Water Jet Cutting

Water jet cutting gives manufacturers, artists, woodworkers, and others the power to precisely shape or alter a wide range of materials—including plastics, ceramics, and stainless steel ;without introducing heat or compromising quality.

History of Water Jet Cutting

The origins of water jet cutting trace back to 19th-century mining operations in New Zealand and South Africa. At the time, miners used high-pressure water streams to clear rocks and coal debris from excavation sites, allowing them to work from a safer distance. This early application was born out of necessity, as it reduced the risk of injury from flying debris.

By the 1930s, Russian engineers adapted the concept for cutting massive stones, using water cannons that delivered pressure up to 7,000 bars. The technology gained further traction in the 1970s, when U.S. innovators developed water jet systems that combined water pressure of up to 40,000 bars with mechanical drills. Eventually, industrial designers enhanced the method by introducing abrasive particles like sand into the stream—creating a cutting process that could also deliver custom finishes.

Advantages of Water Jet Cutting

Unlike plasma, laser, or traditional blade methods, water jet cutting delivers extreme precision without generating heat. That means no warping, no burnt edges, and no burrs—just clean, accurate cuts. Because there's no heat-affected zone, there's often no need for post-processing, which saves time and cost.

This process works across a wide variety of materials and requires minimal setup, making it ideal for everything from one-off prototypes to high-volume production. Some systems can even be configured with multiple cutting heads to maximize efficiency and output, making water jet cutting one of the most flexible and cost-effective methods in modern fabrication.

Design of Water Jet Cutting

Modern water jet cutting systems operate at pressures ranging from 30,000 to 120,000 PSI. At the higher end of that range, fragile materials like glass and ceramics can be prone to shattering, which is why lower-pressure systems are often used when cutting brittle substrates. The precision of these machines comes from their integration with CNC (computer numerical control) systems, which govern both the pressure output and the intricate, controlled movement of the water jet itself.

Materials Used in Water Jet Cutting

Although water jet cutting is one of the most versatile machining processes available, it's not universally compatible with all materials. Certain types of glass and ceramics—particularly those with unique compositions or excessive thickness—can fracture under the jet’s force. Conversely, extremely hard materials such as diamonds or some high-strength metals can resist being shaped by water jets. Additionally, moisture-sensitive or hydrophobic substances are poor candidates for this method. Still, for the wide range of materials that are compatible, including steel and various forms of sheet metal, water jet cutting provides a powerful, clean, and accurate way to achieve detailed cuts. Among the different applications, metal cutting with water jets stands out as particularly robust, capable of reshaping dense and heavy-duty materials with remarkable precision.

Water Jet Cutting Process

The exceptional performance of water jet cutting systems stems largely from their reliance on CNC control, which ensures consistent accuracy and speed across a wide range of applications. Another strength lies in their ability to reclaim and recycle both the water and the abrasive media used during operation. This capability not only cuts down on waste and supply costs but also supports a more environmentally sustainable workflow. With reduced reliance on raw resources and lower operational expenses, businesses can reinvest those savings into equipment upgrades, better maintenance routines, and increased production capacity.

In terms of workplace safety, water jet cutting holds several advantages over traditional hot-cutting methods like plasma or laser cutting. The process generates no harmful fumes, no sparks, and no flying debris, making it safer for operators and less disruptive to nearby environments. The main concern—noise, especially from high-pressure systems—can be easily mitigated with ear protection and workspacesoundproofing. Because of the minimal safety risks and low thermal output, water jet cutting stations can operate for extended periods, sometimes running for up to 20 hours without interruption, further maximizing productivity.

Applications of Water Jet Cutting

Industries ranging from aerospace and automotive to food processing and telecommunications rely heavily on water jet cutting for its speed, precision, and adaptability. The method is especially effective on heat-sensitive materials like thermoplastics, which can warp or discolor under traditional heat-based cutting tools. With a water jet, the plastic retains its integrity outside the immediate area of the cut, preserving both appearance and performance. In woodworking, the technique supports custom shaping and etching, enabling the creation of finely detailed furnishings, architectural components, and specialty items like utensil handles or keepsake boxes.

In food manufacturing, water jet cutting delivers clean, accurate cuts without introducing contaminants, making it an ideal choice for preparing items like sausages, noodles, and artistic bento box arrangements. For artists and designers, the ability to replicate intricate shapes and detailed patterns means they can mass-produce high-fidelity renderings of characters or designs for merchandise. These cuts maintain a level of consistency and complexity that’s difficult to achieve through manual methods, even by a skilled team of artisans.

Machinery Used for Water Jet Cutting

Among machining processes, water cutting is relatively straightforward in design and operation. At its core, the system features a nozzle—also known as a focusing or mixing tube—that directs high-pressure water through small apertures. To minimize splashing during operation, this nozzle is fitted with a muff made of sponge or brush material. High-pressure fittings on the mixing tube include weep holes to safely redirect water in the event of a leak. An attenuator regulates and sustains consistent water pressure, especially when working with pumps that deliver variable outputs.

The cutting water may be used in its pure form, or it can be combined with abrasive particles to enhance cutting strength. The rate at which these particles move through the stream is known as the abrasive flow rate, while the particles themselves are classified as abrasive substances. The particle concentration and thickness in a single stream is referred to as the mesh. The most complex component of the setup is the CNC system, which governs the cutter’s motion. This computerized control system varies by installation, often using a blend of CAD/CAM-like software, nesting, and scanning tools. Once configured, the system guides the water jet along a cutting path with a resolution of up to 2,000 points per inch. Apertures—commonly called jewels—differ in spacing, material, and size, and are frequently made from high-durability substances such as sapphire, ruby, or diamond.

Stainless steel is a typical choice for the construction of nozzles and supply components due to its strength and resistance to corrosion. A protective catch tank or enclosed area is commonly used to manage water runoff and contain debris. The process is highly adaptable based on the size of the apertures, the pressure settings, the materials being cut, and the capabilities of the CNC system controlling the operation.

Water Jet Cutting Images, Diagrams and Visual Concepts

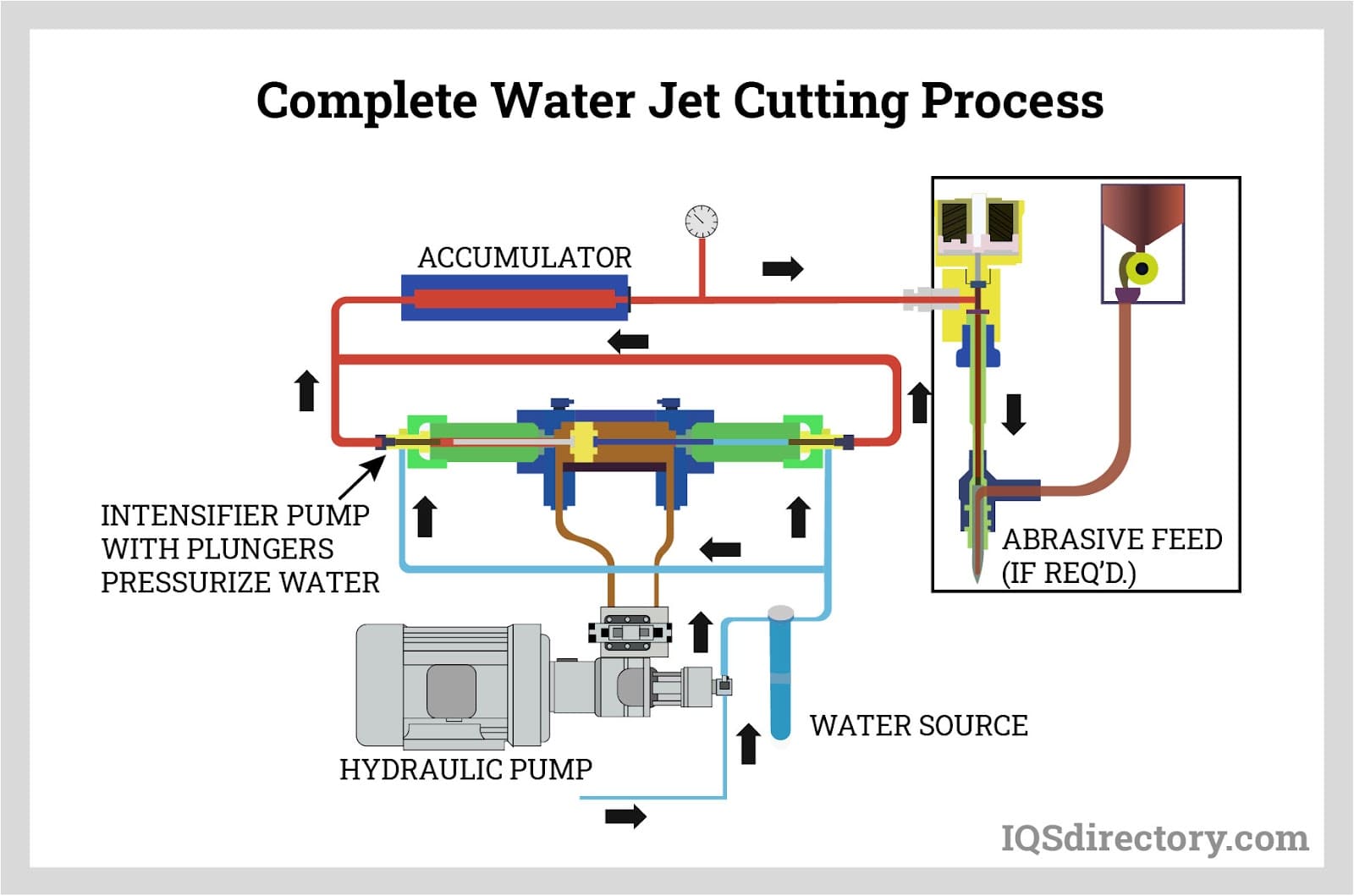

Water jet cutting, a manufacturing process using high pressure jets of water provided by pressurizing pumps to deliver a supersonic stream of water to shape various materials.

Water jet cutting, a manufacturing process using high pressure jets of water provided by pressurizing pumps to deliver a supersonic stream of water to shape various materials.

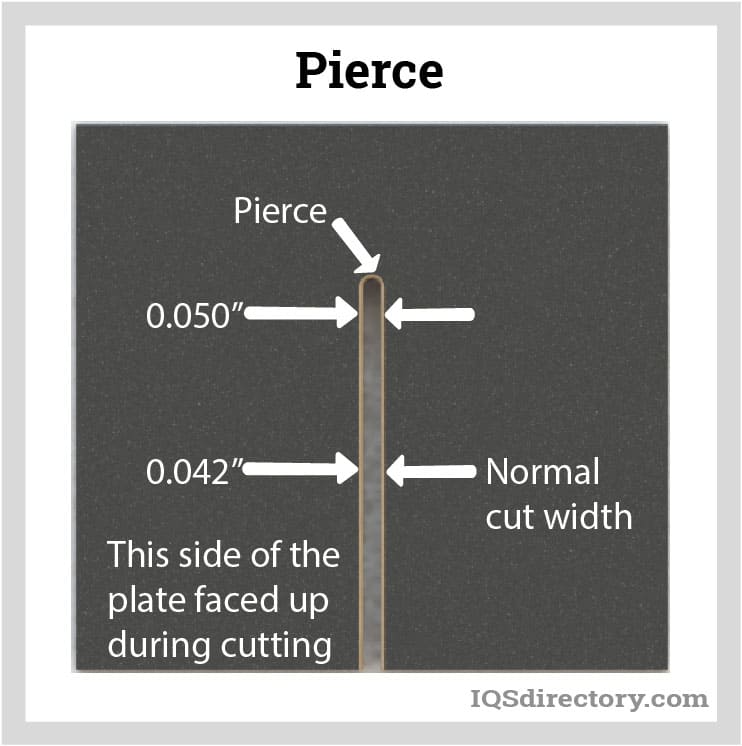

The initial cut is the pierce.

The initial cut is the pierce.

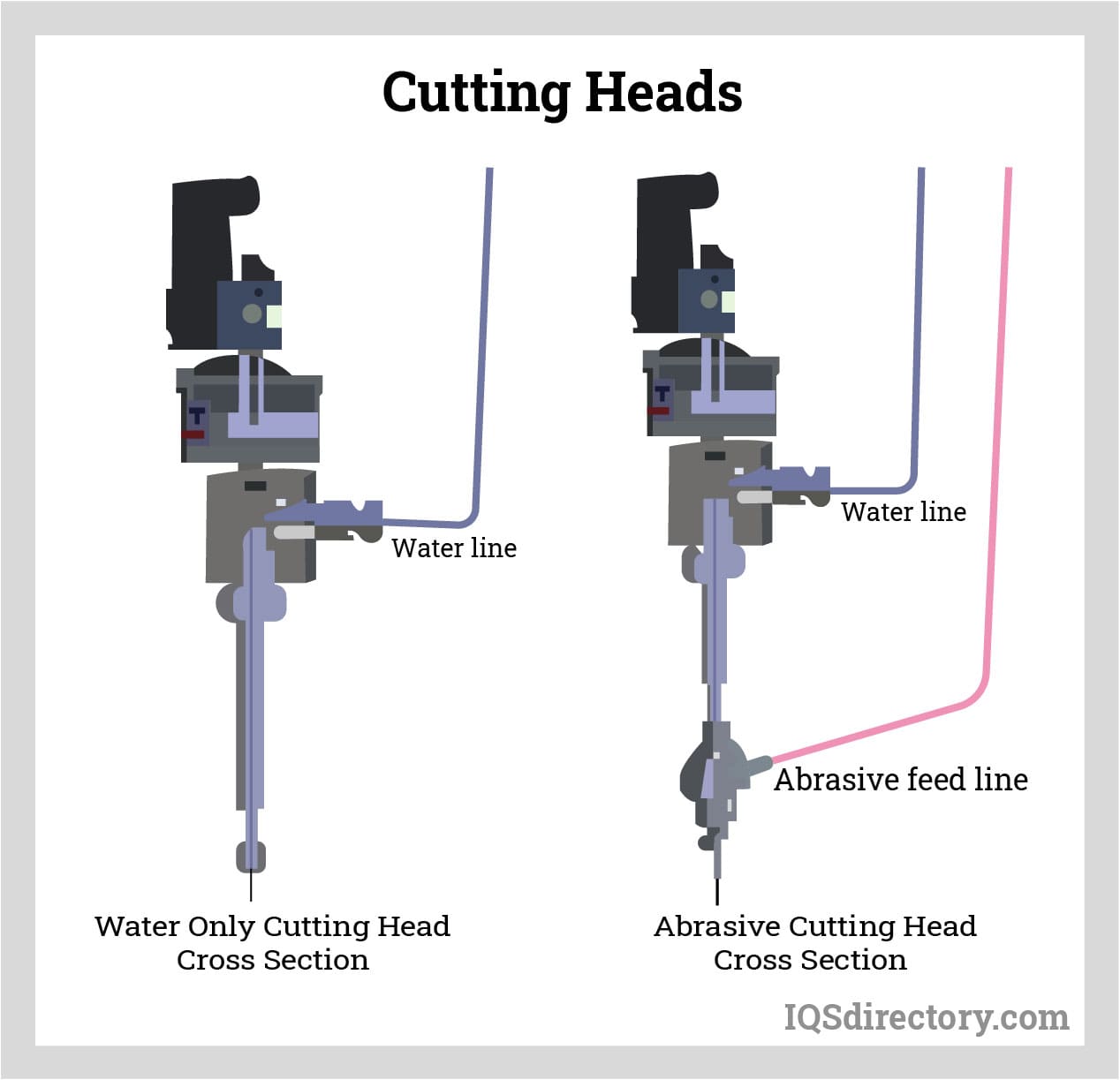

The pressurized water passes through the orifice of the cutting head with a hole smaller than the point of a pin and as water passes through, its velocity radically increases to over 90,000 psi.

The pressurized water passes through the orifice of the cutting head with a hole smaller than the point of a pin and as water passes through, its velocity radically increases to over 90,000 psi.

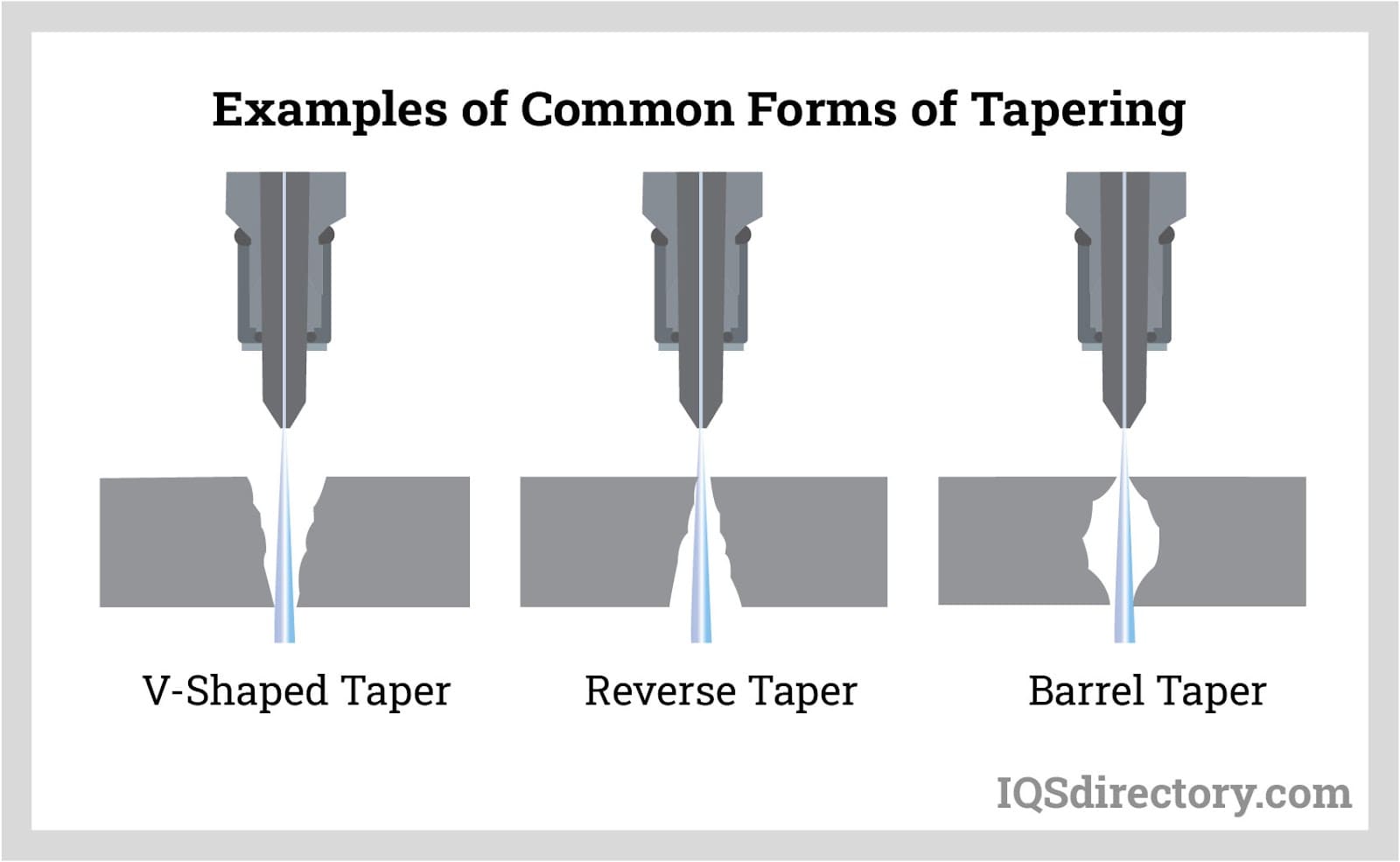

Examples of the different forms of tapering used in water jet cutting.

Examples of the different forms of tapering used in water jet cutting.

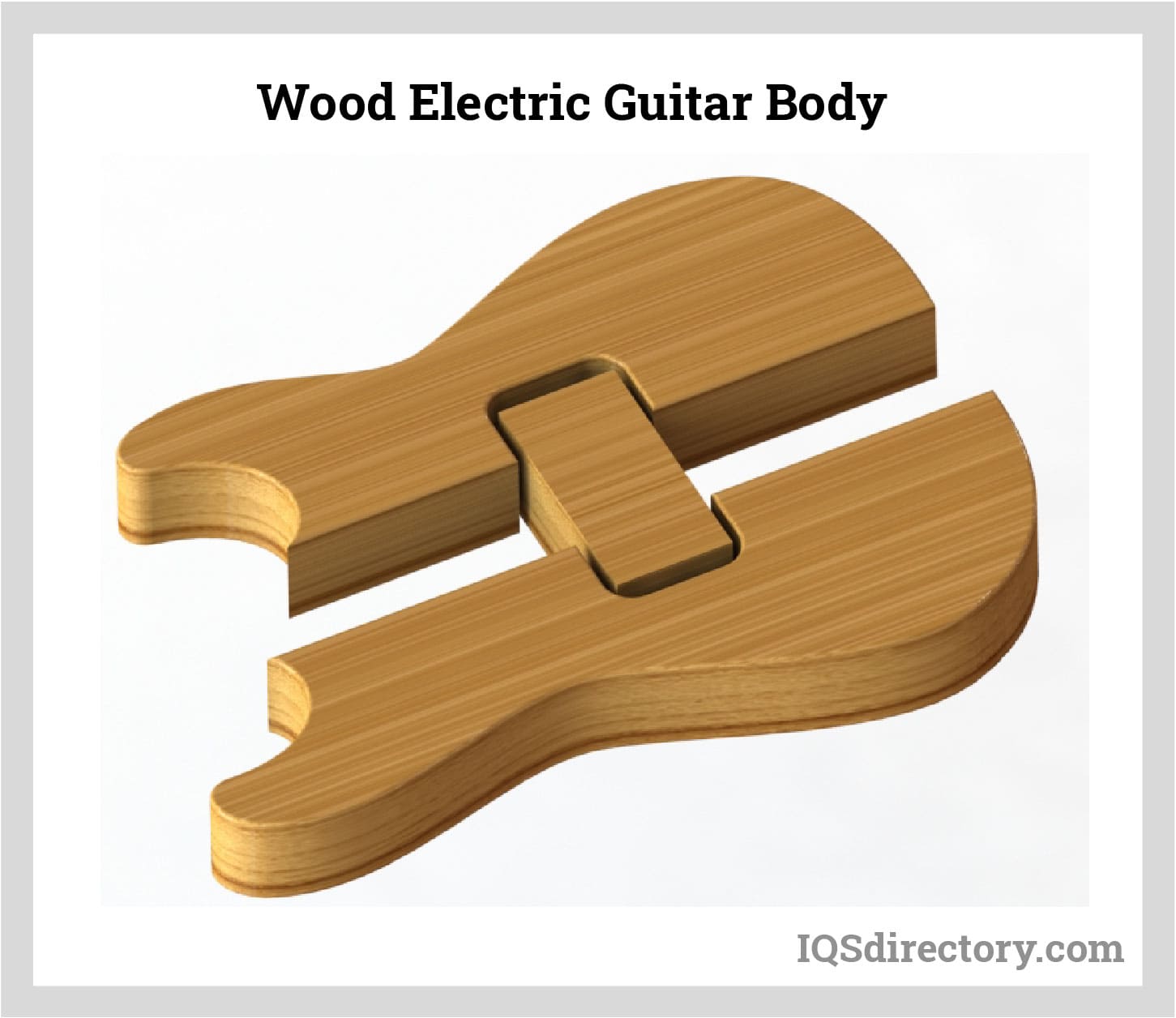

Since water jet cutting does not place a load on the piece, it is capable of cutting without damaging the grain of the wood.

Since water jet cutting does not place a load on the piece, it is capable of cutting without damaging the grain of the wood.

Water jet cutting of rubber is easier other cutting methods, since water jet cutting does not require special tools or dies.

Water jet cutting of rubber is easier other cutting methods, since water jet cutting does not require special tools or dies.

Water Jet Cutting Types

Water jet cutting encompasses a wide range of specialized methods, each designed to handle specific materials or achieve particular results.

- Abrasive Flow Machining (AFM)

- This secondary finishing process uses abrasive-laden water to smooth, polish, radius, and remove imperfections like cracks and burrs from internal or hard-to-reach surfaces of parts, products, and machinery.

- Abrasive Jet Machining

-

By introducing abrasive particles into the water stream, this method enhances cutting power, making it effective for machining tougher materials. The erosion is achieved not just by water, but by the high-speed impact of the abrasive.

- Abrasive Waterjet Cutting

- Instead of relying on pure water, this process mixes in abrasive materials such as garnet or diamond to cut through hard surfaces like metal, stone, ceramics, brick, and composite materials, offering precision shaping capabilities.

- CNC Water Jet Cutting

- This computer-controlled technique eliminates manual handling by automating the cutting, drilling, and engraving of various materials through programmable software, ensuring accuracy and repeatability.

- High Pressure Water Cutting

- Operating at extremely high PSI, this process can shape or cut virtually any material, including glass, marble, foam, plastics, and ceramics, without producing heat-affected zones.

- Hydro Cutting

- Also known as cold cutting, this method uses a high-pressure stream of water to cleanly slice through a wide array of materials without generating heat, making it ideal for applications where thermal stress must be avoided.

- Pure Waterjet Cutting

- This original form of water jet cutting involves a thin stream of high-pressure water directed through a tiny nozzle to cut soft materials like foam, rubber, textiles, and paper with remarkable precision.

- Water Jet Glass Cutting

- Tailored for glass, this method allows for clean separation, intricate detail work, and precision hole-drilling across different glass types without the risk of cracking from thermal shock.

- Water Jet Machining

- A versatile subtractive manufacturing process that uses high-pressure water jets to contour and shape materials, delivering consistent cuts regardless of material type or thickness.

- Water Jet Metal Cutting

- Capable of cutting through nearly any metal, this method combines the force of pressurized water with abrasives to handle steel, aluminum, and other dense materials with efficiency and minimal edge distortion.

Products Made From Water Jet Cutting

Water jet cutting offers virtually limitless potential when it comes to the types of products that can be manufactured. Its precision, combined with the absence of heat distortion or rough edges, allows us to make the most efficient use of sheet materials, especially metals. This capability is particularly beneficial for industries like automotive and electronics manufacturing, where highly detailed patterns for various components must be produced rapidly and with minimal waste. Because the process leaves excess material undamaged, scrap can be recovered from the catch tanks and reused, further boosting efficiency and sustainability.

For parts that require tight tolerances and mechanical compatibility—like bolts, gears, and interlocking components—water jet cutting delivers clean, repeatable results on a large scale. The control we have over jet paths through CNC programming makes it possible to create holes and internal geometries of virtually any dimension. Whether it’s a basic circular cut or a complex custom design, the process consistently produces accurate and reliable parts. This makes it well-suited not only for mass production but also for unique artistic pieces and experimental prototypes that haven’t yet been brought to market. Because it can process materials ranging from cork, wood, and foam to aluminum, copper, steel, acrylic, and granite, water jet cutting meets the needs of a remarkably wide range of product categories.

Glass remains one of the few challenging materials in this process—but only when excessive pressure is used. That challenge is easily addressed by specialists who tailor pressure and technique to suit each glass application. Beyond the technical advantages, water jet cutting stands out as an environmentally responsible option. The process generates no heat-affected zones, and the water itself can be filtered and reused multiple times. Since the abrasives involved are typically benign, the operation avoids introducing pollutants into the environment. Thanks to this adaptability and minimal environmental impact, water jet cutting continues to be an ideal solution for industries undergoing frequent design updates and material changes, helping companies roll out new features or reengineer parts with minimal delay and cost.

Things to Consider when Choosing Water Jet Cutting

Selecting the right water jet cutting manufacturer begins with understanding the materials you need to process and the volume of production required. Some manufacturers are well-suited for creating small runs or custom prototypes, while others are equipped for high-volume production that spans thousands or even millions of parts. Each manufacturer will have particular expertise in how different materials respond to jet cutting, especially those like metal, which vary widely in form—stainless steel, galvanized, rolled metal, and others—each with different thicknesses and processing characteristics. These variables influence what’s known as the cutting index or machinability, particularly for abrasive water jet processes. Thicker materials may call for a stationary pierce, where the jet remains in place to initiate a clean entry point, a method often applied to thinner metals as well to reduce distortion at the start of the cut.

An experienced manufacturer won't just know the nuances of cutting a specific material—they'll also have a clear understanding of how to manage your intended production size, whether that’s a single intricate part or a full-scale production run. Since water jet cutting encompasses a range of methods, a skilled shop will recognize distinctions such as etching versus full cutting, and be adept at techniques like bridging, where small tabs are left in place to prevent parts from falling into the catch tank mid-process.

One of the most telling indicators of a manufacturer’s capability is their past work. Reviewing actual samples, or speaking with clients they’ve served, provides insight into their strengths and specializations. A reputable shop should have no issue offering sample cuts to demonstrate their capabilities. Additionally, they should be able to give you a realistic timeline for your order, taking into account any existing lead times. While a busy production schedule may require a longer wait, it’s often a sign of a shop trusted for their precision and quality.

Disadvantages

Despite its many strengths, water jet cutting does have limitations depending on the material. Certain types of glass and ceramics may be too brittle to withstand the pressure without cracking, while materials at the extreme end of hardness—such as diamonds or some high-performance alloys—can resist even the most abrasive-enhanced jets. Similarly, water-sensitive or hydrophobic materials are not good candidates for this process. Still, these exceptions aside, water jet cutting remains one of the most adaptable and powerful methods available, particularly for shaping metal. It excels in producing clean, burr-free cuts in everything from thick steel to delicate sheet metal, making it a cornerstone process in both industrial and custom manufacturing.

Water Jet Cutting Terms

-

Abrasive Flow Rate

This refers to the speed at which abrasive material is introduced into the cutting head of a water jet system, directly affecting the cutting force and precision of the operation.

Abrasive Substances

These are the cutting agents in abrasive water jet systems, typically materials like garnet or sand-like particles, which enhance the jet’s ability to erode and slice through tough materials.

Attenuator

A pressurized vessel that helps stabilize and maintain consistent water output by compensating for fluctuations from the pump, ensuring smooth water jet performance.

Bridge/Bridging

A technique used during cutting where parts remain attached via a thin strip of metal to prevent them from falling into the catch tank; the bridge is removed once cutting is complete.

Catch Tank

Located beneath the cutting head, this tank dissipates the force of the water jet, prevents floor damage, and collects spent abrasive material from the cutting process.

Common Line Cutting

An efficiency-driven method where multiple parts are cut along shared edges to save time, though it is more complex to program and may reduce cutting accuracy.

Crankshaft Pump

A mechanical pump where plungers, powered by a crankshaft, generate the necessary pressure for the water jet to perform its cutting operations.

Cutting Index/Machinability

A numerical value representing how easily a material can be cut using a water jet or abrasive water jet process, factoring in material hardness, density, and thickness.

Cutting Model

A simulation or representation used to anticipate how the jet will behave during the cut, aiding in compensations for tool flexibility and process variables.

Draft Angle

The angle created by tapering during the cutting process, often noticeable on thicker materials or when using high-speed cuts.

Dynamic Pierce

This method initiates the cut by allowing the jet to move while piercing, reducing stress on the material and increasing precision.

Etch

A low-pressure marking process where the jet partially erodes the material surface without fully cutting through, commonly used for identification or decorative purposes.

Feed Rate

The speed at which the cutting head travels across the material during operation, influencing the cut quality and efficiency.

Focusing/Mixing Tube

A highly durable tube that channels and unifies the water and abrasive materials into a single, powerful cutting stream.

Frosting/Hazing

A visual effect caused by stray abrasive particles, typically appearing as a frosted area along cut edges or around initial pierce points.

Garnet

A durable, commonly used abrasive that offers excellent cutting power while preserving the lifespan of mixing tubes.

Hard Limit

A mechanical restriction built into the machine to physically prevent movement beyond certain boundaries, protecting both the equipment and the operator.

Hard Water

Water with high mineral content that can leave behind deposits, requiring more frequent maintenance of parts like filters, pipes, and jewels.

Intensifier

A hydraulic pump that multiplies input pressure to generate the extremely high pressures needed for water jet cutting.

Jet Lag

The offset or delay observed between where the water jet enters and exits the material, often visible as a curved or distorted edge on thicker parts.

Jewel

A precision-crafted orifice made from ruby, sapphire, or diamond through which the high-pressure water exits to form the cutting stream.

Kerf

The width of material removed by the cutting stream, determined by the nozzle size, abrasive flow, and cutting parameters.

Kick Back

The backward jolt or motion of the cutting head as it accelerates from a corner or sudden directional change during the cut.

Mesh

A grading scale for abrasives that indicates particle size and coarseness, affecting cutting power and surface finish.

Muff

A protective brush or sponge around the nozzle that helps contain splashback and water spray during operation.

Nozzle

The assembly that includes the mixing tube, jewel, and surrounding housing, responsible for shaping and directing the water jet stream.

Pierce

The process of initiating a hole through the material by holding the cutting jet steady until full penetration is achieved.

Reverse Osmosis

A water purification method used to filter minerals and impurities from the water supply, protecting equipment from scaling and buildup.

Slat

A support structure beneath the material being cut, designed to be replaceable as it becomes worn or damaged during use.

Soft Limit

A software-defined boundary set in the machine’s programming to control the cutting head’s range of motion and prevent collisions.

Splash Back

A messy byproduct of piercing, caused by water and abrasive bouncing off the support slats or material surface before full penetration.

Stationary Pierce

A method used to carefully pierce thin materials by keeping the water jet still until the hole is fully formed.

Striation Marks

Ripple-like patterns on the cut surface caused by minor fluctuations in jet motion; faster cuts typically show more pronounced striations.

Super-Water®

A proprietary additive that enhances cutting speed, stream concentration, and reduces wear on high-pressure components.

Tab/Tabbing

A method of leaving small material connections between the part and the base to keep the piece stable during cutting and prevent it from falling.

Taper

The deviation in cut width between the top and bottom surfaces of a part, often influenced by material thickness and jet behavior.

Tool Offset

A calibration adjustment that positions the jet slightly away from the cutting path to account for the stream's kerf width.

Traverse

The movement of the cutting head when it is repositioning between cuts or aligning itself, without performing any active cutting.

Velocity

The rate at which the jet or head moves through space, often expressed in feet per second, impacting precision and cut smoothness.

Water Jet Cutters

Machines that use high-pressure water—sometimes mixed with abrasives—to cut through a wide range of materials.

Water Knives

Tools that apply pressurized water streams to cleanly slice food products with minimal waste or deformation.

Waterjet

A high-pressure stream of water used to erode and cut through material surfaces with pinpoint accuracy.

Waterjet Cutting Machinery

Industrial systems designed to harness water under immense pressure to cut, shape, and grind material with fine control.

Weep Hole

A small opening in high-pressure fittings designed to safely release water in the event of a leak, preventing internal damage.

Wiggle Pierce

A faster piercing technique where the jet oscillates in place to break through material, typically used on tougher or thicker surfaces.