Tungsten

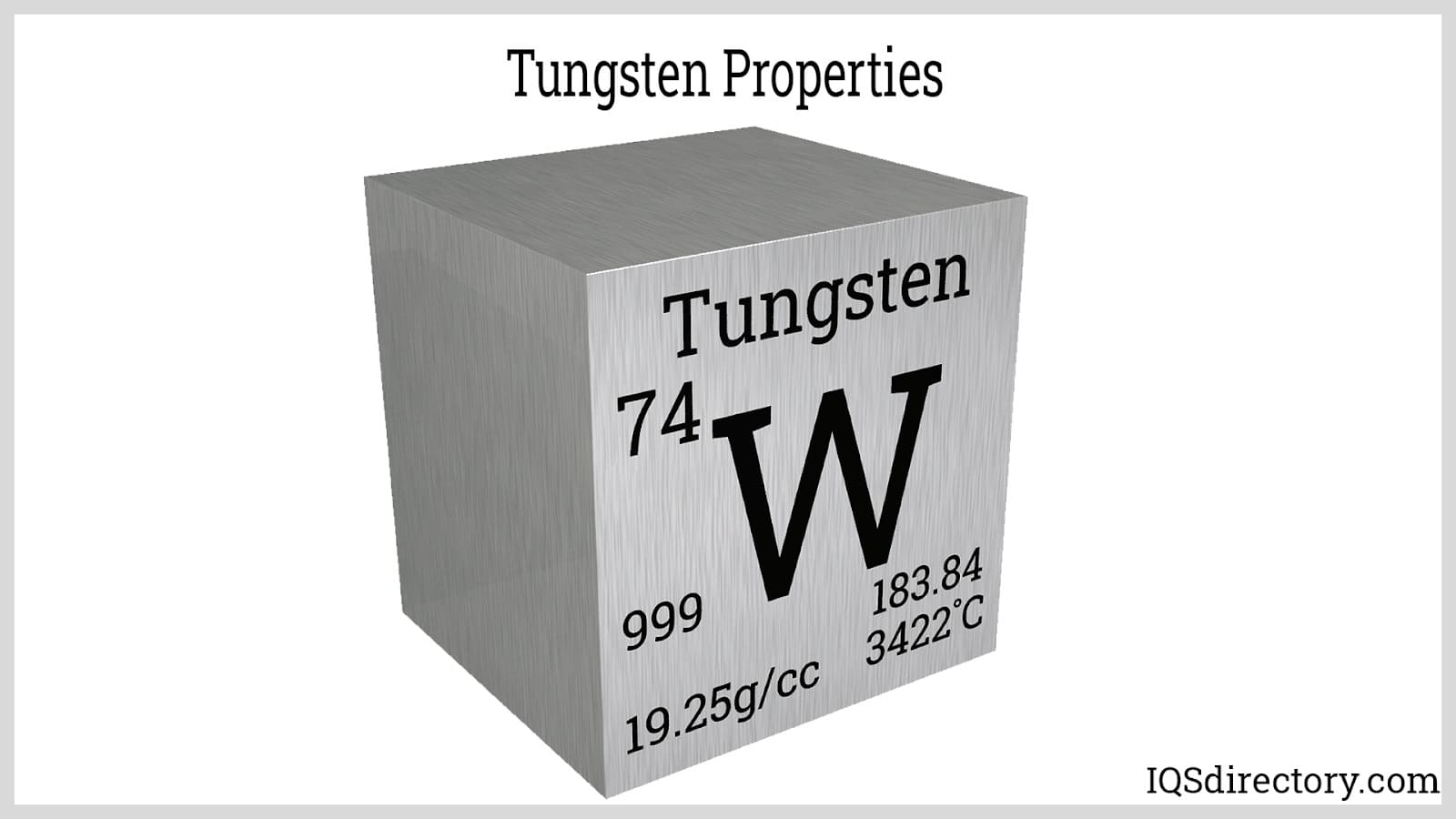

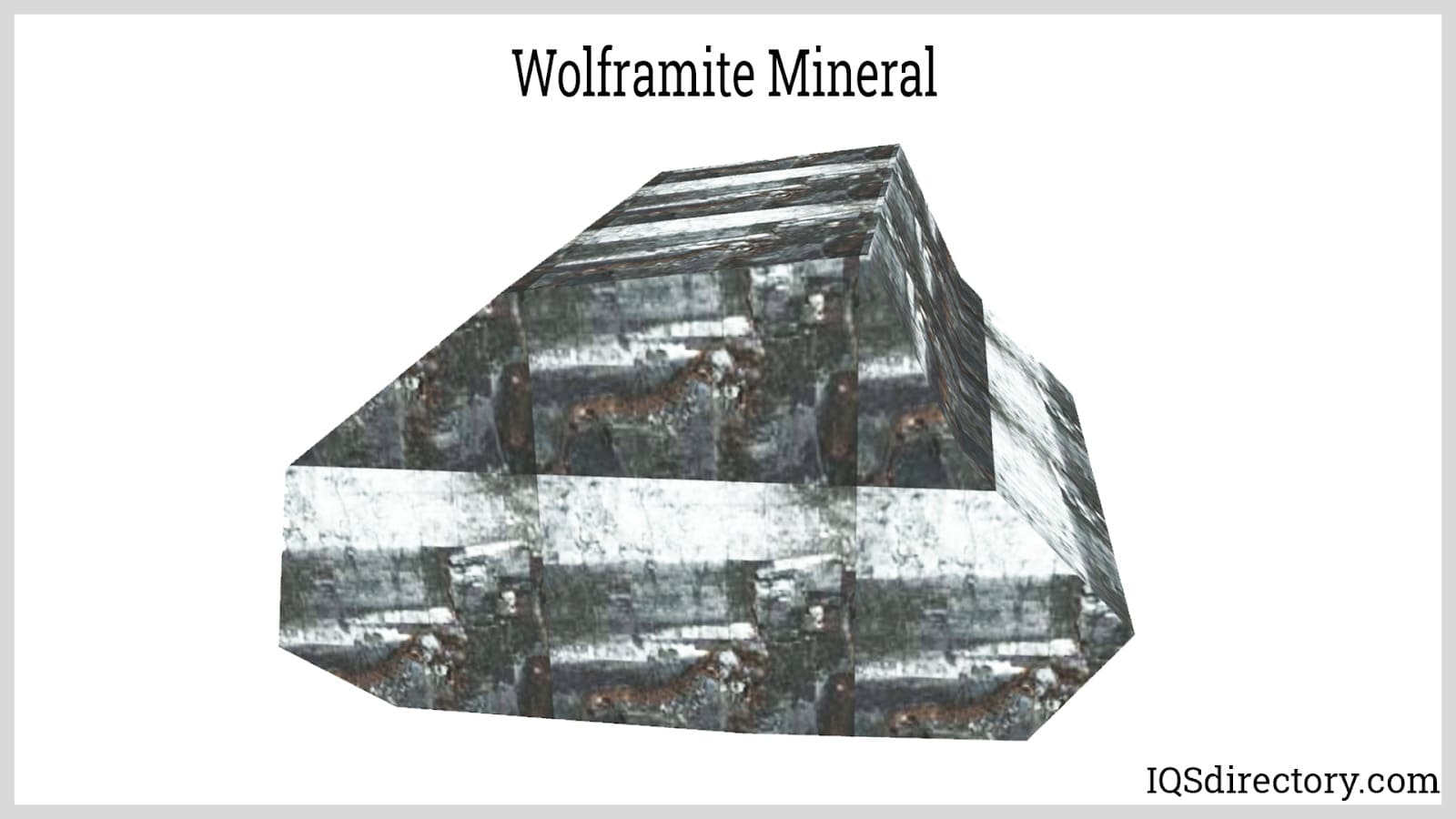

Tungsten is a naturally occurring metallic element with the atomic number 74, often referred to as "wolfram." Its main source is wolframite ore, which gives tungsten its periodic table symbol, W. Tungsten is also extracted from scheelite. Its color ranges from steel gray to tin white. Tungsten is renowned for its exceptional tensile strength, high density, and outstanding resistance to extreme temperatures. It holds the highest melting point (6192 °F) and the lowest vapor pressure among all pure metals. Additionally, tungsten is the heaviest usable chemical element.

Quick links to Tungsten Information

Benefits of Tungsten

Tungsten provides numerous advantages. It is low in toxicity, which benefits both humans and the environment. Tungsten is also highly recyclable, reducing production costs and minimizing environmental impact. The metal is extremely strong; when alloyed with carbon, it is surpassed in hardness only by diamond. Even in its pure form, tungsten rivals titanium in strength.

The History of Tungsten

Tungsten was first encountered in the 1500s by miners working in the Erz Mountains of Central Europe, along the border of present-day Germany and the Czech Republic. While mining tin, they discovered a troublesome mineral that caused slag and made tin extraction difficult. The miners called it "wolfrahm," meaning "wolf froth," because it "devoured" the tin like a wolf and formed a foamy layer during smelting. The mineral’s dark, hairy appearance contributed to its name. In 1546, Georgius Agricola noted this mineral in his work De Natura Fossilium, referring to it as "spuma lupi," Latin for "wolf froth" or "wolf cream."

- During the 1700’s

- Tungsten's name comes from another ore, scheelite, known in Swedish as "tung sten" or "heavy stone." In 1758, Swedish chemist Axel Fredrik Cronstedt named scheelite and believed he had found a new element, though he could not confirm it. Around 1781, Carl Wilhelm Scheele, also Swedish, successfully isolated tungsten. In 1783, Spanish chemists Fausto and Juan José de Elhuyar y de Suvisa reduced wolframite to obtain tungsten.

- During the 1800’s

- Efforts to create tungsten steel began in 1855, with the first tungsten-steel patents appearing in 1858. Initially, these steels were too expensive to gain popularity. Later in the century, tungsten became valuable for hardening and alloying steel, leading to the development of high-speed steels. These steels were showcased at the 1900 World Exhibition in Paris and remain widely used today.

- During the 1900’s

- In 1903, American engineer W.D. Coolidge developed ductile tungsten wire and pioneered tungsten powder metallurgy by doping tungsten oxide, producing a metal powder. He pressed, sintered, and forged the tungsten powder into tungsten rods, then drew fine wire from them. Using Coolidge’s tungsten filaments, European inventors built the first tungsten light bulb in 1904, replacing less efficient carbon filament bulbs.

- In 1923, German scientists, including Franz Skaupy and K. Schröter at Osram Studiengesellschaft, invented cemented carbide, also known as hardmetal. Osram allowed its patent to expire, and Friedrich Krupp AG acquired it in 1926, using cemented carbide extensively during World War II.

- Since then, tungsten and tungsten alloys have played significant roles in various industries. Although tungsten light bulbs lost favor around 1950, tungsten found new uses. In 1969, corrosion-resistant tungsten coatings were introduced. Today, tungsten is vital to high-tech sectors including semiconductors and aerospace.

Applications of Tungsten

Tungsten metal's extremely high melting point and superior hardness at elevated temperatures make it ideal for demanding applications such as light bulb filaments, cathode tubes, vacuum tube filaments, arc welding, gas tungsten arc welding, and electrical discharge machining.

Tungsten is used across many industries, including construction, aerospace, engineering, semiconductors, consumer products, jewelry, laser welding, industrial machinery, mining, electronics, lighting, and healthcare.

Design of Tungsten

Tungsten and its alloys possess excellent electrical and thermal conductivity, making them valuable in electrical engineering. They also have superior resistance to corrosion. However, tungsten in its raw form is quite brittle, which can make it challenging to process, especially when subjected to mechanical stress.

Tungsten Production Process

To produce tungsten products, manufacturers usually begin by sintering or molding tungsten and its alloys into billets, which are solid blocks or bars (see suppliers listed here). These billets are then fabricated into tungsten bar, tungsten sheet, tungsten plate, tungsten foil, rods, or tungsten wire using methods such as drawing, grinding, molding, and die cutting. Additional finishing may be required for certain products.

Tungsten products are available in three conditions: black, which retains a lubricant and oxide coating; cleaned, where the coating is chemically removed; and ground, in which the coating is removed and the tungsten is precision-machined with diamond or silicon carbide tools to achieve specific smoothness and diameter.

Tungsten Images, Diagrams and Visual Concepts

Tungsten is a durable tin white or steel gray metal, considered among the hardest metals found on earth.

Tungsten is a durable tin white or steel gray metal, considered among the hardest metals found on earth.

Tungsten is a naturally occurring element extracted from the minerals wolframite and scheelite.

Tungsten is a naturally occurring element extracted from the minerals wolframite and scheelite.

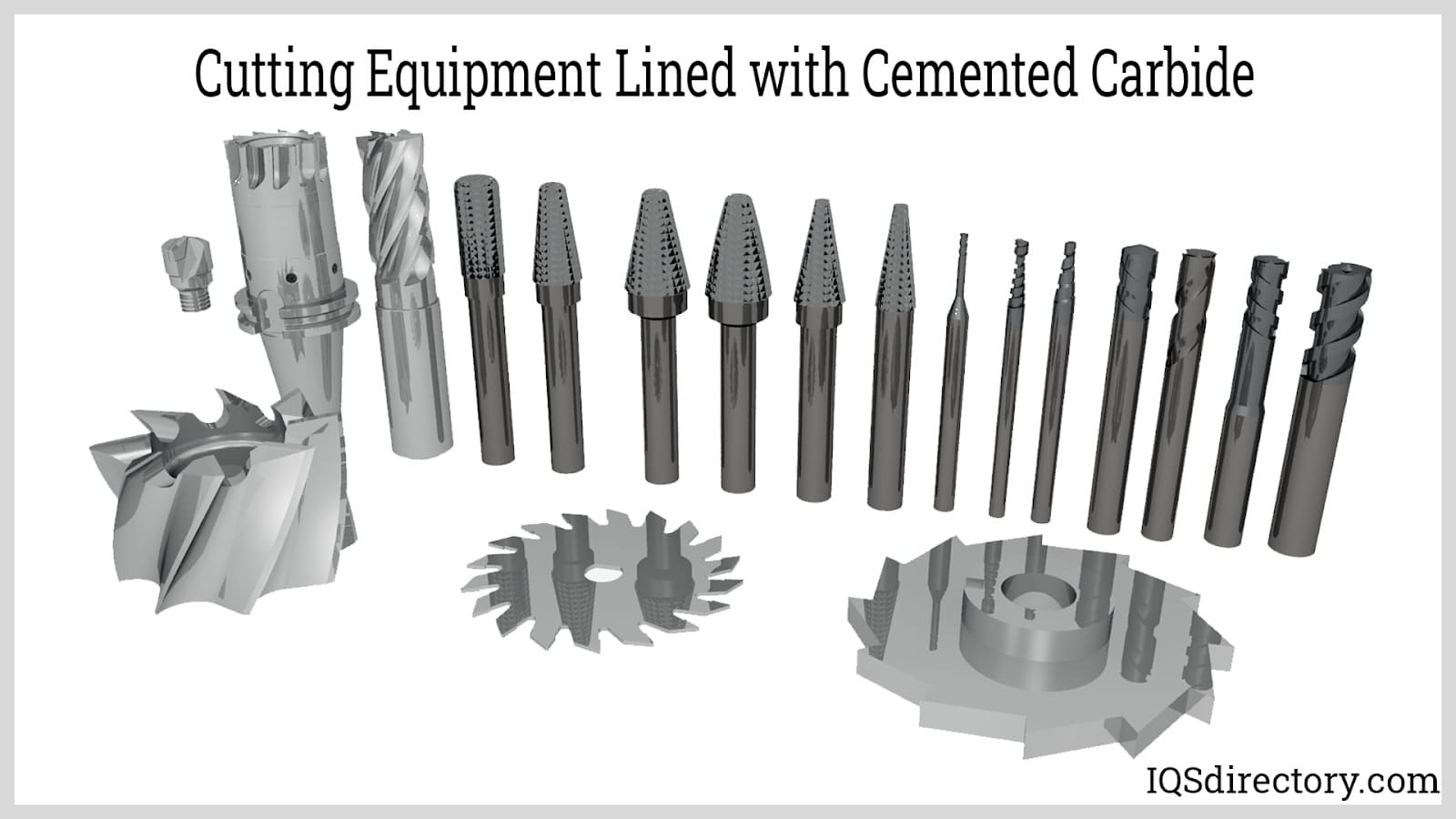

Products manufactured from tungsten are used in applications ranging from electrodes to construction machinery.

Products manufactured from tungsten are used in applications ranging from electrodes to construction machinery.

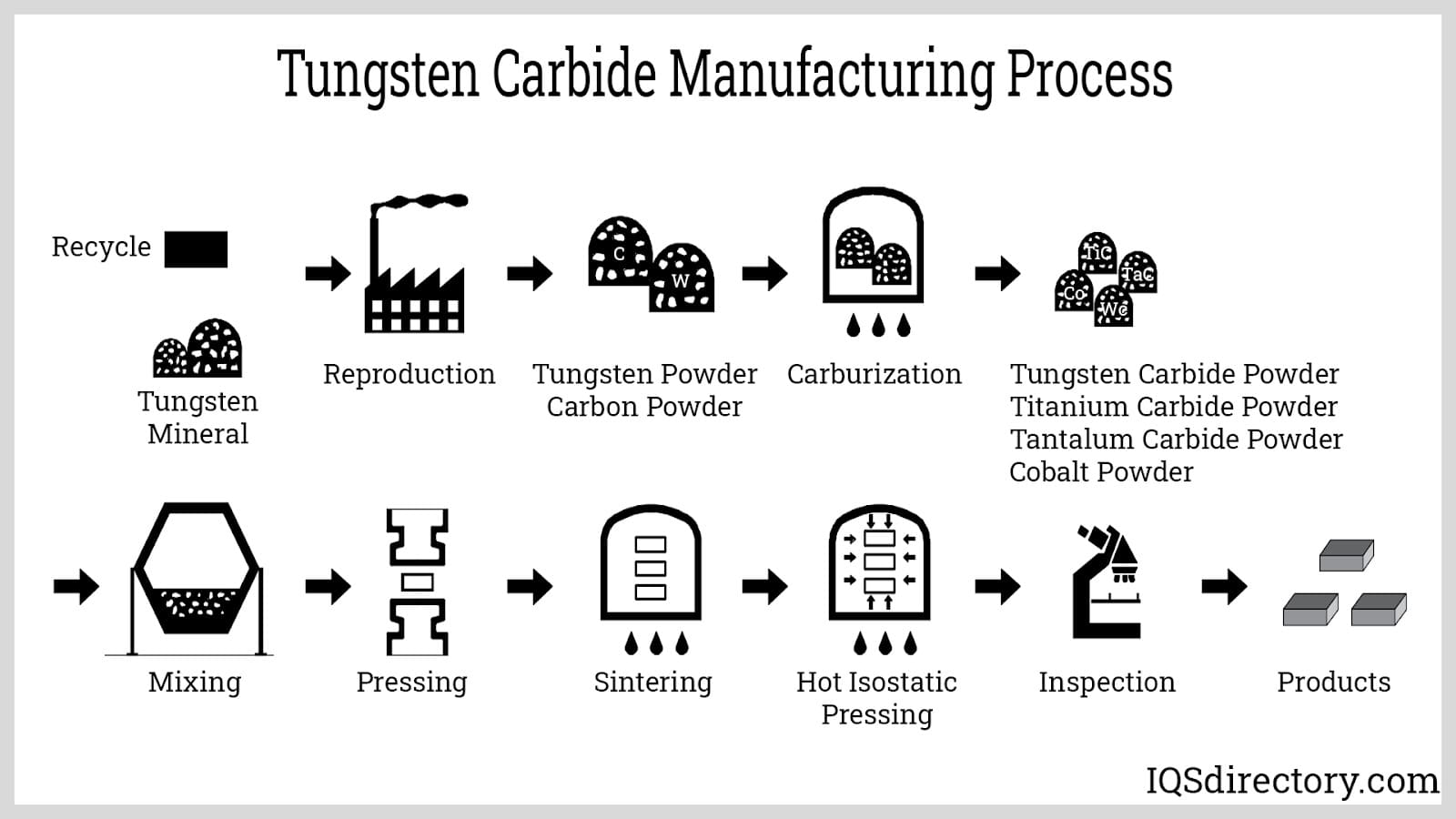

Cemented carbide, a common tungsten alloy, is formed by combining tungsten carbide with cobalt as a binding agent.

Cemented carbide, a common tungsten alloy, is formed by combining tungsten carbide with cobalt as a binding agent.

Tungsten carbide alloys are produced by reacting tungsten with carbon at high temperatures or through a low-temperature fluid bed process.

Tungsten carbide alloys are produced by reacting tungsten with carbon at high temperatures or through a low-temperature fluid bed process.

Alloyed tungsten describes various alloys created by mixing tungsten with other metals.

Alloyed tungsten describes various alloys created by mixing tungsten with other metals.

Heavy metal tungsten alloys contain up to 90% tungsten and may include around 2% thorium oxide.

Heavy metal tungsten alloys contain up to 90% tungsten and may include around 2% thorium oxide.

Pure tungsten features high electrical conductivity and is used to make connections in circuit panels.

Pure tungsten features high electrical conductivity and is used to make connections in circuit panels.

Types of Tungsten

Tungsten suppliers provide tungsten in five main categories: tungsten carbide, cemented carbide, alloyed tungsten (including heavy metal tungsten alloys), pure tungsten, and tungsten-based chemicals. Tungsten alloys are further classified by their tungsten content and tensile strength.

- Tungsten Carbide

- Composed of equal parts carbon and tungsten, this compound is extremely strong and highly wear-resistant. Tungsten carbide is twice as hard as the best steel and denser than titanium or steel. Over 20 grades of tungsten carbide powder exist, each with unique grain size, hardness, tensile strength, and melting point properties.

- Tungsten manufacturers press and sinter tungsten carbide into a variety of robust tools and parts. Tungsten carbide and crushed tungsten carbide are widely used in metalworking, mining, and construction. In fact, 60% of tungsten carbide products serve these industries.

- Cemented Carbide

- A widely used tungsten alloy, cemented carbide is tungsten carbide bonded with cobalt. The cobalt binder prevents brittleness in high-pressure applications, making this alloy suitable for structural and cutting tools. These wear-resistant materials are essential in metalworking, mining, and construction.

- Alloyed Tungsten

- This general category includes many tungsten alloys mixed with various metals, commonly copper or iron. Most suppliers offer tungsten alloys such as copper tungsten and tungsten carbide for industrial or commercial use.

- Heavy-metal Tungsten Alloys

- These alloys contain at least 90% tungsten with minor additions of other elements. Heavy metal tungsten alloys are often combined with about 2% thorium oxide to enhance gas tungsten arc welding electrodes, improving thermionic electron emission and arc starting characteristics.

- Pure Tungsten

- Known for extremely high electrical conductivity, pure tungsten is primarily used in electronics to connect components on circuit panels.

- Tungsten-based Chemicals

- The rarest form of tungsten, these chemicals are used in the production of organic dyes, pigment phosphors, and x-ray screens.

Products Produced from Tungsten

Tungsten materials are used to manufacture a broad array of products such as tungsten electrodes, light bulbs, drilling tools, industrial machinery parts, weapons, tungsten boats for vacuum evaporation and material coating, construction equipment, and x-ray screens. Tungsten alloys serve in armaments, heat sinks, turbine blades, industrial components, and dense products like ballasts and weights. Tungsten coatings can also be applied to tools, significantly extending their service life.

Tungsten electrodes are among the most widely used tungsten products. In electric arc welding, these electrodes conduct high voltages to metal surfaces, generating heat that fuses the parts together. They are also essential for electric discharge machining and gas tungsten arc welding.

Things to Consider When Choosing Tungsten

When sourcing tungsten products, it is important to choose a trustworthy and experienced tungsten supplier, such as those featured on this page. Ensure they understand your requirements, including budget, timeline, delivery needs, and quality standards. Additionally, confirm they have the capacity to meet your order volume and maintain high-quality production. The best supplier will offer reliable service and the ability to fulfill your specific needs.

To identify the ideal manufacturer, review the interactive profiles and websites provided. Select several companies to contact directly, discuss your project with them, and compare their responses. This process will help you select the tungsten supplier best suited for your application.

Overseas Market of Tungsten

The broad range of tungsten applications keeps demand high in industrial and commercial markets. Approximately 45,000 tons of tungsten are mined annually, primarily in China and Russia. Other significant producers include Portugal, Austria, Peru, and Bolivia. In the United States, tungsten mining is nearly nonexistent due to environmental concerns, low import prices, and shifting government policies. Still, affordable imports allow U.S. companies to offer competitively priced tungsten products. Additionally, tungsten’s recyclability means manufacturers can reuse the material repeatedly.

Working with U.S.-based manufacturers offers several benefits, including improved communication, faster delivery, fewer regulatory hurdles (such as tariffs and shipping costs), and a thorough understanding of domestic laws and regulations relating to tungsten. These advantages make partnering with an American manufacturer a strong option, even with the availability of overseas suppliers.

Tungsten Terms

- Alloy

- A solid solution or homogeneous mixture formed by combining two or more metals or elements.

- Brittle

- Prone to breaking under stress; brittle materials exhibit minimal deformation before fracturing.

- Filament

- A thin metal wire, typically made of tungsten, that emits light when electricity passes through it in a bulb.

- Melting Point

- The specific temperature at which a solid material transitions to a liquid state.

- Superalloy

- An alloy exhibiting high strength, hardness, and excellent resistance to corrosion, usually based on nickel, cobalt, or iron.

- Tensile Strength

- In engineering, the maximum stress a material can withstand before failure under tension.

- Wolfram

- Another name for tungsten, originating from wolframite ore, the principal source of the metal.