Stainless Steel Tubing

Stainless steel is an iron-based alloy containing chromium, nickel, and other elements, known for its ability to resist rust, staining, and rapid deterioration from harsh weather and chemical exposure. With over 57 recognized stainless steel alloys, each with varying metal compositions, choosing the right stainless steel alloy is essential for successful application. Understanding the types, benefits, limitations, and accessories of stainless steel ensures that the selected material meets specific performance requirements.

Stainless steel tubing refers to this robust metal alloy formed into a tube shape. It is produced in different sizes to suit many functions and applications. Today, stainless steel tubing is widely used for car exhaust systems, aircraft hydraulic lines, cutlery, kitchen tools, construction, and outdoor gear. Its strength and corrosion resistance also make it ideal for fuel and heat lines.

Quick links to Stainless Steel Tubing Information

History of Stainless Steel Tubing

Stainless steel was first developed in France in the early 1900s when Leon Guillet created the alloy using aluminothermic reduction methods previously being explored. However, Guillet initially overlooked stainless steel's corrosion resistance. In 1911, Monnartz and Borchers discovered the link between chromium content and corrosion resistance. The first patent for stainless steel was granted in 1912. Harry Brearly, a researcher at Brown-Firth Lab, was studying erosion-resistant materials and noticed that discarded metal samples containing chromium did not rust over time. Another account suggests Brearly tested his chromium alloys with nitric acid and found that the alloy remained intact, leading him to further test with other chemicals like lemon juice. These discoveries marked the beginning of stainless steel’s widespread use as a corrosion-resistant metal.

Advantages of Stainless Steel Tubing

There are many advantages to using stainless steel tubing compared to traditional metal. The advantages of stainless steel tubing are that the tubing is durable, can transport hot or cold liquids and gases, does not deteriorate easily upon being introduced to most chemicals, can be formed into many grades and tube radii, and can even be formed cheaper for lower pressure systems.

Stainless Steel Tubing Design

Before discussing how stainless steel tubing is manufactured, a discussion of the manufacturing of stainless steel is required. Stainless steel is produced by first melting the raw metals in an electric furnace for several hours at a very intense heat. After making the alloy, the steel is stored as square forms called billets. To decrease the internal stress of stainless steel and strengthen the finished product, the metal alloy is annealed (heated and cooled in a systematic way) by heating the alloy to 900 degrees Fahrenheit. The strength of the steel is less dependent on the rate of heating and more affected by the rate of cooling. The annealing process causes a buildup of unwanted material on the stainless steel. This buildup is removed by acid treatment.

Once the stainless steel is finished, the steel is formed into a shape such as a pipe. The process of producing stainless steel can be highly customized to meet the needs of the application. For example, if the steel needs to be more malleable rather than strong, the annealing process can be shortened. If a seamless tube is needed, then a seamless tube can be made by heating a billet and extruding it to the desired radius and length. If stainless steel tubing is needed in a low pressure and indoor environment, then a lower cost method of manufacturing such as seamless stainless steel tubing or welded tubing can be utilized.

The degree of precision required of the stainless steel tubing manufacturers depends on the industrial application. It can also be produced through metal spinning, which is a cold worked metal fabrication technique comparable to a potter forming clay, except a metal spinner uses a flat round disc of sheet metal which is rotating on a spinning lathe. However, the metal spinning process is limited to the production of concentric shapes, including tubes and pipes.

Stainless Steel Tubing Images, Diagrams and Visual Concepts

Stainless steel tubing is a strong and long-lasting material that offers superior corrosion resistance and requires minimal maintenance.

Stainless steel tubing is a strong and long-lasting material that offers superior corrosion resistance and requires minimal maintenance.

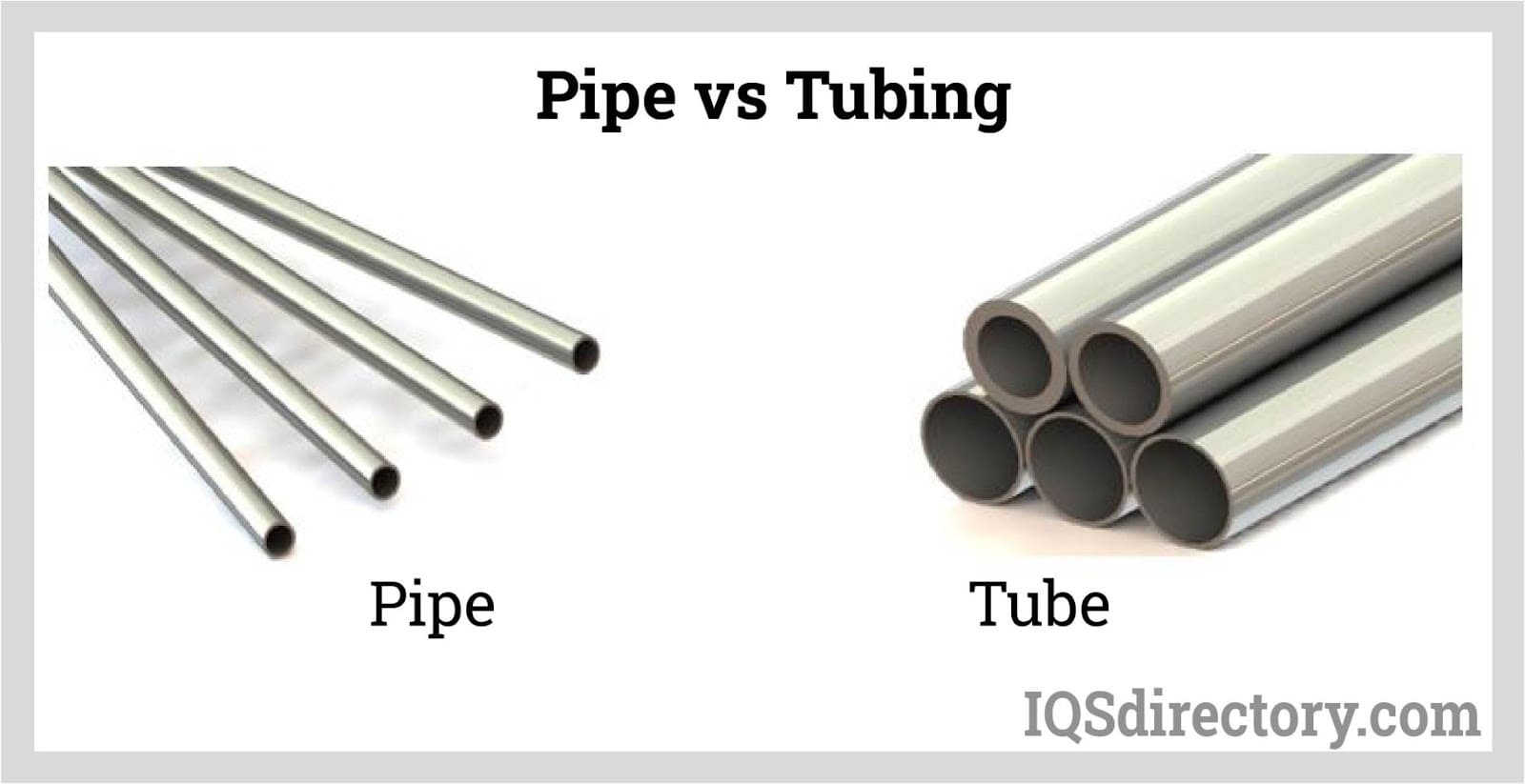

Tubing is primarily used for structural applications where outer diameter is key, while piping is designed to transport gases or liquids where capacity is most important.

Tubing is primarily used for structural applications where outer diameter is key, while piping is designed to transport gases or liquids where capacity is most important.

304 stainless steel tubes are made with carbon, iron, and chromium levels ranging from 18 to 20%, and nickel content between 8 and 18%.

304 stainless steel tubes are made with carbon, iron, and chromium levels ranging from 18 to 20%, and nickel content between 8 and 18%.

316 stainless steel tubes feature carbon and chromium concentrations of 10%, providing enhanced corrosion resistance in demanding environments.

316 stainless steel tubes feature carbon and chromium concentrations of 10%, providing enhanced corrosion resistance in demanding environments.

Corrugated stainless steel tubing is a multi-layered hollow cylinder used as an alternative to standard steel piping for transporting gases.

Corrugated stainless steel tubing is a multi-layered hollow cylinder used as an alternative to standard steel piping for transporting gases.

Hypodermic tubing is commonly used in medical applications for administering medications beneath the skin.

Hypodermic tubing is commonly used in medical applications for administering medications beneath the skin.

Stainless steel pipe fittings connect or seal the ends of pipes and tubing, allowing for various mounting, in-line, offset, and multiport configurations.

Stainless steel pipe fittings connect or seal the ends of pipes and tubing, allowing for various mounting, in-line, offset, and multiport configurations.

Types of Stainless Steel Tubing

There are many types of stainless steel tubing and there are many ways that one stainless steel tube varies from another stainless steel tube. For example, one stainless steel tube could have a different grade, could have seams or be seamless, have a different length, radius, or wall thickness, and be polished or unpolished.

- 304 Stainless Steel Tubing

- A hollow, cylindrical machine and piping component made of grade 304 stainless steel alloy and used most commonly to transport fluids and gases.

- 316 Stainless Steel Tubing

- A hollow, cylindrical machine and piping component made of grade 316 stainless steel alloy and used most commonly to transport fluids and gases.

- Corrugated Stainless Steel Tubing

- A multilayered hollow cylindrical object used as an alternative to traditional steel piping as the medium through which gases are transported.

- Hypodermic Needles

- Medical instruments that use stainless steel tubing to move fluids.

- Hypodermic Tubing

- A slender, hollow, cylindrical length of stainless steel, a puncturing point made at one end to form a needle which is commonly used as the medium for introducing medicine or drugs under skin.

- Medical Tubing

- Often made from stainless steel because of its hygienic nature. Medical tubing is also used in the production of instruments and implants for the medical industry.

- Nickel Tubing

- A common type of tubing. Nickel is often used in combination with copper in many applications, including those in the marine industry that involve moderate exposure to chlorine, to which nickel-copper alloys are resistant.

- Small Diameter Tubing

- Used in equipment found in medical and dental applications, including those used in minimally invasive procedures. Capillary tubing, for example, measures less than or equal to 0.188 inches in outside diameter.

- SS Tubes

- Hollow cylindrical objects, similar to pipes, used as the medium through which fluids and gases are transported as well as various other equipment components, such as hydraulic cylinders.

- Stainless Steel Bars

- Of different shapes are utilized in the construction and transportation industries because of the bars’ high strength and low maintenance requirements. Stainless bars and rods provide excellent structural support and reinforcement.

- Stainless Steel Pipes

- Used in applications involving corrosive fluids, high temperatures and high contaminant levels because of the great corrosion resistance of stainless steel pipes. Industries in which stainless steel pipes are popular include the oil/gas, pulp and paper and water/wastewater industries.

- Stainless Steel Pipe Fittings

- Attachments used to connect or close the end of pipes and tubing to increase in-line, offset, multiport and mounting capabilities.

- Stainless Steel Square Tubing

- A pipe-like hollow piece of hardware having four sides of equal length which is used in applications in which traditional round or oval stainless tubes are not acceptable.

- Stainless Steel Tubes

- Hollow cylinders made of stainless steel that are often used for the transportation of liquids and gases.

- Syringes

- Small, hollow tubes used for injecting or withdrawing fluids for medical purposes.

- Thin Wall Tubing

- Consists of extremely thin stainless tubing, the walls of which usually measure 0.12 inches or thinner. Despite its thinness, thin wall tubing still provides insulation and strength and is commonly used in medical and aerospace applications.

Stainless Steel Tubing Applications

Stainless steel tubing is widely used in products and infrastructure, ranging from machinery in factories to automotive exhaust systems. In most uses, stainless steel tubing serves to transport or control the flow of gases or liquids. Its ability to support hot gases and corrosive liquids without breaking down makes it a preferred choice. The versatility and durability of stainless steel tubing means its applications are limited only by project requirements and budget.

Stainless steel tubing can be used in almost any setting, subject to available budget. It withstands outdoor exposure for long periods without rusting or deteriorating. Due to its corrosion resistance, stainless steel tubing is chosen in many industries, including damp industrial environments, outdoor gear and firearms, kitchenware with sanitary tubing, and automotive manufacturing.

Stainless Steel Tube Grades

There are several grades of stainless steel tubing which affects how corrosive resistant the tubing will be based on the percentages of each metal that makes up the alloy. The grades are 304, 304L, 316, 316L, and 430. For example, grade 304 is a basic chromium-nickel alloy and is highly malleable into different shapes while grade 430 is a chromium ferritic alloy that has lower corrosion resistance and is typically used for indoor products.

Seamless Tubing and Welded Tubing

As well as the grading, stainless steel tubing differs in the way that it is formed. For example, if tubing seamless is needed, then the seamless steel is extruded from a billet until the desired length, radius, and wall thickness is acquired. If a smaller radius is needed, then the tubing is rolled such that hypodermic tubing is created. When a company needs to create a lower pressure system, then electric resistance welded tubing can be used. Electric resistance welded tubing is created by fusing together smaller stainless steel pipe pieces into a longer tube using electric charge.

Polished Versus Unpolished Stainless Steel

As well, various finishes can be used on stainless steel. For example, unpolished stainless steels are very dull and used for applications that are not seen by many people. Polished stainless steels are treated with abrasives that range from low to high grit. While polished stainless steel has a pleasant aesthetic look, care should be taken because too much polishing could leave unwanted scrapes and signs of deterioration on the stainless steel.

Standards and Specifications of Steel Tubing

There are many standards in the stainless steel tubing industry set forth by ASTM International standards organization. ASTM ensures that proper standards are known across the world. Stainless steel tubing standards include the chemical composition (grades), fractional radii and wall thickness (mm), tube wall (in), weight (typically in lbs per ft), and working pressure (typically in psig) are all industry standards in stainless steel tubing.

Things to Consider When Purchasing Stainless Steel Tubing

There are many factors to think about when it comes to choosing the right manufacturer. Answering the following questions may help to choose the right manufacturer: What does the stainless steel tubing need to be able to do? How much money is budgeted toward the stainless steel tubing? Does the manufacturer adhere to industry standards? What do recent and past clients have to say about the manufacturing quality? Does the manufacturer offer custom stainless steel?

Hopefully this article offers a helpful overview of stainless steel tubing. There are many ways that one piece of stainless steel tubing can differ from another piece. More detailed information can be found on manufacturer's sites.

Proper Care for Stainless Steel Tubing

The protective chromium oxide layer on stainless steel tubing forms when chromium reacts with oxygen in the air, but accumulated dirt or contaminants can disrupt this process. Debris on the tubing surface can trap corrosive materials, making regular cleaning and maintenance important depending on the stainless steel grade. Care methods vary: for smudges and fingerprints, sodium carbonate and glass cleaner are commonly used, followed by a final rinse with hot water and soap.

If basic cleaners do not remove dirt or oils, solvent cleaning can be applied using non-abrasive, low-chloride detergents and solvents. Special types of tubing, such as ultra-high purity tubing, chemically cleaned tubing, and thermocouple cleaned tubing, offer enhanced cleanliness. Ultra-high purity tubing is often electropolished inside to minimize dirt accumulation, while chemically and thermocouple cleaned tubing help meet strict cleanliness requirements.

Stainless Steel Tubing Accessories

Stainless steel tubing is commonly paired with tube fittings, valves, regulators, tube benders, and tube cutters. Fittings and adapters connect stainless steel tubes and are rated for various pressure, temperature, and wall thickness requirements. Similarly, valve accessories are available for different pressure and temperature levels. Regulators control the pressure and flow of fluids through the tubing and are also rated for application-specific needs. Tube benders are available as hand-held tools for single tubes or hydraulic models for efficiently bending multiple tubes at once.

Stainless Steel Tubing Terms

- Annealing

- Reducing hardness and stress in a metal, such as stainless steel, through heating and cooling applications.

- Bright Annealing

- A form of annealing in which the level of atmospheric gas is reduced in order to remove surface oxides from the surface of the stainless steel and to prevent discoloration during the annealing process. This process is responsible for the bright, shiny appearance associated with stainless steel.

- Burst Pressure

- The internal pressure limit of stainless steel tubing at which point the tube material will expand to the point of deformation or bursting.

- Cold Drawing

- A cold forming process, commonly used in tube and pipe diameter reduction, in which a tube is drawn through a carbide die. The diameter of the emerging stainless steel tube or stainless steel pipe reflects the size of the die.

- Concentricity

- A characteristic of a welded stainless steel tubing in which wall thickness remains consistent throughout the stainless steel tubing, and the inside and outside diameter centers are equivalent to one another.

- Corrosion

- The decay of metals by chemical agents, which convert them to nonmetallic products. Stainless steel has a passive film created by the presence of chromium and often other alloying elements, such as nickel and molybdenum, that resists this process.

- Degree of Bend

- The depth of bend or the sweep of the arc. The minimum degree of bend is about five degrees, while the maximum degree of bend in rotary-draw bending is 180 degrees.

- Destructive Testing

- The testing of stainless steel tubing properties, such as tensile strength, yield strength, hardness, burst pressure and bending.

- Eccentricity

- A characteristic of seamless tubing in which wall thickness is not consistent throughout the tube.

- Hardness

- A characteristic of tubular products that is measured on samples of tubing using a standard Rockwell Penetrator and recording the results on the Rockwell "B" scale. Hardness is the direct result of annealing temperatures and material properties; in general, as the hardness number increases, both tensile and yield strengths increase along with a corresponding decrease in elongation (ductility).

- Hydrostatic Testing

- A test in which water is introduced into the stainless steel tubing at high pressure levels in order to test for holes and porous parts. Because hydrostatic testing is a nondestructive test, the water pressure level does not surpass the stainless steel tubing yield strength.

- I.D. (Inside Diameter)

- A term that refers to the diameter of the interior portion of stainless steel tubing and pipes. The measurement of the stainless steel tube or stainless steel pipe is not included in I.D.

- IPS

- A pipe specification system that associates certain nominal pipe diameters with standardized wall thickness called “schedules.” The same schedule number will have a different fixed decimal inch value for each nominal diameter.

- O.D. (Outside Diameter)

- A term that refers to the diameter of the exterior portion of stainless steel tubing and pipes. The tube or pipe is included in the O.D. measurement.

- Ovality

- A quantitative measurement of how "round" a tube is, which is derived by comparing width to height. Limits of ovality are specified on the appropriate ASTM specification of a product.

- Passivation

- The creation of a passive oxide layer on stainless steel, which is responsible for the high corrosion resistance of stainless steel used in stainless steel tubing.

- Residuals

- The impurities remaining in mini-mill stainless steels, which result from the wide variety of metals entering the process.

- Seamless Tubing

- The creation of stainless steel tubing through the use of a piercing mill. During the process, a round blank is pierced to produce the stainless steel tubing, which produces inconsistency in wall thickness throughout the tube that can be fixed through secondary operations.

- Welded Tubing

- The creation of stainless tubes through roll forming and fusing the stainless steel along a seam. Welding provides consistency throughout the stainless steel tubing.