Vacuum Cleaners

Vacuum cleaners are powerful cleaning machines that rely on suction to collect dirt, dust, industrial waste, and other debris for disposal, recycling, or reuse. A vacuum is created when air is fully or partially removed from a space, leading to a pressure imbalance. On Earth's surface, every object is subject to atmospheric pressure. When air pressure drops in a particular area, higher-pressure air from surrounding spaces rushes in to restore equilibrium—a principle that also explains the movement of wind. Vacuum cleaners take advantage of this phenomenon by using fans or a system of fans to artificially reduce air pressure within their collection chambers. As external air flows in to equalize the pressure, it carries dust, dirt, and other particles along with it, effectively pulling debris into the machine.

All vacuum cleaners operate using an air pump, typically a centrifugal fan, to generate the suction force necessary for extracting dirt and debris from floors, furniture, and other surfaces. The primary distinction between commercial and industrial vacuum cleaners lies in their scale and capabilities. Industrial vacuums are built for heavy-duty applications, tailored to professional cleaning and industrial maintenance needs, while commercial vacuums are designed for more economical, light-duty cleaning tasks. Smaller, portable vacuum cleaners collect debris in fabric filter bags or removable plastic containers, often supplemented by disposable filters lined with larger, secondary filters to enhance air purification. Many vacuum models accommodate specialized attachments for cleaning various surfaces and hard-to-reach spaces. Carpet vacuums are typically equipped with agitators that loosen dirt from carpet fibers, while automotive vacuums feature attachments designed for maneuvering through tight spaces. Continuous duty vacuums incorporate large collection chambers that can be emptied quickly and efficiently, ensuring minimal downtime before resuming operation.

Every manufactured product must be made somewhere, and most are produced by companies that follow streamlined processes to maximize efficiency. These processes generate vast amounts of debris, requiring effective cleanup solutions. Vacuum cleaners serve as ideal industrial cleaning tools, offering a superior alternative to sweepers, which can stir up dust—sometimes creating hazardous conditions. Additionally, vacuums require minimal labor, making them an efficient choice for industrial environments.

Designed for versatility, industrial vacuums can be configured to collect nearly any type of material. Whether dealing with fine powders, abrasives, explosive media, litter, non-free-flowing substances, metalworking chips, toxic materials, coolant, oil mist, or welding fumes, vacuums can be customized to handle the task. However, the design of a vacuum built for wood chips differs significantly from one intended for liquid waste, ensuring optimal performance based on the specific application.

Beyond waste removal, vacuums play a crucial role in reclaiming and reusing valuable materials from industrial processes. Unlike other collection methods, vacuums preserve the integrity of these materials, allowing them to be processed and reused efficiently. Specialized filters help separate unwanted contaminants like dust and dirt, ensuring only the desired materials are recovered. Once collected, these materials can be cleaned and reintegrated into production, reducing waste and improving sustainability.

An added advantage of using vacuums in industrial settings is their ability to enhance air quality. When equipped with HEPA filters, vacuums not only remove larger debris but also capture fine particulates that can degrade workspace air quality. In facilities where large volumes of dust or shavings are produced, HEPA-filtered vacuums provide an essential layer of protection, maintaining cleaner, safer working conditions.

Industrial Vacuum Cleaners FAQ

How do industrial vacuum cleaners create suction?

Industrial vacuum cleaners use an air pump, often a centrifugal fan, to reduce air pressure inside the unit. As surrounding air rushes in to balance pressure, it carries dust and debris into the vacuum chamber for collection and filtration.

What distinguishes industrial vacuum cleaners from commercial models?

Industrial vacuum cleaners are built for heavy-duty cleaning in manufacturing and warehouse environments. They feature larger collection chambers, stronger suction, and continuous-duty motors, unlike commercial models designed for lighter, intermittent cleaning tasks.

Why are HEPA filters important in industrial vacuums?

HEPA filters capture 99.97% of particles 0.3 microns or larger, improving air quality by trapping dust, allergens, and contaminants. In industrial settings, HEPA filtration maintains cleaner air and supports OSHA compliance for worker safety.

What are explosion-proof vacuums used for?

Explosion-proof vacuums are designed for facilities handling combustible dust or flammable materials. Built to prevent ignition, they are essential in ATEX-regulated zones or industries dealing with volatile substances like chemicals and fine powders.

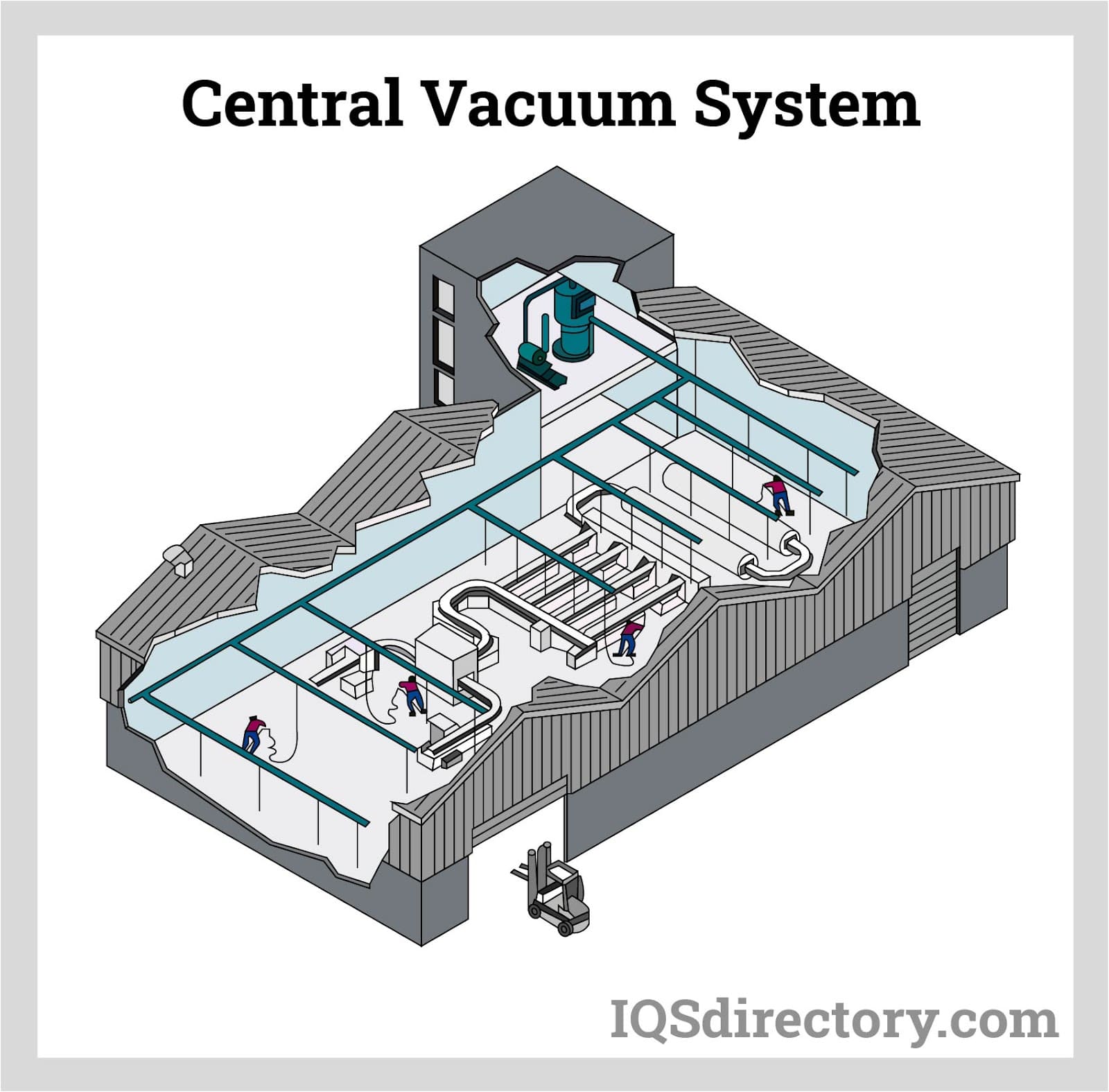

How do central vacuum systems benefit large facilities?

Central vacuum systems integrate multiple inlets into one unit, reducing noise and simplifying maintenance. Common in schools, factories, and Midwest manufacturing plants, they enable continuous cleaning without moving portable vacuums between areas.

What materials can industrial vacuums handle?

Industrial vacuums can collect a wide range of materials, including powders, metal shavings, abrasives, coolant, and liquids. Units are configured for specific uses, such as handling oil mist in machine shops or reclaiming metal chips for reuse.

What are key factors when selecting an industrial vacuum?

Consider airflow, water lift, and duty cycle. High airflow is best for fine dust, while strong water lift suits heavy debris or liquids. Continuous-duty models fit demanding environments, and multi-stage systems offer higher performance for long-term industrial use.

Applications of Industrial Vacuum Cleaners

Industrial vacuum cleaners come in many forms, each designed for specific applications. Small vacuum cleaners and portable industrial vacuums, though sometimes used in industrial settings, are primarily found in commercial environments where cleaning demands are less intensive. However, industries like woodworking and metalworking, where debris accumulates continuously, require vacuum equipment that surpasses the capabilities of commercial models. Continuous duty vacuums are engineered for round-the-clock operation, ensuring uninterrupted debris collection with minimal downtime. In environments where hazardous materials pose a risk, explosion-proof vacuums are essential for reducing the likelihood of fires or other dangers. HEPA vacuum cleaners are frequently deployed on manufacturing floors, serving a dual purpose—removing debris while filtering and improving air quality. Auto vacuums, including wet-dry models, are specialized high-capacity systems designed for vehicle cleaning. In building maintenance and large-scale industrial applications, central vacuum systems provide an efficient, built-in solution for debris collection by linking multiple vacuuming inlets to a single, centralized unit.

Various portable vacuum configurations further enhance versatility. Backpack vacuums, canister vacuums, walk-behind or rider vacuums, and vacuum trucks offer different mobility options depending on the application. Most vacuum cleaners are at least semi-portable, and many are highly mobile, even continuous duty models, which are often mounted on wheels for easier maneuverability in warehouses or factory settings. The least portable of all vacuum systems are central vacuum systems, which offer significant advantages in large buildings where continuous cleaning is required. These systems feature built-in ductwork with strategically placed inlets, allowing maintenance personnel to attach hoses and vacuuming accessories without the need for multiple portable machines. Since the central vacuum unit is usually housed in a remote mechanical closet or basement, noise levels are significantly reduced, making these systems ideal for environments like schools and universities where cleaning must be performed without disrupting daily activities. Additionally, central vacuum systems streamline maintenance by consolidating debris collection into a single unit, eliminating the need for multiple vacuums and filters, which simplifies servicing and enhances overall efficiency.

History of Industrial Vacuum Cleaners

Industrial vacuum cleaners trace their origins to a series of smaller, less powerful models, beginning with manually operated designs. In the 1860s, Daniel Hess developed one of the earliest versions, featuring a rotating brush and bellows to generate suction. This was followed by the first powered vacuum, patented in 1898 by John S. Thurman, which used air to blow dust into a receptacle rather than drawing it in. While some early models incorporated suction, true vacuum technology advanced rapidly in the following years. By 1905, British manufacturer Walter Griffiths introduced the first commercially available domestic vacuum cleaner, followed in 1906 by James B. Kirby’s “Domestic Cyclone.” Kirby’s innovations laid the foundation for the well-known Kirby Vacuum brand.

Through the 1920s and 1930s, vacuum cleaner technology underwent significant refinements. Industrial designer Henry Dreyfuss, working with Hoover, revolutionized vacuum design by making it lighter, more efficient, and visually appealing, even adding a full-bag indicator. Despite these advancements, vacuum cleaners remained a luxury until after World War II, when mass production made them household staples.

Industrial vacuum cleaners gained widespread use in the latter half of the 20th century as technology advanced to meet the growing need for large-scale debris removal and air purification. With innovations such as the wet-dry vacuum, capable of handling both liquid and solid waste, businesses and manufacturers could efficiently clean workspaces with powerful, specialized machines. Today, industrial vacuums continue to evolve, adapting to new challenges across various industries while improving performance, safety, and efficiency.

Industrial Vacuum Cleaner Production and Design

Industrial vacuum cleaners come in a variety of styles, each suited for specific applications. Some of the most common include auto vacuums, backpack cleaners, canister vacuums, central vacuum cleaners, continuous duty vacuums, explosion-proof vacuums, HEPA vacuum cleaners, rider sweepers (also known as walk-behind sweepers), and vacuum cleaner trucks.

- Production Process

- Industrial vacuum cleaners are assembled on a production line with dedicated subassembly stations. Small metal components are typically supplied by subcontractors and stored by the manufacturer until needed for assembly. Meanwhile, plastic components such as exterior housings, hoses, handle parts, wheels, and bag supports are often produced on-site using injection molding. This method ensures consistency, durability, and the ability to manufacture high-volume parts with precision.

- Materials

- The materials used in industrial vacuums vary based on their intended use. Wet-dry vacuums, for instance, typically feature housings made from rotationally molded polyethylene, ensuring durability and resistance to moisture. Canister vacuums often include removable canisters made from high-strength plastic, while dust bags are constructed from woven or non-woven synthetic fiber. Many dust bags are lined with plastic to enhance filtration efficiency. Stainless steel is another key material in industrial vacuums, providing structural strength and corrosion resistance. Some models, like tank shop vacuums, are built almost entirely from stainless steel, making them particularly robust for heavy-duty applications.

Design Aspects

- Airflow

- The velocity of the air stream generated by a vacuum cleaner’s motor varies based on the application. Some industrial vacuums require stronger airflow to handle dense or heavy debris, while others are designed for lighter particulate collection. To increase suction power, manufacturers adjust air pressure levels to optimize performance for different environments.

- Filter

- Filters are a critical component of industrial vacuum cleaners, designed to match the type of material being collected and the required cleanliness level. Some filters are specialized for dry materials, while others are engineered to handle wet substances. Many industrial vacuums feature dual-function filters capable of collecting both. Precision filters, such as water filters, force contaminated air through a water bath before releasing it back into the environment, preventing dust particles from becoming airborne again. Other vacuums use activated charcoal filters, which trap odors and contaminants, improving air quality in the workspace

- Dirt Storage

- Once debris is collected, industrial vacuums manage dirt storage in different ways. Some models utilize separation chambers that spin the air to isolate dust particles from the airflow, enhancing efficiency. Others rely on disposable or reusable bags, providing a straightforward and effective method of debris containment. Each design approach is tailored to the specific needs of industrial applications, ensuring optimal performance and ease of maintenance.

Benefits of Industrial Vacuum Cleaners

- Fast, Large-Scale Cleaning

- Industrial vacuum cleaners are built for efficiency, allowing for large-scale cleaning with minimal effort. Designed with powerful suction and specialized attachments, they effectively tackle even the most demanding cleaning applications, ensuring thorough debris removal across expansive spaces.

- Improved Air Quality and Health

- Equipped with advanced filtration systems, including HEPA filters, industrial vacuums effectively capture allergens, bacteria, industrial debris, and airborne contaminants. By preventing these particles from recirculating in the air, they contribute to a healthier environment for employees and customers, reducing respiratory risks and improving overall workplace safety.

- Long-Term Savings

- Engineered for durability, industrial vacuum cleaners are built to withstand harsh conditions and extended use. While their upfront cost is higher than residential models, their longevity and superior performance result in significant cost savings over time. Fewer replacements, reduced maintenance, and increased efficiency make them a smart investment for businesses.

- Deep Cleaning

- With greater suction power and specialized technology, industrial vacuums penetrate deep into carpets, rugs, and flooring to extract embedded dirt and debris. Their ability to deliver a more thorough clean ensures surfaces remain in top condition, reducing wear and extending the lifespan of flooring materials.

Installation of Vacuum Cleaners

Most vacuum cleaners are portable and require no installation beyond access to a power outlet. However, central vacuum systems necessitate a more involved setup. Installing a central system involves integrating processing lines, hoses, tubing, and attachments with the facility’s duct inlets. Additionally, a suitable location must be designated for housing the vacuum’s motor and dirt filtration unit, ensuring optimal performance and minimal noise disruption.

Industrial Vacuum Cleaner Standards and Compliance

In the United States, industrial vacuum cleaners must comply with regulations set by OSHA (Occupational Safety and Health Administration) to ensure workplace safety and proper handling of industrial debris.

For those operating within the European Union in environments where explosive atmospheres may be present, compliance with the ATEX directive is essential. This directive consists of two regulations governing the type of equipment permitted in potentially explosive environments and the safety standards required for those workplaces. Such areas, known as ATEX zones, are categorized based on atmospheric conditions, and both the manufacturer and user must adhere to the specific standards applicable to their assigned zone.

Beyond these broad regulatory requirements, industrial vacuums must also meet industry-specific standards. For example, vacuums used in large restaurants must comply with FDA regulations to ensure they meet hygiene and sanitation requirements. Each application has unique compliance needs, making it crucial to verify that the vacuum system aligns with the necessary standards for its intended use.

Points to Consider When Selecting an Industrial Vacuum

- Power

-

Evaluating a vacuum’s power and performance goes beyond just considering horsepower. Instead, airflow and water lift specifications determine its effectiveness. A vacuum with high airflow is ideal for capturing fine, powdery substances like dry whey or flour, while one with strong water lift is better suited for collecting heavier debris such as cooking oil, water, or dense particles. Understanding these metrics ensures the right vacuum is selected for the intended application.

- Continuous Duty vs. Intermittent Duty

- Industrial vacuums are categorized as either continuous duty or intermittent duty models. Continuous duty vacuums are designed for prolonged operation and can efficiently handle heavy debris, making them ideal for demanding industrial settings. Intermittent duty vacuums, on the other hand, are better suited for lighter workloads and occasional cleaning, where extended run times are not required.

- Single-Stage vs. Multiple Stage

- For the most challenging industrial environments, multi-stage continuous duty vacuums—typically two- or three-phase units—offer superior efficiency, durability, and reliability. They are built to withstand heavy use and maintain consistent performance over long periods. In contrast, single-phase units are best for general cleanup tasks in less demanding conditions. While effective for short-term use, they do not have the longevity or resilience of multi-stage models.

- Central Vacuum Systems vs. Portable Vacuums

- When routine cleaning is required in a designated area, a central vacuum system offers efficiency by integrating suction points into the facility’s infrastructure. These systems streamline waste disposal through processing lines, eliminating the need for disposable bags or onboard collection containers. Instead, they feature a powerful suction unit connected to hoses, which can be attached at various processing points during operation. However, for greater mobility and adaptability across multiple areas, portable vacuums provide the flexibility needed for dynamic industrial environments.

Choosing the Right Manufacturer

Selecting the right manufacturer means finding one that fully understands your requirements and is committed to delivering the best possible solution. To ensure the ideal match, reach out to one or more of the reputable companies listed at the top of this page. Provide them with detailed information about your application so they can customize their products to meet your specific needs.

Vacuum Cleaner Images, Diagrams and Visual Concepts

A heavy duty piece of cleaning equipment to remove debris, industrial waste, and matter left behind.

A heavy duty piece of cleaning equipment to remove debris, industrial waste, and matter left behind.

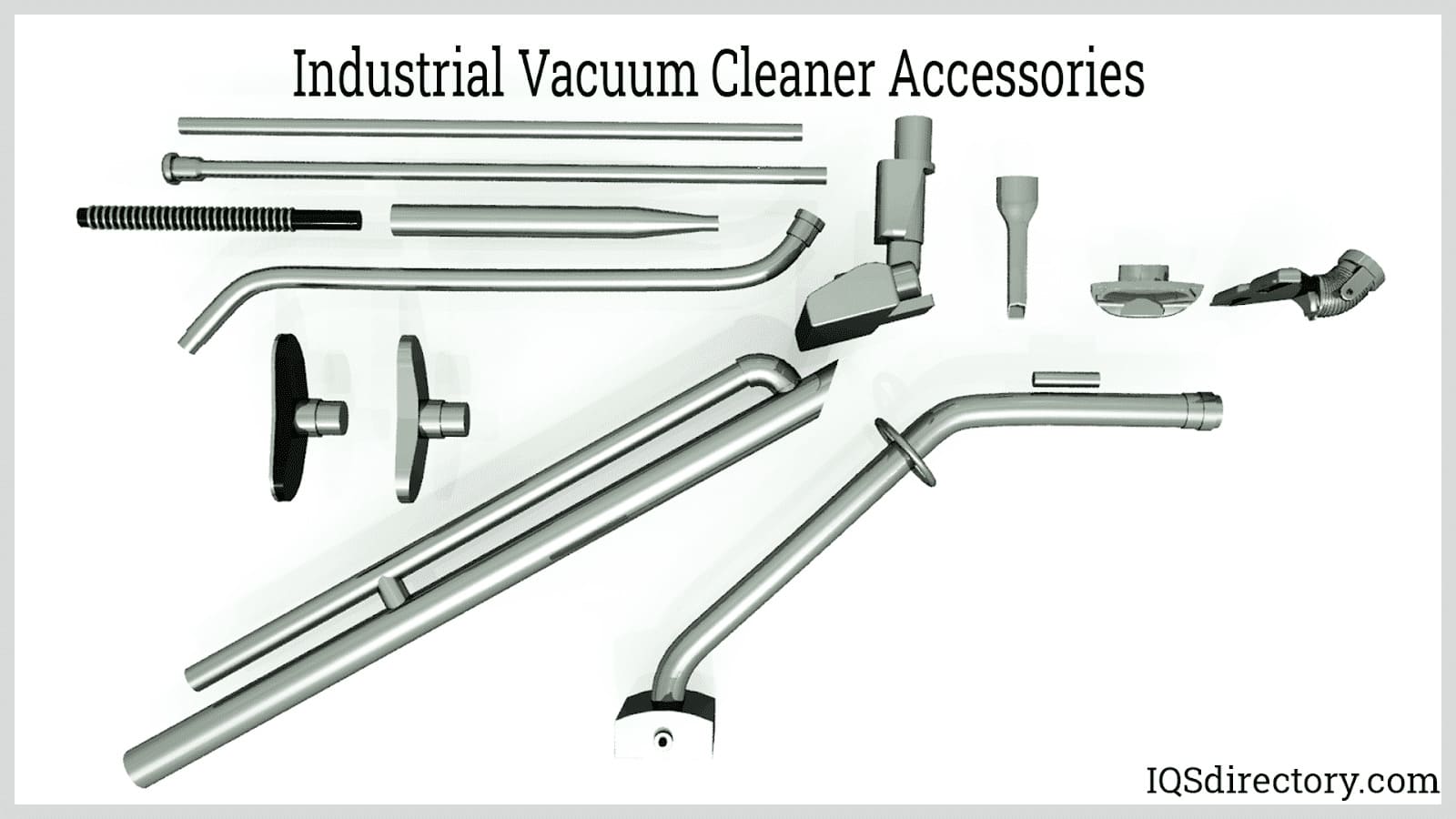

Accessories help adapt to fit the necessary working conditions.

Accessories help adapt to fit the necessary working conditions.

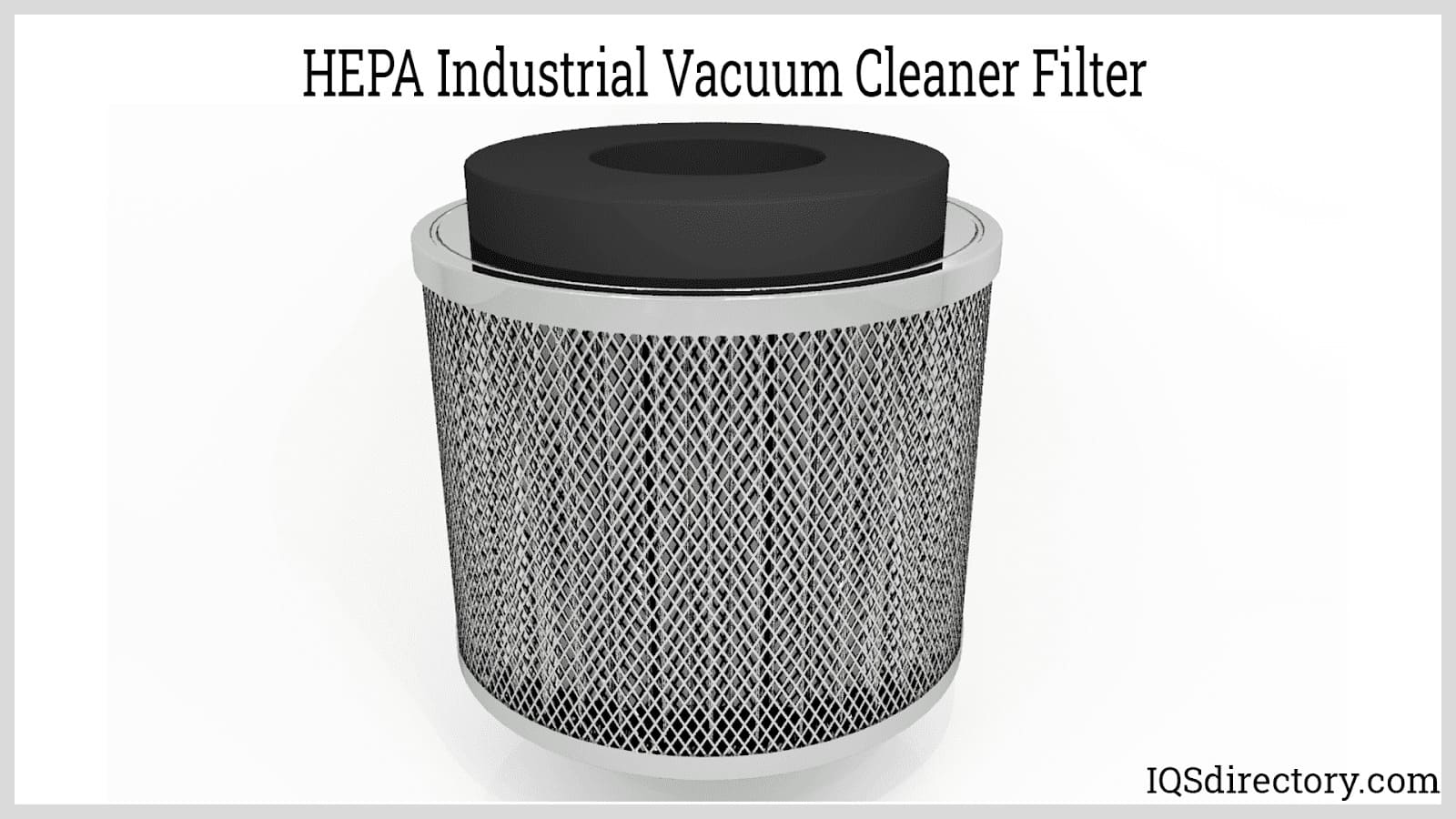

Filters out large particles into a collection unit and has an efficiency rating of 99.99%.

Filters out large particles into a collection unit and has an efficiency rating of 99.99%.

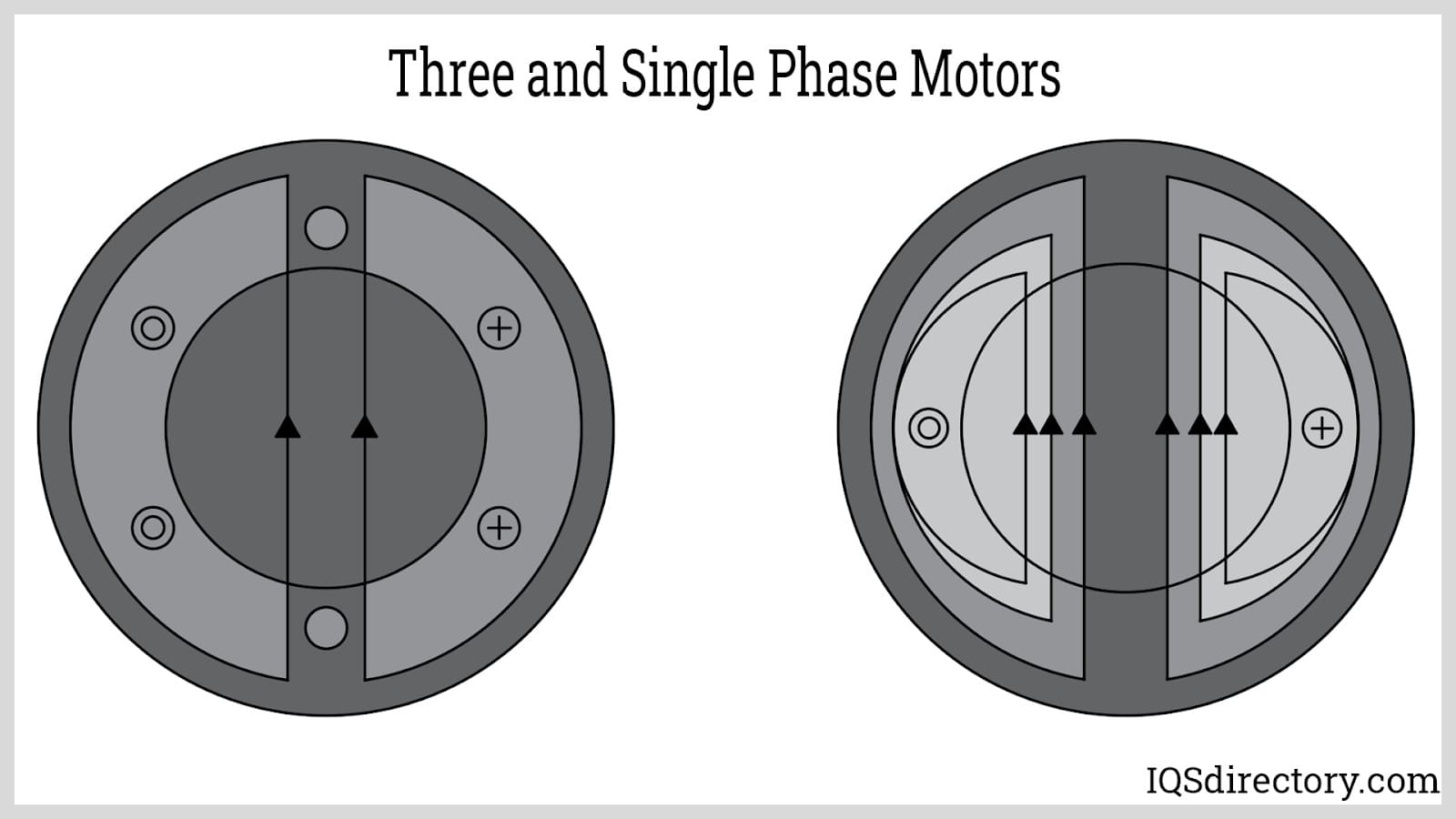

The two types of motors produce different outputs of power, with three phase motors being more powerful, while the single phase motor has a longer lifespan.

The two types of motors produce different outputs of power, with three phase motors being more powerful, while the single phase motor has a longer lifespan.

A vacuum system that is built into the building to provide an efficientive method for removing of debris.

A vacuum system that is built into the building to provide an efficientive method for removing of debris.

Designed to handle tougher cleaning tasks with resilient debris.

Designed to handle tougher cleaning tasks with resilient debris.

Vacuum Cleaner Types

- Auto Vacuums

- Designed for cleaning vehicle interiors and upholstery, these vacuums are commonly used at automotive service centers and car washes. Available in both portable and Stationary models, they feature specialized attachments tailored for thorough vehicle cleaning.

- Backpack Vacuum Cleaners

- Worn on the user’s back, these vacuums offer enhanced mobility and cleaning efficiency, particularly for hard-to-reach areas such as stairways.

- Canister Cleaners

- Unlike standard walk-behind units, these vacuums have wheeled canisters that house the motor and filtration system. Users pull the unit behind them while operating a separate suction attachment.

- Central Vacuums

- Designed for large-scale cleaning, these systems connect to an integrated duct network. Typically used in buildings such as college dorms or academic facilities, they feature an external motor and filtration unit linked to vacuum inlets throughout the structure.

- Central Vacuum Systems

- Extensive duct networks that connect to a central vacuum unit, offering efficient cleaning solutions for large facilities.

- Commercial Vacuum Cleaners

- Built for use in commercial and industrial settings where durability and efficiency are essential.

- Continuous Duty Vacuums

- Engineered for non-stop operation, these vacuums handle constant cleaning in industrial environments, ensuring uninterrupted workflow.

- Explosion Proof Vacuums

- Designed to safely vacuum combustible dust, flammable liquids, and other hazardous materials without igniting a fire or explosion. Essential for industries dealing with volatile substances.

- HEPA (High Efficiency Particulate Air) Filters

- Secondary filtration systems that remove ultrafine dust and contaminants before they reach the operator. Frequently used in food processing and other sensitive environments.

- HEPA Vacuum Cleaners

- Equipped with HEPA filters, these vacuums are crucial in industries requiring high air purity. Common in food production, they remove fine dust and debris from processing equipment, pipes, and structural surfaces.

- Industrial Vacuum Cleaners

- Heavy-duty vacuums designed for exclusive use in industrial applications where superior suction and durability are required.

- Portable Vacuum Cleaners

- Compact, maneuverable vacuums that provide flexibility for applications requiring mobility.

- Rider Sweepers

- Similar to walk-behind sweepers but designed for the operator to ride. These motorized units have large storage capacities, making them ideal for cleaning expansive areas efficiently.

- Small Vacuum Cleaners

- Light-duty vacuums that prioritize portability and ease of use for smaller cleaning tasks.

- Truck Mounted Vacuum Cleaners

- Vacuum cleaning machines installed on trucks, specifically designed to load and transport bulk materials using powerful suction mechanisms.

- Vacuum Equipment

- The full range of machinery and accessories associated with vacuum cleaners, including hoses, filters, and attachments.

- Walk-Behind Sweepers

- Battery or gas-operated machines designed for cleaning large floor areas, both hard surfaces and carpets. Many feature rechargeable batteries for extended use.

- Wet Dry Vacuums

- Versatile canister vacuums capable of handling both liquid spills and dry debris, making them suitable for a variety of cleaning applications.

Vacuum Cleaner Terms

-

Air Watts

A measurement of a vacuum cleaner's output power, assessed at the vacuum inlet by airflow suction. Also known as "suction power," this specification provides a more accurate indication of performance than input power alone.

By-Pass

A feature of vacuum motors in which air cooling is provided by a ventilator separate from the cleaning air. This design is typically found in tangential or peripheral exhaust systems.

Certified Energy Manager (CEM)

An internationally recognized professional designation obtained through training and testing by the Association of Energy Engineers (AEE), signifying expertise in energy management and efficiency.

CFC (Chlorofluorocarbon)

A group of chemical compounds formerly used as refrigerants. Due to their harmful effects on the ozone layer, they have been strictly regulated and phased out of production. Common examples include R-11, R-12, R-113, R-114, and R-115.

Clean-Air Design

A vacuum cleaner design in which air passes through the filtering system before reaching the suction motor’s fan(s). This setup prevents debris from damaging the fan and typically generates stronger suction, especially when using hoses and attachments.

Cyclonic Filters

A filtration system that removes dust particles by spinning air inside a separation chamber. The centrifugal force pushes debris outward while allowing clean air to exit from the center. Some vacuums feature multiple chambers, and most integrate additional filters to enhance overall filtration efficiency.

Direct Air System

A vacuum cleaner design where dirt-laden air first passes through the fan of the suction motor before entering the collection bag. While it generates greater airflow for wide-open areas, it typically produces less suction when using attachments with restricted airflow.

Dirty Air Design

A vacuum system in which the airflow moves through the suction motor’s fan before being filtered, exposing the motor to debris and potential wear.

Electric Hoses

Specialized vacuum hoses embedded with internal wiring to deliver electrical power to the motorized nozzle. Some models also reinforce the hose material for increased durability, though crush-resistant hoses may not always include this feature.

Electrostatic Filter

A filtration medium made of fine synthetic fibers that generate a static electric charge as air moves through. This charge attracts and traps tiny dust particles and allergens, enhancing filtration efficiency.

Fan

The impeller or blade mechanism within the vacuum that creates the necessary suction force to pull in dirt and debris.

Filtration Efficiency

A measurement of how effectively the primary filter captures particles as air flows through it. The higher the efficiency, the greater the percentage of particles removed.

HEPA (High-Efficiency Particulate Air)

A filtration standard originally developed to remove radioactive dust from industrial plant exhausts. To qualify as true HEPA, a filter must capture 99.97% of all particles 0.3 microns or larger from the air passing through it.

HEPA-Type Filter

A filter designed similarly to a true HEPA filter, often using the same materials, but without meeting the strict HEPA efficiency requirements. While it significantly improves filtration compared to standard filters, it may not be fully sealed, allowing some particles to escape.

Micron Filter

A high-efficiency filter capable of trapping micron-sized particles, preventing fine dust and allergens from circulating back into the air.

Peripheral Exhaust

A vacuum motor design that expels cleaned air through multiple small openings around the motor’s perimeter.

Resistance

In the context of vacuum cleaners, resistance refers to the opposition to airflow within the system, which can affect suction performance.

Spun Aluminum

A manufacturing process in which a flat aluminum disc is shaped into a seamless, deep container without soldering. This technique ensures airtight construction, commonly used for dust recovery tanks and other vacuum components that require high vacuum strength.

Tangential Exhaust

A vacuum motor design that expels cleaned air through a single outlet located on the motor’s side, directing airflow away from the motor assembly.

Thru-Flow

A vacuum motor characteristic in which cleaning air passes through the motor casing to provide cooling.

ULPA (Ultra Low Penetration Air)

A filtration standard used in extreme clean environments such as pharmaceutical labs. ULPA filters must remove 99.999% of particles 0.12 microns or larger, exceeding HEPA-level efficiency.

Velocity of the Airflow

The speed of air movement at any given point in the vacuum system. Higher airflow velocity increases the force exerted on dirt and debris, improving collection efficiency.

Water Lift

A measurement of a vacuum’s suction strength, determined by how high water is lifted in a sealed tube when attached to a vacuum hose. This metric indicates the vacuum’s ability to lift heavy debris or liquids.