Storage Racks

Storage racks are sturdy frameworks designed to display, store, and organize products, parts, equipment, tools, materials, boxes, and pallets, optimizing space utilization in warehouses, manufacturing facilities, shipping areas, and assembly rooms. These racks enhance efficiency by keeping inventory easily accessible while maintaining an orderly work environment.

Manufacturers design industrial storage racks to withstand heavy-duty use, tailoring them to meet specific product requirements and accessibility needs. Many racks are built to accommodate palletized inventory, ensuring seamless storage and retrieval processes. Constructed primarily from strong and durable metals such as aluminum and steel, these racks provide exceptional load-bearing capacity and longevity. Steel storage racks, in particular, are widely used for industrial applications due to their superior strength. However, some lighter-duty storage racks are made from materials like titanium, wood, or particle board, offering flexibility for less demanding applications. These racks support a diverse range of inventory, from boxed goods and packaged products to oversized items such as long carpet rolls and tubing, making them an essential component in organized storage solutions.

Storage Racks FAQ

What are industrial storage racks used for?

Industrial storage racks are used to store, organize, and display products, tools, and materials in warehouses, factories, shipping areas, and workshops, optimizing space while keeping inventory accessible and orderly.

What materials are storage racks made from?

Most storage racks are built from durable metals like steel, stainless steel, or aluminum. Some lighter-duty racks use titanium, wood, or particle board, offering flexibility for less demanding storage applications.

How did forklifts change the history of storage racks?

The introduction of forklifts in 1915 transformed warehousing by allowing pallets of boxes to be lifted and stacked, leading to the invention of pallet racks and the widespread use of vertical storage systems.

What is the difference between FIFO and LIFO storage systems?

FIFO (first in, first out) ensures older inventory is used first, preventing spoilage, while LIFO (last in, first out) pushes older stock back, maximizing space but best for nonperishable goods.

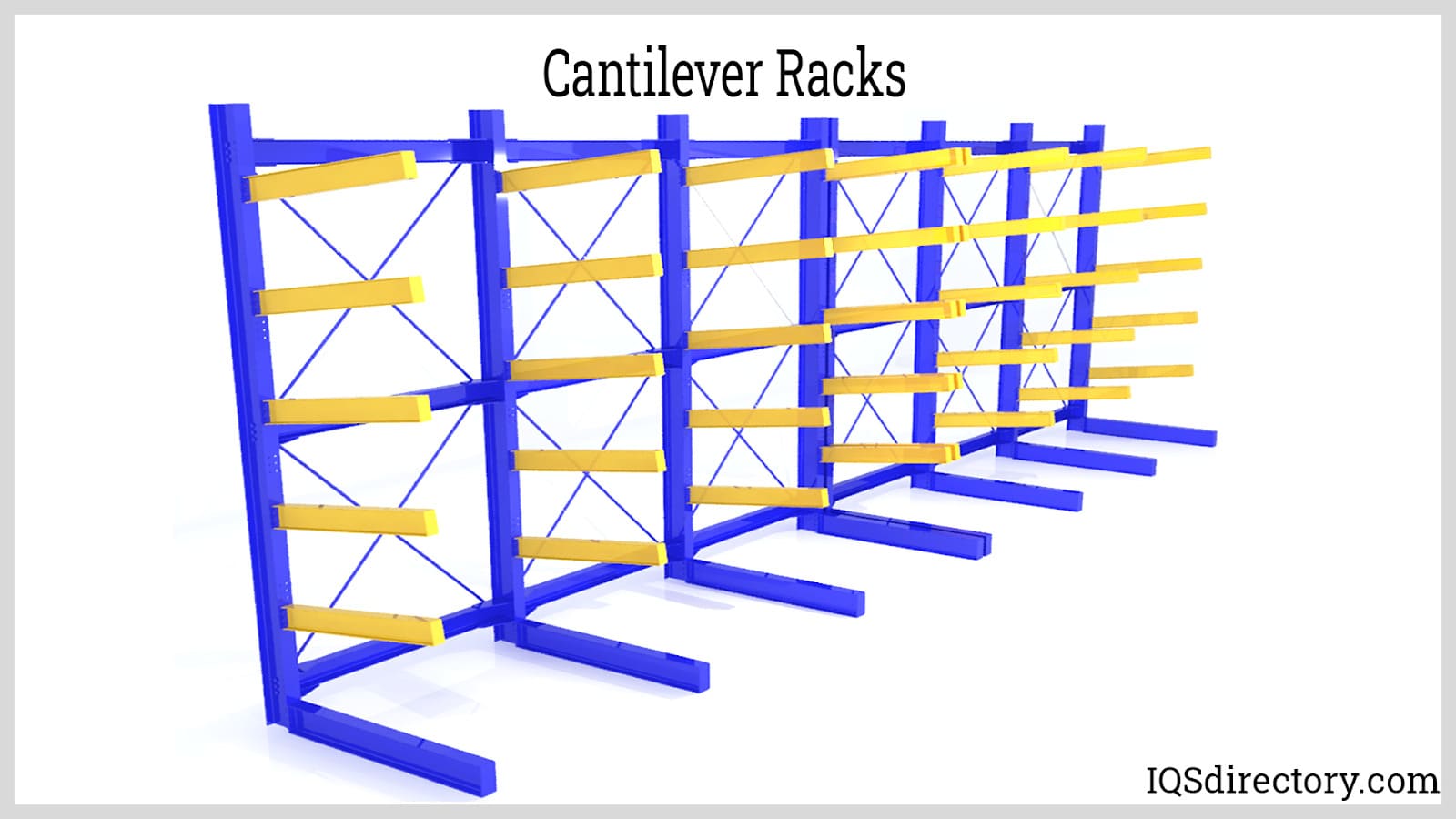

What are cantilever racks used for?

Cantilever racks are designed to store long, bulky, or irregularly shaped items such as beams, sheet metal, pipes, or lumber, keeping them organized and off the floor while allowing easy access.

Why is stainless steel popular for storage racks?

Stainless steel storage racks resist rust, withstand extreme temperatures, and are easy to clean, making them ideal for industries requiring sanitation, such as food processing, pharmaceuticals, and healthcare.

Where are storage racks commonly used?

Storage racks are widely used in warehouses, manufacturing plants, retail facilities, healthcare, education, government buildings, and even residential or office environments to organize and maximize available space.

History of Storage Racks

In the early 1900s, product transportation relied heavily on trucks, railways, and boats, with heavy boxes and materials moved manually. This labor-intensive process required significant time and incurred high costs. However, this changed in 1915 with the development of the forklift, a groundbreaking innovation pioneered by various companies. The forklift revolutionized warehousing by enabling workers to stack and transport pallets of boxes, regardless of individual weight. This advancement dramatically reduced loading and unloading times while minimizing physical strain on workers. As technology progressed, forklifts were adapted to lift pallets several meters into the air, leading to the invention of the first pallet racks—an essential milestone in storage rack history.

By the late 1920s, warehouses began utilizing vertical pallet storage systems, marking a significant shift in inventory management. This innovation soon led to the development of multi-level storage racks, which allowed for stacking multiple layers of pallets. With this advancement, warehouse owners could expand their facilities both upward and outward, maximizing available space while increasing storage efficiency. The ability to stack pallets two to four levels high transformed warehousing into a more cost-effective and organized operation.

Over time, engineers and warehouse operators continued refining storage rack designs to enhance efficiency and functionality. In 1968, Thomas J. Finlayson secured a patent for the drive-in pallet rack, a system that enables forklift operators to drive directly into the rack structure to place and retrieve loads. Later, in 1986, Charles Agnoff introduced the gravity flow storage system, an energy-efficient design that remains widely used today. Modern storage racks now cater to a broad range of needs, incorporating features for portability, ergonomics, and accessibility. As warehousing and logistics continue to evolve, storage racks remain a fundamental component in optimizing space and streamlining operations.

Storage Rack Design

-

Production Process

Before beginning production, manufacturers carefully assess the space where the storage system will be installed, taking detailed notes on its requirements. Key considerations include inventory accessibility, rotation needs, the diameter and weight of stored products, building height, available floor space, and overall layout, including door placement. These factors determine how the storage system must be constructed, the features it requires, and the materials best suited for its durability and performance.

To fabricate the storage system, manufacturers typically assemble pre-formed components through welding, weaving, extrusion, molding, or other shaping techniques. This ensures the final structure is both sturdy and efficient for its intended application.

- Rack Materials

-

Most storage racks are constructed from strong, durable metals such as steel, stainless steel, or aluminum. Some are made from lightweight yet robust metals like titanium, while a smaller number are produced using wood or particle board for lighter-duty applications. Many metal storage racks incorporate wire components for added support and structural integrity.

Among the available materials, stainless steel is the most widely used due to its superior durability, resistance to extreme temperatures, and ability to prevent oxidation, which leads to rusting. These qualities make it ideal for long-term storage solutions across a range of industries.

- Considerations and Customization

- Manufacturers offer a broad selection of standard storage racks in various sizes and designs, but they also provide customization options to meet specific needs. When designing a custom storage rack, they take into account product specifications, accessibility requirements, and budget constraints. Every aspect of the rack can be tailored, including height, width, depth, weight capacity, material choice, and finish. By offering fully customized solutions, manufacturers ensure that storage racks align perfectly with operational needs and space constraints, maximizing efficiency and usability.

Storage Rack Images, Diagrams and Visual Concepts

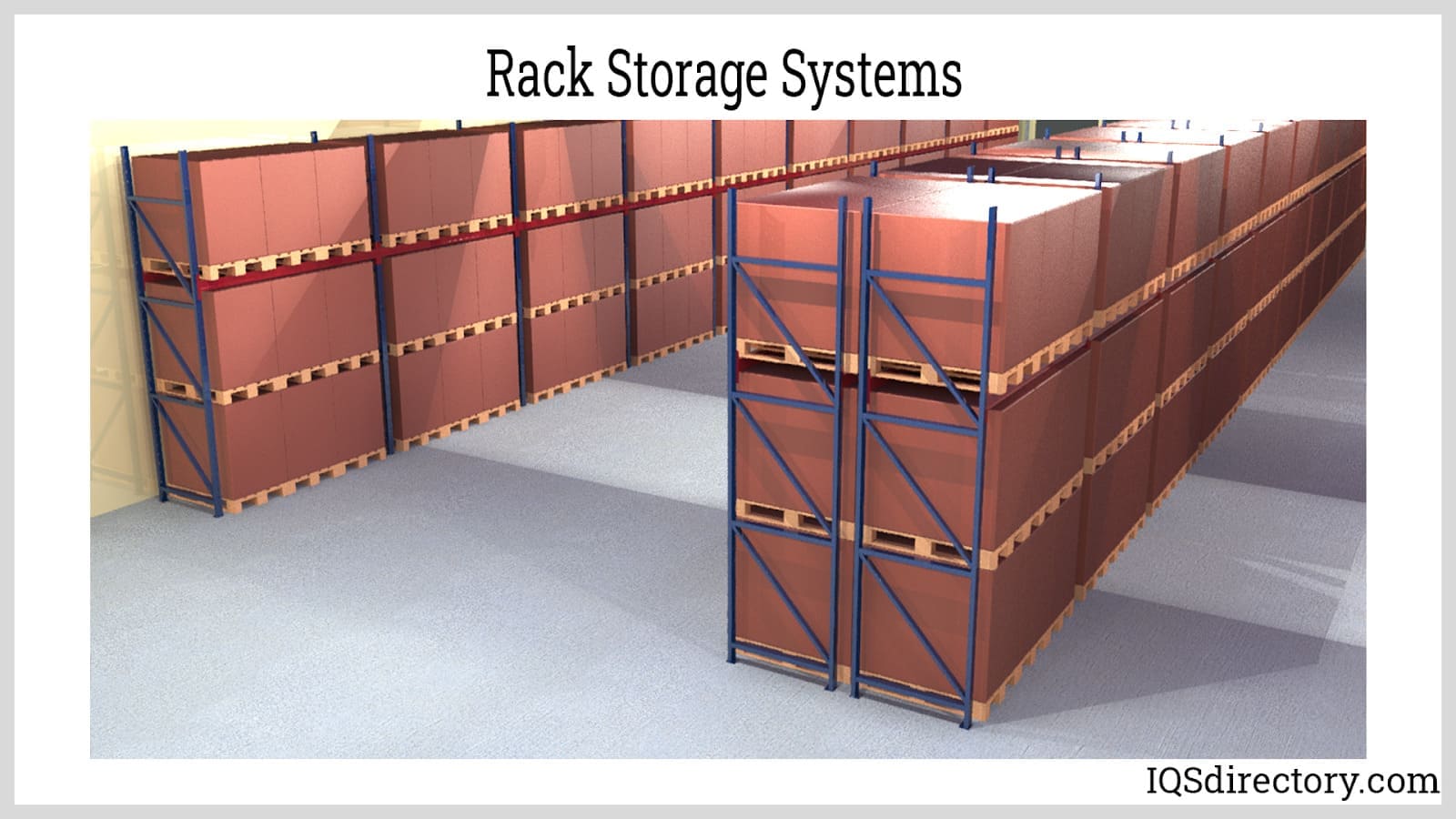

Storage rack system depends on the items or materials being stored, which can affect the decking and the configuration of the racks.

Storage rack system depends on the items or materials being stored, which can affect the decking and the configuration of the racks.

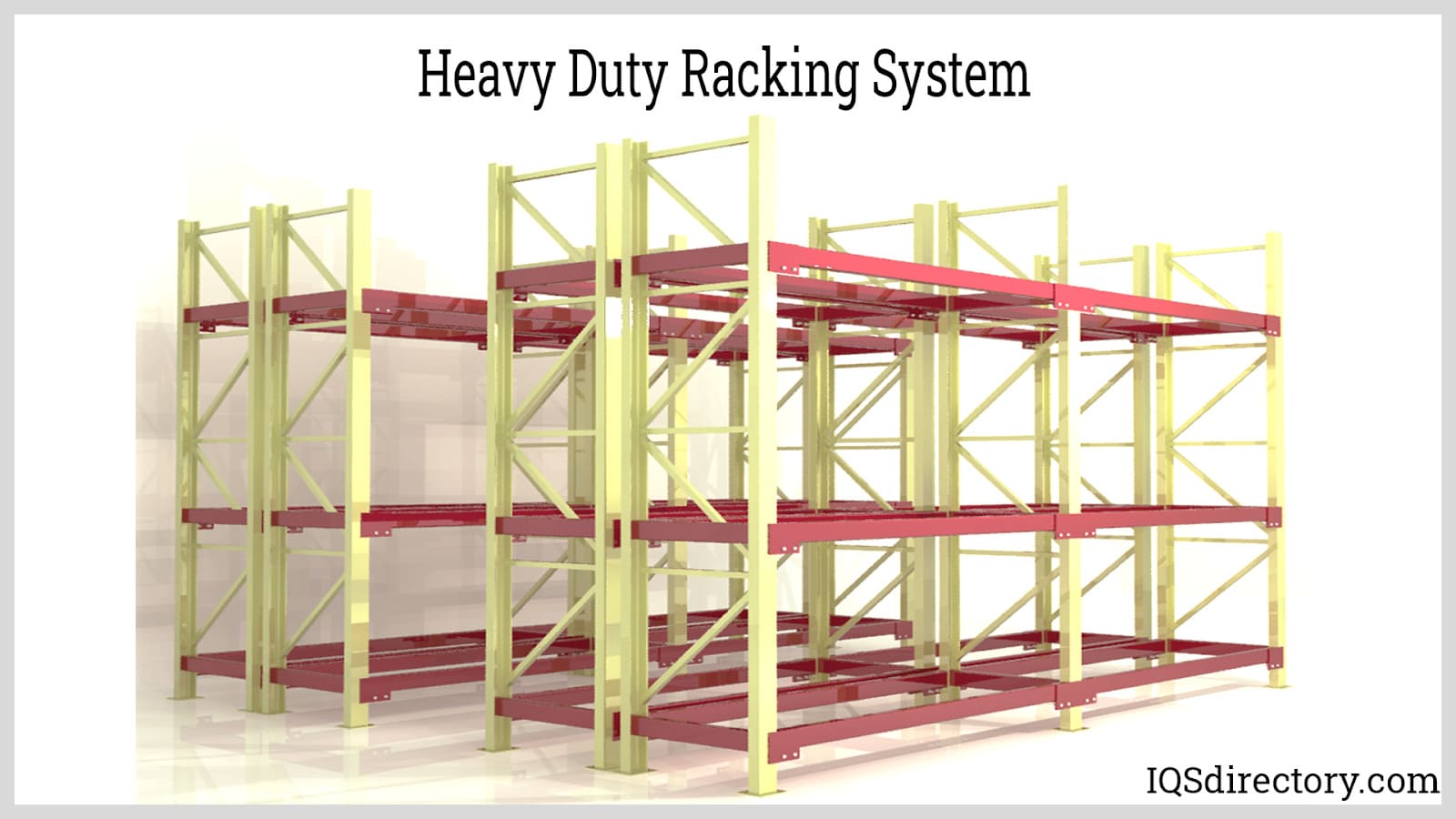

Heavy duty systems are for products that have a heavier weight making the racks more sturdy and able to support the items.

Heavy duty systems are for products that have a heavier weight making the racks more sturdy and able to support the items.

Pallet rack decking includes solid, wire mesh, wire, bars, wood, metal, and punched sheets for storage.

Pallet rack decking includes solid, wire mesh, wire, bars, wood, metal, and punched sheets for storage.

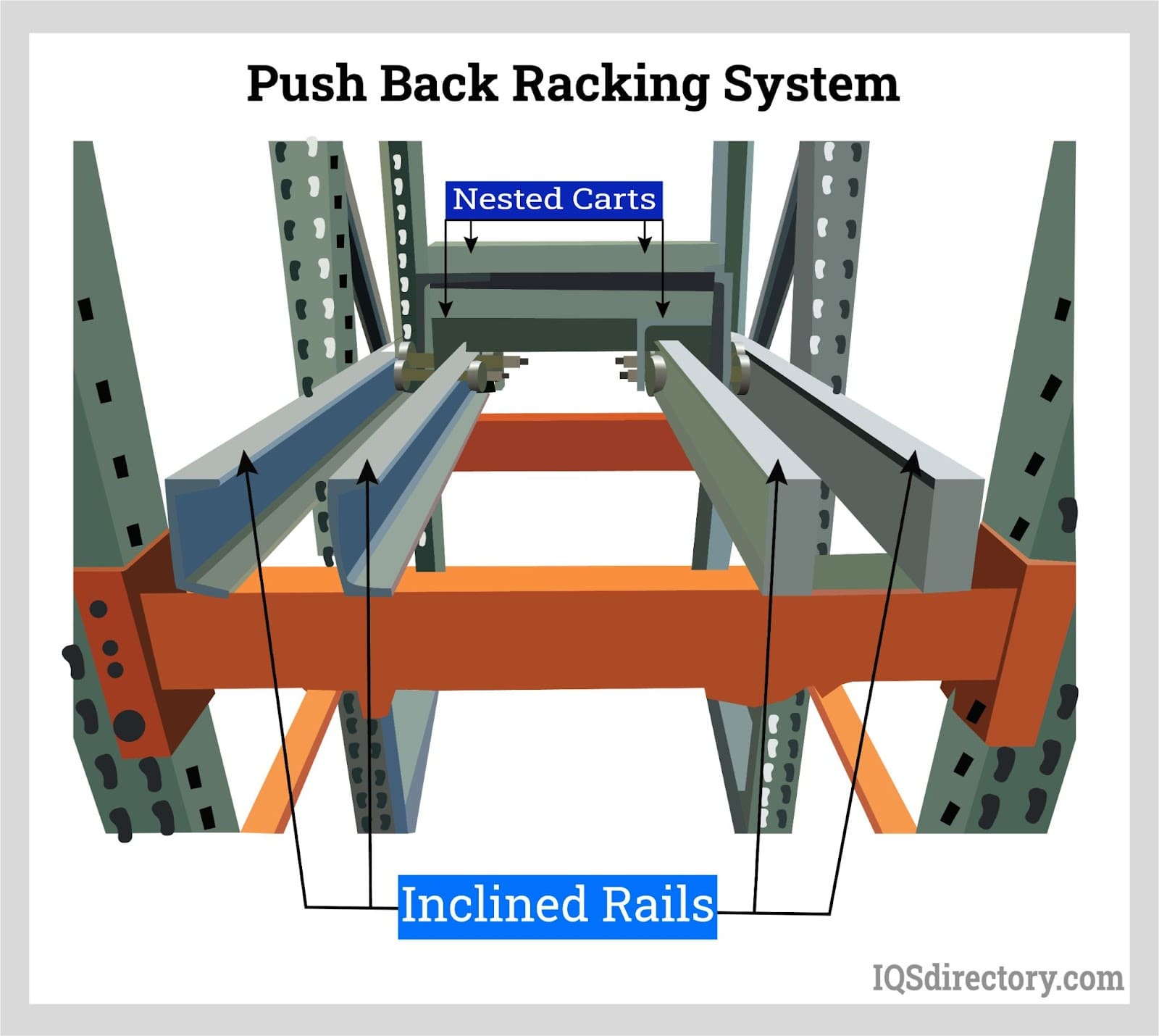

Push back pallet racking is ideal for density storage when space is limited, which utilizes last in first out.

Push back pallet racking is ideal for density storage when space is limited, which utilizes last in first out.

Selective pallet racking has the lowest storage density and is used in where products are at a low volume in storage.

Selective pallet racking has the lowest storage density and is used in where products are at a low volume in storage.

Horizontal carousels are sorting devices used with small parts and products, to conserve space while organizing materials or products.

Horizontal carousels are sorting devices used with small parts and products, to conserve space while organizing materials or products.

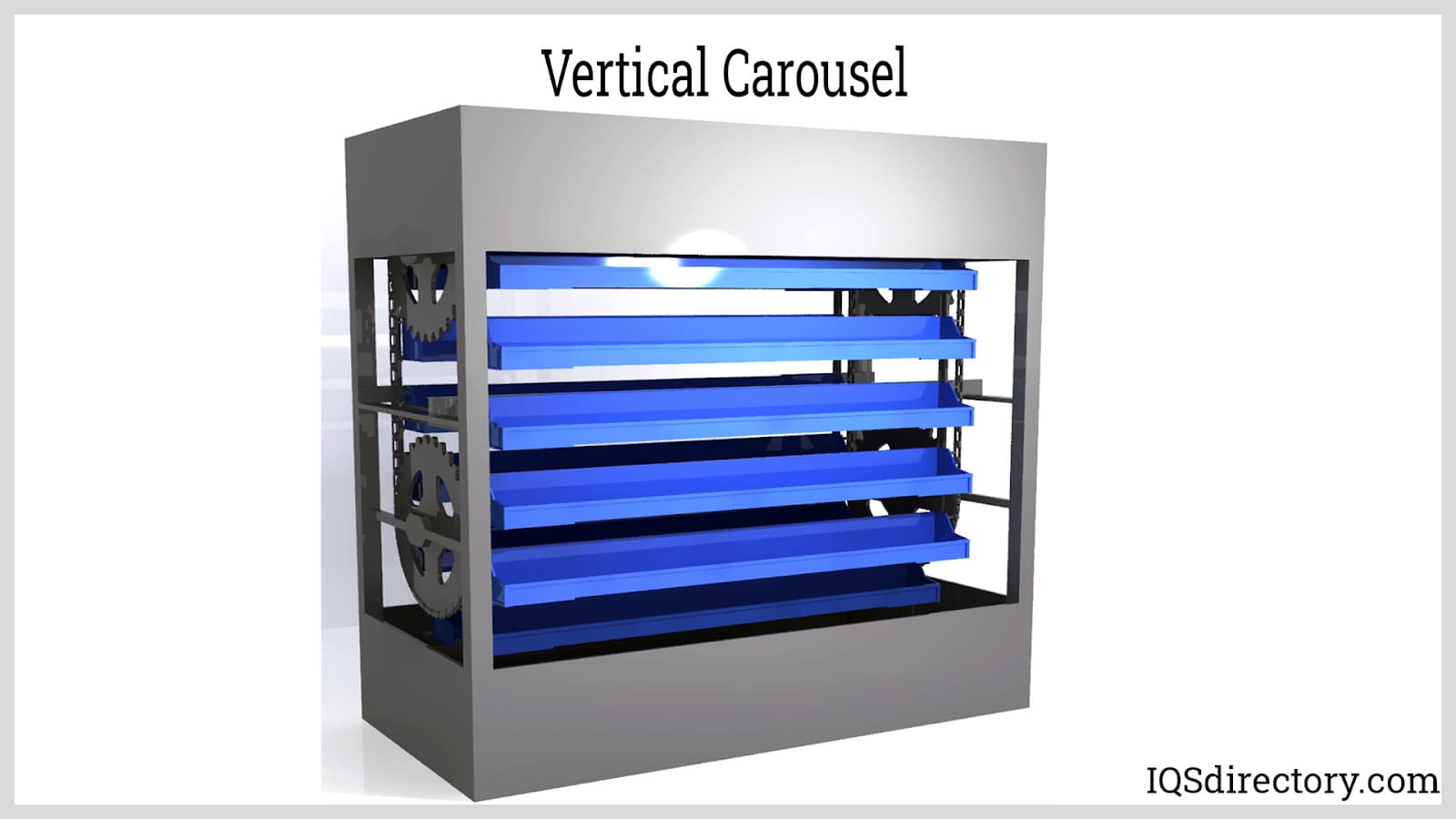

Vertical carousels is much like horizontal carousels except they sort items vertically.

Vertical carousels is much like horizontal carousels except they sort items vertically.

Cantilever racking store products with length or with irregulary shaped items.

Cantilever racking store products with length or with irregulary shaped items.

Types of Racks

-

Pallet Racks

Designed to hold palletized inventory, pallet racks offer the advantage of vertical stacking, maximizing storage space. These racks are typically deep, allowing for a high volume of pallets or boxes to be stored simultaneously. With open access on all sides, they provide an efficient solution for facilities that require easy retrieval of goods without shifting other items. Their design ensures accessibility and streamlined warehouse operations.

Roller Racks

A type of flow and push-back pallet rack, roller racks are named for their built-in rollers that facilitate easy movement of stored goods. Unlike traditional racks, they do not require forklifts and are ideal for systems where items are frequently moved. Manufacturers often equip them with slanted rails, using gravity to assist in transporting heavy loads. When a new load is added, it pushes the front load back, and when the front load is removed, the remaining loads automatically shift forward. Push-back storage racks are accessible from one side and can be positioned against walls or other obstructions without sacrificing functionality.

Warehouse Racks

Designed to accommodate forklifts, warehouse racks make it easy to locate and retrieve pallets from industrial shelf units. Many of these shelves incorporate inclined rails or rollers, allowing loads to move forward automatically as front pallets are removed. This design eliminates wasted space while utilizing gravity to streamline the movement of stored materials.

Cantilever Racks

Built to store long, thin materials such as rails, boards, beams, and sheet metal, cantilever racks offer a specialized storage solution for oversized and irregularly shaped items. Some variations are also designed to accommodate pallets and large boxes. These racks consist of uprights, arms, and brace sets, ensuring structural stability while keeping heavy, elongated products off the floor. Their modular nature allows for expansion and customization, making them adaptable to changing storage needs.

Drive-In Racks

Designed to maximize available space, drive-in racks provide an efficient storage solution for warehouses that utilize a high volume of pallets. These racks are ideal when inventory rotation is not a priority, allowing forklifts to drive directly into the rack system for loading and retrieval.

Drive-Thru Racks

Built for accessibility from both sides, drive-thru racks operate on a first-in, first-out (FIFO) inventory system. This makes them particularly effective for high-volume applications with a low mix of products, ensuring continuous movement and efficient stock rotation.

Gravity Racks

Functioning similarly to push-back racks, gravity racks allow loads to be placed on one side and naturally flow to the other using gravity. Suitable for both cartons and pallets, these racks enhance safety and efficiency by separating picking areas from forklift operations, reducing workplace congestion.

Carton Flow Racks

A specialized live storage system, carton flow racks use gravity to move cartons from one side to the other, ensuring easy access and high-density storage. These racks create a dynamic inventory flow, keeping products positioned at the front for ergonomic and efficient picking. By reducing the number of required pickers and minimizing aisle space, carton flow racks significantly lower labor costs and improve warehouse organization.

Carton flow racks are available in two frame styles:

Square front carton flow racks, which feature straight shelving ideal for picking full cartons.

Layback carton flow racks, which use diagonal shelving, making them more effective for picking from open cartons.

Additionally, they incorporate various shelving options to accommodate different picking methods:

Straight shelves, the most common type, provide a simple and efficient storage solution.

Knuckled shelves, designed for easy access to individual items within cartons.

Reverse knuckled shelves, suited for split-case picking applications where items are removed from the front of cartons.

Weld-in trays, offering a secure and permanent shelving solution.

Industrial Storage Racks

Heavy-duty metal frameworks designed for the storage of goods, industrial storage racks are built for strength and durability. Typically constructed from materials such as steel or stainless steel, these racks provide a robust solution for handling large and heavy inventory.

Steel Storage Racks

Offering a smooth, easy-to-clean surface, steel storage racks are highly resistant to fire and heat, making them ideal for environments where flammable materials are present. Their durability and ability to withstand washdowns make them a preferred choice for industries requiring sanitation and safety.

Wire Racks

Used for storage, display, and organization, wire racks are constructed from welded or woven wire mesh decks secured to vertical metal rails. These racks provide a cost-effective and durable alternative to solid shelving materials like wood or plastic. Their open-grid design enhances visibility, prevents dust accumulation, and promotes airflow, making them a practical option for applications requiring ventilation and easy access.

Applications of Storage Racks

Storage rack systems play a crucial role in optimizing space utilization and organizing inventory for easy access to products and materials. Designed to streamline storage and retrieval processes, these systems enhance efficiency in a variety of settings. While primarily used in warehouses and industrial environments, storage racks are also found in homes, offices, workshops, retail facilities, manufacturing plants, and factories. Some racks, such as chest freezer racks, are tailored for specialized applications, ensuring optimal storage for temperature-sensitive products.

Manufacturers rely on storage racks to simplify operations, accommodating diverse inventory types ranging from boxed goods to oversized items like carpet rolls and tubing. These versatile systems support a wide array of industries, including material handling, food and beverage, military, industrial production, commercial businesses, education, healthcare, and government facilities. No matter the industry, storage racks provide a structured and efficient solution for managing materials, improving workflow, and maximizing available space.

Features of Storage Racks

Storage rack systems are designed to accommodate different inventory management methods, with most facilities utilizing either the FIFO (first in, first out) or LIFO (last in, first out) approach. Both methods have designated areas for stocking and material retrieval, which can be handled manually by workers or with the assistance of lift trucks.

The FIFO system organizes inventory by placing newly stocked items at the rear while picking is done from the front. This method ensures that older inventory is accessed first, preventing spoilage and reducing the risk of products being lost or buried within the shelves. FIFO is widely used for perishable goods, such as food products, pharmaceuticals, and other time-sensitive materials that must be cycled efficiently.

The LIFO system, commonly used with push-back racks, operates differently. These racks are positioned at a slant and arranged in rows of two, eliminating the ability to stock from the rear. With only one aisle for both stocking and picking, newly added inventory pushes older stock further back. Because products can remain in storage for extended periods, LIFO is best suited for nonperishable goods. The primary advantage of this system is its efficient use of space, as it reduces the number of required aisles while maximizing storage capacity. By doubling up on shelf space, LIFO enables facilities to store higher volumes of materials within a smaller footprint.

Things to Consider When Purchasing Storage Racks

Choosing the right manufacturer is essential to ensuring that your storage rack system meets all of your requirements, including budget constraints, project timelines, and industry standards. The ideal manufacturer will work with you to design and build a system that optimizes storage space and improves operational efficiency. To find the best fit for your needs, explore the storage rack companies listed on this page.

IQS Directory provides a comprehensive resource for sourcing storage rack manufacturers and suppliers. Our platform allows you to review and connect with companies capable of designing, engineering, and manufacturing storage racks to your exact specifications. With user-friendly features, you can easily locate manufacturers that specialize in storage rack shelves, warehouse storage racks, or industrial storage solutions.

Through our request-for-quote forms, reaching out to leading storage rack manufacturers is quick and hassle-free. Access detailed company profiles, website links, locations, contact information, product videos, customer reviews, and industry news articles to stay informed about the latest advancements in storage solutions. As a trusted manufacturer directory, we ensure that you connect with the right supplier for your storage rack needs.

Rack Accessories

Storage rack accessories include: shelving, drawer rack add-ons, castors, baskets, bumpers, feet, anchors, dividers, braces, arms and more. To learn what accessories might best serve your application, talk to your supplier.

Storage Racks Terms

-

Barrel Beam

A structural angle welded to a beam that prevents cylindrical objects from rolling off the rack.

Cantilever

A horizontally projecting structure supported at one end that carries a load along its length, commonly used for storing long and bulky items.

Clear Aisle

The unobstructed space between racks in a storage area, subtracting any pallet or load overhang, ensuring accessibility and movement efficiency.

Clear Stacking Height

The available vertical storage space within a rack system, determining how high inventory can be stacked.

Deck

A roofless platform attached to at least two sides of a storage rack, providing the surface on which products are placed.

Dedicated Aisle

An aisle in a warehouse designated for a single function, such as storage or order selection, improving organization and workflow.

Double Deep

A storage arrangement in which pallets are placed two deep, one behind the other. This configuration allows access only from the front and is ideal for high-volume, low-variation inventory.

First-In, First-Out (FIFO)

An inventory rotation method where the first and oldest product stored is retrieved first, ensuring freshness and reducing waste.

First-In, Last-Out (FILO)

A storage system in which the first product stored is the last to be retrieved, offering minimal selectivity but maximizing space efficiency.

First-In, Still Here Somewhere (FISHS)

A term referring to inventory that has been misplaced or buried within a storage system.

Fork Bar Spacers

Components that create clearance between beams and loads, allowing forklifts to enter and retrieve materials more easily.

Forklift

A small industrial vehicle equipped with two elongated prongs, designed for lifting, transporting, and stacking cargo in warehouses and storage areas.

Insert Plates

Heavy plates welded inside the flanges of uprights, enhancing rack strength and increasing load capacity.

Mezzanines

An elevated platform above the main warehouse floor, creating additional storage both underneath and on top of the structure.

Pallet

A movable platform, typically made of wood or plastic, used for handling, transporting, and storing cargo in warehouses and industrial facilities.

Post Guard

A protective device designed to shield upright rack posts from damage caused by forklift or equipment impact.

Stacker

A compact rolling device with elongated forks, similar to a forklift, used to move and lift cargo. Stackers can be manually operated or equipped with mechanical lifts.

Storage Aisle

A designated aisle where inventory is stacked or where materials are picked for distribution or shipment.

Wall Tie

A stabilizing device that maintains proper distance between upright rack posts and warehouse walls, enhancing rack stability and structural integrity.