Wire Forms

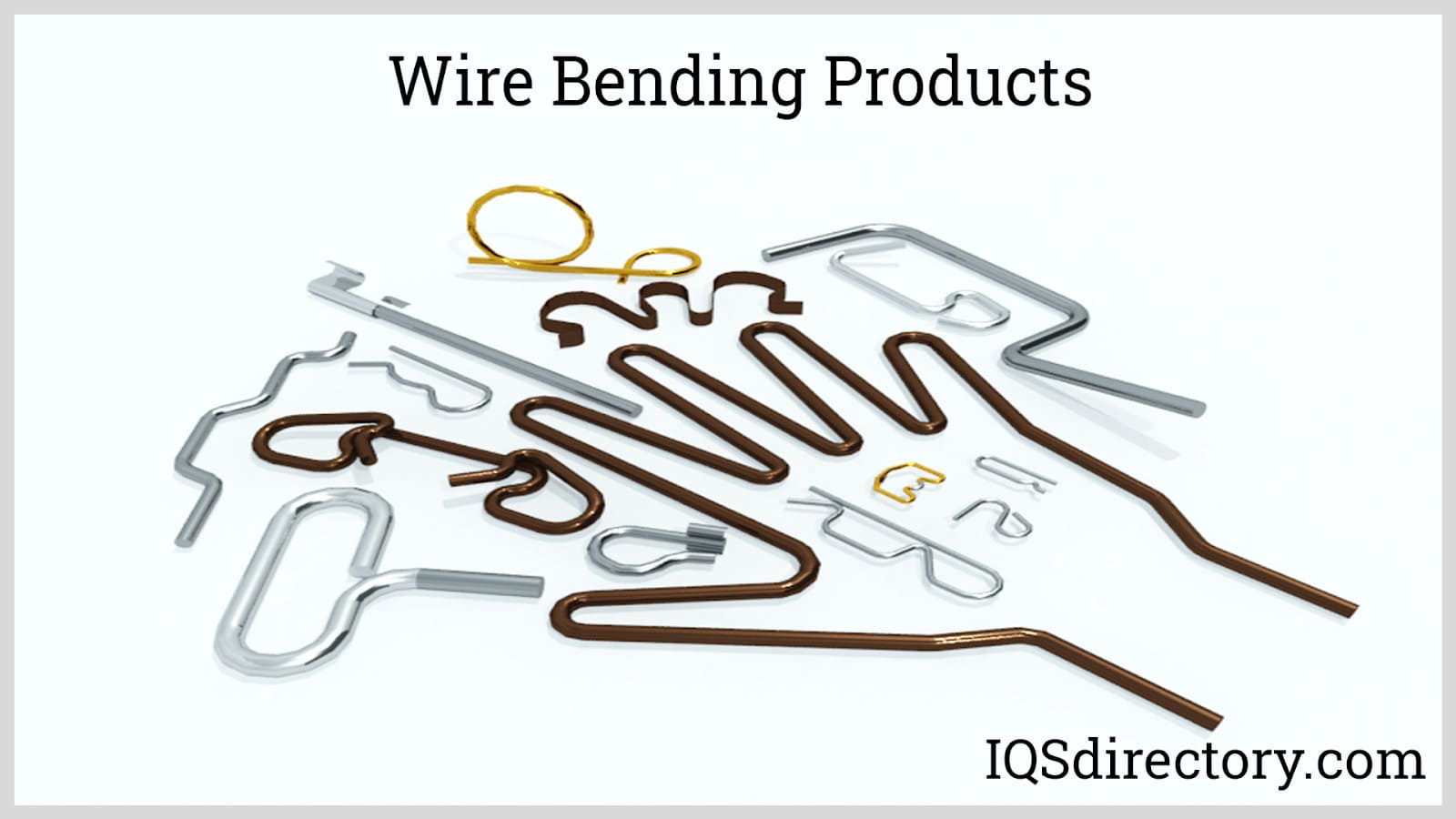

Wire forms are custom-shaped components fabricated by expertly manipulating wire through processes such as cutting, bending, and heat treating. This versatile fabrication method allows us to produce complex wire products tailored to nearly any specification, from simple two-dimensional profiles to sophisticated three-dimensional structures.

Wire Forms FAQs

What are wire forms used for in manufacturing?

Wire forms are custom-shaped metal components used in industries like automotive, healthcare, electronics, and construction. They serve as springs, guards, baskets, racks, and hooks, providing structural support, protection, and functionality in diverse applications.

How are wire forms fabricated?

Wire forms are produced by cutting, straightening, and bending wire into specific shapes. Processes include CNC wire forming, hydraulic pressing, and four-slide stamping, followed by finishing operations like cutting, coining, or plating for a refined product.

What materials are commonly used for wire forming?

Common wire form materials include steel, stainless steel, brass, copper, and aluminum. Stainless steel is popular for its corrosion resistance and strength, while copper and brass are favored for conductivity and aesthetic appeal.

What is CNC wire forming?

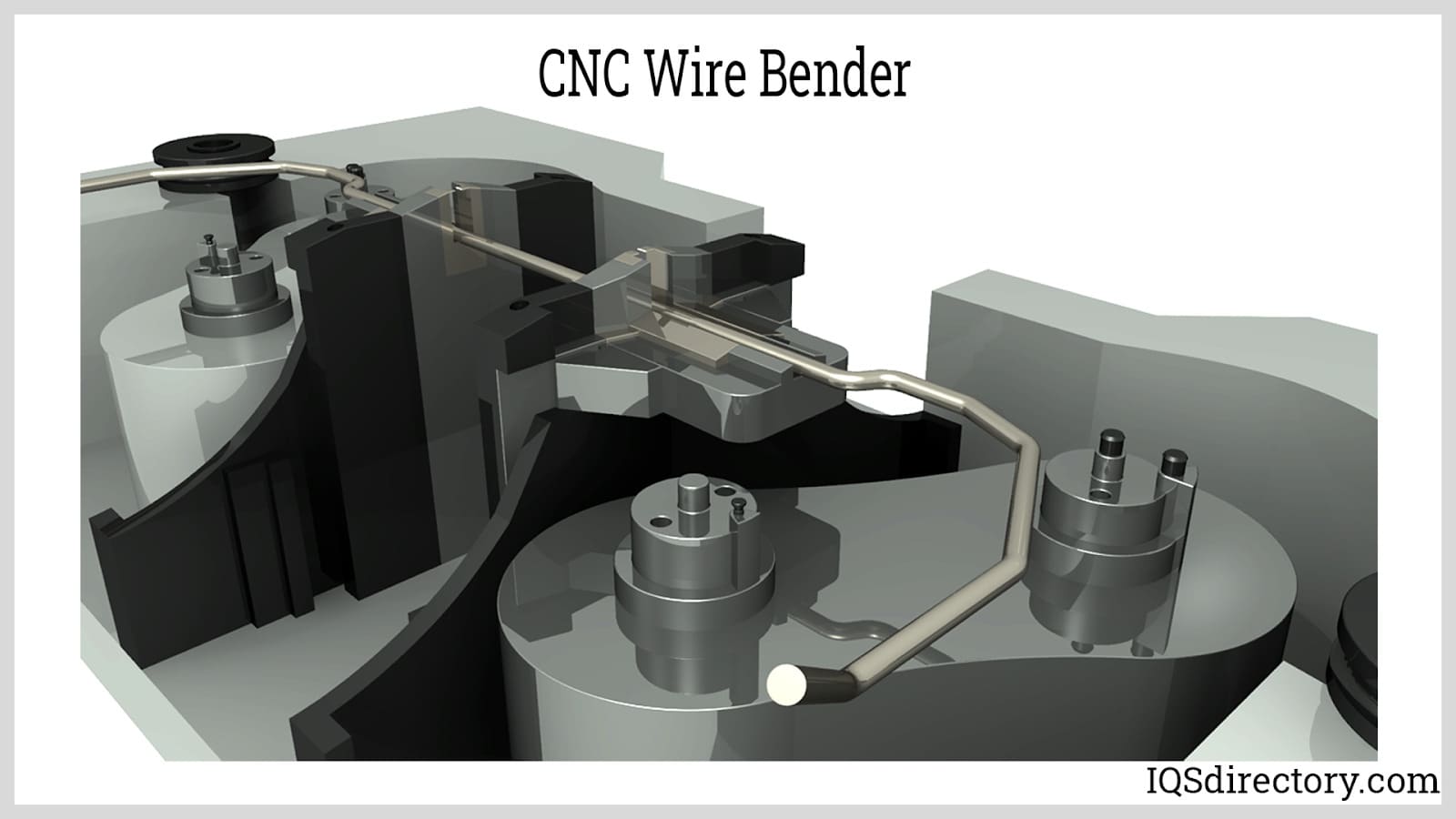

CNC wire forming uses computer-controlled machinery to bend wire into precise 2D or 3D shapes. This method improves accuracy, reduces human error, and allows manufacturers to switch quickly between complex custom designs.

What industries rely most on wire forms?

Industries such as automotive, healthcare, aerospace, construction, and retail depend heavily on wire forms. They are used for suspension springs, medical trays, display racks, safety guards, and filtration screens in these sectors.

How do wire baskets differ from wire racks?

Wire baskets are enclosed structures designed for storage or washing, while wire racks and shelves are open, flat frameworks used for display or organization. Both are durable and easily customized for industrial or retail use.

What should be considered when selecting a wire form manufacturer?

When choosing a manufacturer, evaluate their customization capabilities, material expertise, and service quality. For complex designs, request prototypes to ensure precision and confirm the design meets your application’s specifications.

Wire Form Products

- Wire Displays

- Wire displays encompass a broad range of functional wire products like grids, racks, shelves, and baskets. Wire grids, or grid panels, are constructed from intersecting horizontal and vertical wires, resembling wire mesh o rmetal gratings, but fabricated at a larger scale and exclusively from wire rather than solid bars. Wire Shelves and racks extend outward from walls, providing sturdy, flat storage surfaces that optimize available space.

- Wire Basket

- Wire baskets are durable, cage-like containers useful in various display, storage, and protective applications. Their open, airy designs offer convenient visual access while maintaining structural integrity.

- Wire Hardware

- Wire hardware includes diverse wire forms that function as essential tools, accessories, or support equipment. Typical examples include wire hooks and screens, each customized to fulfill specific roles across numerous applications.

- Wire Hooks

- Wire hooks are straightforward yet vital components fashioned by bending wire into distinctive shapes such as S-hooks, C-hooks, or J-hooks, serving practical hanging, connecting, or holding purposes.

- Wire Screens

- Wire screens involve intricate weaving of slender metal wires into precise crisscross patterns. These configurations form effective yet permeable barriers, ideal for use as filtering mechanisms or protective shields, regulating airflow and material passage while ensuring adequate protection.

- Wire Guards

- Specialized wire guards provide critical safety and protection, shielding operators from hazardous machinery and preventing damage to sensitive equipment. Our wire guards encompass an array of designs, including fan guards, finger guards, window and flooring protectors, face guards, and fixture shields, each crafted to deliver reliable performance in demanding environments.

Wire forms are essential components utilized across a wide spectrum of industries, including commercial and retail, medicine and healthcare, energy storage, maintenance, industrial washing, lighting, automotive, aerospace, construction, hardware, and storage. Below are brief descriptions illustrating a selection of wire form applications.

- Automotive

- In the automotive sector, wire springs represent one of the most prevalent wire forms, found in virtually every type of machinery. Robust springs such as compression coil springs and volute springs frequently provide support in suspension systems. Smaller, more delicate springs, including torsion springs and tension springs, fulfill various functional roles throughout vehicles. Additionally, specialized springs like conical springs play a key role in manufacturing battery contacts.

- Healthcare

- Healthcare applications demand adherence to rigorous sterilization and hygiene protocols, utilizing specialized equipment designed for stringent washing procedures. Ultrasonic washers, for instance, rely heavily on precisely engineered wire-form metal baskets to securely hold medical instruments and protect sensitive washer components like transducers. Other healthcare-specific wire forms include gauged trays and medical-grade hand-held pliers.

- Household

- Many common household items incorporate wire forms into their construction, including mouse traps, clothes hangers, and even components within music players.

- Electronics

- Within electronic devices, wire forms serve critical purposes. Antennas often comprise carefully shaped wire forms, and spring-based wire forms enable smooth opening and closing mechanisms in numerous electrical appliances.

- Commercial and Retail

- In commercial and retail environments, wire forms support merchandise displays, prominently used in point-of-purchase structures. Wire racks and shelving units also serve practical storage functions, while protective wire guards shield equipment used by retail personnel.

- Construction and Hardware

- Construction and hardware applications utilize wire forms in various ways, from clips and pins to wire hooks, springs, and protective wire screens. These items contribute to both functional utility and structural support across construction projects.

Wire Form History

Wire forming boasts a rich and lengthy history. Originally crafted manually, early wire forms most commonly took the shape of jewelry, meticulously fashioned by skilled artisans—a practice still honored today on a smaller scale.

The industrialization of wire forming accelerated notably during the late 17th century with Great Britain's establishment of its first wire mill, soon leading to the proliferation of similar mills and increasingly sophisticated manufacturing techniques.

In recent times, wire form manufacturing underwent a major advancement with the introduction of computer numeric control (CNC) machinery. CNC technology enables precise, automated fabrication of wire forms. Once programmed, CNC-driven machines reliably produce complex wire parts or complete wire forms, significantly reducing human error and contamination risks while consistently achieving higher levels of precision and efficiency.

Manufacturers are able to create wire forms from a wide array of materials, such as steel, stainless steel, brass, copper, aluminum, and various alloys. Among these, steel is the most commonly used material in wire forming.

- Steel

- An alloy primarily composed of iron and carbon, steel is affordable and well-known for its high tensile strength. It is sometimes referred to as carbon steel.

- Stainless Steel

- A steel alloy that is strong, lightweight, corrosion-resistant, rust-resistant, and has antibacterial properties. Stainless steel is available in 15 different grades.

- Brass

- An aesthetic alloy with a gold-like appearance, brass is relatively resistant to tarnishing and offers excellent thermal conductivity.

- Copper

- A naturally occurring element with a reddish hue, copper performs well at various temperatures and is resistant to rust when exposed to water. It is also an outstanding conductor of heat and electricity.

- Aluminum

- Aluminum offers good corrosion and rust resistance, along with heat resistance, strength, and durability.

- Wire Selection

- The first step in wire forming is choosing the appropriate type of wire for the specific application.

- Wire Straightening

- Wire forming typically begins with straightening the wire, which is often supplied in coil form weighing anywhere between 5 pounds and 5,000 pounds. In this stage, any stress-induced deformations in the wire are removed. There are two types of stress: avoidable and unavoidable. For high-quality wire forms, manufacturers typically avoid most of the preventable stresses during processing. However, unavoidable stresses are difficult to mitigate. The most common technique for stress avoidance is machine rolling, where rolls are adjusted either manually or automatically by machines. In some cases, manufacturers use a rotary arbor to straighten the wire.

The wire straightening stage is crucial, as any imperfections left at this point will result in defective products. Therefore, high-quality mill products should be selected, and factors such as the wire's helix and camber must be consistent and carefully monitored.

- Application of Force

- Wire forms are produced by applying varying degrees of force, either manually or mechanically, to reshape the wire. Depending on the application, the wire can be shaped into various forms, such as hexagonal, triangular, round, oval, square, flat, or even elliptical and D-shaped.

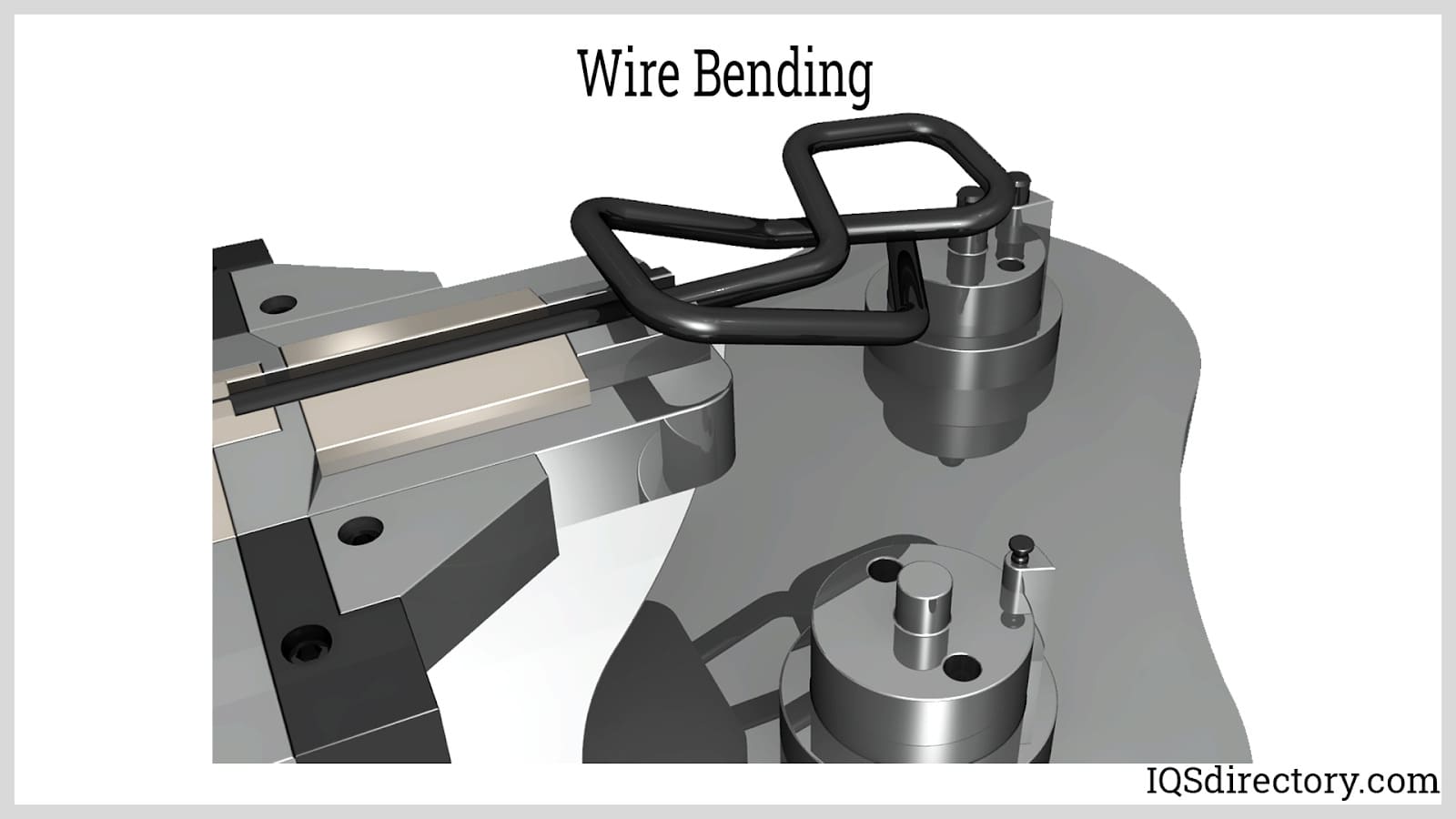

The simplest wire shaping method involves using a hand-held lever and spindle. More advanced methods utilize mechanized equipment like hydraulic presses, benders with dies, and air benders. For high-volume production, manufacturers may use four-slide machines or modern computer numerical control (CNC) benders. CNC wire forming allows for the efficient production of pre-programmed parts in three-dimensional configurations.

- Finishing/Secondary Operations

- To ensure the final product is free from burrs and sharp edges, manufacturers perform a range of secondary operations after wire forming. These can include cutting, stamping, forming, heading, and coining.

When choosing a wire form design and fabrication method, manufacturers must consider several important factors:

- Volume Required (Large or Small)

- Tolerance Value Required

- Mechanical and Chemical Characteristics

- Configuration of the Design

- Intended Application

These factors should be carefully considered for both the end-product and its intended use.

In addition to these considerations, manufacturers also take into account the wire form ends and the interior geometries of the wire form. Both the ends and interior shapes are customized based on the specific purpose of the wire form. Here are some common ends and interior geometries chosen by manufacturers:

- Machine Cut End

- This is a simple, straight cut made by a machine die, such as a guillotine knife. The burrs created by the cut are very small (0.13mm) and not visible to the naked eye, making this acceptable for most manufacturing applications.

- Chamfered End

- This is a simple, straight cut made by a machine die, such as a guillotine knife. The burrs created by the cut are very small (0.13mm) and not visible to the naked eye, making this acceptable for most manufacturing applications.

- Winging

- Also known as swaging, this process involves pressing a die onto the wire to displace the metal and form a wing-type shape.

- Pierced Swaging

- This is a two-step process. First, the wire is pressed to create a swaging shape, and then a hole is pierced through the center of the metal.

- Custom-Shaped Hole

- Similar to pierced swaging, a custom hole is created at the end of the wire. After the wire is pressed and shaped by a die, a custom die punctures the material to create the desired hole.

- Chisel Point and Turned End

- A die removes metal in a punch operation to achieve a chisel point. This approach is considered coarse but effective. A turned end can also be made, where diagonals are removed in a jagged punch manner.

- Ball End

- To create a ball end, a lathe is used instead of a die. The lathe creates a smooth, rounded end with no edges.

- Groove

- A groove is created using a lathe and is typically used to hold a retaining ring.

- Cold Heading

-

Cold heading involves two gripping dies. The first die holds the wire tightly, and the second die smashes the wire to form either a flat or round head. This method is used for button heading, carriage heading, and collar heading.

Manufacturers can create custom wire forms to meet any specific requirements. For example, they can apply a powder coating to enhance the wire form’s protection or appearance. They can also design custom assemblies with varying shapes, sizes, and dimensions, and work with virtually any wire diameter. To achieve the perfect custom wire fabrications, manufacturers often use a variety of secondary services such as nickel plating, painting, anodizing, and powder coating.

- Manual Lever

-

The oldest and most common method of wire form fabrication involves using a hand-held lever and spindle. In this process, a professional manually bends the wire around a past and an anvil, which is a solid iron block with concave sides and a flat top.

- Machine with Preset Pins

- Some wire forming equipment includes preset pins for various bending operations. These machines represent early attempts at semi-automated wire forming. While they improve efficiency over manual bending, they still require manual intervention and often lead to inconsistencies.

- Hydraulic Systems

- Hydraulic systems are another common method for wire form development, involving a press and dies with a hopper. In this process, a resource manually loads material onto the die from a straightening machine. The hydraulic press performs the rest of the work under the supervision of an operator. The wire straightening step is crucial for removing accumulated stresses during the wiring process, ensuring consistency in the wire's properties. As technology has progressed, hydraulic systems have evolved with the addition of pick-and-place robots, eliminating the need for manual wire movement from the straightening machine.

- Fourslide Machines

-

An alternative to hydraulic presses, fourslide machines are highly versatile and can also produce stampings. These machines work on a single workpiece from four sides, increasing production speed. Modern fourslide machines, with multi-purpose dies, can produce up to 3,500 simple wire forms per hour, significantly improving production turnaround.

- CNC Wire Bending Machines

- The most advanced method of wire bending uses computer numerically controlled (CNC) machines, capable of both two-dimensional and three-dimensional bending. CNC wire forming offers unmatched versatility, allowing quick adjustments between projects in under an hour. These machines are particularly valuable for producing custom wire forms, as they allow for easy pre-programming of design, configuration, and dimensions compared to other methods.

To reach the variety of wire forms available, there are numerous wire forming processes; the most common of which include coil making, roll forming, metal stamping, and welding.

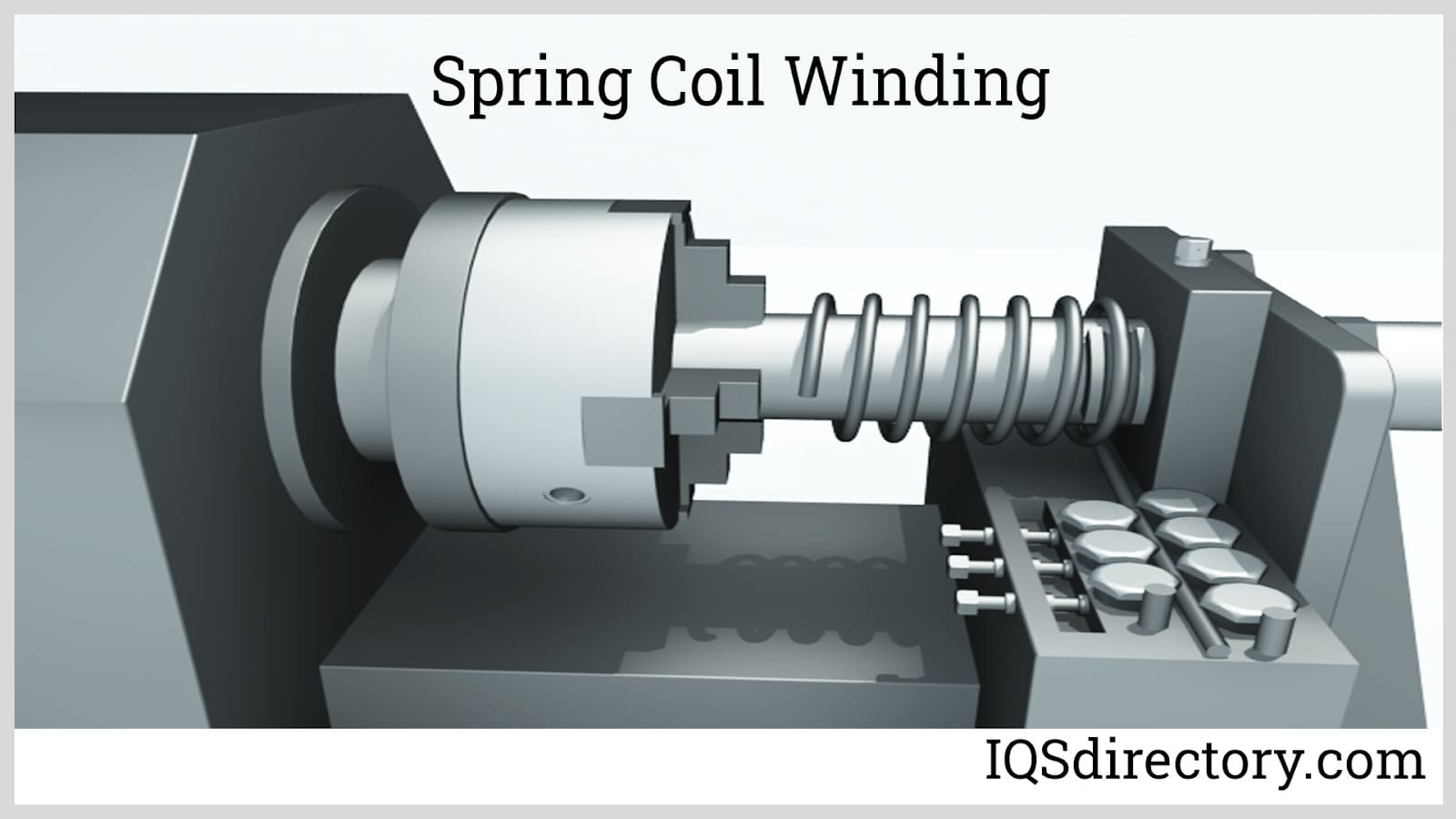

- Coil Making

- Also known as spring making or coil winding, this process involves winding wire around mandrels or metal blanks to create coils.

- Roll Forming

- A versatile process used to produce flat, round, and shaped wire parts. Roll forming is a continuous operation that employs calendars and die punches to shape the wire.

- Metal Stamping

- Metal stamping is another key wire forming technique where wire is shaped into various forms using a stamping press. Several methods of metal stamping are used for wire forms, including fourslide stamping and deep drawn stamping. Fourslide stamping, also called multislide stamping, uses a metal stamp press with four horizontal forming slides, enabling the wire to be shaped in multiple directions. Deep drawing, in contrast, creates deeper wire forms than other methods, providing greater depth.

- Welding

- Welding refers to several processes used to join metal wire, such as electric resistance welding (ERW), metal inert gas (MIG) welding, or tungsten inert gas (TIG) welding. ERW utilizes an electric current and mechanical pressure to join wire. MIG and TIG welding, types of ERW, employ inert gases to prevent contamination. While TIG welding provides the highest precision, it is more complex and requires skilled operators and longer production times, which is why MIG welding is often preferred for faster results. Additionally, weaving may be used to create wire forms such as screens, grids, or guards.

When considering a wire form purchase, it’s a good idea to choose a custom manufacturer. Custom manufacturers can provide the most specialized and tailored options to meet your needs. However, it’s equally important to evaluate not only the manufacturer’s capabilities but also their customer service record. A company with great technical skills is of little use if their staff doesn’t effectively collaborate with customers.

If you have a particularly complex request, consider asking for a prototype. This ensures both you and the manufacturer are aligned before making a significant investment.

To find the right manufacturer, explore the companies listed above. Each one we partner with produces high-quality work. Contact one or more to see how they can assist you!

Wire bending process, wire can be shaped into unlimited configurations to fit any application.

Wire bending process, wire can be shaped into unlimited configurations to fit any application.

Wire baskets are made from a series of wires woven together or welded to form a shape of a basket.

Wire baskets are made from a series of wires woven together or welded to form a shape of a basket.

Wire racks are made from the wire forming process of acquiring a wire, from either a blank length or spooled coil, and bending it into definite forms.

Wire racks are made from the wire forming process of acquiring a wire, from either a blank length or spooled coil, and bending it into definite forms.

Wire bending produces a wide array of shapes and configurations and creates no scrap or waste sicne the wire is bent before cutting..

Wire bending produces a wide array of shapes and configurations and creates no scrap or waste sicne the wire is bent before cutting..

CNC bending is an abbreviation for “computer numerical controlled” bending are extremely accurate.

CNC bending is an abbreviation for “computer numerical controlled” bending are extremely accurate.

Hand machines, which features a spindle and hand lever may be rotary die or drawn and have gears that increase the facilitated bending pressure.

Hand machines, which features a spindle and hand lever may be rotary die or drawn and have gears that increase the facilitated bending pressure.

Coil wire forming, involves winding wire around a metal blank which takes different forms depending on the final product.

Coil wire forming, involves winding wire around a metal blank which takes different forms depending on the final product.

- Coil

- Wire shaped into rings or spirals.

- Flat Springs

- Flat or curved steel pieces formed into a coil, designed to provide a nearly constant force.

- Medical Wire Forms

- Used in orthopedic and prosthetic devices, offering a secure closure.

- S Hooks

- Wire hooks used for connecting or hanging components.

- Spring Washers

- Springs that store energy to tighten the nut or bolt they are under.

- Springs

- Coiled materials that bend when load is applied, returning to their original position when the load is removed.

- Wire Baskets

- Used across industries for storing and displaying products.

- Wire Displays

-

Often used for showcasing items like books, food, clothing, and more. Wire displays can be customized to meet specific manufacturing needs.

- Wire Fabrications

- Include various wire forms tailored for a wide range of purposes.

- Wire Forming

- Encompasses various processes that shape wire into different forms.

- Wire Grids

- Also known as wire grid panels, these consist of interwoven horizontal and vertical wires to form a framework.

- Wire Guards

- Protective devices used to shield parts and machinery from damage.

- Wire Hooks

- Curved metal pieces used to hold or hang items.

- Wire Parts

- Commonly called wire forms, these are made from wire shaped into specific designs.

- Wire Products

- Include a wide range of items and shapes made from wire.

- Wire Racks

- Made from various materials and widely used in retail environments, including food and clothing industries.

- Wire Screens

- Metal wires woven in a crisscrossed pattern to create open yet protective barriers.

- Wire Shelves

- Produced for both industrial and consumer use, offering durability, versatility, and a range of load strengths and wire densities.

- Active Coils

- Coils that deflect freely when subjected to a load.

- Closed Ends

- The ends of coils that touch each other, created by reducing the pitch at the end of a compression spring.

- CNC (Computer Numerical Control)

- Machines that use computer memory to control their operations, commonly used in the manufacturing and production of wire forms.

- Deflection

- The movement of the spring arms or ends when a load is applied or removed.

- Elastic Limit

- The maximum strain a material can endure without experiencing permanent deformation.

- Fine Blanking

- A precise technique for blanking material, resulting in smooth, accurate cuts without requiring secondary operations.

- Free Angle

- The angle between the torsion spring arms when the spring is in an unloaded position.

- Gauge

- The measurement of the thickness of a wire used in wire forms.

- Helix

- The spiral shape of a spring, whether it is open or closed.

- Hooks

- The open ends of extension springs.

- Hysteresis

- The loss of mechanical energy during the cyclic loading and unloading of a spring. This is related to the space between the loading and unloading deflection curves.

- Load

- The force applied to a spring that causes it to deflect.

- Multislide Stamping

- A process of stamping or forming pieces and segments from multiple directions.

- Pitch

- The distance between the center of one adjacent active coil and the next in a spring.

- Rate (R)

- The change in load for each unit of deflection, typically expressed in pounds per inch (N/mm).

- Rod Bending

-

A general term for forming tools used to create bends in a workpiece, ranging from small handheld devices to automated machines.

- Set

- Permanent deformation that occurs when a spring is stressed beyond the material's elastic limit.

- Spring Index

- The ratio of the mean coil diameter to the wire diameter.

- Stress Relief

- A process involving exposure to low heat to reduce residual stresses in a spring.

- Torque

- A measurement of a torsion spring's twisting action in relation to the distance from the spring’s axis.

- Wire Forming

- The process of shaping wire into various forms.

- Wire

- A flexible, cylindrical rod or strand of metal produced through the metalworking process known as drawing. It comes in various materials and thicknesses and is used to create a wide range of parts and products.