Warehouse Automation

Whether it is making various tasks easier to enhance worker productivity, or by totally automating repetitive manual activities, technology is improving the efficiency of many warehouse processes and allowing employees to concentrate on more challenging duties. This aspect has benefited the working firms financially by properly adjusting their staffing levels while enabling them to improve their overall efficiency. Warehouse automation is a modernized engineering solution that is widely adopted in different working sectors around the globe. Reducing the involvement of manual labor via warehouse automation has played an exceptional role in workplace safety too by removing employees from many dangerous tasks.

Quick links to Warehouse Automation Information

What is Warehouse Automation?

Any procedure that aids in automating your standard warehouse production is considered warehouse automation. It could involve moving supplies inside your warehouse, moving products in and out of your warehouse, or making sure merchandise gets to clients quickly and effectively.

Many repetitive chores that might otherwise put a lot of stress on your personnel can be eliminated with warehouse automation, allowing you to both lessen the workload on your workforce and utilize them for more important tasks. Compared to a warehouse that depends solely on human employees to handle those crucial activities, an automated warehouse can handle distribution issues more effectively.

Types of Warehouse Automation

In order to maintain inventory and distribute items, warehouses manage a range of duties and processes. Due to this fact, there are a variety of technologies available for warehouse automation that can speed up various warehouse procedures. Below are the various types of warehouse automation technologies:

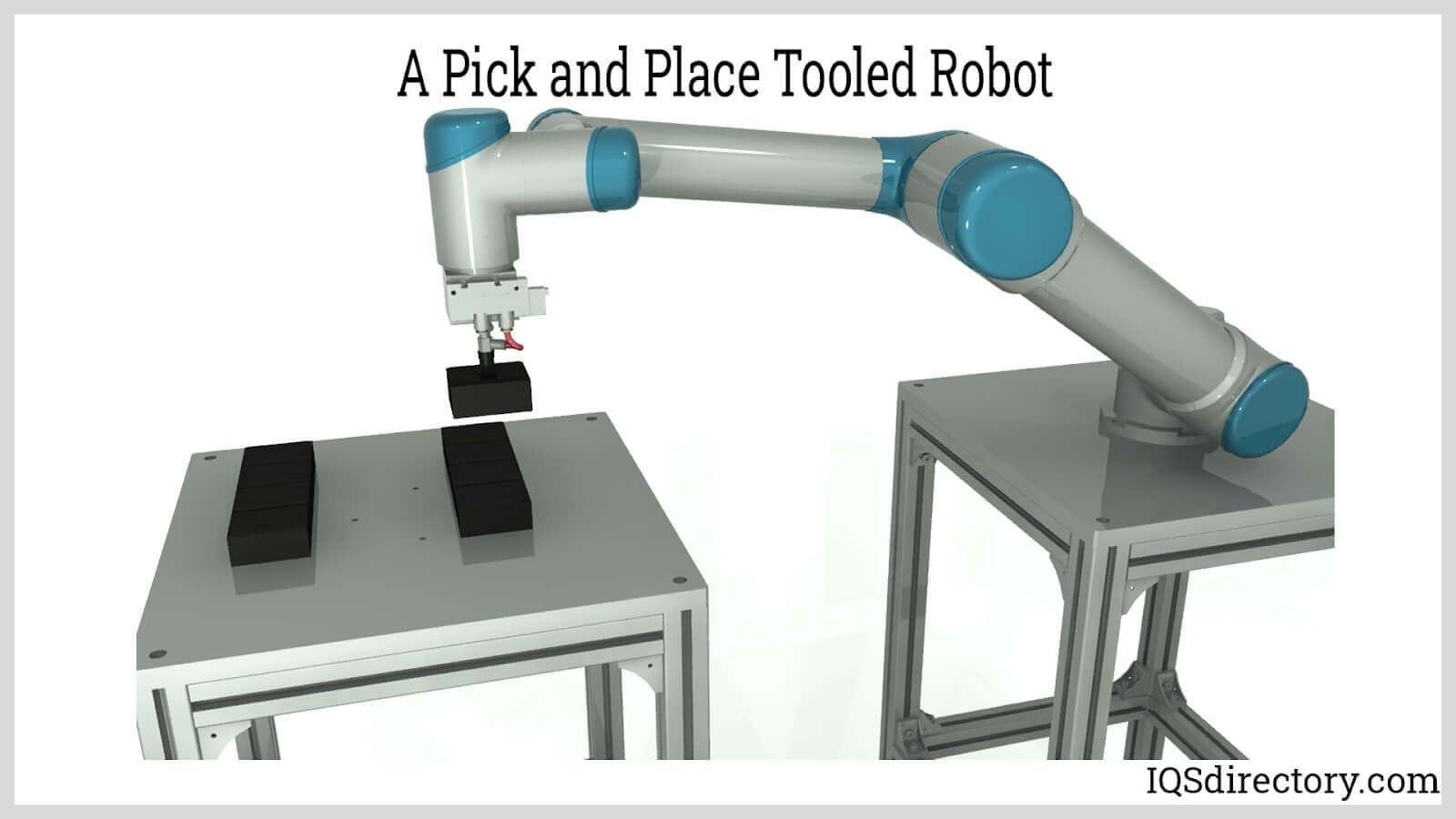

Goods-to-Person Technologies

Robots or other equipment that deliver materials to workers for assembly or packing make up the majority of goods-to-person (GTP) solutions. It might make use of cars that drive around the warehouse collecting materials or cranes. Conveyor systems, automated storage, and retrieval solutions are also included in GTP.

Voice Picking and Voice Tasking

A warehouse order picker's routine can be enhanced with communication technology through voice picking or voice tasking solutions. Pickers and taskers coordinate mobility and picking jobs more efficiently by speaking to one another, typically using wireless headsets.

Drones

Though technically a robot, most drones lack efficient onboard computers. Barcode scanner-equipped drones are utilized for inventory management to conduct inventory counts and notify warehouse employees of products that need replenishing or those that are in inappropriate storage places. Drone deliveries are another application that some warehouse automation businesses are exploring.

Cloud Storage

There is no longer a need for a large amount of space in the warehouse for servers and technology if automated technology is employed. One can use cloud technology as an alternative. Cloud technology might offer improved security, more storage space overall, and better scalability, allowing one to easily extend its use as warehouse needs change over time.

Benefits of Warehouse Automation

Below are some of the useful benefits of warehouse automation:

- Increased throughput in the warehouse

- Better use of resources

- Decreased operating and labor costs

- Enhanced client services

- Cheaper handling and storage

- Decrease in human error

- Reduced manual work

- Increased effectiveness and productivity

Applications of Warehouse Automation

Warehouse automation is useful in numerous processes for various industries. The processes which were previously conducted manually in the warehouse may now be automated. Below are the warehouse processes which can benefit from automation:

- Shipping

- Replenishment

- Returns

- Receiving

- Sorting

- Stocking

- Picking