of life.

Design Considerations and Customization

Stainless steel tanks are available in a range of shapes and configurations, including vertical and horizontal cylindrical designs, as well as open-top and closed-top variations. Bottom profiles vary as well, with options such as flat, cone, sloped, or dish bottoms, each designed to accommodate different storage and drainage needs. Covers can be rectangular, circular, or oval, featuring opening mechanisms such as levers, bolts, clamps, or swivel arms for secure sealing and easy access.

When designing both standard and custom tanks, manufacturers consider critical factors such as pressure levels, required capacity—ranging from a single gallon to millions of gallons—and the frequency of transportation. Large liquid storage tanks, for example, are often designed with vertical cylindrical sides or cylindrical bodies with rounded corners to effectively manage hydrostatic pressure and maintain structural integrity.

The manway, which serves as the access point for filling and extracting contents, is another customizable feature. Factors such as tank pressure, temperature requirements, and inspection frequency determine the ideal manway design, including its seal materials, thickness, diameter, and locking mechanisms. For example, neoprene gaskets are well-suited for tanks storing contents at temperatures of up to 200°F. To explore additional customization options and find the best tank configuration for specific needs, consulting a trusted supplier is essential.

Stainless Steel Tank Images, Diagrams and Visual Concepts

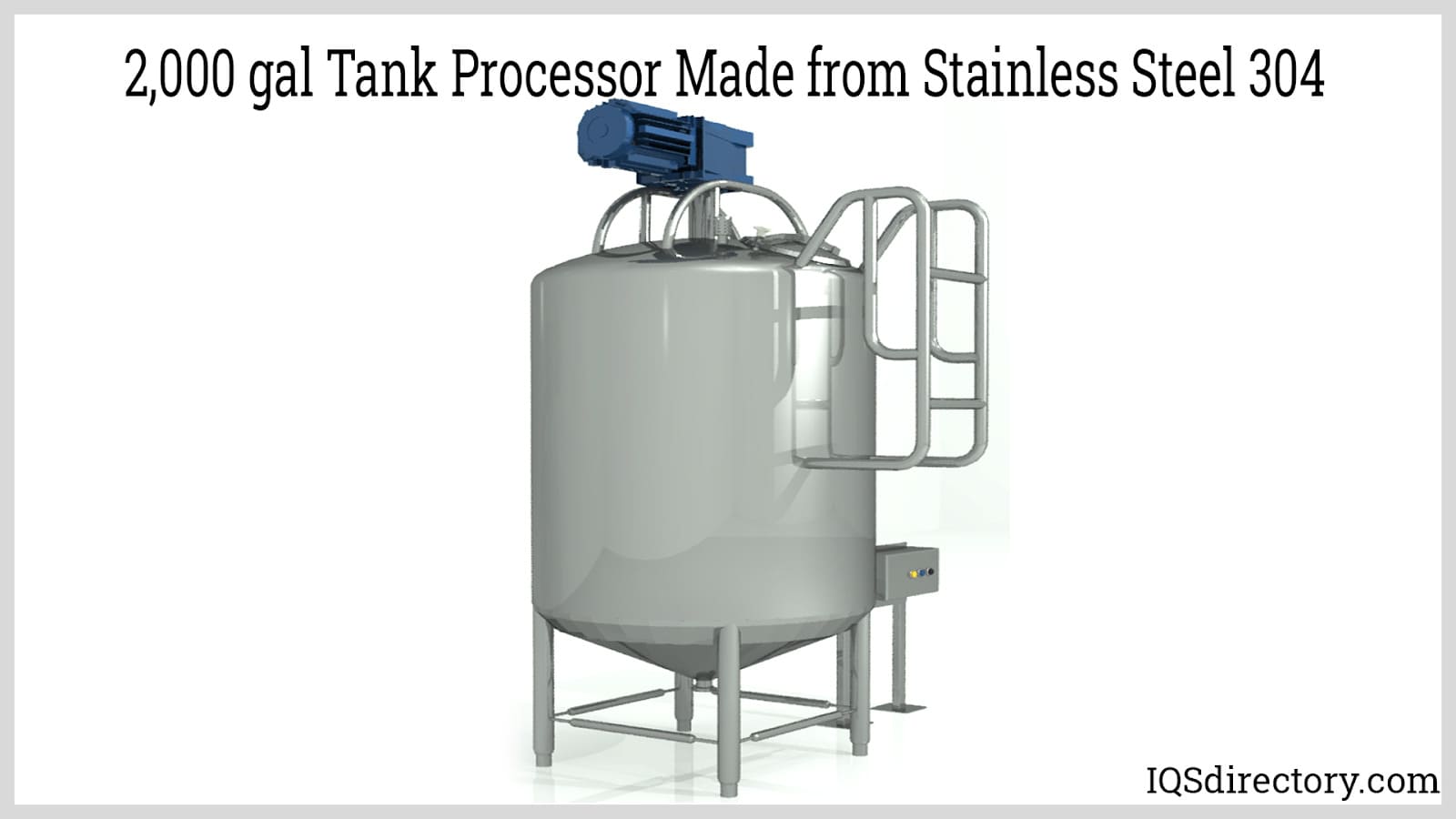

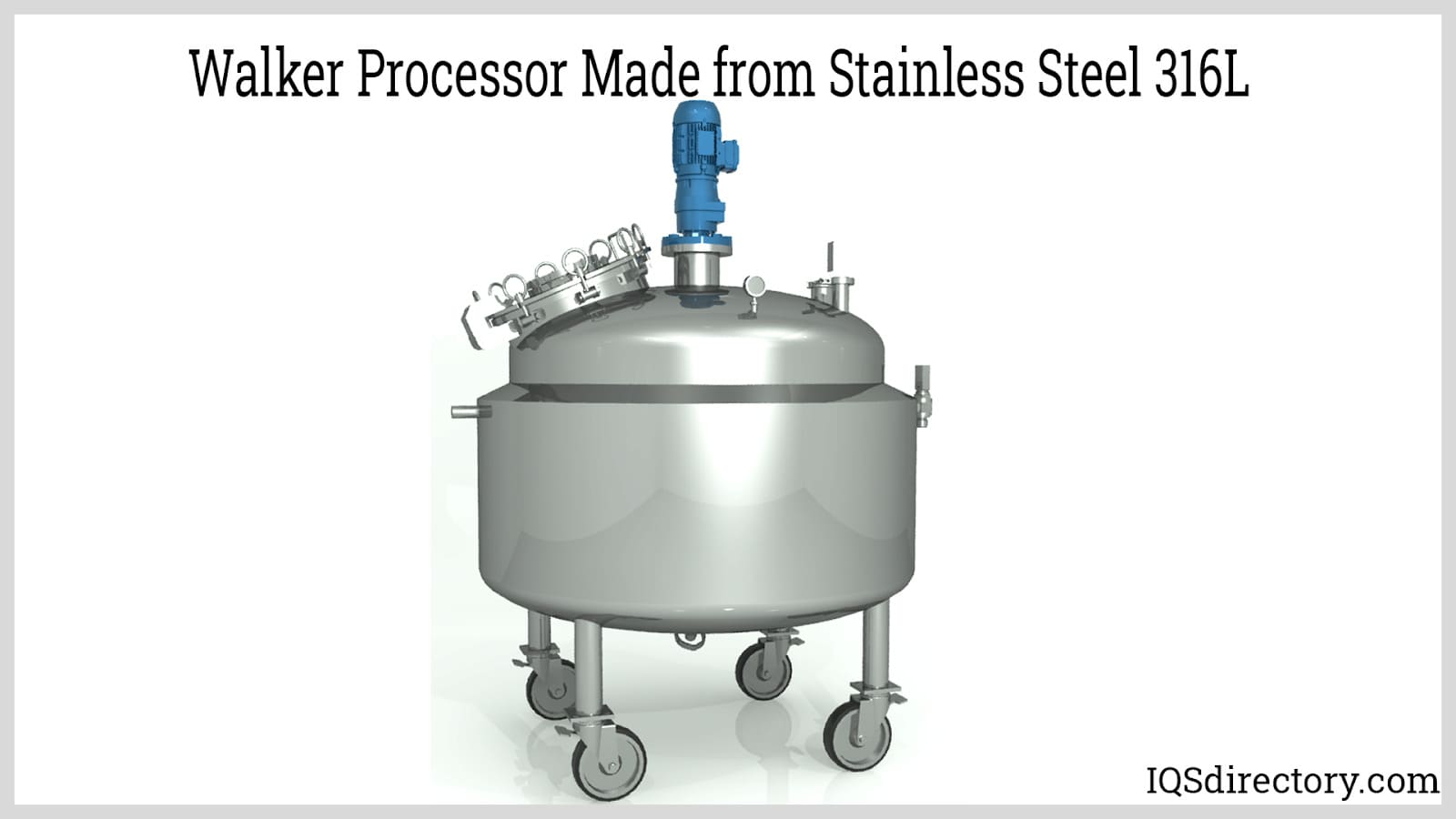

Stainless steel tanks are widely used in manufacturing processes where cleanliness and purity are important.

Stainless steel tanks are widely used in manufacturing processes where cleanliness and purity are important.

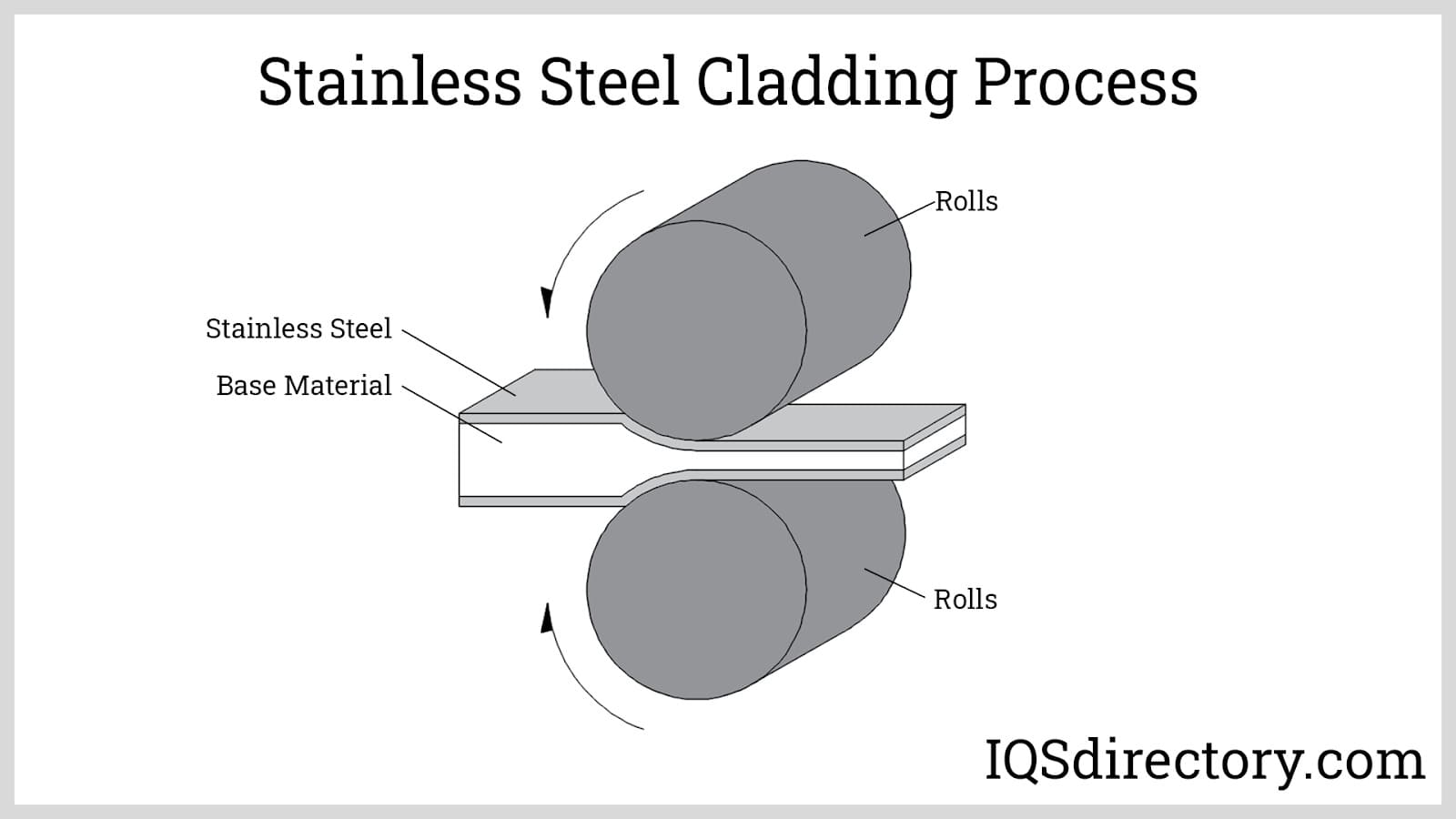

Stainless steel cladded carbon steel plates are formed by pressing and heating the two metals together.

Stainless steel cladded carbon steel plates are formed by pressing and heating the two metals together.

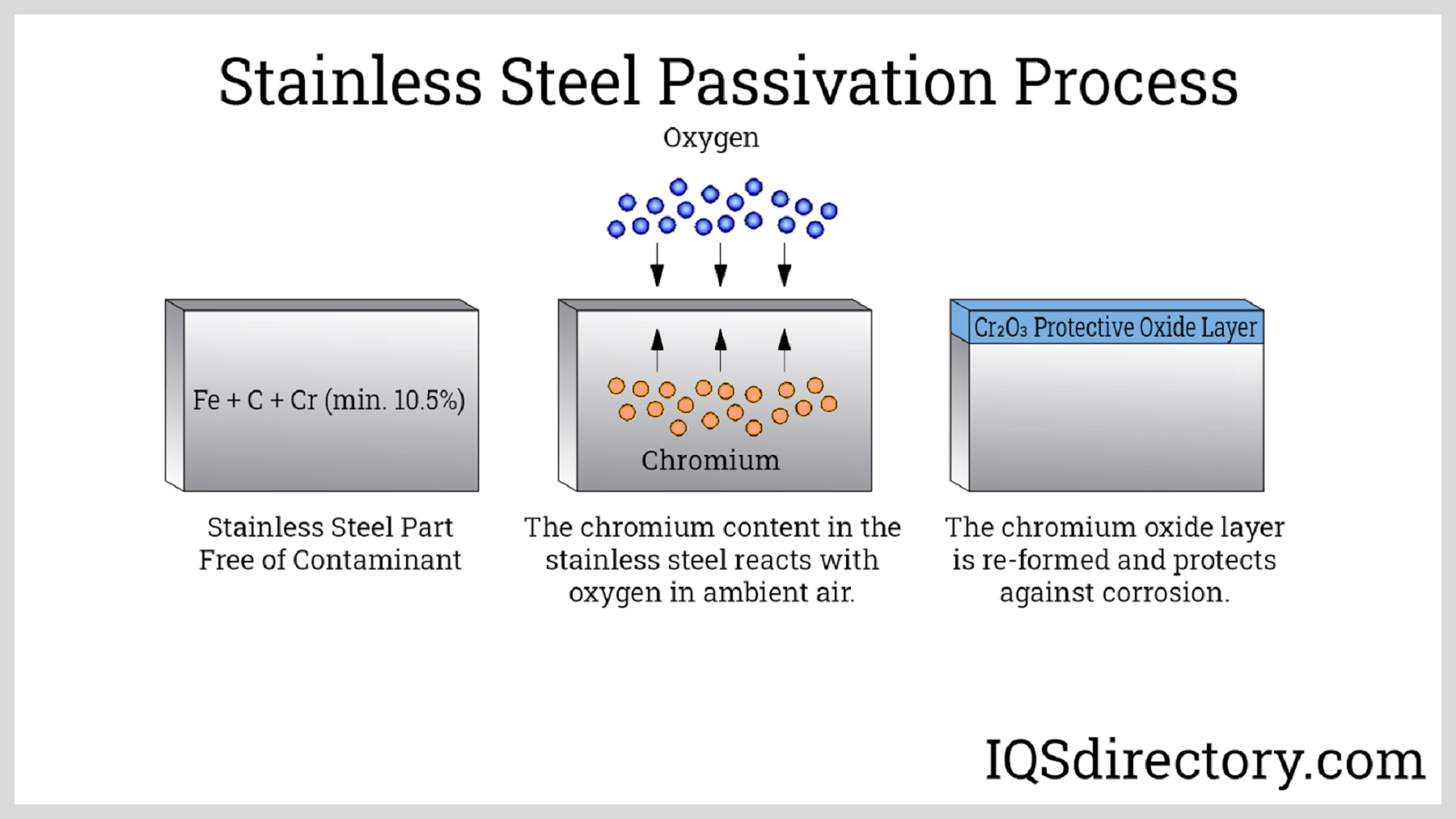

Stainless steel utilizes the principle of passivation wherein metals becomes unreactive to oxidation from corrosive compounds in the atmosphere and process fluids.

Stainless steel utilizes the principle of passivation wherein metals becomes unreactive to oxidation from corrosive compounds in the atmosphere and process fluids.

Stainless steel 304, is composed of 18-20% chromium, 8-11% nickel, and 2% manganese making it corrosion resistance and less expensive.

Stainless steel 304, is composed of 18-20% chromium, 8-11% nickel, and 2% manganese making it corrosion resistance and less expensive.

Stainless steel 316 contains 16-18% chromium, 10-14% nickel, 2-3% molybdenum, and 2% manganese making it more corrosion resistant.

Stainless steel 316 contains 16-18% chromium, 10-14% nickel, 2-3% molybdenum, and 2% manganese making it more corrosion resistant.

Duplex stainless steel contains 20-28% chromium, 2-5% molybdenum, and 5-8% nickel this makes have higher corrosion resistance and mechanical strength then either stainless steel 316 or 304.

Duplex stainless steel contains 20-28% chromium, 2-5% molybdenum, and 5-8% nickel this makes have higher corrosion resistance and mechanical strength then either stainless steel 316 or 304.

Types of Stainless Steel Tanks

Stainless steel tanks come in a wide variety of forms, each designed with unique properties to suit specific applications. Their construction and features vary depending on factors such as size, shape, material composition, and intended use.

Stainless Steel Storage Tank

Designed to hold large quantities of liquid or gas, storage tanks vary widely in shape, size, and application. Most are built in a cylindrical form to withstand hydraulic pressure and structural stress. Their capacities range from small waste bins to enormous stainless steel silos capable of storing millions of gallons.

Stainless Steel Mixer

Built for blending substances, stainless steel mixers play a crucial role in food processing, where they combine large volumes of ingredients. These tanks are equipped with motor-powered propellers that continuously stir the contents to ensure uniform consistency.

Food-Grade Tank

Specifically engineered for storing perishable goods, food-grade tanks provide a clean, sterile, and temperature-controlled environment. Dairy tanks are a prime example, ensuring the safe storage of milk and other sensitive food products.

Storage in Silos

Among the largest stainless steel storage vessels, silos are commonly used in the agricultural and food industries. These towering, vertically standing cylindrical tanks hold both solids and liquids, with frequent applications in storing animal feed, crops, and dairy products.

Stainless Steel Vat

A staple in the beverage industry, stainless steel vats are widely used in wineries, breweries, and distilleries. They accommodate alcohol during the refinement process, with variations in size and shape tailored to meet specific production needs.

Stainless Steel Bin

Versatile in function, stainless steel bins serve as waste receptacles, kitchen storage solutions, and general-purpose containers. Their durability and corrosion resistance make them ideal for high-use environments.

Stainless Steel Water Tank

Essential for water storage, these tanks supply potable water for drinking, irrigation, firefighting, and food preparation. Found both above and below ground, they require regular monitoring to ensure water quality remains safe for consumption.

Small Stainless Steel Tank

Constructed with thin walls in cylindrical or drum-like shapes, these tanks are made from various stainless steel alloys. Stainless steel is a broad category of chromium-based steel alloys, all containing at least 10.5% chromium. Depending on the grade, they may also include aluminum, carbon, nickel, molybdenum, or silicon to enhance specific properties such as strength, durability, and corrosion resistance.

Fuel Tank

Commonly found in automobiles, fuel tanks securely store gasoline while preventing diffusion into the air. Since fuel evaporation leads to environmental harm and wasted gas, these tanks are coated with aluminum or zinc to enhance protection. Designed for longevity, they resist corrosion, cracking, and flaking, ensuring reliable performance throughout their lifespan.

Stainless Steel Tank Applications

Stainless steel tanks are primarily designed for storage, providing a reliable solution for holding a wide range of substances, including food, beverages, chemicals, gases, and water. Their popularity stems from the durability and corrosion resistance of stainless steel, along with its ability to maintain precise temperature control. These tanks are also easy to clean and sterilize, making them an excellent choice for industries where hygiene is essential.

Manufacturers supply stainless steel tanks to a diverse range of industries, particularly those requiring sanitary and corrosion-resistant storage solutions. Agricultural sectors, including the dairy industry, rely on these tanks for milk storage and processing. The food and beverage industry depends on them for safe ingredient containment and fermentation processes. In the medical field, stainless steel tanks ensure the sterile storage of pharmaceuticals and other sensitive materials. The chemical industry benefits from their ability to safely house reactive substances, while wastewater and sewage management operations use them for efficient treatment and containment of liquid waste. Across all these sectors, stainless steel tanks provide long-term reliability, sanitary conditions, and resistance to environmental and chemical degradation.

Standards and Specifications for Stainless Steel Tanks

Stainless steel tanks designed to store food, beverages, or any other consumable products must meet stringent health and safety standards. To ensure public health protection, these tanks must comply with regulations set by the FDA (Food and Drug Administration), USDA (United States Department of Agriculture), and 3-A Sanitary Standards. These guidelines dictate material selection, surface finishes, and sanitation requirements to prevent contamination and maintain product integrity.

Beyond food and beverage applications, it is highly recommended to choose ASME-certified tanks for most industrial uses. The ASME Boiler & Pressure Vessel Code (BPVC), established by the American Society of Mechanical Engineers (ASME), governs the design, construction, and testing of pressure vessels, including stainless steel tanks. This code is backed by the U.S. government and ensures that tanks meet rigorous safety and performance criteria, making them suitable for high-pressure and demanding environments. Adhering to ASME standards guarantees structural integrity, reliability, and compliance with industry best practices.

Things to Consider When Purchasing Stainless Steel Tanks

IQS Directory offers a comprehensive resource for finding stainless steel tank manufacturers and suppliers capable of designing, engineering, and producing tanks tailored to your specifications. Our website allows you to explore top manufacturers with detailed product descriptions and interactive roll-over ads. You can easily connect with companies through our streamlined request-for-quote form, which provides access to company profiles, website links, locations, phone numbers, product videos, and detailed product information. Stay informed with customer reviews and industry news articles to make well-informed purchasing decisions.

To ensure you select the right manufacturer or supplier, consider reaching out to at least three or four companies from our listings. Discuss key specifications such as available space (measured in cubic feet), storage capacity, and material compatibility. Additionally, factor in budget constraints, lead times, required certifications, delivery options, and secondary services. Choosing a supplier goes beyond basic competence—you want a company that is genuinely committed to delivering high-quality products, regardless of your price range. Throughout the selection process, keep in mind that customer service is just as important as product quality, ensuring a smooth purchasing experience and long-term reliability.

Proper Care for Stainless Steel Tanks

While stainless steel is exceptionally strong, it can still be vulnerable to buckling when fabricated with thin material. Tanks are most susceptible to damage during fabrication, transportation, and installation, making careful handling essential. Interestingly, a fully loaded stainless steel tank benefits from added stability due to the weight of its contents. For this reason, the first key to proper care is treating tanks with caution, especially before they are filled. Regular inspections are also critical, whether through pressure testing, subsurface testing, or complete tank removal, to ensure ongoing integrity.

For tanks used in food storage or production, thorough cleaning is required after each emptying to maintain hygiene and prevent contamination. When storing perishable foods, temperature control is equally important to prevent spoilage and maintain product safety.

Leak detection is another essential aspect of stainless steel tank maintenance, particularly for pressure vessels and underground tanks. Underground tanks require specialized monitoring systems that allow for remote leak detection, ensuring any potential issue is identified before it leads to environmental contamination. A leaking tank can introduce toxins into surrounding vegetation and underground water supplies, posing significant health and safety risks. Regular maintenance and proactive monitoring are essential to preserving the longevity and performance of stainless steel tanks.

Stainless Steel Tank Accessories

Stainless steel tanks can be equipped with a variety of accessories to enhance functionality, safety, and efficiency. Among these are manway assemblies, which include a complete set of components such as a cover, O-ring, gasket, yokes, bolts, and nuts. These assemblies ensure a secure and reliable sealing mechanism for accessing the tank’s contents. Hinged closures provide convenient access while maintaining a tight seal, making them ideal for frequent use. Fittings allow for the secure connection of pipes, valves, and other equipment necessary for fluid transfer.

For leak management and fluid control, emergency bilge pumps play a critical role. These pumps are designed to quickly remove any remaining liquid from a leaking tank or extract contaminated soil content, minimizing environmental damage. Submersible pumps, on the other hand, are built to operate fully immersed within a tank. Their oil-filled motor cavities provide protection against contact with the transfer media, ensuring longevity and consistent performance. These pumps are highly effective for treating groundwater, extracting pollutants, and, when necessary, completely draining a tank’s contents. With the right accessories, stainless steel tanks can be optimized for a wide range of industrial, agricultural, and environmental applications.

Stainless Steel Tanks Terms

-

Atmospheric Pressure

The force exerted by the Earth's atmosphere, measured at 14.7 psi at sea level. Tanks that maintain internal pressures above this level are classified as pressure vessels, while those operating below it are considered vacuum tanks.

Brittle Fracture

A failure mode in certain steels caused by exposure to extremely low temperatures, often occurring even when stress levels remain below the material's yield strength.

CIP (Clean-In-Place) Fixtures

Tank cleaning systems that eliminate the need for disassembly. These fixtures, which include spray balls, dishes, and T-balls, provide an efficient method for maintaining hygiene and operational efficiency.

Canadian Registration Number (CRN)

A unique identifier assigned to pressure vessels intended for use in Canada, ensuring compliance with Canadian safety and regulatory standards.

Cladding

A stainless steel coating applied to a lower-alloy steel base to enhance corrosion resistance. This method is more cost-effective than using solid stainless steel and can be achieved through welding, pouring, or coating.

Corrosion Allowance

An intentional increase in vessel shell thickness to account for expected material loss due to corrosion and abrasion. Protective coatings and linings are often added to further extend the tank’s lifespan.

Creep

A gradual, permanent deformation of steel caused by prolonged exposure to high temperatures, leading to a reduction in material strength over time.

Duplex Steel

A high-strength stainless steel alloy that combines austenitic and ferritic steel, resulting in superior corrosion and crack resistance compared to either metal alone.

Electropolishing

A process that removes surface imperfections from stainless steel by dissolving a thin layer of metal in an electrolyte solution while applying an electric current, improving both cleanliness and corrosion resistance.

FDA (Food and Drug Administration)

The U.S. federal agency responsible for regulating food, drugs, medical devices, and cosmetics. It also sets standards for stainless steel tanks used in industries requiring sanitary storage conditions.

Fouling

The accumulation of marine organisms and other deposits on submerged metal surfaces, which can lead to reduced efficiency and potential corrosion.

Gauge

A measurement that indicates the thickness of a sheet of steel, influencing its strength and durability.

Manway

An access port that allows entry into the internal section of a tank or pressure vessel for maintenance, inspection, or cleaning.

National Board Inspection Code

A globally recognized standard governing the inspection, alteration, and repair of pressure vessels to ensure safety and compliance.

Psi (Pounds per Square Inch)

A unit of pressure measurement that indicates the force exerted on an object. It is commonly used to specify the internal pressure within a pressure vessel.

Sanitary Piping

A specialized piping system designed to interconnect stainless steel tanks while maintaining hygienic conditions. These systems are easily cleanable to prevent contamination.

Stainless Steel

A steel alloy containing between 10% and 12% chromium, prized for its corrosion resistance and ability to withstand high temperatures, making it a preferred material for tanks used in various industries.

USDA (United States Department of Agriculture)

A federal agency overseeing the agricultural industry, including food safety regulations. The USDA enforces stringent sanitation and storage requirements for stainless steel tanks used in dairy and meat processing applications.