Vacuum Pumps

Vacuum pumps are devices that form either partial or full vacuums. They do so by eliminating or removing gas from a sealed and enclosed space. The vacuum pump is not to be confused with the air compressor, a device that increases gas by reducing its volume, which is often sold alongside it.

Quick Links to Vacuum Pumps Information

The History of Vacuum Pumps

The first artificially created vacuums were intended for use in demonstrations and research. Their enclosures were usually glass and were not much larger than a large glass jar. The glass enclosure would be placed upside-down on a surface after its edges had been coated with some kind of liquid sealant. Air would then be removed by an air pump through an outlet in the surface.

The first true vacuum pumps, though, were invented by Otto Von Guericke, a Prussian physicist and engineer. In 1650, he invented the first air pump, by which he created a partial vacuum. His vacuum pumps could achieve far lower pressure than its predecessors. In 1654, he proved the efficacy of his pump by conducting his Magdeburg hemispheres experiment. During this experiment, he pitted two teams of horses against each other to separate two hemispheres that were joined together by evacuating the air between them. No horse team could separate the hemispheres, thus proving how well his vacuum worked. After this, both Robert Boyle and Robert Hooke improved upon Guericke’s model.

Vacuum pumps were not explored again until 1855, when Heinrich Geissler invented the mercury displacement pump, which in turn led to the invention of vacuum tube. Also in the 19th century, Nikola Tesla developed an apparatus containing a Sprengel pump; this device could create a high degree of exhaustion.

The first vacuum pumps from that time were simple, low-capacity fans. Every time a fan blade spun near the vacuum enclosure outlet, it would push air away from the outlet and through an exhaust port located elsewhere in the pump, creating a small vacuum. Air pressure imbalances correct themselves naturally, so some of the air from the enclosure would flow out to correct the imbalance. This air would be pushed away by the spinning fan, and the process would repeat itself until much of the air from the enclosure had been evacuated.

Today, many pump systems still resemble this model, though great improvements in vacuum pump efficiency and effectiveness have been made since then. Many options are available to the great diversity of industries and processes for which the use of vacuum pumps is necessary.

Advantages of Vacuum Pumps

Vacuum pumps make systems run more efficiently and they offer the advantage of atmospheric pressure control. In addition, vacuum pumps are able to evacuate gas better than any other method, including suction. Another advantage of vacuum pumps is the fact that they are so durable.

Design of Vacuum Pumps

The basic vacuum pump assembly consists of one or more pumps, an inlet port and an outlet (exhaust) port. Some higher vacuum systems also feature metal chambers with metal gasket seals. Vacuum pump components are typically made of tough, corrosion resistant materials such as stainless steel or titanium.

When designing a vacuum pump system, manufacturers consider a number of factors, including: maximum and minimum flow rate, maximum and minimum vacuum level, required pump speed, dimensions of the enclosed space in which the vacuum system will go, and the type of liquid or gas to be manipulated by the vacuum system.

If they so choose, manufacturers of vacuum systems can develop unique configurations and operational procedures. For instance, while a more simple system will easily achieve a low vacuum, to achieve a high vacuum, manufacturers will have to design a system with a series of pumps, most often a fast pump and a positive displacement pump, as well as a chamber.

All vacuum pumps work by directing air out of an enclosure and preventing it from re-entering. For the best results, many varieties rely on vacuum pump oil, which lubricates the system and helps it run smoothly.

Vacuum Pump Images, Diagrams and Visual Concepts

Vacuum pumps are capable of generating a partial or low-pressure vacuum by pushing air molecules out of a sealed chamber.

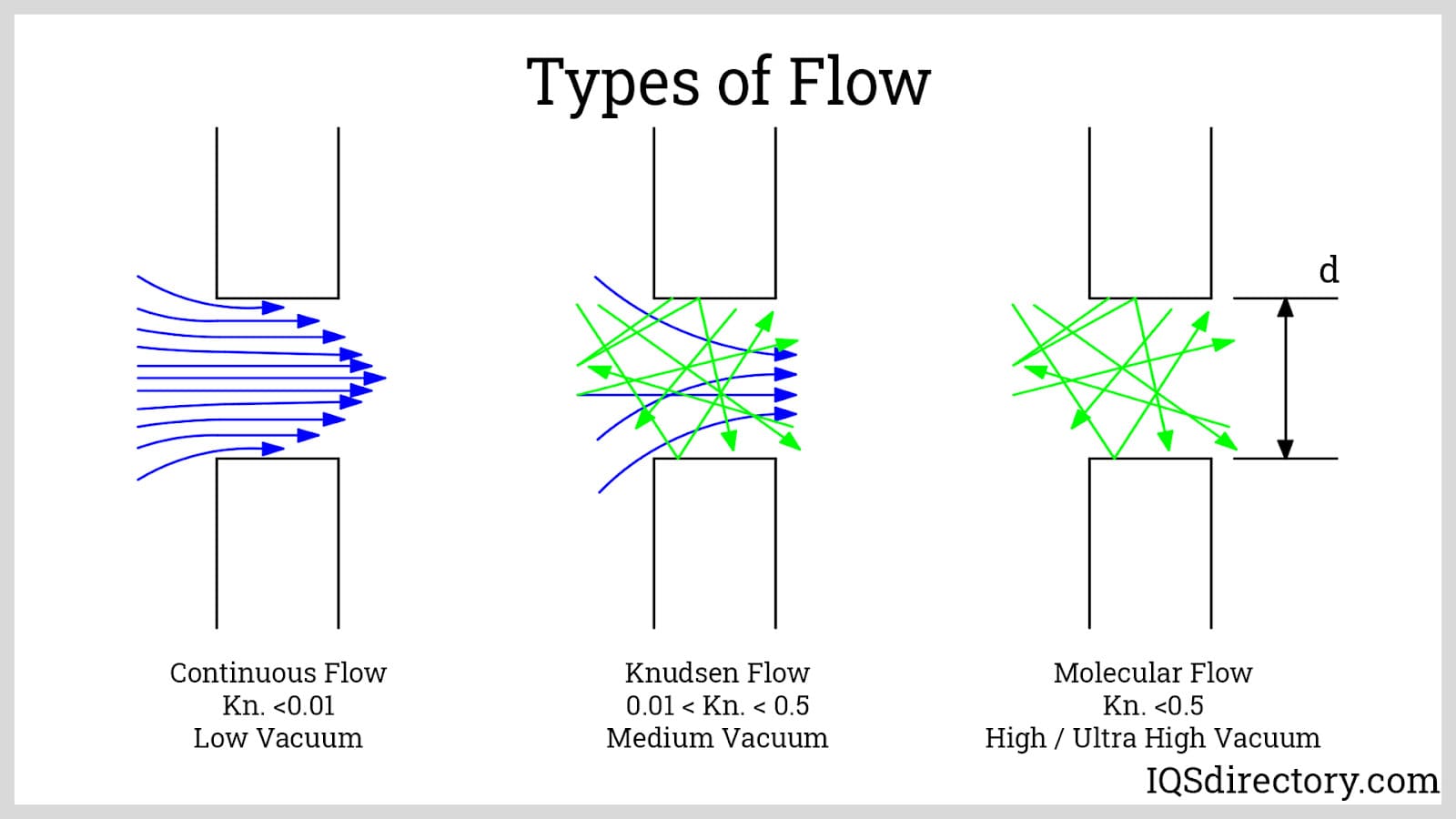

Fluids flowing under viscous flow can be pumped mechanically by positive displacement pumps.

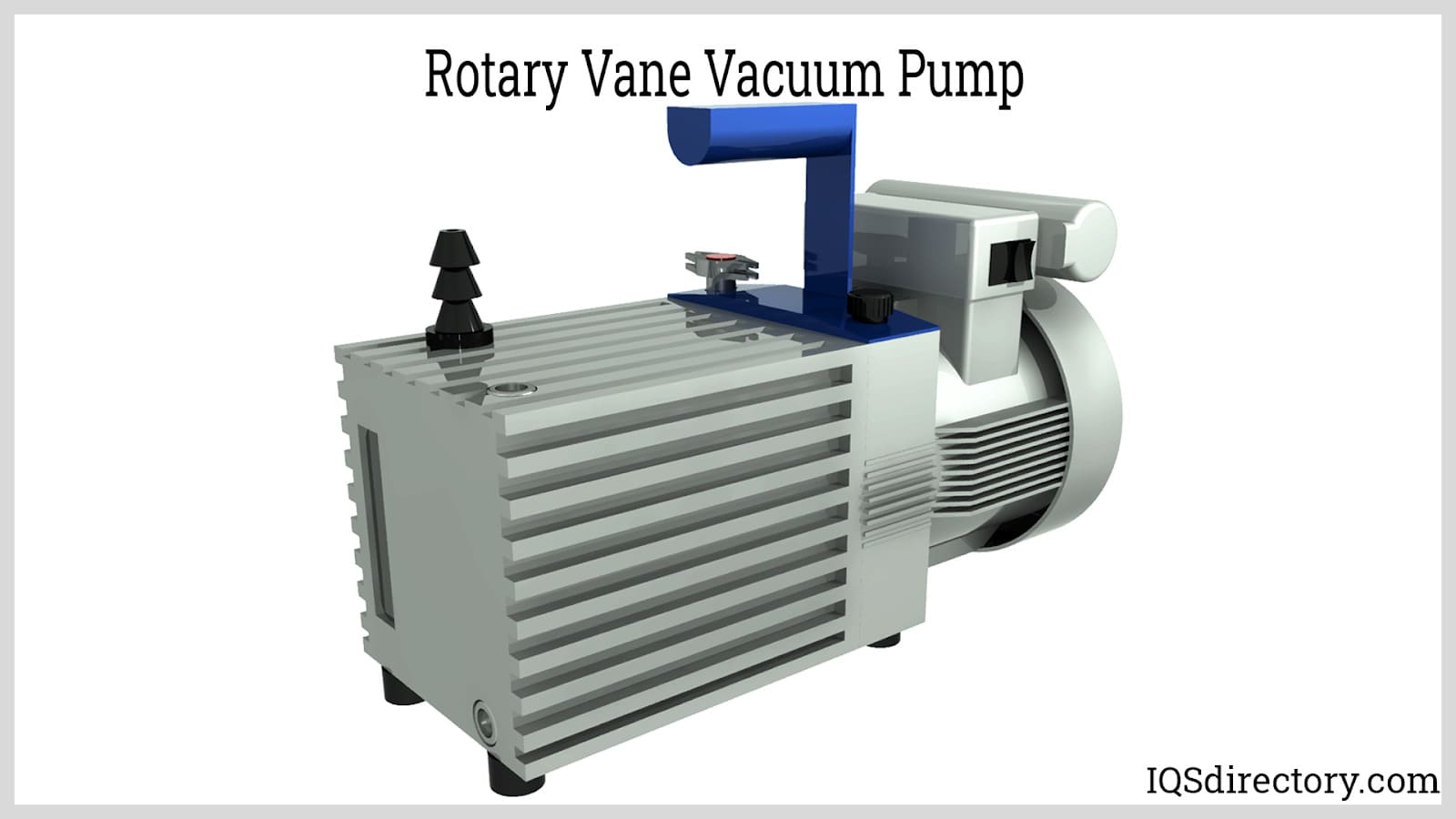

Rotary vane vacuum pumps generates low-pressure zones by rotating the moving parts against the pump casing.

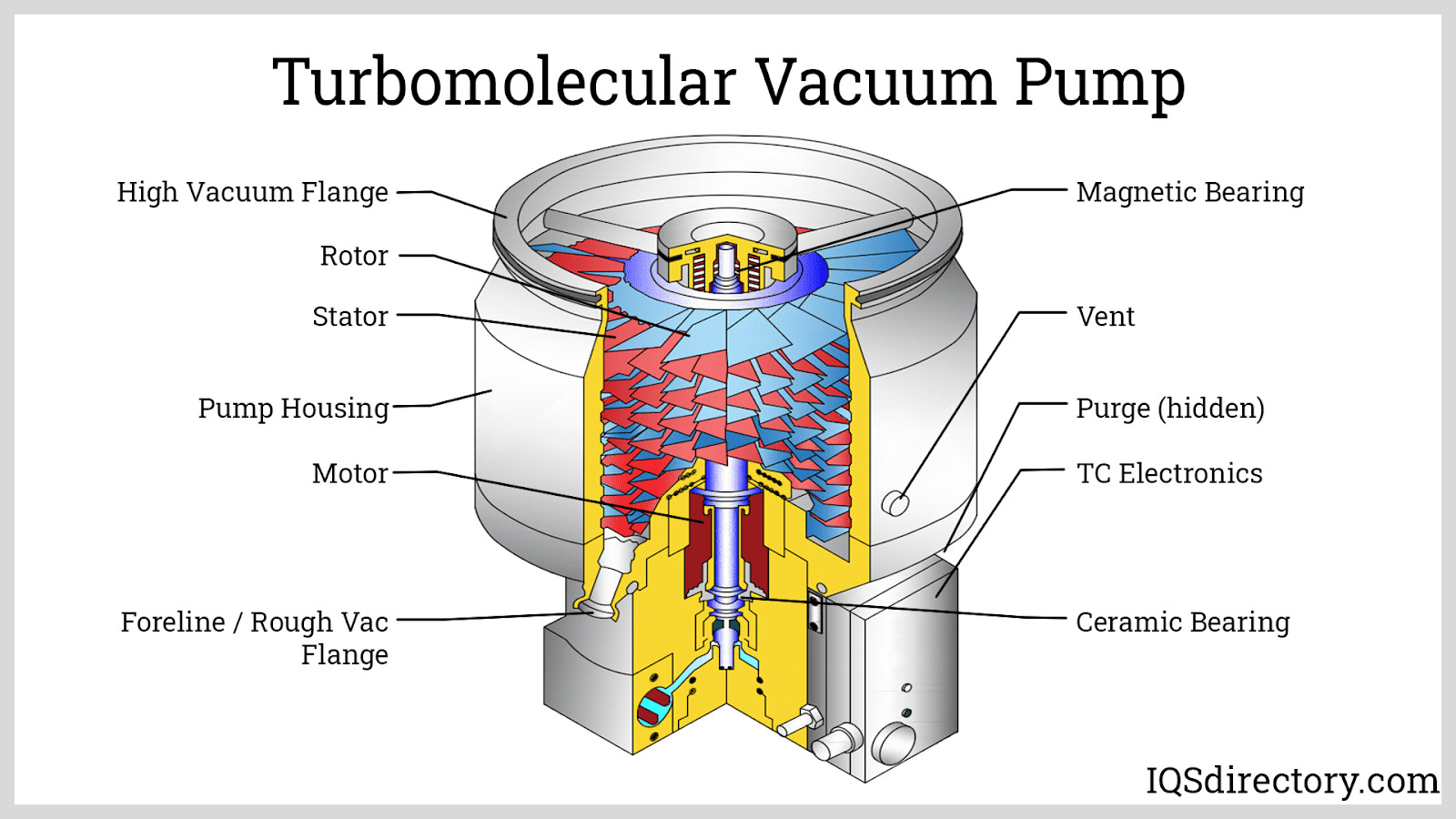

Turbomolecular vacuum pump has multiple stages of rotating and stationary turbine blades, the rotating blades are angled to transfer sufficient momentum to the gas molecules moving them axially towards the exhaust.

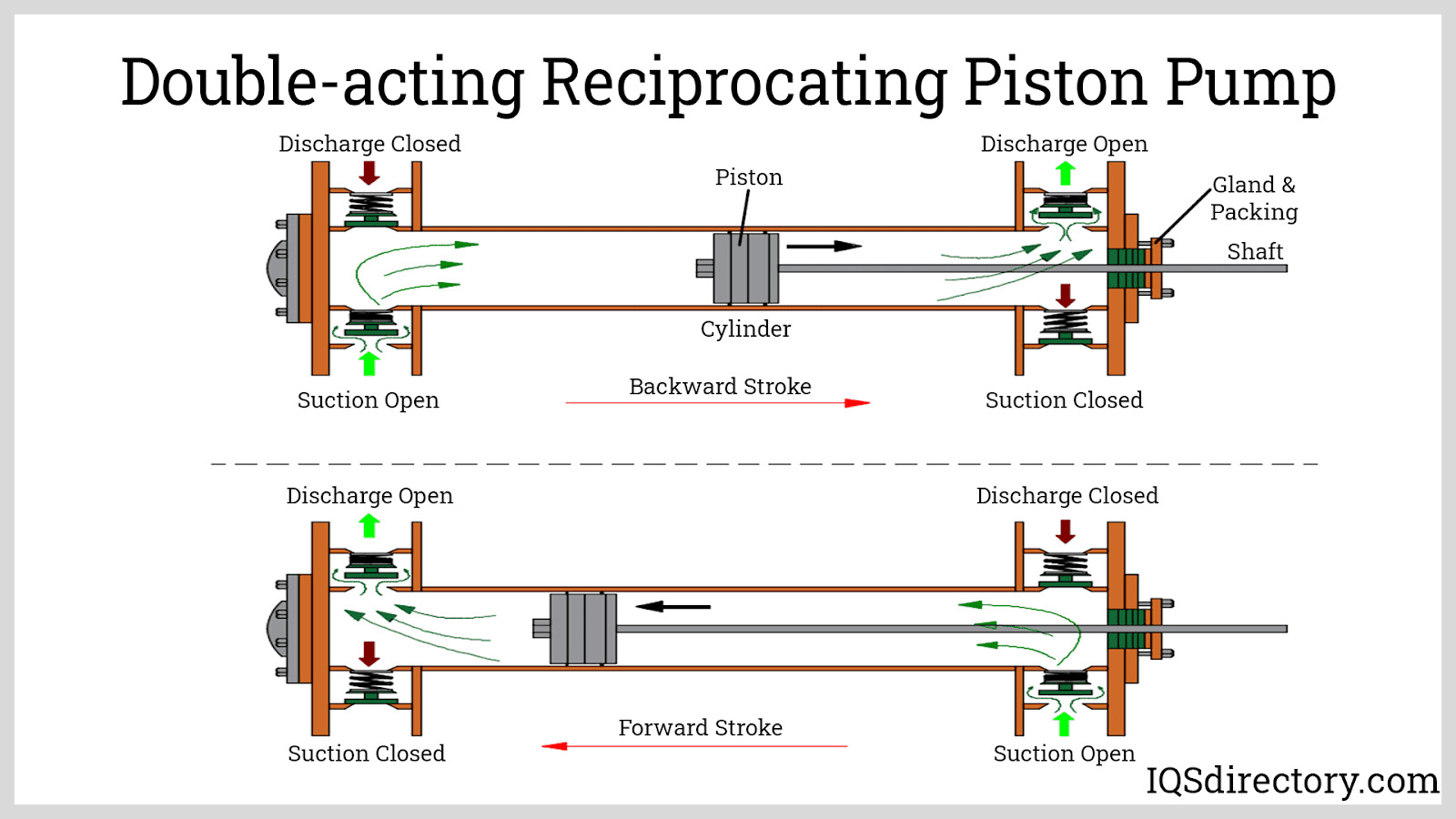

Double-acting pump creates both vacuum and compression with a single stroke.

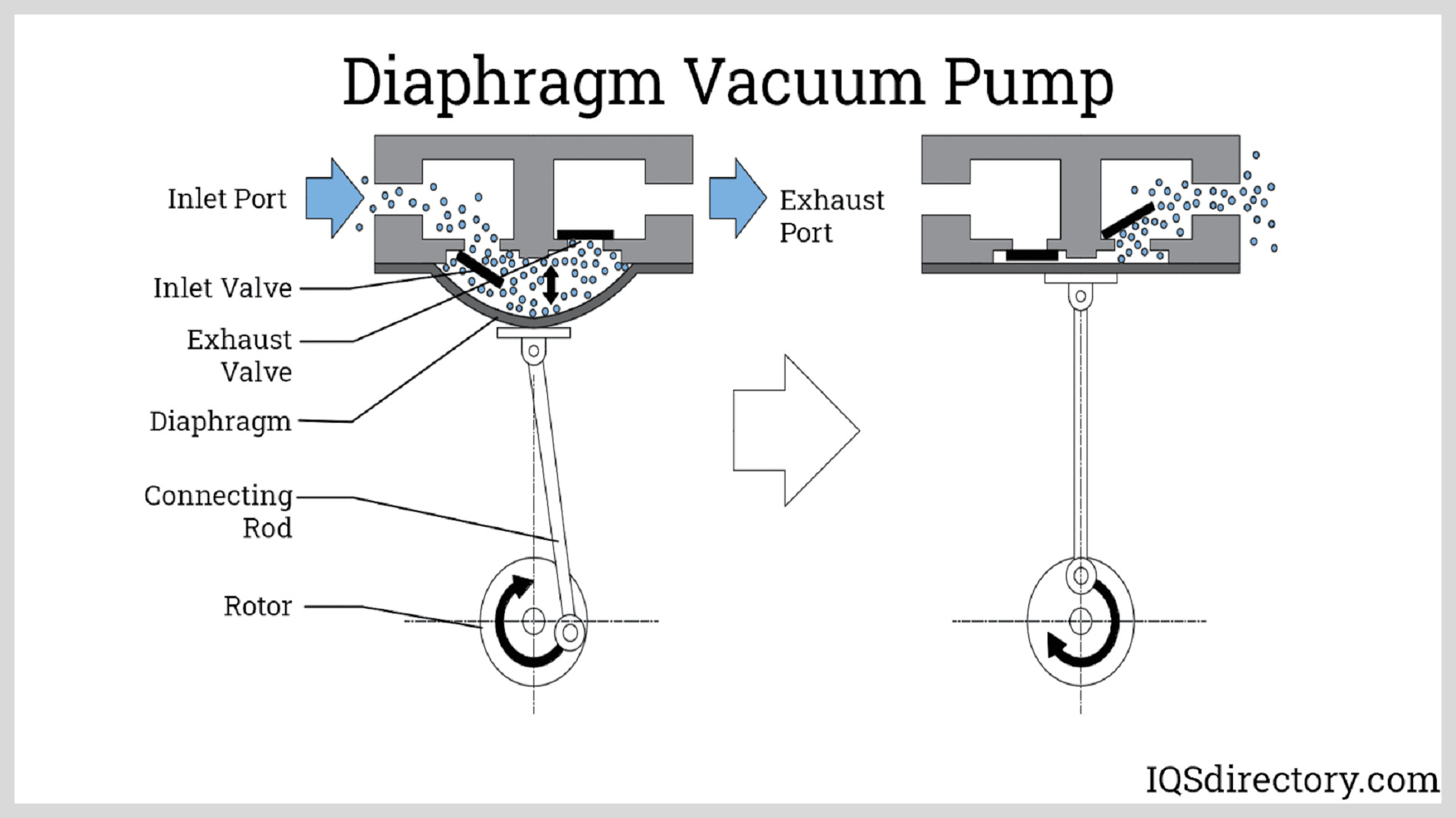

Diaphragm vacuum pumps use a deformable metallic or elastomer membrane joined into the chamber creating a hermetic seal.

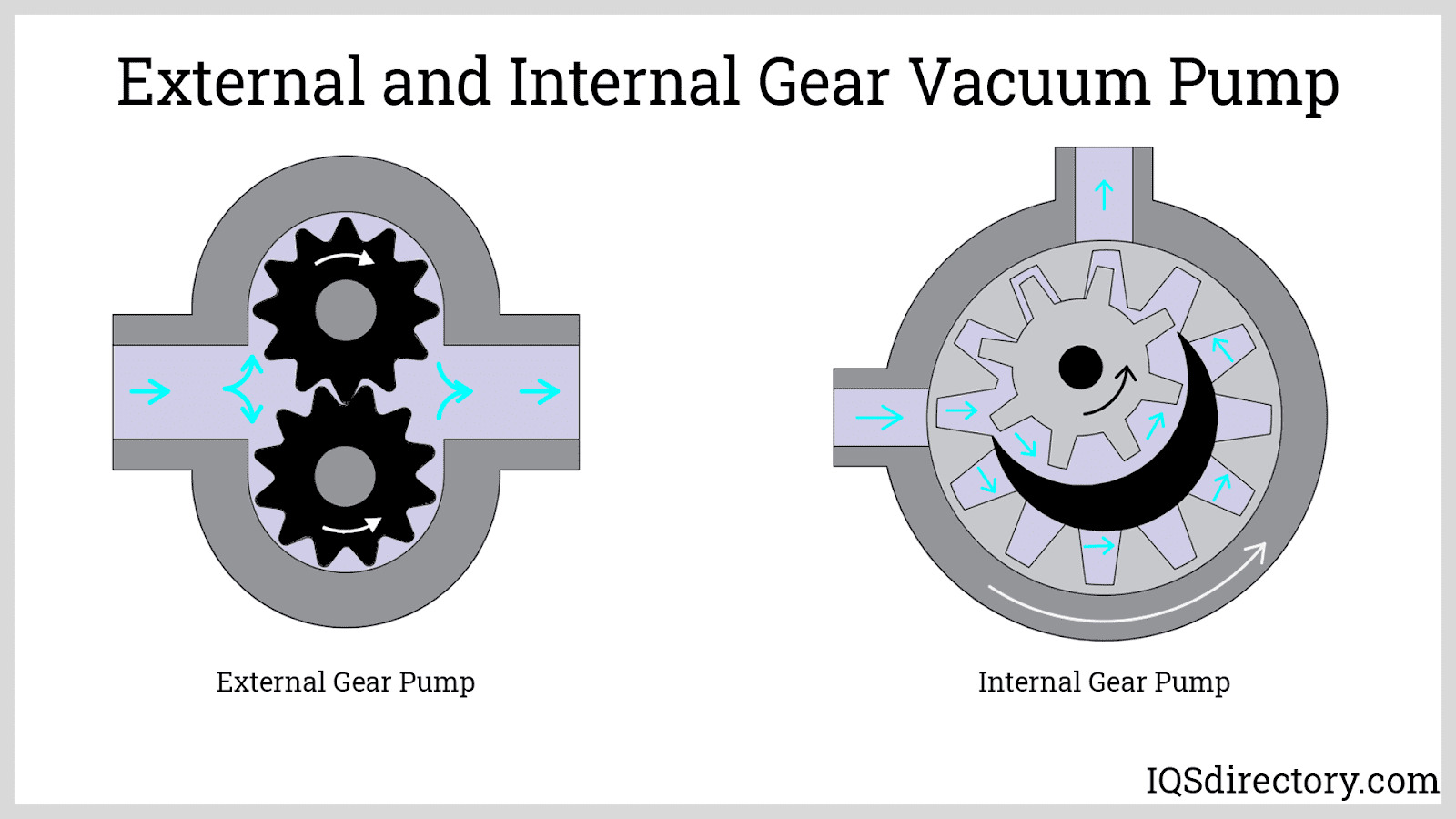

Gear vacuum pump has rotors in the form of two meshing gears where one gear drives the other, either external or internal.

Types of Vacuum Pumps

Positive Displacement Pump

Create a vacuum by repeatedly expanding and exhausting a closed cavity. Examples of positive displacement pump subtypes include the: rotary vane vacuum pump, scroll pump, piston pump, diaphragm pump and liquid ring vacuum pump. Most positive displacement pumps feature simple designs and are used to create low-intensity vacuums.

In a positive displacement pump, a vacuum is created by expanding or increasing the volume of a sealed off cavity; this results in lower pressure in the cavity than the atmospheric pressure. As the pressure goes down, gas or other material, for which the pump is designed, flows in from the chamber, then the cavity is sealed off, and afterwards, through an outlet, the material is exhausted out. However, through this pump, only partial vacuum is achieved. The manual water pump is an example of a positive displacement pump.

Rotary-Vane Pump

An air-cooled, oil-sealed, direct-driven model, designed for use with clean, dry, and non-reactive gases. In addition, this pump is known for its small carbon footprint and, when properly maintained, its reliability.

Similar to the rotary vane pump is the screw air compressor, also known as a rotary-screw compressor, which is a type of gas compressor that also uses positive displacement.

Screw Air Compressor

Also known as rotary-screw compressors, are a type of gas compressor that uses positive displacement.

Piston Vacuum Pump

Also a type of regenerative pump, consists of rotating pistons of varying stroke lengths that pump fluids through check valves.

Diaphragm Pump

Feature one or two flexible diaphragms that pulsate to displace fluid, while check valves control fluid flow direction.

Liquid Ring Vacuum Pump

A model used primarily for the evacuation of dry and wet gases. What sets the liquid ring pump apart is the fact that it can also deal with condensable vapors and small bits of liquid suspended in incoming gas. In fact, the condensing effect, which takes place at the liquid ring as the incoming gas makes contact, can significantly enhance the pump's upstream capacity.

Momentum Transfer Pump

Expel air molecules from a sealed vacuum pump by accelerating the molecules using high speed gas jets or fans. Diffusion pumps and turbomolecular pumps are examples of momentum vacuum pumps and can be used to create very low-pressure vacuums.

In a momentum transfer pump, molecules in the chamber are blown out-by either high-speed rotating blades or jets-to the exhaust side. As the name suggests, the pump adds momentum to the gas molecules that are diffused in. Molecular pumps are designed as an alternative to mechanical pumps to sweep up a larger area. As they are capable of higher pumping speeds, they sweep the area more frequently.

Diffusion Pump

Employ jets of oil or mercury to blow out gas molecules. Diffusion pumps are vacuum pumps in which heated oil or another substance is pushed through jets as a vapor that collides with gas molecules and carries them out of the compartment being evacuated.

Turbomolecular Pump

Fitted with high-speed fans to impart momentum to the gas molecules.

Turbo molecular pumps are axial-flow turbines designed for operation in the molecular flow range. Turbo molecular pumps consist of a series of alternate circular rotor and stator disks, both of which have inclined blades designed to impart momentum change to gas molecules in a preferential direction from the pump inlet to the outlet.

Neither pump can work independently, as the exhaust from molecular pumps cannot be released directly to the environment with standard atmosphere pressure. Instead, they need a partial vacuum at the exhaust line or they will stall. For this reason, they work in conjunction with mechanical pumps.

Entrapment Pump

Trap gasses using a heating or cooling process that makes them easier to catch. They mainly are of two types of entrapment pumps: Cryo and ion pumps. These types of pumps use fundamentally different approaches to create vacuum.

Cryogenic Pump

Cryopumps make use of cold temperatures to entrap gases in a solid state; they freeze gases on cold surfaces known as arrays. Cryogenic pumps, also called "cryopumps," are gas binding vacuum pumps that work by the condensation and/or sorption of gas at surfaces maintained at temperatures, kept low enough through refrigeration, for the vapor pressures of the condensed gases to be insignificant.

Cryogenic pumps, which are vacuum pumps working in a range below 120° Kelvin, cause the vapor pressures to be lower than the vacuum pressure.

Ion Pump

Used for achieving ultra-high vacuum levels; they react with gases in the chamber and bury gases on the wall of the pump. Both of these pumps need the regeneration process, including various pumps and valves to work efficiently. As they are used to attain ultra-high vacuum, they require a combination with other getter pumps, including evaporable barium getters and non-evaporable getters.

Another way to categorize vacuum pumps is by whether they are wet or dry systems.

Wet Vacuum Pump

Any vacuum pumps that make use of a liquid at any point in a pumping process. Wet systems can make use of oil as a lubricant or sealant. Liquid seal vacuums use liquids within their mechanical enclosures to create air-tight compression seals.

Oil-Sealed Vacuum

Used when high-intensity vacuums are needed because oil provides a good seal between moving parts. When oil-seals are used, a downstream oil separator must be employed to ensure that neither the enclosure nor the exhaust areas are contaminated with oil.

Dry Vacuum Pump

The opposite of wet systems; at no point during a dry pump process is any liquid used. Dry vacuum pumps operate without fluids, such as steam or water, eliminating environmental worries and the cost of contaminant disposal. Dry vacuum pumps, which can be configured to operate either hot or cool depending on the application, reduce emissions and ease solvent recovery.

Wet vacuum pumps generally achieve lower vacuum pressure levels, but they also require more frequent maintenance and can cripple operations if they fail. In applications like aircraft instrumentation in which long-term, failure-free performance is absolutely critical, dry vacuum pumps are almost always preferred over wet pumps.

Laboratory Vacuum Pump

Create carefully controlled environments for electron microscopy and other tests and experiments.

Medical Vacuum Pump

Produce products which are used for suction during surgical procedures and for radiotherapy. Medical vacuum pumps remove air molecules from a volume by creating a vacuum within a sealed device and have been adapted for the medical field.

Finally, some pumps are difficult to categorize, and thus stand on their own. Examples of these include high vacuum pumps and electric vacuum pumps.

High Vacuum Pump

Remove air particles from a sealed volume of gas; they seek to reach pressure between 10-2 and 10-8 Torr. As it removes gas, it also converts mechanical force from a rotating component into pneumatic force; this creates hydraulic or pneumatic suction and flow.

Electric Vacuum Pump

Pumps that feature an electric connector for grounding and receiving power. They offer high efficiency and high levels of vacuum power. Electric vacuum pumps are especially with automotive manufacturers trying to meet their low emission requirements.

Air Pumps

Cause a gas to flow against a pressure, converting mechanical force and motion into pneumatic fluid power.

Ejector Pumps

Vapor pumps in which the vapor streams primarily under viscous flow conditions.

Heavy Duty Vacuum Pumps

Have the ability to operate under the most difficult conditions, such as when highly saturated vapors form in or solid particles get into the inlet stream.

Industrial Vacuum Pumps

Heavy-duty pumps used to create a vacuum in industrial settings.

Laboratory Vacuum Pumps

Devices that remove gas molecules from a sealed volume, creating a vacuum that is used for medical and scientific applications. Laboratory vacuum pumps have special features that make them suitable for use with tight spaces, delicate equipment, sanitary conditions and a variety of substances.

Mechanical Pumps

Have moving parts such as pistons, rotating vanes or eccentric rotary members used for pumping vapor or gas.

Non Positive Displacement Pumps

Utilize kinetic energy to produce pressure gradients (slopes) for air in motion.

Oilless Vacuum Pumps

Devices used to create a vacuum by removing gas molecules from a sealed volume without the use of oil for lubrication.

Rotary Piston Vacuum Pumps

Reliable industrial-grade, heavy-duty pumps that are used in high contaminate applications.

Side Channel Pumps

Consist of many circular hollow rings, half of which are in the upper and lower side of the pump housing and the other half in either side of the impeller, which has scoops on both sides. Side channel pumps generate very low pulse suction air, making them ideal for a wide variety of industrial applications that require precisely defined functions.

Small Vacuum Pumps

Modest-sized devices used to create a vacuum by removing gas molecules from a sealed chamber. They are the opposite of industrial vacuum pumps in terms of size and dimensions but are otherwise quite similar.

Vac Pumps

Also known as vacuum pumps, are devices that remove gas molecules from a sealed space, creating a vacuum.

Vacuum Pump Systems

Composed of one or more vacuum pumps combined with the parts and accessories necessary to successfully remove gas molecules from a sealed chamber, resulting in suction, pneumatic or hydraulic flow and a vacuum.

Vacuum Pump Applications

Companies from a wide range of industries rely on vacuum pumping systems for the proper operation of their various applications.

Such industries include: industrial manufacturing, science and lab, healthcare, coating, and food processing.

Within these industries, their respective applications include:

- Ion implantation, semiconductor processing, dry etching, photolithography and atomic layer deposition.

- Electron microscopy (for procedures that need suction, such as uranium enhancement), and the analyzation of solid, liquid, gas, and biological materials.

- Radiotherapy, radiopharmacy, and radiosurgery.

- Vacuum coating on materials, such as metal, glass, and plastic for aesthetic purposes and for toughness (ex. engine covering in Formula One).

- Milking machineries and other tools and gear in sheds.

Other vacuum forming applications include: eyeglass lens fabrication, light bulb manufacturing, plastic molding operations, lamination, safety glass fabrication, and impurity elimination in air conditioning units.

Standards and Specifications for Vacuum Pumps

Your vacuum pump system may need to adhere to any number of safety and construction standards, depending on your application and location. A good place to start is with ISO and (if you’re in the USA) OSHA certification. These certifications will make sure that your system is both effective and safe.

Things to Consider When Purchasing Vacuum Pumps

Given the wide varieties and alternatives available, it is a daunting task to select the industrial vacuum pump that suits your requirements. Understanding the terms related to pumps can help you to make the right decision.

Important Terms

While comparing pumps, you often will see the term Cubic Feet per Minute (CFM), which tells the speed of the vacuum flow. The term is relevant to electric rotary vane pumps and piston pumps, also known as reverse air compressors. The CFM is pivotal to how fast the pump can remove the air from a refrigeration system or tank.

Another major term that you should know about is Inches of Mercury (Hg). It is a measure of power, which can be compared to horsepower. The term plays a big role when holding power is the most important factor, regardless of the time it takes to reach the full vacuum. Holding power is a key attribute of a pump in the machining metals and plastics industry.

The Right Manufacturer

Perhaps the biggest contributing factor to your success is the vacuum pump manufacturer or supplier with whom you partner. It’s important that you find a company that is not only proven skilled and knowledgeable, but capable of and willing to meet all of your needs. To find a manufacturer like this, start by browsing the list of suppliers we’ve provided above. Check out their respective websites, get a feel for what they offer, pick three or four in whom you’re interested, and then call them. Talk to each of them about your specifications, including your budget and your timeline. Choose the manufacturer that demonstrates that they will be able serve you best.

Proper Care for Vacuum Pumps

When properly cared for, you can expect your vacuum pump system to be durable, and last for a long time to come. So, what is proper care?

One of the components of proper vacuum pump care involves familiarizing yourself with the common issues of your pump type, so that you can keep an eye out for them. That way, you can catch any potential issues early, before they become a larger problem. In addition, if your pump system uses lubricating oil, make sure that you never allow its coverage to lapse.

Vacuum Pump Accessories

Vacuum pump accessories you may want to consider, depending on your specifications, include: a vacuum gauge component, a vacuum bag set, a compressor kit, extra safety valves, a power cord assembly, and vacuum hoses.

Vacuum Pump Terms

Absorption

The process involving the penetration of a gas or vapor beyond the surface of a solid or liquid, usually by some kind of diffusion and its subsequent binding or capture.

Absolute Pressure

The sum of atmospheric and gauge pressures, it is the total force per unit area exerted by a fluid and the pressure above a perfect vacuum (zero pressure) in vacuum systems. U.S. units for absolute pressure are pounds per square inch absolute (psia).

Adsorption

Gas or vapor bonding on, or "sticking" to, a solid or liquid surface.

Air Intake Filter

Device installed at the intake port of a compressor or vacuum pump that is used to capture insoluble contaminants from a fluid with porous material.

Anneal

A vacuum heat treatment process in which a material is relaxed and uneven or heterogeneous regions of a substrate, which result from the application of internal stress, are homogenized.

Atmosphere

Unit of pressure that will sustain a column of mercury of 29.92" at 0°C, sea level. Actual daily atmospheric pressure fluctuates about this value.

Atmospheric Pressure

Pressure exerted by the atmosphere in all directions, equal at sea level to about 14.7 psi. Also the force exerted on a unit area by the weight of the atmosphere.

Back Pressure

Resistance to flow in the system.

Backstreaming

The movement of the vapor of the operational fluid of a pump in the direction of the area being depleted.

Baffle

A system of cold surfaces placed between the inlet of a pump and the area on which it is pumping to condense backstreaming vapor and return it to the pump.

Bake-out

The heating of vacuum system components during the pumping process for the purpose of degassing. The bake-out process increases the evolution of adsorbed and absorbed gases.

Barometer

Mechanism for calculating atmospheric pressure, given in inches of mercury (in. Hg) at a precise point.

Baseplate

A plate that supports a belljar along with its enclosed materials or components subjected to a vacuum, providing mechanical, electrical and other connections to components within the vacuum system.

Belljar

A cylindrical vacuum compartment with a detachable seal supported by a baseplate.

Cathode

The negative electrode in an electron device. A cathode is the most negative electrode in an ion pump, which can discharge electrons and accumulate positive ions.

Check Valve

A two-way directional valve that allows free flow in one direction and blocks flow in the other direction. Check valves can act as either directional or pressure control apparatuses.

Condensation

The process of a vapor becoming a liquid or solid.

Conductance

Under steady-state conservative conditions, the ratio of throughput to the pressure differential between two specified cross sections inside a pumping system.

Cross-over Pressure

The pressure at which pumping is transferred from one pump to another, providing a higher speed and/or a lower pressure.

Degassing

The deliberate removal of gas from a material, usually done by heating the material under vacuum.

Dessicant Dryer

An absorption material that eliminates moisture from air.

Differential Pressure Switch

Switch with a low-pressure and high-pressure adjustment. Fluid pressure activates an electric switch to perform work.

Diffusion

The process of particles moving from an area of higher concentration to one of lower concentration.

Displacement

Meaningful only in positive displacement compressors, the entire volume that is swept by the repetitive motion of the pumping element. Displacement per revolution depends on the size of the pumping chamber or chambers, and displacement per minute is determined by compressor speeds.

Feedthrough

Also known as "pass-through," it is a device used to transmit electrical current, fluids or mechanical motion through the walls of a vacuum system.

Flow Rate

A measurement of the amount of fluid at a point per unit of time, commonly represented by cubic feet per minute (cfm).

Fluid Power

Energy controlled and transmitted through utilization of a pressurized fluid within an enclosed circuit.

Gauge Pressure (psig)

A measurement of the force per area applied by a fluid with atmospheric pressure as the zero reference.

Head

Often used to indicate gauge pressure, this is energy per pound produced by pressure, elevation or velocity. Expressed in linear units, it is the height of a column or body of fluid above a given point.

Hydrostatic Pressure

The exertion of pressure in all directions equally at points within an enclosed gas or liquid at rest.

Ionization

A process that occurs by adding or removing electrons to or from an atom or molecule, resulting in the formation of ions.

Isothermal

Expansion or compression of a gas at a constant temperature. Practically, this is a slow process because of the time required to replace heat absorbed by expansion or to remove heat generated by compression.

Kinetic Energy

Energy due to motion that is added to a fluid either by rotating it at a high speed or by providing a catalyst in a direction of flow.

Laminar Flow

Gas flow of adequate velocity so the gas will flow efficiently over surface obstructions and defects.

Lubricator

Pneumatic component that lubricates through the injection atomized oil into the air stream.

Manometer

An instrument used to measure the pressure of vapors and gases.

Maximum Vacuum Rating

Highest level of vacuum recommended for a vacuum pump.

Mean Free Path

The average distance a gas molecule moves without interacting with a surface or another molecule.

Negative Gauge Pressure

Also called "gauge vacuum" or "vacuum level," it is the pressure drop that results from the system emptying, measured in inches of mercury (in. Hg.). Negative gauge pressure is a term that must be carefully used, because absolute negative pressure does not exist.

Nude Gauge

A vacuum gauge intended to be inserted into a vacuum system that does not have its own envelope.

Open Capacity

The volume of air exhausted per minute, expressed in cfm, when there is no pressure or vacuum load on the pump.

Outgassing

The process of evaporation that substances, such as oil and dirt, undergo after being placed in a low-pressure or vacuum environment.

Permeation

The movement of gas through a solid. The process always involves diffusion through the solid and may involve surface phenomena such as dissociation, sorption, desorption and migration.

Pneumatic Fluid Power

The energy that is controlled and transmitted within an enclosed circuit by use of a pressurized fluid.

Positive Gauge Pressure

The difference in pressure above atmospheric pressure.

Pressure

Force per unit area impacting a surface, typically expressed in pounds per square inch (psi) or in MegaPascals (Mpa).

Pressure Switch

An electrical switch controlled by fluid pressure.

Psia (Pounds per Square Inch Absolute)

Pressure measured from a state of complete absence of air.

Psig (Pounds per Square Inch Gauge)

Pressure above or below (vacuum) atmospheric pressure.

Quick Exhaust Valve

A valve that releases air directly to the atmosphere, bypassing the directional valve, which reduces back pressure resistance.

Receiver Tank

Container in which gas is stored under pressure or vacuum as a source of pneumatic fluid power. Receiver tanks accommodate sudden or unusually high system demands, prevent frequent on/off cycling of an air compressor or vacuum pump and absorb pulsations.

Residual Gas Analyzer

Also referred to as a "partial pressure analyzer" or "partial pressure gauge," it is a device for measuring the amounts and species of various gases present in a vacuum chamber.

Residual Gas

Gas remaining in the vacuum chamber after pump-down.

Safety Valve

A valve that opens to its full capacity to provide a rapid and large reduction in pressure when a predetermined value is exceeded.

Sight Ports

Holes covered with the glass through which the inside of a vacuum system may be observed.

Solid-state

Any element that controls current without moving parts, heated filaments or vacuum gaps.

Sorption

A generic term used to describe the uptake of a gas or vapor by a solid without distinction as to whether the process occurs by adsorption and/or absorption.

Standard Air

Air at a temperature of 68°F, a pressure of 14.7 psia and a relative humidity of 36%.

Standard Temperature and Pressure (STP)

Also referred to as "standard operating conditions," it is a term referring to the temperature and pressure to which all values are referenced for comparison. STP is generally 760 mm Hg (1 atm), 25°C.

Surface Damage

The physical changes of a surface structure to states of less regularity or symmetry, or the chemical changes in its composition.

Torr

A unit of pressure equal to 1/760th of a standard atmosphere.

Trap

A device used to capture and retain vapors and gases on cold and/or adsorbent surfaces.

Turbulent Flow

Gas flow that is not laminar at high pressures and velocities.

Vacuum

A space of air or other gas that is less than atmospheric pressure, expressed in inches of mercury (in. Hg).

Vacuum Chamber

The enclosure or container that is evacuated and in which the process or experiment is performed.

Vacuum Gauge

An instrument for determining gas pressure below atmospheric pressure.

Vacuum Rated Capacity

The cfm of free air exhausted by a vacuum pump at rated speed. Usually given for vacuums ranging from 0 in. Hg to the maximum vacuum rating.

Vacuum Relief Valve

A valve that operates to provide a modulated flow of atmospheric air into the system to control vacuum level of the system.

Vacuum System

A total assembly, composed of vacuum pumps, valves, chambers, lines and monitoring instruments, used to conduct a vacuum process or experiment.

Vapor Pressure

A fixed value that typically refers to the saturated vapor pressure at a specific temperature for all substances.

Venturi Vacuum Pumps

Derive their name from a phenomenon known as the Venturi effect. For the Venturi effect to happen, a liquid or a gas must flow through a tube known as an aspirator. This tube narrows and then expands in a cross-sectional area to allow for more volume. When the tube narrows, the fluid’s pressure decreases.

Viscosity

The resistance to flow of a fluid when subjected to pressure.

Viscous Flow

The flow of gas, which may be turbulent or laminar, through a channel under conditions such that the mean free path is very small in comparison with the smallest dimension of a transverse section of the channel. At these pressures, the flow characteristics are determined mainly by collisions between the gas molecules.

Volumetric Efficiency

Also known as "volumetric ratio," it is the ratio of the actual delivery of a pump to its calculated delivery multiplied by 100%.

More Vacuum Pump Information

Vacuum Pump Informational Video