Titanium

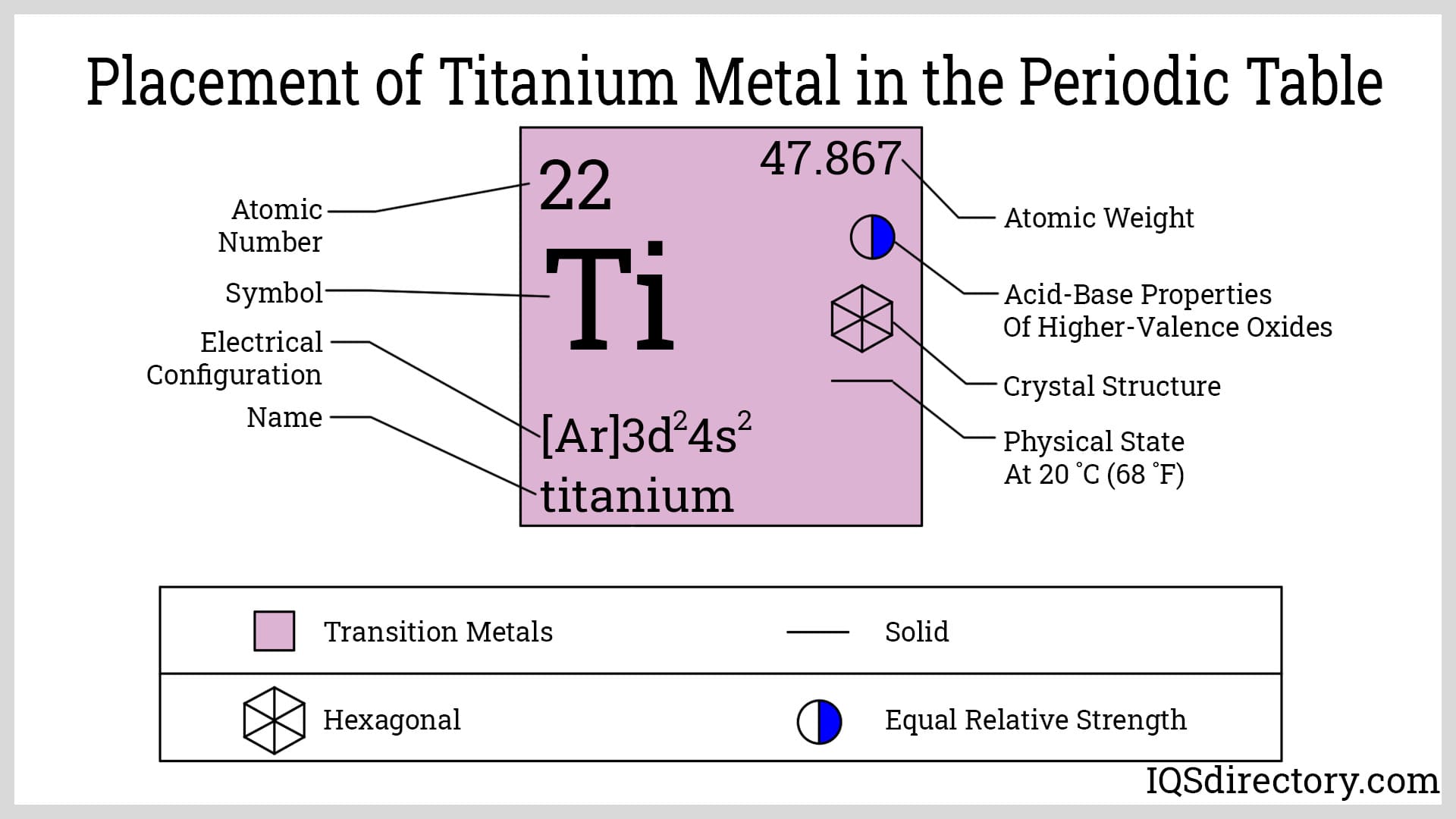

Titanium, symbolized as Ti, is a transition metal with atomic number 22 and an atomic weight of 47.90. This lightweight, silver-colored metal is widely present in the environment and in living organisms. Although titanium is the ninth most abundant element in the Earth's crust, it is the fourth rarest pure metal due to its reactivity. Titanium makes up around 0.62% of the Earth’s crust and is found in minerals, rocks, water, and other natural sources. In nature, titanium commonly occurs in oxide, trichloride, and tetrachloride forms.

Titanium FAQ

What is titanium and where is it found?

Titanium is a lightweight, silver-gray transition metal found naturally in minerals like ilmenite and rutile. Although it makes up about 0.62% of the Earth’s crust, it rarely occurs in pure form due to its reactivity.

Why is titanium used in aerospace and marine industries?

Titanium’s high strength-to-weight ratio and resistance to corrosion make it ideal for aerospace and marine applications. It withstands saltwater, high heat, and pressure, making it valuable for aircraft, submarines, and offshore equipment.

How strong is titanium compared to steel or aluminum?

Titanium is as strong as steel but nearly half its weight. It’s also 60% denser than aluminum yet twice as strong, offering excellent durability without sacrificing lightness.

What are the main types of titanium alloys?

Titanium alloys fall into three groups: Alpha, Alpha-Beta, and Beta. Alpha alloys are ductile and corrosion-resistant; Alpha-Beta alloys balance strength and formability; Beta alloys offer the highest strength and heat treatability for demanding parts.

What is the Kroll process used for in titanium production?

The Kroll process is the primary commercial method for producing titanium sponge. It reduces titanium tetrachloride using magnesium, yielding high-purity titanium suitable for alloying and manufacturing applications.

Why is titanium preferred for medical implants?

Titanium is biocompatible and closely matches the density of human bone. It resists corrosion inside the body, making it ideal for orthopedic implants, dental fixtures, and surgical tools.

Which countries produce the most titanium today?

Major producers of titanium sponge include China, Japan, Russia, Kazakhstan, the United States, Ukraine, and India. U.S. production has grown steadily, particularly in the aerospace and defense sectors.

Benefits of Titanium

Titanium offers a range of advantages, making it a top choice for many industries. Its benefits include the ability to form alloys, outstanding durability, low electrical and thermal conductivity, excellent strength-to-weight ratio, ductility, high resistance to corrosion and heat, a high melting point, and competitive pricing.

- Alloy-Ability

- Titanium can be combined with other metals to create strong and versatile alloys, expanding its use in various industries.

- Strength and Durability

- One of titanium’s greatest strengths is its exceptional durability. It is 60% denser than aluminum, yet twice as strong and much more robust, making it ideal for demanding industrial applications.

- Conductivity (Or Lack Thereof)

- Titanium has poor heat and electrical conductivity. While this may seem like a drawback, it actually makes titanium perfect for electrical appliances and equipment exposed to extreme temperatures.

- Cost

- With its superior strength and corrosion resistance, titanium pipes and fittings can be more cost-effective than those made from steel or stainless steel.

The History of Titanium

Titanium was discovered in 1791 in Cornwall, England by William Gregor, a clergyman and geologist. He noticed that black sand near a stream was magnetic. Upon examination, he found two metal oxides: one was iron oxide and the other, a white metallic oxide (later identified as ilmenite), contained a new metal. Gregor named the new substance Manaccanite after his local parish and published his findings in both the Royal Geological Society of Cornwall and the German journal Crell’s Annalen.

In 1795, Prussian chemist Martin Heinrich Klaproth rediscovered titanium dioxide in a mineral called rutile in Slovakia. He named the element titanium after the Titans of Greek mythology. After learning of Gregor's work, Klaproth confirmed that Manaccanite also contained titanium.

Pure metallic titanium (99.9%) was first produced in 1910 by Matthew A. Hunter at Rensselaer Polytechnic Institute using the Hunter process, which heated titanium tetrachloride (TiCl4) with sodium at 700–800°C under high pressure. In 1932, William Justin Kroll developed the Kroll process, initially using calcium and later magnesium to reduce TiCl4. The Kroll process remains the primary commercial method today, although ongoing research seeks even more efficient processes.

- During 1900’s and Beyond

- In the 1950s and 1960s, the Soviet Union adopted titanium for military and submarine equipment, especially aircraft, to gain a technological edge during the Cold War. Titanium’s unique resistance to atmospheric corrosion made it vital in jet planes. In response, the U.S. Department of Defense supported titanium commercialization and stockpiled the metal for decades. Since 2006, DARPA has funded projects to develop advanced titanium powder production for applications in defense, chemical processing, aerospace, and transportation.

- Today, titanium is utilized across numerous industries. Engineers in biomedical, aerospace, structural, and other fields continue to discover new applications for titanium. The metal’s role is expected to grow in sectors such as healthcare, marine, chemical and petrochemical processing, automotive manufacturing, water desalination, offshore energy production, and architecture.

Applications of Titanium

Titanium is used to manufacture parts and products for a broad range of critical and routine applications. Many components made from titanium are essential for the reliable operation of modern systems. Customers select titanium for its exceptional properties and performance benefits.

Industries where titanium excels include healthcare, aerospace, and defense. Because titanium’s density closely matches that of human bone, it is ideal for orthopedic implants. Additionally, sectors such as marine, metal fabrication, aquariums, automotive racing, and jewelry rely on titanium to manufacture durable and high-quality products.

Design of Titanium

Although titanium is lightweight, it is among the strongest materials available. It closely resembles zirconium and silicon in its properties, and like these elements, titanium is highly resistant to corrosion and heat. Its density, at 4510 kg/m3, is low compared to steel and aluminum, making it suitable for demanding applications in marine and aerospace environments. Titanium can withstand extremely high temperatures, up to about 3,000°F, and boils at around 6,000°F in its liquid state.

With a high strength-to-weight ratio, titanium is as strong as steel but only half its weight per volume. The most commonly used titanium in manufacturing is titanium alloy.

Titanium's unique combination of high tensile strength, low density, ductility, and heat transfer is often enhanced by alloying with other metals. Titanium steel is lighter and more corrosion resistant than standard steels; aluminum titanium alloys offer increased strength and finer structure; and alloys with iron, copper, and manganese benefit from titanium's properties.

Titanium Production Process

The titanium production process involves several steps: extraction, reduction to sponge, ingot formation, primary fabrication, and secondary fabrication.

- Extraction

- Although titanium is abundant (the ninth most abundant element on Earth), it is not found in pure form. It is primarily extracted from mineral sources such as ilmenite, where it occurs as a compound.

- Reduction to Sponge

- Once extracted, titanium is reduced into a porous form known as sponge. This step is commonly performed using the Kroll or Hunter processes.

- Titanium Ingot Formation

- The titanium sponge is then pressed or melted with alloying elements to create ingots—large blocks that are ready for further fabrication.

- Primary Fabrication

- Manufacturers process ingots into stock shapes that are in demand, such as titanium tubing, pipes, wire, bars, plates, foil, rods, and sheets. These materials are finished by hot or cold forming, rolling, extrusion, or welding, and are used as parts or stock for additional processing. Titanium in forms like foil, sheet, wire, granules, sponge, powder, mesh, and rod is easy to fabricate and highly valuable.

- Secondary Fabrication

- Secondary fabrication includes processes to create finished shapes and products, such as cold forming (pressing, bending, shearing), welding (plasma, laser, resistance, electron beam, MIG, friction), machining (drilling, grinding), cutting (torch, waterjet, laser), cladding (explosive bonding, mechanical lining, roll cladding, resistance weld lining, diffusion bonding), heat treating, annealing, and various surface treatments (turning, grinding, polishing). Titanium forgings produced through these methods are known for their exceptional strength.

- Titanium Metal Alloys

- Researchers have developed over a thousand titanium alloys. These can be categorized by grades or structural groups to match specific property requirements.

- Titanium grades identify the characteristics and applications of each alloy type, guiding manufacturers in selecting suitable grades. The ASTM recognizes 38 grades of titanium; the first five are unalloyed, while others contain elements like aluminum, cobalt, vanadium, tin, molybdenum, palladium, zirconium, niobium, nickel, ruthenium, silicon, and iron.

- The three main groups of structural titanium alloys are: Alpha titanium, Alpha Beta titanium, and Beta titanium. Alpha titanium, often alloyed with aluminum and tin, features low to medium strength, is non-heat treatable, weldable, very ductile, and retains high toughness at low temperatures. It offers the best corrosion resistance and is used for airplane parts and chemical processing equipment. Alpha Beta titanium has medium to high strength, is heat treatable, weldable, and suitable for hot forming, though it has limited cold forming capability. It is used in marine equipment, aircraft, and prosthetics. Beta titanium, while the smallest group, offers the highest strength, density, and is fully heat treatable and weldable. Its high formability makes it ideal for heavy-duty aircraft parts that must withstand extreme stress.

Titanium Images, Diagrams and Visual Concepts

Its location in the periodic table identifies titanium as a transition metal and explains its chemical bonding characteristics.

Its location in the periodic table identifies titanium as a transition metal and explains its chemical bonding characteristics.

The tensile strength of titanium is around 434 MPa, making it as strong as lower-grade steel alloys.

The tensile strength of titanium is around 434 MPa, making it as strong as lower-grade steel alloys.

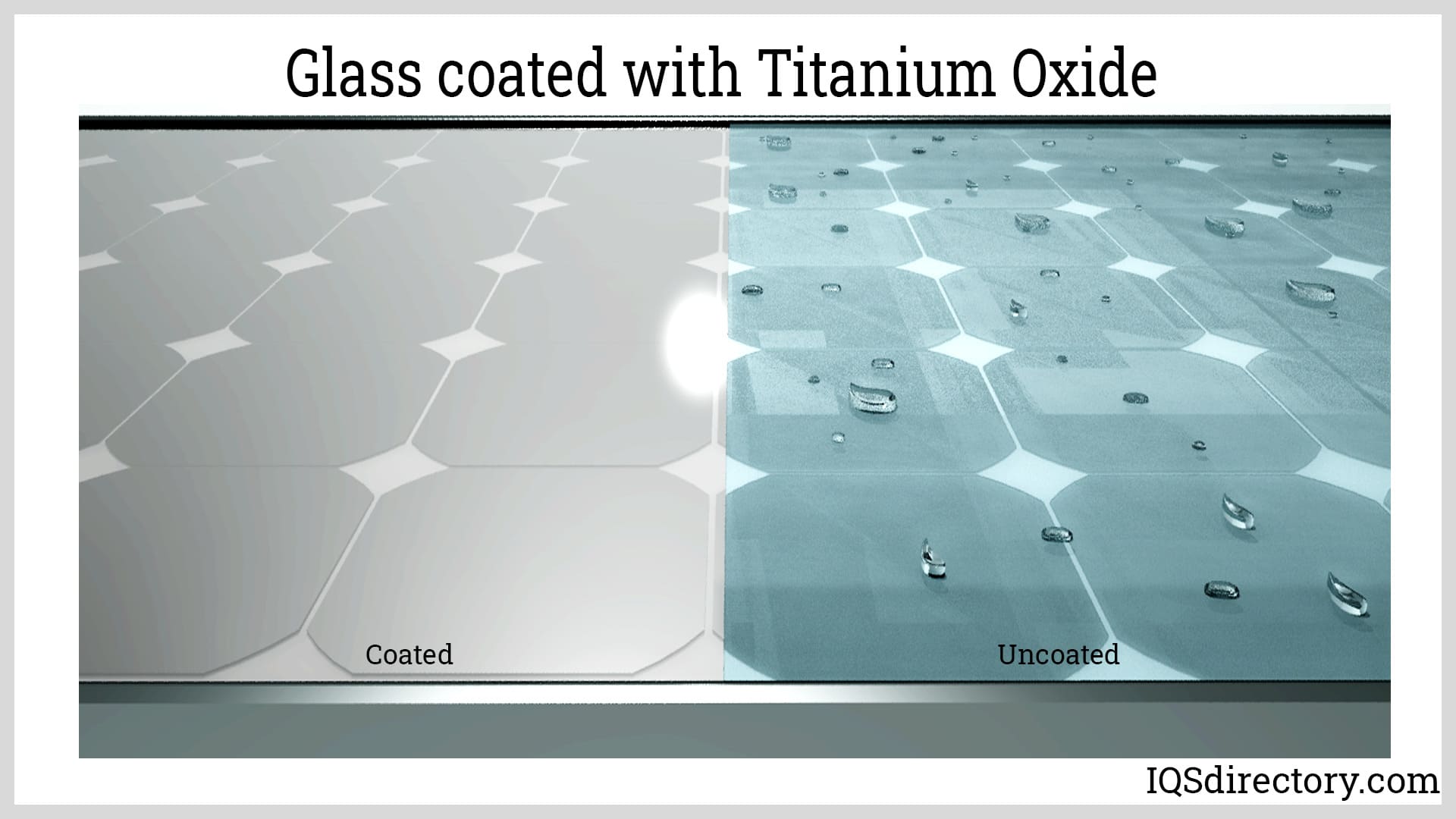

Titanium dioxide is a highly stable compound, resistant to corrosion, and maintains its color even in sunlight.

Titanium dioxide is a highly stable compound, resistant to corrosion, and maintains its color even in sunlight.

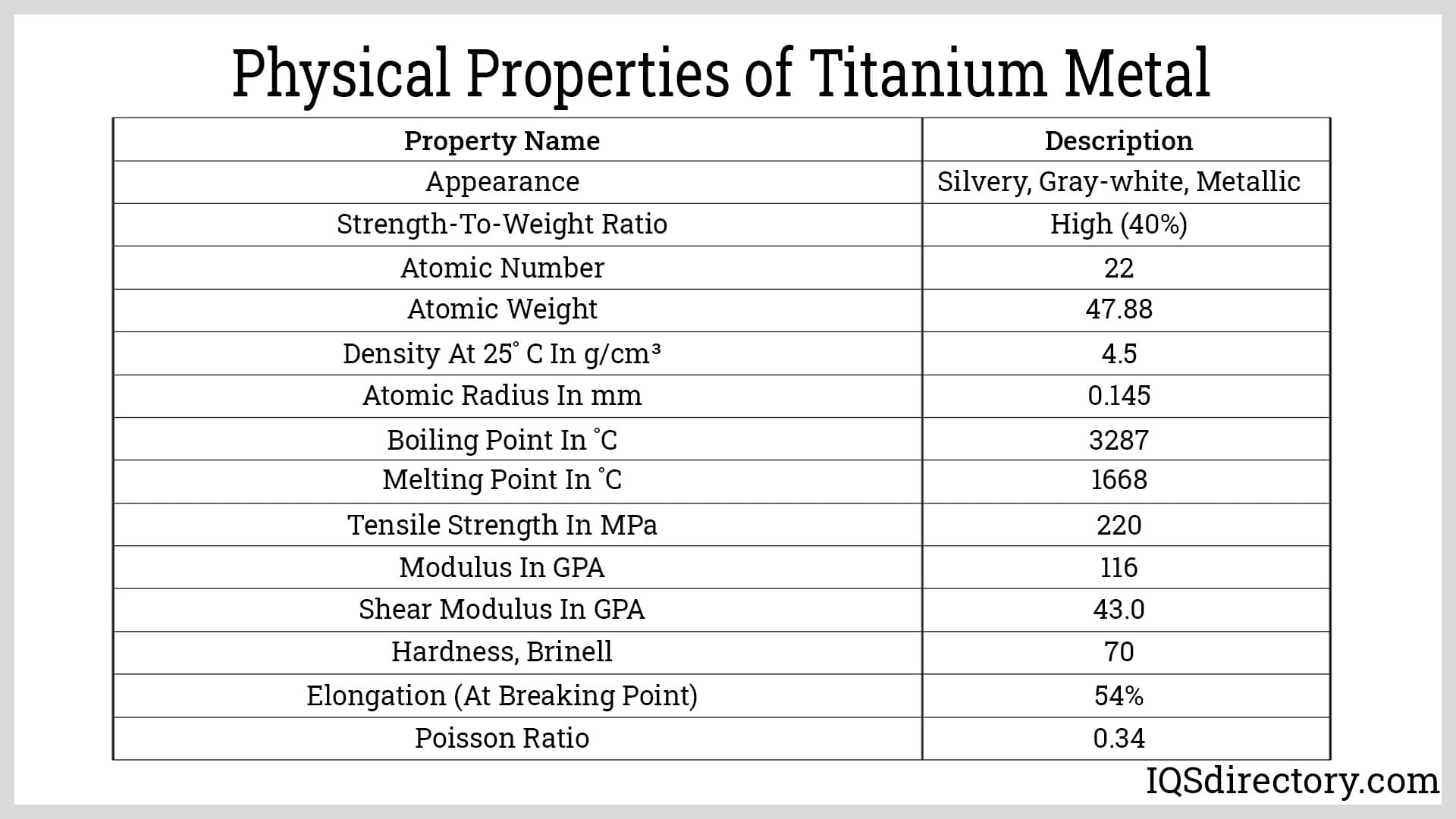

Titanium is known for its superior physical characteristics and is considered physiologically inert as an element.

Titanium is known for its superior physical characteristics and is considered physiologically inert as an element.

Types of Titanium

- 6Al-4V

- This widely used titanium alloy contains 90% titanium, 6% aluminum, and 4% vanadium.

- Aerospace Metals

- These metals, including titanium, aluminum beryllium, and nickel-based superalloys, offer enhanced properties due to specific alloying elements.

- Bought Titanium

- Available at different production stages, from raw mill products to finished components.

- Ferro-Titanium

- A blend of titanium sponge and scrap with iron, melted together to produce a single alloy for various applications.

- High Temperature Alloys

- Special materials with exceptional strength and corrosion resistance at temperatures above 1,000ºF (537ºC), containing large amounts of nickel and other critical elements like titanium, molybdenum, chromium, and columbium.

- Super Alloys

- Engineered for high strength and resistance to corrosion even under extreme temperatures. Commonly used in jet engines, turbines, and valves.

- Titanium Alloys

- Composite materials primarily composed of titanium, blended with other metals to achieve specialized properties.

- Titanium Bars

- Solid titanium pieces machined into bars, often supplied to manufacturers for further processing into finished goods.

- Titanium Billets

- Milled and hot-worked titanium products, shaped into round or square forms, typically used as starting material for forging or extrusion, starting at four inches in diameter.

- Titanium Bolts

- Threaded fasteners made from titanium, valued for their strength and corrosion resistance compared to bolts of other materials.

- Titanium Castings

- Produced by pouring molten titanium into molds, these complex products are used in diverse industries despite the challenges of titanium’s reactivity during casting.

- Titanium Foil

- Thin, flat titanium material produced during extraction, sold to manufacturers for secondary fabrication into various titanium products.

- Titanium Grades

- Classification system distinguishing different titanium and alloy types by their qualities and purities, essential for correct material selection.

- Titanium Ingots

- Large masses, sometimes over 10 tons, primarily made of titanium and alloying elements, often barrel-shaped and used for applications like heat exchangers and piping in heavy industries.

- Titanium Manufacturers

- Companies that supply a range of titanium products to various sectors.

- Titanium Metal

- An extremely strong, lightweight, and corrosion-resistant metal used in many industrial applications where these properties are critical.

- Titanium Pipes

- Hollow titanium tubes designed for transporting liquids and gases in industrial, commercial, and residential settings.

- Titanium Plates

- Commonly used in the medical field to repair or reconstruct the skull and other bone structures.

- Titanium Rods

- Known for their high strength-to-weight ratio, titanium rods are about 20% lighter than comparable steel rods when well-engineered.

- Titanium Sheet

- A thin, flat piece of titanium used in manufacturing and fabrication.

- Titanium Sponge

- Pure, porous titanium produced in a cellular form as a result of extraction processes.

- Titanium Tubing

- Features excellent strength, stiffness, and light weight. Titanium tubing, often made from a 3% aluminum and 2.5% vanadium alloy, is expensive due to the complexity of refining and processing.

- Titanium Wire

- Fine wire or braided cables made from titanium, increasingly used in biomedical and industrial applications for their strength and small diameter, with diameters ranging from 0.0015" to over 0.2".

Products Produced by Titanium

Titanium is used in a vast array of products. The following list categorizes these products by the industries in which they are utilized.

- Medicine and Healthcare Products

- Titanium is used to produce catheters and various orthopedic devices, such as joint replacements, hip prostheses, rods for scoliosis surgery, bone plates, heart stents, dental implants, bowl replacements, and wire and bars for assorted medical uses. When made with pure titanium, these products are less likely to cause allergic reactions or corrode within the body.

- Homecare and Consumer Products

- Titanium alloys are found in many everyday items, including paints, inks, toothpaste, cosmetics, and certain food products.

- Aerospace Products

- Titanium is essential to the aerospace industry, used in missiles, spacecraft, space stations, jet engines, and aircraft.

- Sports and Recreation Products

- Many types of sports equipment utilize titanium, with racing bicycles being a notable example.

- Marine and Naval Products

- Marine industries use titanium tubing and sheets for underwater ship components because titanium resists saltwater corrosion, stress, microbial attack, and pitting.

- Automotive Products

- Automotive manufacturers use lightweight, strong titanium plates for valve springs, rocker arms, connecting rods, exhaust systems, drive shafts, and steering gears.

- Chemical Products

- Titanium alloys are employed to create heat exchange coils, linings, and pump units in industrial and chemical plants.

- Gas and Oil Products

- Titanium is used as a coolant in condenser tubes in oil refineries.

- Industrial Products

- Titanium is increasingly used in construction for its lightweight and corrosion-resistant qualities, making it ideal for outdoor structures and applications.

- Miscellaneous Products

- Other titanium-based products include battery and semiconductor wires, agri-food tubing, paper, plastics, cement, and jewelry.

Things to Consider When Choosing Titanium

With so many titanium manufacturers and suppliers available today, selecting the right one can be overwhelming. Using a directory like this helps you quickly identify reputable titanium manufacturers. To find the best supplier, browse the list at the top of this page, visit their websites, and compare offerings. Contact several companies to discuss your needs, including application, technical requirements, industry standards, pricing, lead times, and delivery. Evaluate and compare their responses to choose the manufacturer who best meets your quality and service expectations.

Overseas Market of Titanium

As of 2015, titanium sponge was produced in major quantities by China, Japan, Russia, Kazakhstan, the United States, Ukraine, and India. China remains the top producer, but its supply currently exceeds domestic demand. Meanwhile, international companies like DuPont have reduced prices in recent years, which has impacted China’s export performance. By contrast, American titanium production and sales have increased over the past decade, particularly in the aerospace sector where innovation drives increased titanium usage. As a result, sourcing titanium from American suppliers is now highly competitive and supply is strong, with titanium prices remaining favorable.

Titanium Terms

- Alloy

- A homogeneous mixture or solid solution of two or more metals. Titanium is frequently used as an alloying element.

- Alpha Case

- A brittle, oxygen-rich surface layer formed on titanium during heat treatment in an oxygen environment. Alpha case must be removed before processing, as it can embrittle titanium and increase susceptibility to stress corrosion.

- Anodize

- A process that coats a metal surface with a protective or decorative oxide layer using electricity. Anodized colors on titanium do not fade because they are not produced by dyes or pigments.

- Blasting

- A mechanical process using grit or abrasives to remove scale from large titanium items like ingots and billets. Grit materials include silica, zircon, and aluminum, which are cleaned from titanium by pickling.

- Chromium

- An alloying element in titanium alloys, usually present in concentrations of 2-12% by weight.

- Density

- The mass per unit volume under standard conditions. Titanium’s density is 4,507 kg/m³, compared to silver’s 10,490 kg/m³.

- ELI (Extra Low Interstitials)

- Refers to reduced levels of oxygen, nitrogen, and carbon in titanium alloys, improving ductility and fracture toughness beyond standard alloy requirements.

- Embrittlement

- A loss of ductility or toughness in metals. In titanium alloys, embrittlement can be caused by hydrogen from water vapor, pickling acids, hydrocarbons, or exposure to liquid cadmium, mercury, and silver.

- Grade

- A classification number for titanium types, distinguishing qualities and purities among titanium and its alloys. Grade 2 is the most common unalloyed titanium; Grade 4 is the strongest pure type.

- Grains

- Microstructures joined together to form titanium. Controlling grain size and shape enhances mechanical properties of titanium alloys.

- Inclusion

- A foreign particle, such as an oxide, sulfide, or silicate, embedded in a titanium product. Inclusions can cause material failure if not properly addressed.

- Laser Cutting

- A popular method for precisely cutting thin titanium products to tight tolerances.

- Melting Point

- The temperature at which a solid turns to liquid at standard atmospheric pressure. Titanium’s melting point is 3,034°F (1,667.8ºC).

- Pickling

- A technique that removes oxide films from titanium surfaces using chemical baths.